Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (9): 923-930.DOI: 10.15541/jim20170546

• Orginal Article • Next Articles

WANG Hai-Long1, WANG Yang1, WANG Xiang-Wei2, ZHANG Hong-Zhi1

Received:2017-11-16

Revised:2018-01-07

Published:2018-09-20

Online:2018-08-14

About author:WANG Hai-Long. E-mail: 13B908071@hit.edu.cn

Supported by:CLC Number:

WANG Hai-Long, WANG Yang, WANG Xiang-Wei, ZHANG Hong-Zhi. Research Progress of Thermal Controlled Cracking of Hard-Brittle Plate[J]. Journal of Inorganic Materials, 2018, 33(9): 923-930.

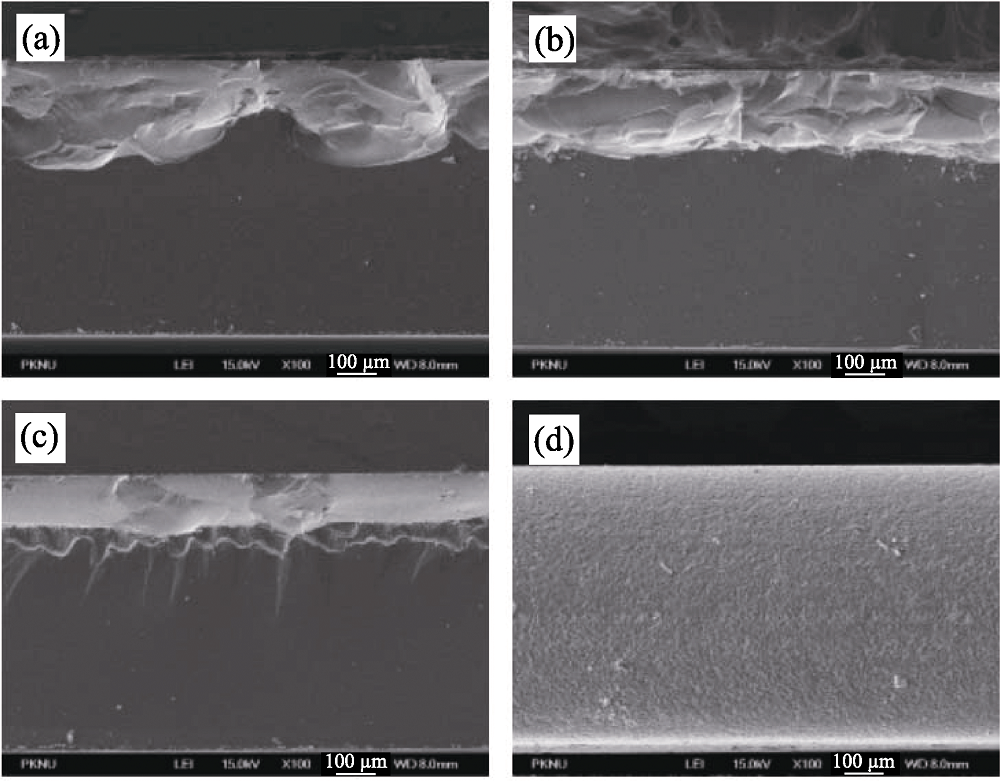

Fig. 14 Cross-sectional views of femtosecond laser scribing followed by CO2 laser heating and rapid cooling[48] (a) After one laser pass; (b) After five laser passes; (c) After six laser passes; (d) Initial crack propagation

| [1] | ZHANG CHONG, YUAN SONG-MEI, AMIN MUHAMMAD,et al. Development of a cutting force prediction model based on brittle fracture for C/SiC in rotary ultrasonic facing milling. International Journal of Advanced Manufacturing Technology, 2016, 85(1-4): 573-583. |

| [2] | SENER KARABULUT, HENIFI CINICI, HALIL KARAKOC.Experimental investigation and optimization of cutting force and tool wear in milling Al7075 and open-cell SiC foam composite.Arabian Journal for Science & Engineering, 2016, 41(5): 1797-1812. |

| [3] | ZHAO GUO-LONG, HUANG CHUANZHEN, HE NING,et al. Fabrication and cutting performance of reactively hot-pressed TiB2-TiC-SiC ternary cutting tool in hard turning of AISI H13 steel. International Journal of Advanced Manufacturing Technology, 2017, 91: 943-954. |

