Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (3): 225-236.DOI: 10.3724/SP.J.1077.2014.13170

• Orginal Article • Next Articles

LI Jian-Lin1, CHEN Bin-Bin1, ZHANG Wen1, WANG Lian-Jun2, JIANG Wan2

Received:2013-03-25

Revised:2013-06-30

Published:2014-03-20

Online:2014-02-18

Supported by:CLC Number:

LI Jian-Lin, CHEN Bin-Bin, ZHANG Wen, WANG Lian-Jun, JIANG Wan. Recent Progress in Ceramic/Graphene Bulk Composites[J]. Journal of Inorganic Materials, 2014, 29(3): 225-236.

Add to citation manager EndNote|Ris|BibTeX

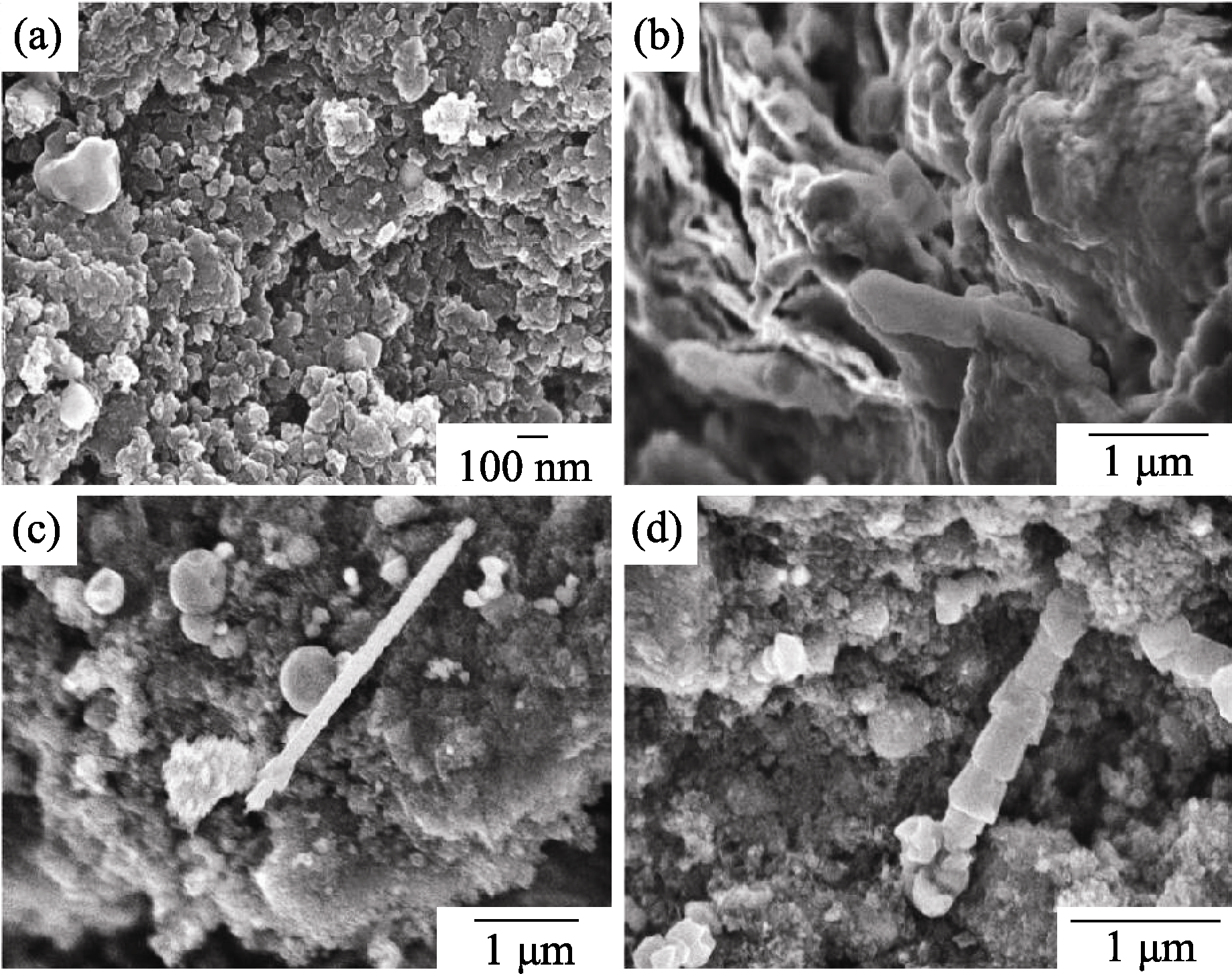

Fig. 2 FESEM micrographs of high energy ball milled graphite powder (a) As-milled graphite powder; (b) Graphite layers with a thickness of 20-50 nm that were highly distorted due to heavy impact of milling balls; (c) and (d) Carbon tubes with a diameter of 80-300 nm and a length of several microns produced during the milling[15]

