Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (4): 349-357.DOI: 10.15541/jim20180347

Yi TAN1,2,Kai WANG1,2

Received:2018-07-25

Revised:2018-11-24

Published:2019-04-20

Online:2019-04-15

CLC Number:

Yi TAN, Kai WANG. Silicon-based Anode Materials Applied in High Specific Energy Lithium-ion Batteries: a Review[J]. Journal of Inorganic Materials, 2019, 34(4): 349-357.

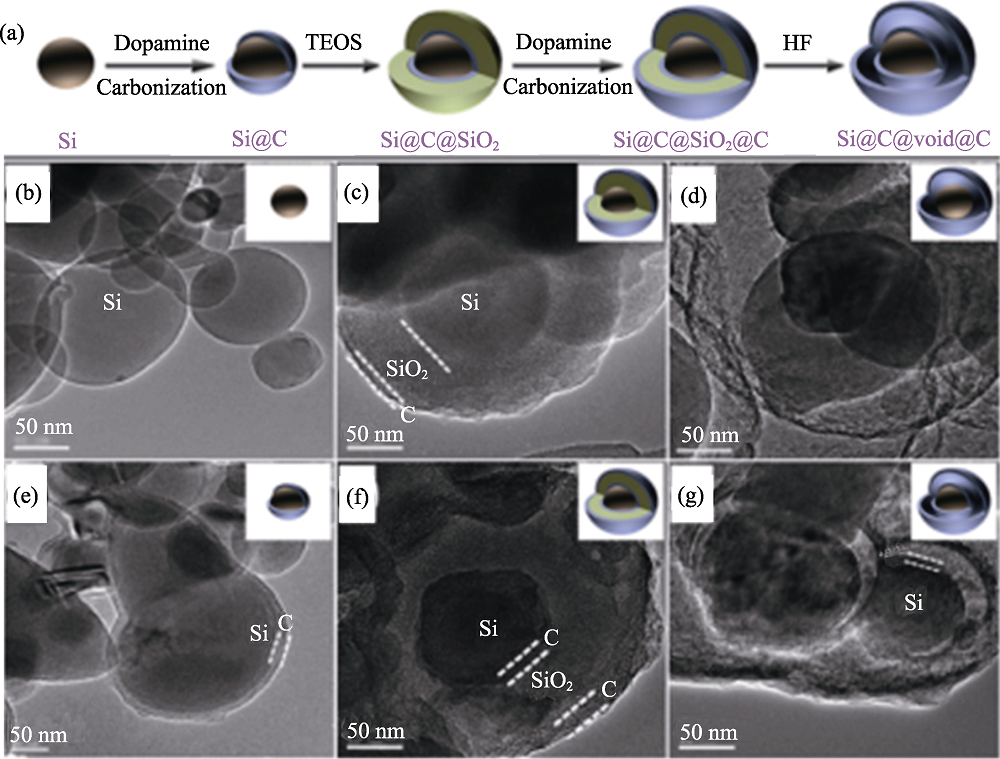

Fig. 6 (a) Schematic diagram of the novel core-shell Si@C@void@C, TEM images of (b) raw Si, (c) Si@SiO2@C, (d) Si@void@C, (e) Si@C, (f) Si@C@SiO2@C, and (g) Si@C@void@C[26]

| Composite type | Si source | Carbon source | Electrochemical performance | Method | Ref. |

|---|---|---|---|---|---|

| Si/Porous-C | Nano-silicon powder | Pitch | 723.8 mAh/g (1st)600 mAh/g (100 mA/g, 100 )a | Spray drying + High-temperature pyrolysis | [35] |

| Si@C@RGO | Silicon powder (80 nm) | Sucrose | 1599 mAh/g (1st)1517 mAh/g (100 mA/g, 100 ) | Spray drying + High-temperature pyrolysis | [36] |

| Si/C/G | Silicon powder (325 mesh) | Phenol-formaldehyde resin (PFR) | 700 mAh/g (1st)550 mAh/g (100 mA/g, 40 ) | High-temperature pyrolysis | [37] |

| Silicon-sponge | Si wafer (>20 μm) | Acetylene | 790 mAh/g (1st)726 mAh/g (100 mA/g, 300 ) | Electrochemical etching+ High-temperature pyrolysis | [38] |

| PS@C | Si powder (5 μm) | Propylene | 1980 mAh/g (1st)1287 mAh/g (100 mA/g, 100) | Chemical etching + CVD | [39] |

| Si/C | Al-Si alloy (2-10 μm) | Polyacrylonitrile (PAN) | 952 mAh/g (1st)826.3 mAh/g (200 mA/g, 300) | Chemical etching + High-temperature pyrolysis | [30] |