| [4] | YUAN SONG-MEI, FAN HUITAO, AMIN MUHANMMAD,et al. A cutting force prediction dynamic model for side milling of ceramic matrix composites C/SiC based on rotary ultrasonic machining. International Journal of Advanced Manufacturing Technology, 2016, 86(1-4): 37-48. |

| [5] | SHARMA VIKAS, VINOD KUMAR.Investigating the quality characteristics of Al5052/SiC metal matrix composites machined by CO2 laser curve cutting.Proceedings of the Institution of Mechanical Engineers Part L: Journal of Materials Design & Applications, 2015, 232(1): 3-19. |

| [6] | SHIN DONGSIG, YONGKWON CHO, HYONKEE SOHN.Towards optimized efficiency of ablation in copper using a 515 nm picosecond laser process.Journal of Laser Micro, 2015, 10(3): 241-244. |

| [7] | YASUHISA SANO, KOHEI AIDA, TAKEHIRO KATO, ,et al. Cutting of SiC wafer by atmospheric-pressure plasma etching with wire electrode. Materials Science Forum, 2012, 717-720: 865-868. |

| [8] | SAVRUN E, TAYA M.Surface characterization of SiC whisker/2124 aluminium and Al2O3, composites machined by abrasive water jet.Journal of Materials Science, 1988, 23(4): 1453-1458. |

| [9] | SON HYEON-TAEK, KIM DAE-GUEN, PARK SOON-SUB,et al. Spark plasma sintering and ultra-precision machining characteristics of SiC. Korean Journal of Materials Research, 2010, 20(11): 559-569. |

| [10] | PRASHANTHA S, VEERESHA R B, SHASHIDHARA S M,et al. A study on machining characteristics of Al6061-SiC metal matrix composite through wire-cut electro discharge machining. Materials Today Proceedings, 2017, 4(10): 10779-10785. |

| [11] | ZHOU WEIGUO, GONG KEYU, WAN JIE,et al. Molecular dynamics simulation study on ablation of silicon by water-jet-guided laser. Proceedings of the Institution of Mechanical Engineers Part E Journal of Process Mechanical Engineering, 2017, 231(6): 1217-1225. |

| [12] | DANIEL LAROUCHE, JOSEPH LANGLAIS, WU WEI-LI,et al. A constitutive model for the tensile deformation of a binary aluminum alloy at high fractions of solid. Metallurgical & Materials Transactions B, 2006, 37(3): 431-443. |

| [13] | SUYITNO, KOOL W H, KATGERMAN L. Integrated approach for prediction of hot tearing.Metallurgical & Materials Transactions A, 2009, 40(10): 2388-2400. |

| [14] | RACHID MHAMDIA, SERIER B, AIBEDAH A,et al. Numerical analysis of the influences of thermal stresses on the efficiency of bonded composite repair of cracked metallic panels. Journal of Composite Materials, 2017, 51(26): 3701-3709. |

| [15] | BILČÍK J, SONNENSCHEIN R, GAŽOVIČOVÁ N. Causes of early-age thermal cracking of concrete foundation slabs and their reinforcement to control the cracking.Slovak Journal of Civil Engineering, 2017, 25(3): 8-14. |

| [16] | CHU DONG-YANG, LI XIANG, LIU ZHANLI.Study the dynamic crack path in brittle material under thermal shock loading by phase field modeling.International Journal of Fracture, 2017, 330: 1-16. |

| [17] | GRAHAM C E, LUMLEY R M, OBERHOLZER D J.Laser Substrate Parting: US, US3629545. 1971. |

| [18] | KARLSSON M N A, DEPPERT K, WACASER B A,et al. Size-controlled nanoparticles by thermal cracking of iron pentacarbonyl. Applied Physics A, 2005, 80(7): 1579-1583. |

| [19] | FRIEDL D I.Method for Laser Thermal Separation of Ceramic or Other Brittle Flat Materials: EP, EP1990168. 2012.06.27. |

| [20] | UEDA T, YAMADA K, OISO K,et al. Thermal stress cleaving of brittle materials by laser beam. CIRP Annals - Manufacturing Technology, 2002, 51(1): 149-152. |

| [21] | TSAI CHWAN-HUEI, HUANG BO-WEN.Diamond scribing and laser breaking for LCD glass substrates.Journal of Materials Processing Technology, 2008, 198(1/2/3): 350-358. |

| [22] | SHEPELOV G V, SHIGANOV I N.Cutting sheet glass with the beam of a solid-state laser.Welding International, 2000, 14(12): 988-991. |