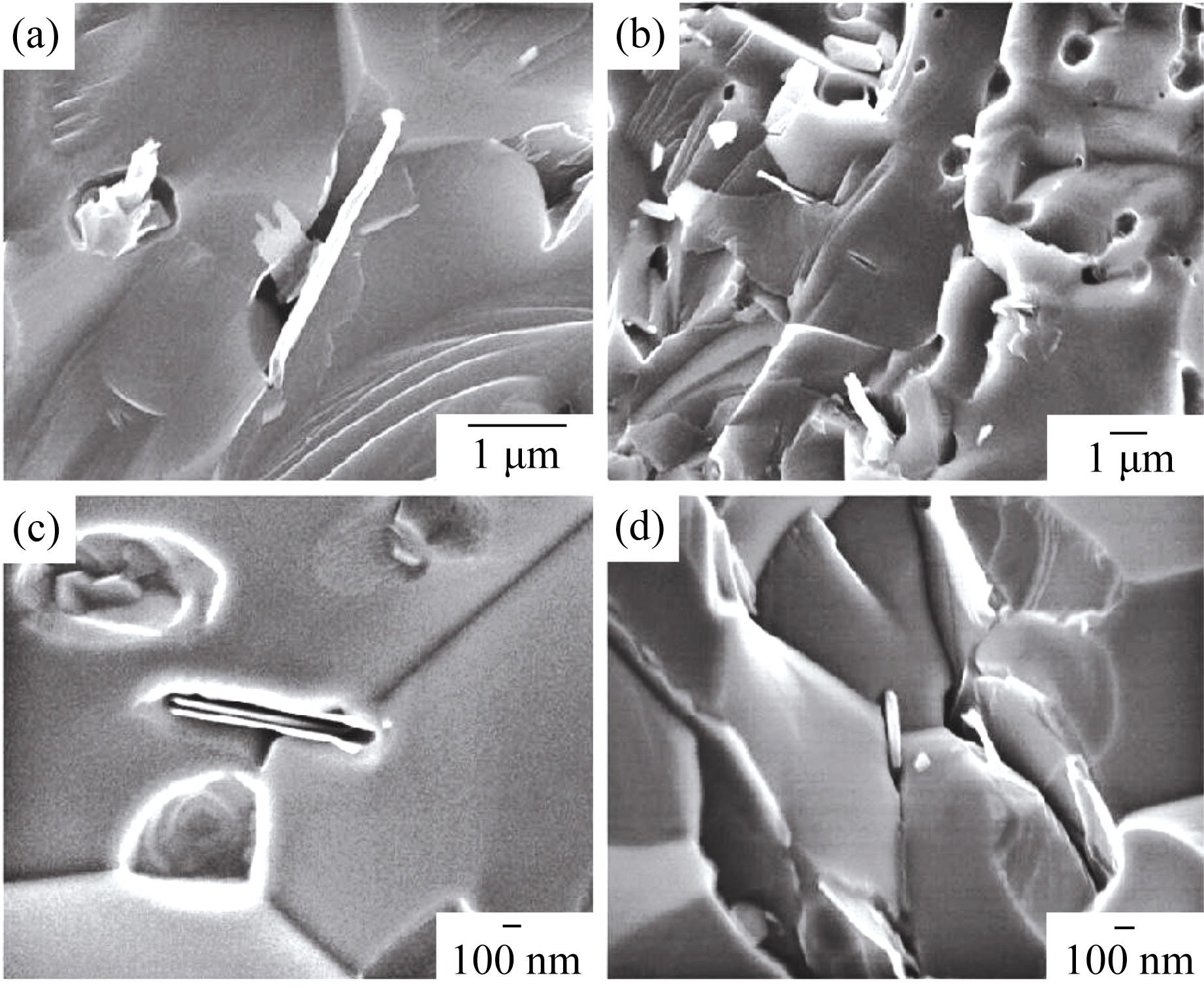

Fig. 3 FESEM micrographs showing nanosized graphene sheets and carbon tubes on fractured surface of TiC/C composite and pores of an average size of about 3 μm with a porosity of about 15%[15]

Fig. 4 FESEM micrographs showing: (a) the raw MWCNTs used as the starting material; (b-c) polished surface with a scratch of MWCNTs ((b) a shiny surface comprised of high- density aggregation CNTs; (c) transition from the dense to the loose CNTs); (d) polished surface with a scratch on it, MWCNTs in the surface have changed their structure and the outer graphene walls have come off the tubes[16]

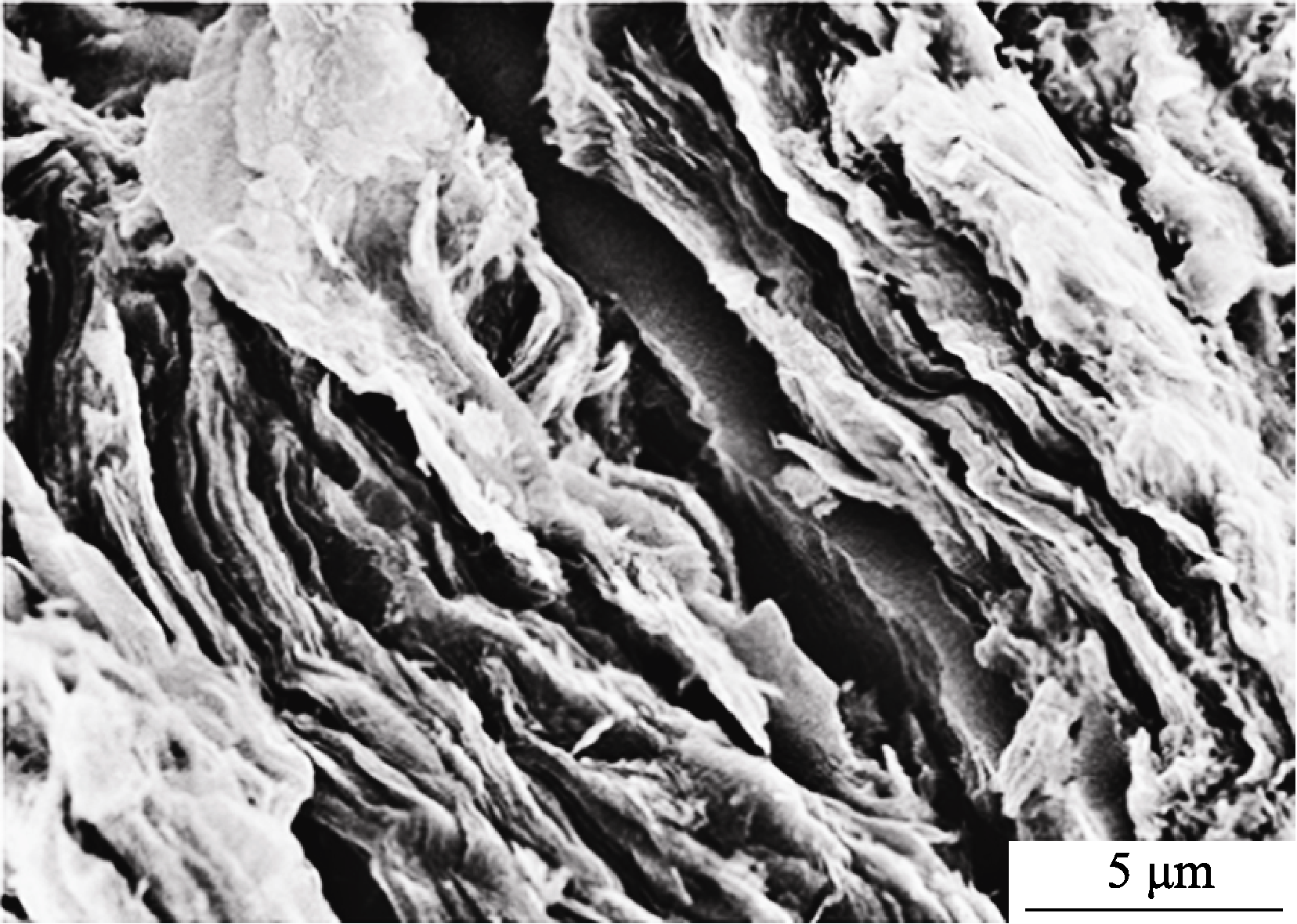

Fig.5 SEM image of the fracture surface of SiOC/GNS composite, with graphene forming a lamellar structure of a certain aligned distribution in the ceramic matrix[20]