Table 1 Electrochemical performance of some silicon/carbon composite anodes for lithium-ion batteries

| Composite type | Si source | Carbon source | Electrochemical performance | Method | Ref. |

|---|---|---|---|---|---|

| Si/Porous-C | Nano-silicon powder | Pitch | 723.8 mAh/g (1st)600 mAh/g (100 mA/g, 100 )a | Spray drying + High-temperature pyrolysis | [35] |

| Si@C@RGO | Silicon powder (80 nm) | Sucrose | 1599 mAh/g (1st)1517 mAh/g (100 mA/g, 100 ) | Spray drying + High-temperature pyrolysis | [36] |

| Si/C/G | Silicon powder (325 mesh) | Phenol-formaldehyde resin (PFR) | 700 mAh/g (1st)550 mAh/g (100 mA/g, 40 ) | High-temperature pyrolysis | [37] |

| Silicon-sponge | Si wafer (>20 μm) | Acetylene | 790 mAh/g (1st)726 mAh/g (100 mA/g, 300 ) | Electrochemical etching+ High-temperature pyrolysis | [38] |

| PS@C | Si powder (5 μm) | Propylene | 1980 mAh/g (1st)1287 mAh/g (100 mA/g, 100) | Chemical etching + CVD | [39] |

| Si/C | Al-Si alloy (2-10 μm) | Polyacrylonitrile (PAN) | 952 mAh/g (1st)826.3 mAh/g (200 mA/g, 300) | Chemical etching + High-temperature pyrolysis | [30] |

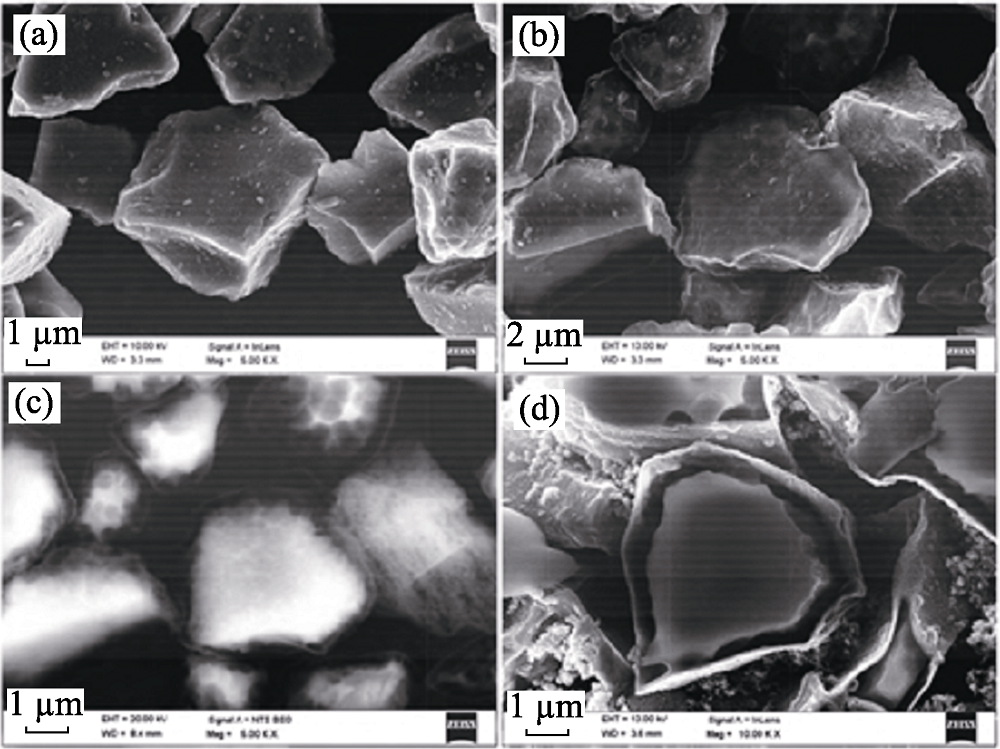

Fig. 12 SEM images of (a) initial SiO@C, surface ((b) secondary electron phase, (c) back scattered) and (d) cross-section of hollow SiO@void@C material[59]

| [1] | GOODENOUGH J B, PARK K S . The Li-ion rechargeable battery: a perspective.[J]. Am. Chem. Soc., 2013,135(4):1167-1176. |