| [23] | KONDRATENKO VLADIMIR S.Method of Splitting Non-metallic Materials: US, US 5609284 A. 1997. |

| [24] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Thermal stress analysis on laser scribing of glass. Journal of Laser Applications, 2008, 20(4): 193-200. |

| [25] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Three-dimensional thermal stress analysis on laser scribing of glass. Precision Engineering, 2008, 32(4): 301-308. |

| [26] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Partial growth of crack in laser scribing of glass. Journal of Laser Applications, 2009, 21(2): 917-923. |

| [27] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Influence of thermal expansion coefficient in laser scribing of glass. Precision Engineering, 2010, 34(1): 70-75. |

| [28] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Influence of glass substrate thickness in laser scribing of glass. Precision Engineering, 2010, 34(1): 55-61. |

| [29] | YAHATA KEISUKE, YAMAMOTO KOJI, ETSUJI OHMURA.Crack propagation analysis in laser scribing of glass (machine elements, design and manufacturing).Journal of Laser Micro, 2010, 5(2): 109-114. |

| [30] | ABRAMOV ANATOLI A, Black MATTHEW L, GLAESEMANN G SCOTT.Laser separation of chemically strengthened glass.Physics Procedia, 2010, 5: 285-290. |

| [31] | ABRAMOV ANATOLI A, SUN YA-WEI, XU WEI, et al. Laser Scoring of Glass Sheets at High Speeds and With Low Residual Stress: US, US8011207. 2011. |

| [32] | NORIO KARUBE, HIROSHI MIURA.Full-body Laser Scribing Method of Fragile Material: US, US20070062921. 2007. |

| [33] | KOJIRO KARUBE, NORIO KARUBE.Laser-induced cleavage of LCD glass as full-body cutting.Proceedings of SPIE, 2008, 6880: 1-10. |

| [34] | SALMAN NISAR, SHEIKH M A, LI LIN,et al. Effect of thermal stresses on chip-free diode laser cutting of glass. Optics & Laser Technology, 2009, 41(3): 318-327. |

| [35] | SALMAN NISAR, KHAN SOHAIB Z, ALI MUHAMMAD,et al. Comparison of cut path deviation between CO2, and diode lasers in float-glass cutting. Journal of Russian Laser Research, 2014, 35(2): 182-192. |

| [36] | SALMAN NISAR, SHEIKH M A, LI LIN,et al. The effect of laser beam geometry on cut path deviation in diode laser chip-free cutting of glass. Journal of Manufacturing Science & Engineering, 2010, 132(1): 165-174. |

| [37] | SALMAN NISAR, LI LIN, ALI MUHAMMAD,et al. The effect of continuous and pulsed beam modes on cut path deviation in diode laser cutting of glass. International Journal of Advanced Manufacturing Technology, 2010, 49(1-4): 167-175. |

| [38] | MIYASHITA YUKIO, MASASHI MOGI, HIROTAKA HASEGAWA,et al. Study on a controlling method for crack nucleation and propagation behavior in laser cutting of glass. Journal of Solid Mechanics and Materials Engineering, 2008, 2(12): 1555-1566. |

| [39] | CAI NA, YANG LI-JUN, WANG YANG, ,et al. Experimental research of YAG laser cutting soda-lime glass sheets with controlled fracture. Key Engineering Materials, 2010, 431-432: 507-510. |

| [40] | SILVIO GEORGI.Separating and structuring of brittle material by the use of laser radiation. Proceedings of SPIE, 2003, 5063: 426-431. |

| [41] | SHALUPAEV S V, SHERSHNEV E B, NIKITYUK YU V,et al. Two-beam laser thermal cleavage of brittle nonmetallic materials. Journal of Optics Technology, 2006, 73(5): 356-359. |

| [42] | CHOI WON-SEOK, KIM JONG-HYEONG, KIM JOOHAN.Thermal cleavage on glass by a laser-induced plume.Optics & Lasers in Engineering, 2014, 53(2): 60-68. |

| [43] | WANG HAI-LONG, ZHANG HONG-ZHI, WANG-YANG.Splitting of glass and SiC ceramic sheets using controlled fracture technique with elliptic microwave spot.Ceramics International, 2017, 43(2): 1669-1676. |

| [44] | HANG KYOUNG-SHIK, HONG SOON-KUG,OH SEOK-CHANG,et al. A study of cutting glass by laser. Proceedings of SPIE, 2002, 4426: 367-370. |