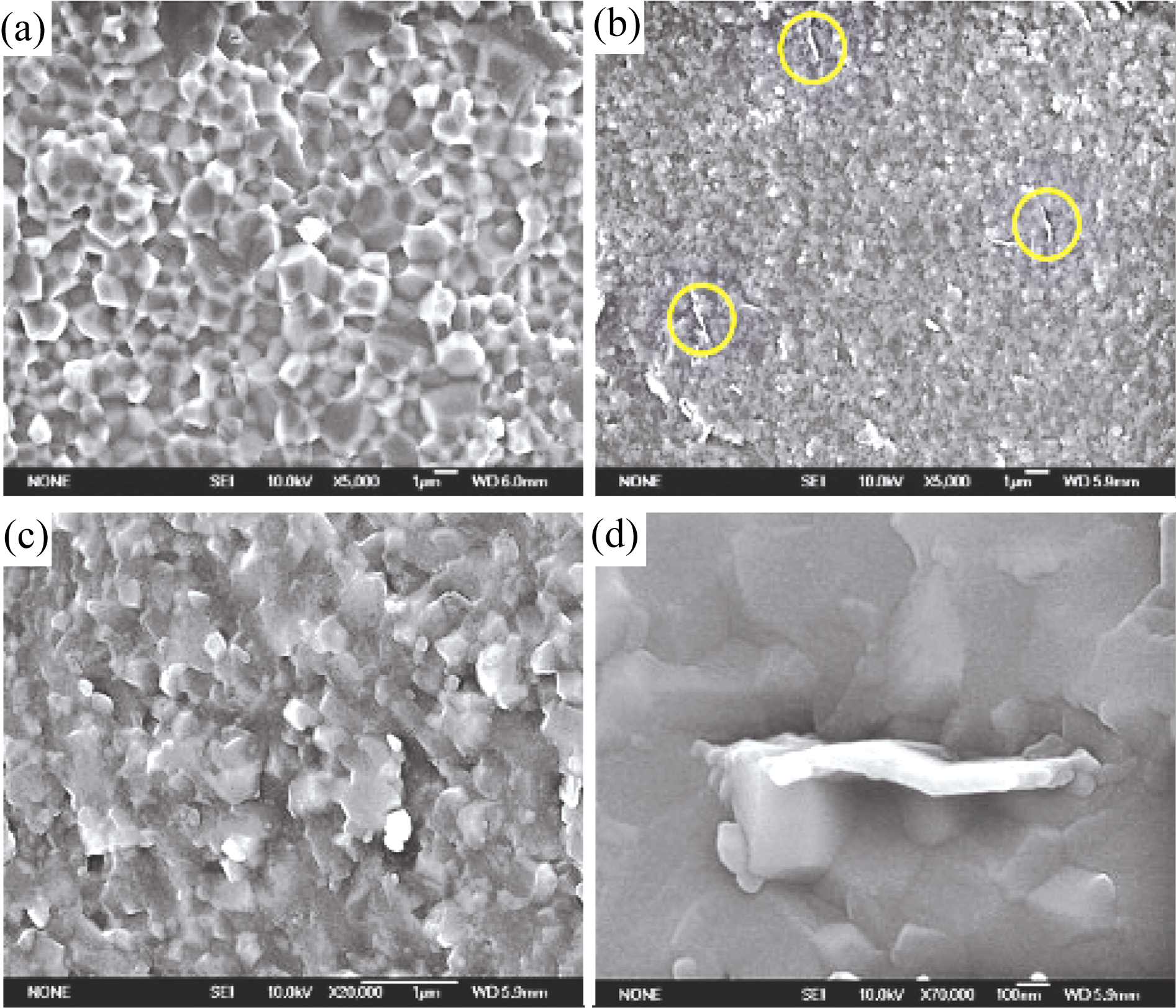

Fig. 7 SEM images of fractured surfaces of a pure Al2O3 ceramic (a) and a GNS/Al2O3 composite containing 1vol% GNSs (b-d) (c) and (d) are magnified parts of (b)[22]