| [2] | TAN Y, XUE B . Research progress on lithium titanate as anode material in lithium-ion battery.[J]. Inorg. Mater., 2018,33(5):475-482. |

| [3] | LUO W, CHEN X, XIA Y , et al. Surface and interface engineering of silicon-based anode materials for lithium-ion batteries. Adv. Energy Mater., 2017, 7(24): 1701083-1-28. |

| [4] | XIAO Q Z, FAN Y, WANG X H , et al. A multilayer Si/CNT coaxial nano fiber LiB anode with a high areal capacity. Energy Environ. Sci., 2014,7(2):655-661. |

| [5] | HUANG S, FAN F, LI J , et al. Stress generation during lithiation of high-capacity electrode particles in lithium ion batteries. Acta Mater., 2013,61(12):4354-4364. |

| [6] | LI J, DAHN J R . An in situ X-ray diffraction study of the reaction of Li with crystalline Si.[J]. Electrochem. Soc., 2007,154(3):A156-A161. |

| [7] | WANG F, WU L J, KEY B , et al. Electrochemical reaction of lithium with nanostructure silicon anodes: a study by in-situ synchrotron X-ray diffraction and electron energy-loss spectroscopy. Adv. Energy Mater., 2013,3(10):1324-1331. |

| [8] | OBROVAC M N, KRAUSE L J . Reversible cycling of crystalline silicon powder.[J]. Electrochem. Soc., 2007,154(2):A103-A108. |

| [9] | DING N, XU J, YAO Y X , et al. Improvement of cyclability of Si as anode for Li-ion batteries.[J]. Power Sources, 2009,192(2):644-651. |

| [10] | SETHURAMAN V A, CHON M J, SHIMSHAK M , et al. In situ, measurements of stress evolution in silicon thin films during electrochemical lithiation and delithiation.[J]. Power Sources, 2012,195(15):5062-5066. |

| [11] | NADIMPALLI S P V, SETHURAMAN V A, BUCCI G , et al. On plastic deformation and fracture in Si films during electrochemical lithiation/delithiation cycling.[J]. Electrochem. Soc., 2013,160(10):A1885-A1893. |

| [12] | GHASSEMI H, MING A, CHEN N , et al. In situ electrochemical lithiation/delithiation observation of individual amorphous Si nanorods. ACS Nano, 2011,5(10):7805-7811. |

| [13] | LIANG B, LIU Y, XU Y . Silicon-based materials as high capacity anodes for next generation lithium ion batteries.[J]. Power Sources, 2014,267:469-490. |

| [14] | WEN Z S, WANG K, XIE J Y . Interface formed on high capacity silicon anode for lithium ion batteries.[J]. Inorg. Mater., 2007,22(3):437-441. |

| [15] | CHAN C K, RUFFO R, HONG S , et al. Surface chemistry and morphology of the solid electrolyte interphase on silicon nanowire lithium-ion battery anodes.[J]. Power Sources, 2009,189(2):1132-1140. |

| [16] | KEY B, BHATTACHARYYA R, MORCRETTE M , et al. Real-time NMR investigations of structural changes in silicon electrodes for lithium-ion batteries.[J]. Am. Chem. Soc., 2009,131(26):9239-9249. |

| [17] | JI H R, KIM J W, SUNG Y E , et al. Failure modes of silicon powder negative electrode in lithium secondary batteries. Electrochem. Solid-State Lett., 2004,7(10):A306-A309. |

| [18] | HONG L, HUANG X, CHEN L , et al. The crystal structural evolution of nano-Si anode caused by lithium insertion and extraction at room temperature. Solid State Ionics, 2000,135(1):181-191. |

| [19] | LIANG J W, LI X N, ZHU Y C , et al. Hydrothermal synthesis of nano-silicon from a silica sol and its use in lithium ion batteries. Nano Res., 2015,8(5):1497-1504. |

| [20] | KIM W S, CHOI J, HONG S H . Meso-porous silicon-coated carbon nanotube as an anode for lithium-ion battery. Nano Lett., 2016,9(7):2174-2181. |

| [21] | ZHOU Y N, XUE M Z, FU Z W . Nanostructured thin film electrodes for lithium storage and all-solid-state thin-film lithium batteries.[J]. Power Sources, 2013,234(21):310-332. |

| [22] | DATTA M K, MARANCHI J, CHUNG S J , et al. Amorphous silicon- carbon based nano-scale thin film anode materials for lithium ion batteries. Electrochim. Acta, 2011,56(13):4717-4723. |