| [45] | HUANG KUO-CHENG, WU WEN-HONG, TSENG SHIH-FENG,et al. The mixed processing models development of thermal fracture and laser ablation on glass substrate. International Conference on Advances in Materials and Processing Technologies, 2010, 1: 1612-1617. |

| [46] | HUANG KUO-CHENG, HSIAO WEN-TSE, HWANG CHI-HUNG,et al. The laser ablation model development of glass substrate cutting assisted with the thermal fracture and ultrasonic mechanisms. Optics & Lasers in Engineering, 2015, 67: 31-35. |

| [47] | SU CHAO-TON, HSIAO YU-HSIANG, CHANG CHIA-CHIN.Parameter optimization design for touch panel laser cutting process.IEEE Transactions on Automation Science and Engineering, 2012, 9(2): 320-329. |

| [48] | KIM KWANG-RYUL, KIM JAE-HOON, FARSON DAVE F,et al. Hybrid laser cutting for flat panel display glass. Japanese Journal of Applied Physics, 2008, 47(8): 6978-6981. |

| [49] | TSAI CHWAN-HUEI, CHANG WEI-HAN.Pulsed laser breaking technique for glass substrates.Proceedings of SPIE, 2009, 7204: 1-9. |

| [50] | WANG XU-HUANG, YAO JIAN-HUA, ZHOU GUO-BIN,et al. Research of the technology of laser cutting LCD glass substrates based on thermal cracking method. Laser Technology, 2011, 35(4): 472-476. |

| [51] | WANG XU-HUANG, YAO JIAN-HUA, ZHOU GUO-BIN,et al. Numerical simulation and experiment of laser cuttingLiquid crystal display glass substrates . Chinese Journal of Lasers, 2011, 38(6): 1-5. |

| [1] | YU Leyangyang, ZHAO Fangxia, ZHANG Shuxin, XU Yixiang, NIU Yaran, ZHANG Zhenzhong, ZHENG Xuebin. Preparation of High-entropy Boride Powders for Plasma Spraying by Inductive Plasma Spheroidization [J]. Journal of Inorganic Materials, 2025, 40(7): 808-816. |

| [2] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [3] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [4] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [5] | ZHANG Jiawei, CHEN Ning, CHENG Yuan, WANG Bo, ZHU Jianguo, JIN Cheng. Electrical Properties of Bismuth Layered Piezoelectric Bi4Ti3O12 Ceramics with A/B-site Doping [J]. Journal of Inorganic Materials, 2025, 40(6): 690-696. |

| [6] | TANG Ying, LI Jie, XIANG Huaicheng, FANG Weishuang, LIN Huixing, YANG Junfeng, FANG Liang. Rattling Effect: A New Mechanism Affecting the Resonant Frequency Temperature Coefficient of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 656-666. |

| [7] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [8] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [9] | ZHOU Yangyang, ZHANG Yanyan, YU Ziyi, FU Zhengqian, XU Fangfang, LIANG Ruihong, ZHOU Zhiyong. Enhancement of Piezoelectric Properties in CaBi4Ti4O15-based Ceramics through Bi3+ Self-doping Strategy [J]. Journal of Inorganic Materials, 2025, 40(6): 719-728. |

| [10] | YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid [J]. Journal of Inorganic Materials, 2025, 40(6): 711-718. |

| [11] | HUANG Zipeng, JIA Wenxiao, LI Lingxia. Crystal Structure and Terahertz Dielectric Properties of (Ti0.5W0.5)5+ Doped MgNb2O6 Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 647-655. |

| [12] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [13] | YIN Changzhi, CHENG Mingfei, LEI Weicheng, CAI Yiyang, SONG Xiaoqiang, FU Ming, LÜ Wenzhong, LEI Wen. Effect of Ga3+ Doping on Crystal Structure Evolution and Microwave Dielectric Properties of SrAl2Si2O8 Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 704-710. |

| [14] | WU Lukang, FU Zhengqian, YU Ziyi, YANG Jun, ZHOU Bin, CHEN Xuefeng, XU Fangfang. Application of Electron Energy-loss Spectroscopy to BaTiO3 Multi-layer Ceramic Capacitors [J]. Journal of Inorganic Materials, 2025, 40(6): 683-689. |

| [15] | CHEN Xi, YUAN Yuan, TAN Yeqiang, LIU Changsheng. Strategic Study on the Development of Inorganic Non-metallic Biomaterials [J]. Journal of Inorganic Materials, 2025, 40(5): 449-456. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||