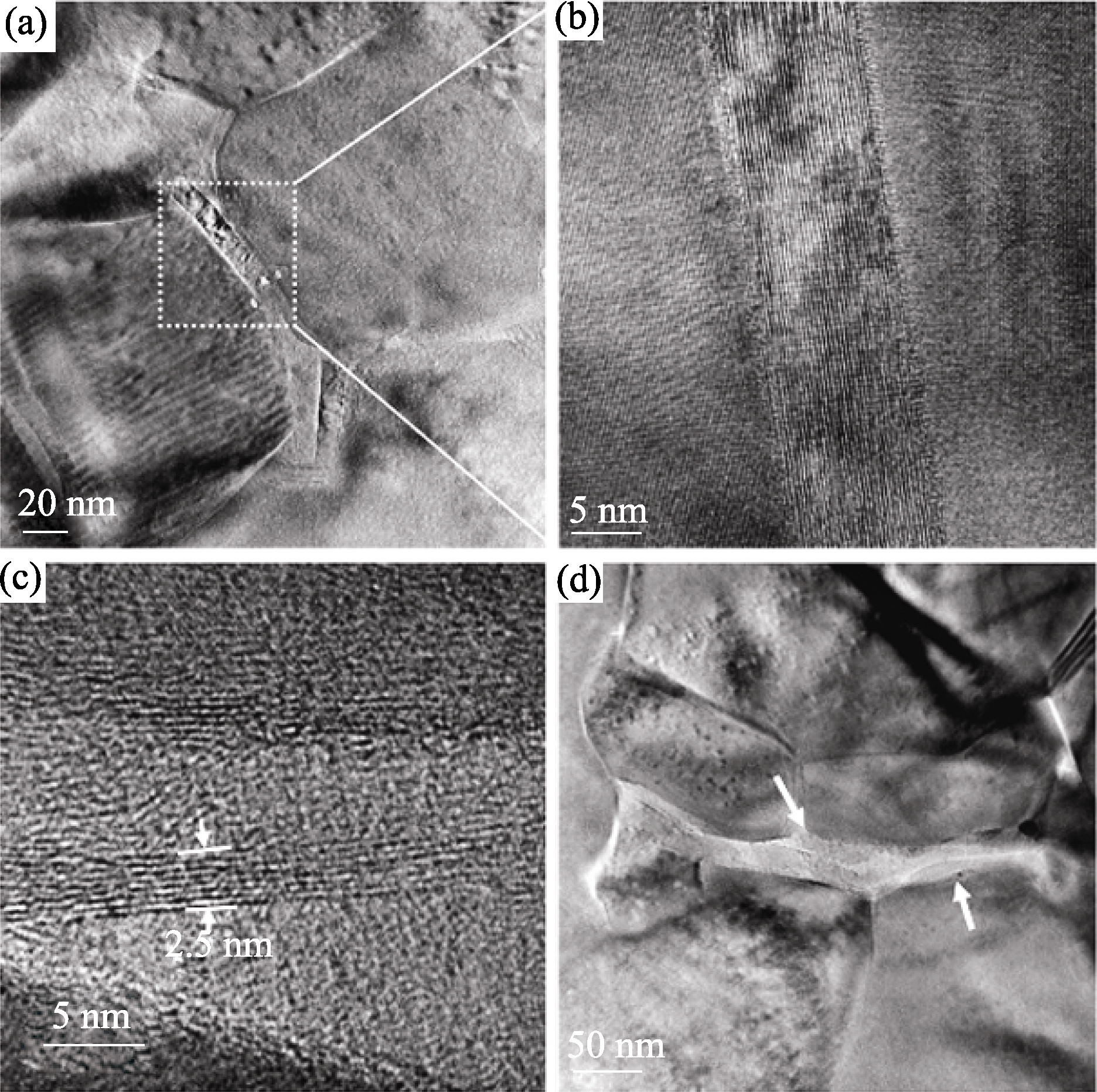

Fig. 8 TEM and HRTEM images of a GNS/Al2O3composite containing 5vol% GNSs (a) GNSs surrounding Al2O3 nanoparticles; (b) A magnified image of GNSs with a thickness of about 10 nm in (a); (c) GNSs with a thickness of 2.5 nm; (d) Overlap of GNSs between Al2O3 nano-particles[22]

| Starting powders / wt% | Additives / wt% | Type of GPL additive | Hardness HV/GPa | Fracture toughness KIC/(MPa•m1/2) | ||

|---|---|---|---|---|---|---|

| Si3N4 | Al2O3 | Y2O3 | C | |||

| 90 | 4 | 6 | 1 | Multilayer graphene | 16.38 ± 0.48 | 9.92 ± 0.38 |

| 90 | 4 | 6 | 1 | Nanographene platelets:Angstron Noo6-010-P | 14.59 ± 0.43 | 8.89 ± 0.37 |

| 90 | 4 | 6 | 1 | Exfoliated graphene nanoplatelets xGnp-M-25 | 15.05 ± 0.31 | 8.62 ± 0.17 |

| 90 | 4 | 6 | 1 | Exfoliated graphene nanoplatelets xGnp-M-5 | 14.59 ± 0.25 | 7.84 ± 0.43 |

| 90 | 4 | 6 | 0 | - | 15.38 ± 0.48 | 6.89 ± 0.39 |

Table 1 Mechanical properties of different Si3N4/graphene composites [34]

| Starting powders / wt% | Additives / wt% | Type of GPL additive | Hardness HV/GPa | Fracture toughness KIC/(MPa•m1/2) | ||

|---|---|---|---|---|---|---|

| Si3N4 | Al2O3 | Y2O3 | C | |||

| 90 | 4 | 6 | 1 | Multilayer graphene | 16.38 ± 0.48 | 9.92 ± 0.38 |

| 90 | 4 | 6 | 1 | Nanographene platelets:Angstron Noo6-010-P | 14.59 ± 0.43 | 8.89 ± 0.37 |

| 90 | 4 | 6 | 1 | Exfoliated graphene nanoplatelets xGnp-M-25 | 15.05 ± 0.31 | 8.62 ± 0.17 |

| 90 | 4 | 6 | 1 | Exfoliated graphene nanoplatelets xGnp-M-5 | 14.59 ± 0.25 | 7.84 ± 0.43 |