| [23] | CHENG H, XIAO R, BIAN H , et al. Periodic porous silicon thin films with interconnected channels as durable anode materials for lithium ion batteries. Mater. Chem. Phys., 2014,144(1/2):25-30. |

| [24] | TONG Y, XU Z, LIU C , et al. Magnetic sputtered amorphous Si/C multilayer thin films as anode materials for lithium ion batteries.[J]. Power Sources, 2014,247(2):78-83. |

| [25] | LIU N, LU Z, ZHAO J , et al. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat. Nanotechnol., 2014,9(3):187-192. |

| [26] | XIE J, TONG L, SU L , et al. Core-shell yolk-shell Si@C@Void@C nanohybrids as advanced lithium ion battery anodes with good electronic conductivity and corrosion resistance.[J]. Power Sources, 2017,342:529-536. |

| [27] | BANG B M, LEE J I, KIM H , et al. High-performance macro porous bulk silicon anodes synthesized by template-free chemical etching. Adv. Energy Mater., 2012,2(7):878-883. |

| [28] | GE M, LU Y, ERCIUS P , et al. Large-scale fabrication, 3D tomography, and lithium-ion battery application of porous silicon. Nano Lett., 2014,14(1):261-268. |

| [29] | GE M, RONG J, FANG X , et al. Scalable preparation of porous silicon nanoparticles and their application for lithium-ion battery anodes. Nano Res., 2013,6:174-181. |

| [30] | TIAN H, TAN X, XIN F , et al. Micro-sized nano-porous Si/C anodes for lithium ion batteries. Nano Energy, 2015,11:490-499. |

| [31] | LIU N, WU H, MCDOWELL M T , et al. A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes. Nano Lett., 2012,12(6):3315-3321. |

| [32] | KIM H, HAN B, CHOO J , et al. Three-dimensional porous silicon particles for use in high-performance lithium secondary batteries. Angew. Chem. Int. Ed., 2008,47(52):10151-10154. |

| [33] | JIANG H, ZHOU X, LIU G , et al. Free-standing Si/graphene paper using Si nanoparticles synthesized by acid-etching Al-Si alloy powder for high-stability Li-ion battery anodes. Electrochim. Acta, 2016,188:777-784. |

| [34] | WRODNIGG G H, WRODNIGG T M, BESENHARD J O , et al. Propylene sulfite as film-forming electrolyte additive in lithium ion batteries. Electrochem. Commun., 1999,1(3/4):148-150. |

| [35] | LI M, HOU X, SHA Y , et al. Facile spray-drying/pyrolysis synjournal of core-shell structure graphite/silicon-porous carbon composite as a superior anode for Li-ion batteries.[J]. Power Sources, 2014,248(2):721-728. |

| [36] | PAN Q, ZUO P, LOU S , et al. Micro-sized spherical silicon@carbon@graphene prepared by spray drying as anode material for lithium-ion batteries.[J]. Alloys Compd., 2017,723:434-440. |

| [37] | ZUO P, YIN G, MA Y , et al. Electrochemical stability of silicon/ carbon composite anode for lithium ion batteries. Electrochim. Acta, 2007,52(15):4878-4883. |

| [38] | LI X, GU M, HU S , et al. Mesoporous silicon sponge as an anti- pulverization structure for high-performance lithium-ion battery anodes. Nature Commun., 2014, 5(5): 4105-1-7. |

| [39] | KIM J S, HALIM M, BYUN D , et al. Amorphous carbon-coated prickle-like silicon of micro and nano hybrid anode materials for lithium-ion batteries. Solid State Ionics, 2014,260:36-42. |

| [40] | MIN K K, BO Y J, JIN S L , et al. Microstructures and electrochemical performances of nano-sized SiOx (1.18≤ x ≤1.83) as an anode material for a lithium(Li)-ion battery.[J]. Power Sources, 2013,244:115-121. |

| [41] | TAKEZAWA H, IWAMOTO K, ITO S , et al. Electrochemical behaviors of nonstoichiometric silicon suboxides (SiOx) film prepared by reactive evaporation for lithium rechargeable batteries.[J]. Power Sources, 2013,244:149-157. |

| [42] | SCHULMEISTER K, MADER W . TEM investigation on the structure of amorphous silicon monoxide. J. Non-Cryst. Solids, 2003,320(1):143-150. |

| [43] | HOHL A, WIEDER T, AKEN P A V , et al. An interface clusters mixture model for the structure of amorphous silicon monoxide (SiO). J. Non-Cryst. Solids, 2003,320(1):255-280. |