| 90 | 4 | 6 | 0 | - | 15.38 ± 0.48 | 6.89 ± 0.39 |

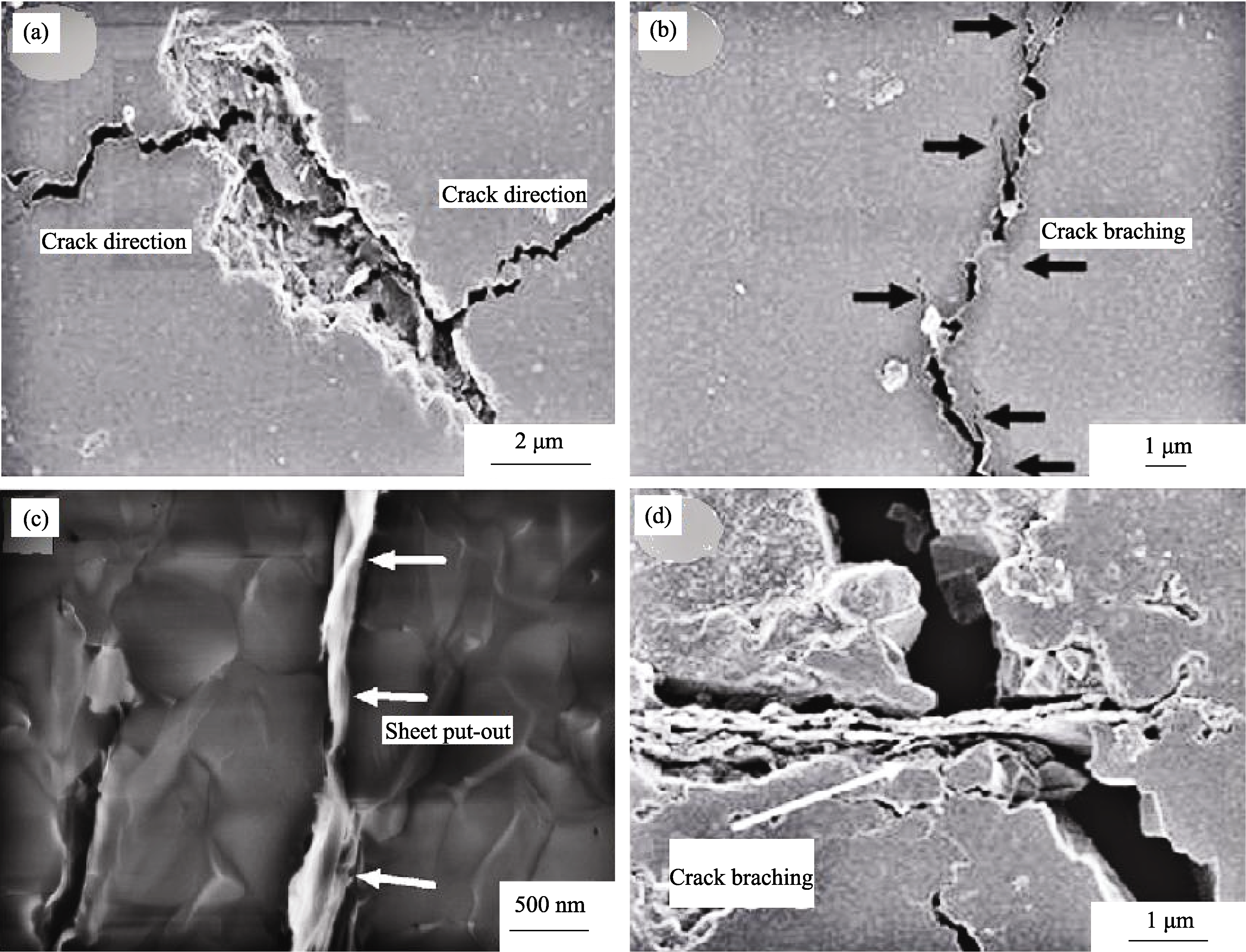

Fig. 10 Toughening mechanisms of composites (a) Crack deflection on a plane with larger size and crack plane orientation almost parallel (fracture line)[29]; (b) Crack branching during crack propagation in the nanographene platelet-reinforced composite (fracture line)[34]; (c) Sheet put-out with a GPL on the fracture surface, with the plane of the sheet perpendicular to the plane of the fracture surface[28]; (d) Crack bridging by GPLs on the fracture line with the plane orientated of sheet nearly perpendicular to the plane of the polished surface[34]

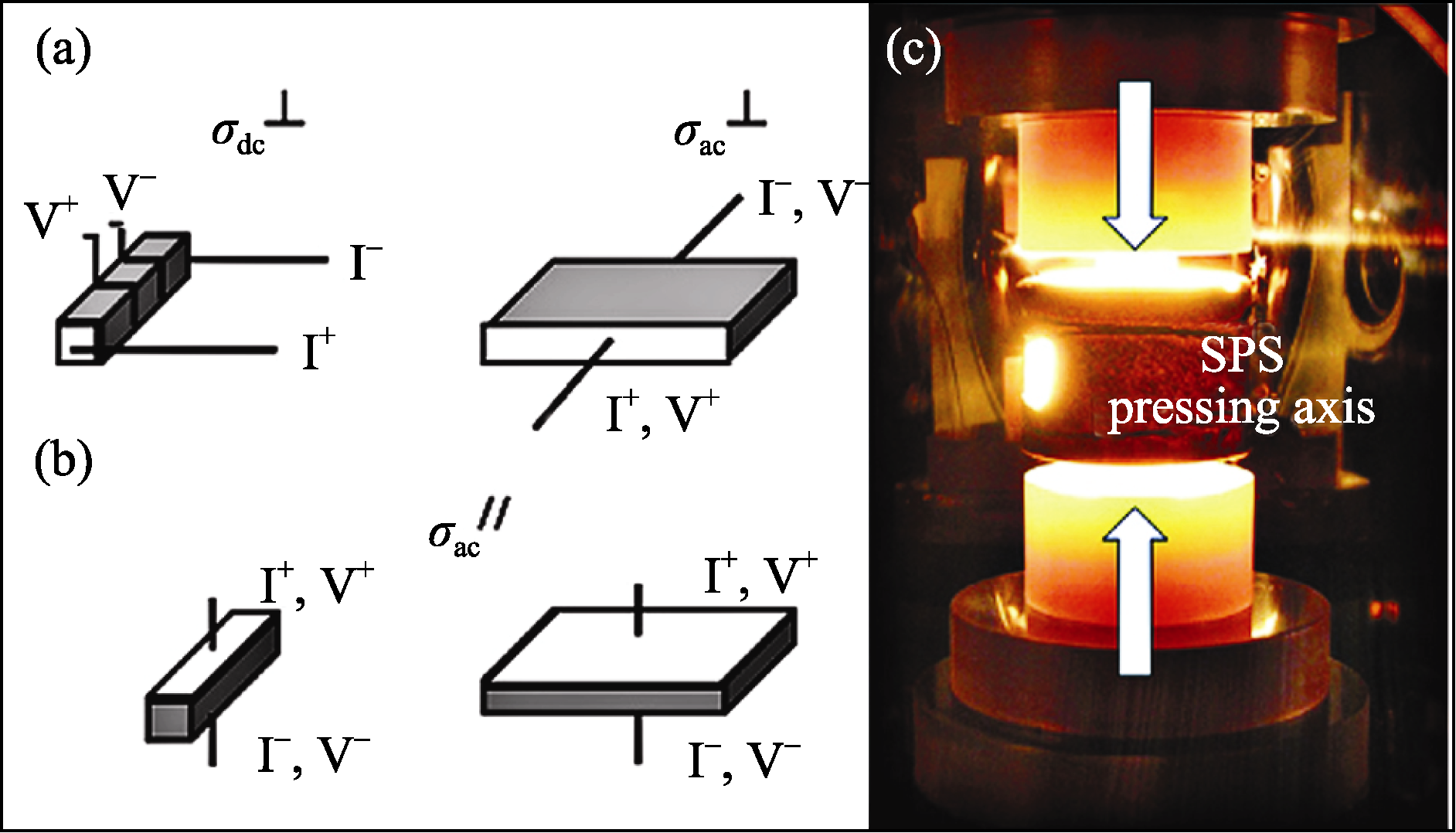

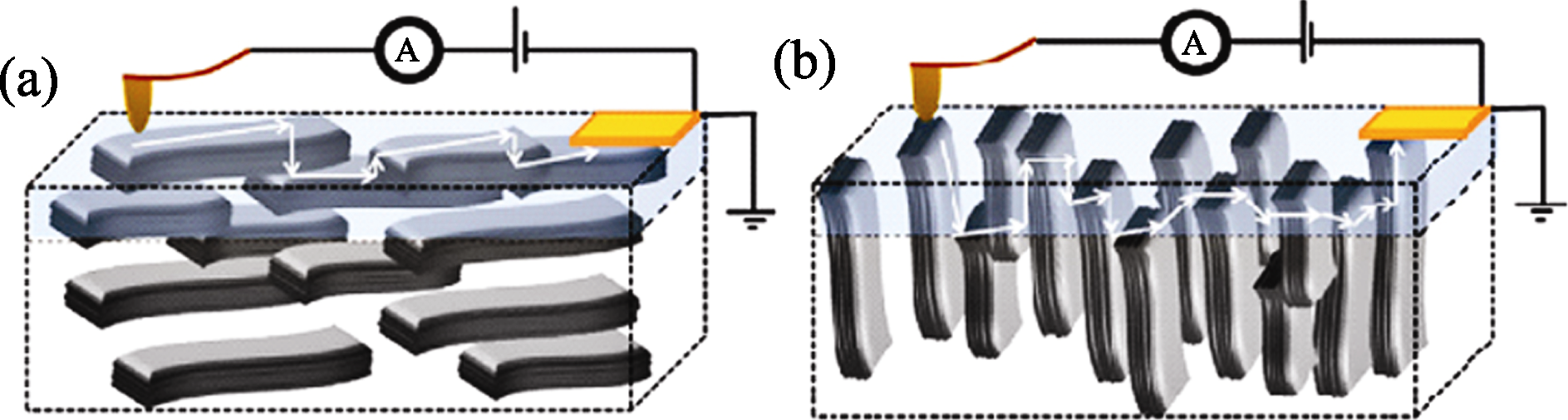

Fig. 11 Diagram of experimental setup of dc and ac electrical conductivity (σdc ,σac) measurements along different directions[35] (a) perpendicular (defined by superscript┴) and (b) parallel (superscript″) to the SPS pressing axis; (c) sample and graphite die in the SPS furnace

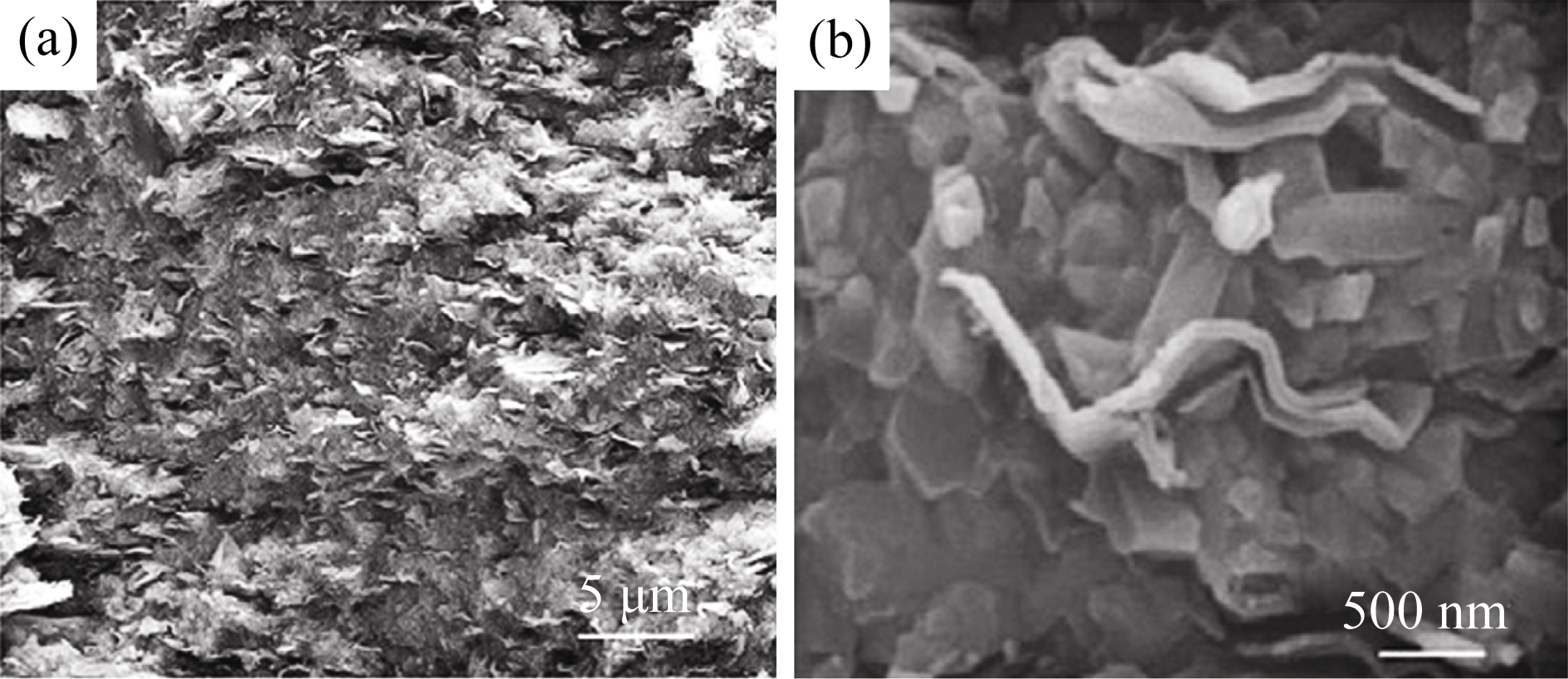

Fig. 12 FESEM micrographs of the fracture surface of the Si3N4/GNP composite where nanoplatelets protrude from the surface (a) and high magnification image showing the zigzag bending of nanoplatelets along the matrix grain boundaries (b)[36]