| [44] | LÜ P P, ZHAO H L, WANG J , et al. Facile preparation and electrochemical properties of amorphous SiO2/C composite as anode material for lithium ion batteries.[J]. Power Sources, 2013,237(259):291-294. |

| [45] | LIU X, ZHAO H L, JIE J Y , et al. SiOx(0<x≤2) based anode materials for lithium-ion batteries. Prog. Chem., 2015,27(4):336-348. |

| [46] | PHILIPPE B, DEDRYVÈRE R, ALLOUCHE J , et al. Nanosilicon electrodes for lithium-ion batteries: interfacial mechanisms studied by hard and soft X-ray photoelectron spectroscopy. Chem. Mater., 2017,24(24):1107-1115. |

| [47] | PARK C M, CHOI W, HWA Y , et al. Characterizations and electrochemical behaviors of disproportionate SiO and its composite for rechargeable Li-ion batteries.[J]. Mater. Chem., 2010,20(23):4854-4860. |

| [48] | MORITA T, TAKAMI N . Nano Si cluster-SiOx-C composite material as high-capacity anode material for rechargeable lithium batteries.[J]. Electrochem. Soc., 2006,153(2):A425-A430. |

| [49] | YANG X L, ZHANG P C, WEN Z Y , et al. High performance silicon/carbon composite prepared by in situ carbon-thermal reduction for lithium ion batteries.[J]. Alloys Compd., 2010,496(1):403-406. |

| [50] | SEONG I W, KIM K T, YOON W Y , et al. Electrochemical behavior of a lithium-pre-doped carbon-coated silicon monoxide anode cell.[J]. Power Sources, 2009,189(1):511-514. |

| [51] | KIM H J, CHOI S, LEE S J , et al. Controlled prelithiation of silicon monoxide for high performance lithium-ion rechargeable full cells. Nano Lett., 2016,16(1):282-288. |

| [52] | XING A, ZHANG J, BAO Z , et al. A magnesiothermic reaction process for the scalable production of mesoporous silicon for rechargeable lithium batteries. Chem. Commun., 2013,49(60):6743-6745. |

| [53] | YU B C, HWA Y, KIM J H , et al. A new approach to synthesis of porous SiOx, anode for Li-ion batteries via chemical etching of Si crystallites. Electrochim. Acta, 2014,117(4):426-430. |

| [54] | FENG X J, YANG J, LU Q W , et al. Facile approach to SiOx/Si/C composite anode material from bulk SiO for lithium ion batteries. Phys. Chem. Chem. Phys., 2013,15(34):14420-144206. |

| [55] | YANG T, XIAO L I, TIAN X D , et al. Preparation and electrochemical performance of Si@C/SiOx as anode material for lithium-ion batteries.[J]. Inorg. Mater., 2017,32(7):699-704. |

| [56] | LIU Y H, OKANO M, MUKAI T , et al. Improvement of thermal stability and safety of lithium ion battery using SiO anode material.[J]. Power Sources, 2016,304:9-14. |

| [57] | MIYUKI T, OKUYAMA Y, SAKAMOTO T , et al. Characterization of heat treated SiO powder and development of a LiFePO4/ SiO lithium ion battery with high-rate capability and thermo stability. Electrochemistry, 2012,80(6):401-404. |

| [58] | MASAYUKI Y, KAZUTAKA U, ATSUSHI U . Performance of the “SiO”-carbon composite-negative electrodes for high-capacity lithium-ion batteries; prototype 14500 batteries.[J]. Power Sources, 2013,225:221-225. |

| [59] | LIU X . Facile synthesis and electrochemical performance of hollow SiO@void@C composite as anode material for lithium-ion batteries. Chin. Batt. Indust., 2017,21(6):3-9. |

| [60] | LIU W R, YEN Y C, WU H C , et al. Nano-porous SiO/carbon composite anode for lithium-ion batteries.[J]. Appl. Electrochem., 2009,39(9):1643-1649. |

| [61] | CHOI I, MIN J L, OH S M , et al. Fading mechanisms of carbon- coated and disproportionated Si/SiOx negative electrode (Si/SiOx/C) in Li-ion secondary batteries: dynamics and component analysis by TEM. Electrochim. Acta, 2012,85(1):369-376. |

| [62] | SHI C C, YAN X L, ZHANG L L , et al. High-performance SiO/C/G composite anode for lithium ion batteries.[J]. Inorg. Mater., 2013,28(9):943-948. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||