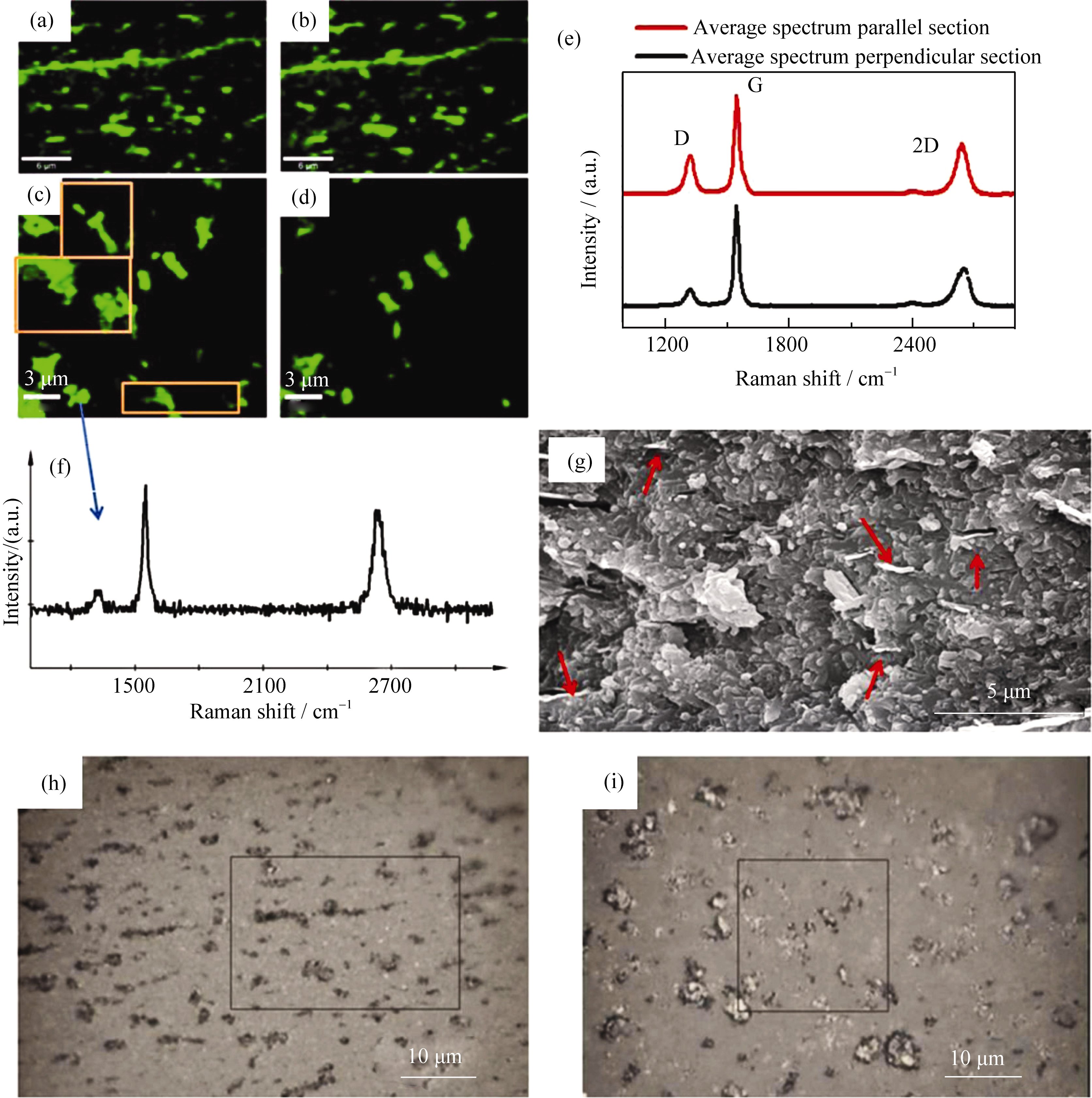

Fig. 13 Raman images built from G (a and c) and D peak intensities (b and d) for both composite orientations: parallel (a and b) and perpendicular (c and d) to the SPS pressing axis. Average spectra of both scanned regions (e). Example of a single spectrum extracted from the collection of image (c) with the intense 2D peak of few layer graphene (f). SEM micrograph of the fracture surface (parallel orientation) (g), showing the preferential orientation of projected GNPs (pointed by arrows). (h and i) Optical images of the scanned zones (outlined) for both specimen orientations parallel (left) and perpendicular (right) to the SPS axis[38]

Fig. 14 Simplified schematics of the measuring geometry (counter-electrode at the sample surface edge) to illustrate the conducting paths for the orientations perpendicular (a) and parallel (b) respect to the SPS pressing axis[36]

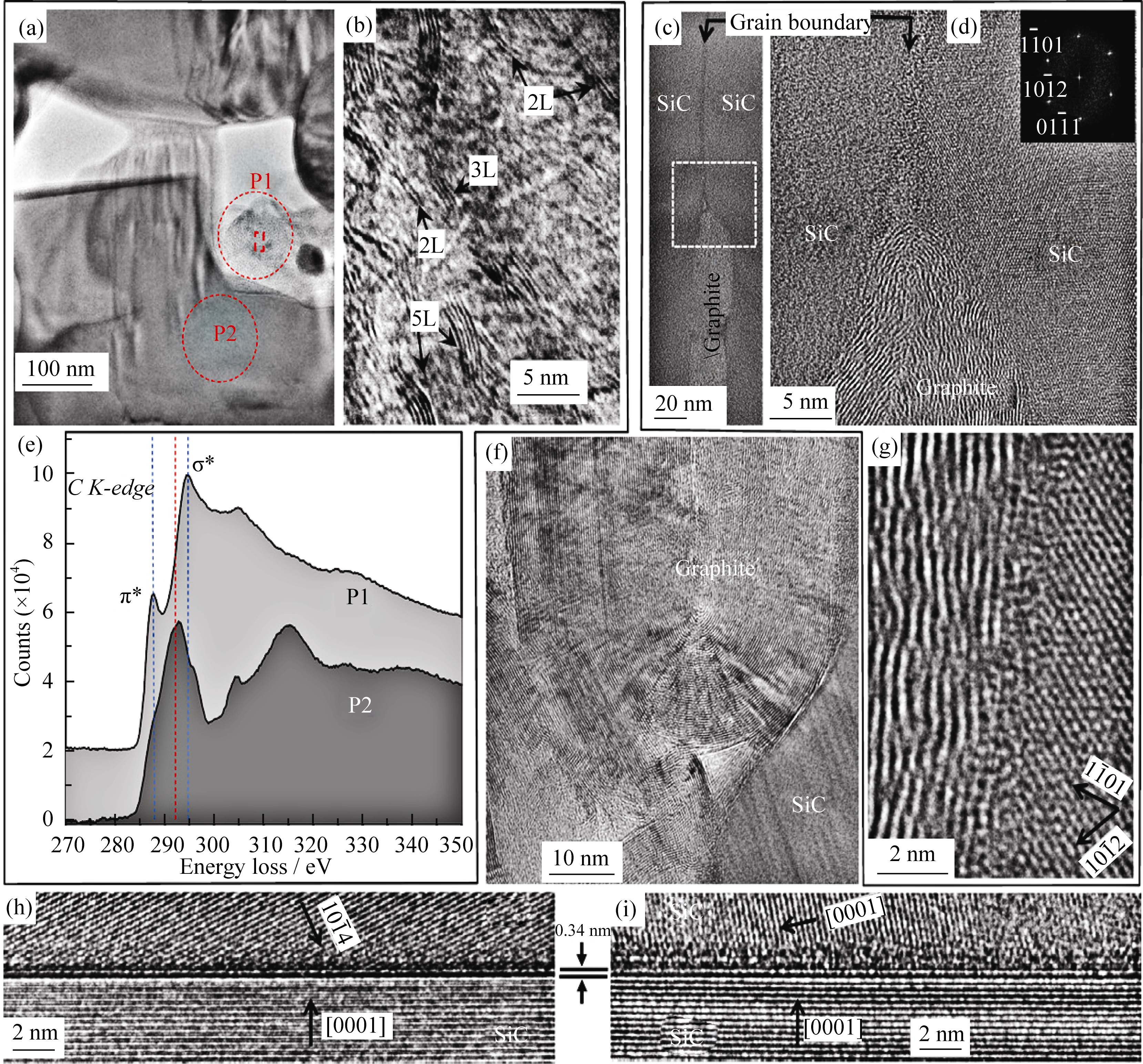

Fig. 15 TEM images of the α-SiC composite sample, showing several regions with different number of graphene layers. Region 1: (a) low magnification TEM image of the region of interest. (b) is a higher magnification image of the P1 region (inside the highlighted rectangular region) which is rich in sp2 carbon, showing different cross-section views of few-layers graphene flakes (2L, 3L and 5L); the spacing between dark contrast lines is consistent with the spacing between graphene sheets. (e) are electron energy loss spectroscopy spectra (after multiple-scattering background removal) of the carbon K edge at positions P1 and P2, respectively. Region 2: (c) low magnification TEM image of a grain boundary with formation of a graphite island, (d, g) high-resolution TEM images of the same region, the inset is SEAD of the right side SiC grain. Region 3: (f) graphitic formation of several tens of nanometers. Region 4: (h and i) two different grain boundaries presenting bi-layer graphene[40]

| [1] | GEIM A K, NOVOSELOV K S. The rize of graphene. Nature Materials, 2007, 6(3): 183-191. |

| [2] | NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films. Science, 2004, 306(5696): 666-669. |

| [3] | WEITZ R T, YACOBY A. Nanomaterials: graphene rests easy. Nat. Nanotechnol., 2010, 5(10): 699-700. |

| [4] | LEE C, WEI X, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer grapheme. Science, 2008, 321(5887): 385-388. |

| [5] | GEIM A K. Graphene: status and prospects. Science, 2009, 324(5934): 1530-1534. |

| [6] | VAN B J. Graphene: from strength to strength. Nat. Nanotechnol., 2007, 2(4): 199-201. |

| [7] | NAIR R, BLAKE P, GRIGORENKO A, et al. Fine structure constant defines visual transparency of grapheme. Science, 2008, 320(5881): 1308. |

| [8] | NOVOSELOV K S, JIANG Z, ZHANG Y, et al. Room-temperature quantum hall effect in grapheme. Science, 2007, 315(5817): 1379. |

| [9] | KATSNELSON M I, NOVOSELOV K S, GEIM A K. Chiral tunnelling and the Klein paradox in graphene. Nat. Phys., 2006, 2(9): 620-625. |

| [10] | HEERSCHE H B, JARILLO-HERRERO P, OOSTINGA J B, et al. Bipolar supercurrent in graphene. Nature, 2007, 446(7131): 56-59. |

| [11] | WANG Y, HUANG Y, SONG Y, et al. Room temperature ferromagnetism of grapheme. Nano Lett., 2009, 9(1): 220-224. |

| [12] | ZHAO Y, HUANG W J. Research progress on preparation and performance of grephene and its composite. Journal of Chongqing University of Technology (Natural Science), 2011, 7(25): 64-70. |

| [13] | XIE P, LU Q, WANG L E, et al. Research progress in preparation and modify of graphene and polymers/graphene nanocomposities. Materials Review, 2010, 11(24): 163-166. |

| [14] | LI Y X, CHEN Y, ZHUANG X D, et al. Chemistry and potential application of graphene. Journal of Shanghai Second Polytechnic University, 2010, 4(27): 259-269. |

| [15] | LI J L, BAI G Z, WANG L J, et al. Microstructure and mechanical properties of in-situ produced TiC/C nanocomposite. Scripta Materialia, 2005, 52(9): 867-871. |

| [16] | LI J L, BAI G Z, WANG L J, et al. Microstructure and mechanical properties of hot-pressed bulk carbon nanotubes compacted by spark plasma sintering. Carbon, 2005, 43(13): 2649-2653. |

| [17] | LI J L, WANG L J, JIANG W, et al. Surface graphitization and mechanical properties of hot-pressed bulk carbon nanotubes compacted by spark plasma sintering. Carbon, 2007, 45(13): 2636-2642. |

| [18] | CHEN J T, CHEN L Q, ZHANG Z C, et al. Graphene layers produced from carbon nanotubes by friction. Carbon, 2012, 50(5): 1934-1941. |

| [19] | JI F, LI Y L, FENG J M, et al. Electrochemical performance of graphene nanosheets and ceramic composites as anodes for lithium batteries. J. Mater. Chem., 2009, 19(47): 9603-9607. |

| [20] | KANG Y R, JI F, LI Y L, et al. Synthesis of graphite oxides by chemical oxidation method and ceramic composites. Journal of the Chinese Ceramic Society, 2010, 8(38): 1558-1561. |

| [21] | HE T, LI J L, WANG L J, et al. Preparation and consolidation of alumina/graphene composite powders. Materials Transactions, 2009, 50(4): 749-751. |

| [22] | FAN Y C, WANG L J, LI J L, et al. Preparation and electrical properties of graphene nanosheet/Al2O3 composites. Carbon, 2010, 48(6): 1743-1749. |

| [23] | FAN Y C, JIANG W, AKIRA K. Highly conductive few-layer graphene/Al2O3 nanocomposites with tunable charge carrier type. Advanced Functional Materials, 2012, 22(18): 3882-3889. |

| [24] | WANG K, WANG Y F, WEI T, et al. Preparation of graphene nanosheet/alumina composites by spark plasma sintering. Materials Research Bulletin, 2011, 46(2): 315-318. |

| [25] | LIU J, YAN H X, MIKE J R, et al. Toughening of zirconia/alumine composites by the addition of graphene plateles. Journal of the Europen Ceramic Society, 2012, 32(16): 4185-4193. |

| [26] | LIU J, YAN H X, JIANG K. Mechanical properties of graphene platelet-reinforced alumina ceramic composites. Ceramics International, 2013, 39(6): 6215-6221. |

| [27] | WALKER L S, MAROTTO V R, RAFIEE M A, et al. Toughening in graphene ceramic composites. ACS Nano, 2011, 4(5): 3182-3190. |

| [28] | KUN P, TAPASZTÓ O, WÉBER F, et al. Determination of structural and mechanical properties of multilayer graphene added silicon nitride-based composites. Ceramics International, 2012, 38(1): 211-216. |

| [29] | DUSZA J, MORGIEL J, DUSZOVÁ A, et al. Microstructure and fracture toughness of Si3N4+ graphene platelet composites. Journal of the European Ceramic Society, 2012, 32(12): 3389-3397. |

| [30] | KVETKOVÁ L, DUSZOVÁ A, KAŠIAROVÁ M, et al. Influence of processing on fracture toughness of Si3N4 + graphene platelet composites. Journal of the European Ceramic Society, 2013, 33(12): 2299-2304. |

| [31] | TAPASZTÓ O, TAPASZTÓ L, MARKÒ M, et al. Dispersion patterns of graphene and carbon nanotubes in ceramic matrix composites. Chemical Physics Letters, 2011, 511(4/5/6): 340-343. |

| [32] | BELMONTE M, RAM-REZ C, JULIAN J G, et al. The beneficial effect of graphene nanofillers on the tribological performance of ceramics. Carbon, 2013, 61: 431-435. |

| [33] | HVIZDOŠ P, DUSZA J, BALÁZSI C. Tribological properties of Si3N4- graphene nanocomposites. Journal of the European Ceramic Society, 2013, 33(12): 2359-2364. |

| [34] | KVERTKOVÁ L, DUSZOVÁ A, HVIZDOŠ P, et al. Fracture toughness and toughening mechanisms in graphene platelet reinforced Si3N4 composites. Scripta Materialia, 2012, 66(10): 793-796. |

| [35] | RAMIREZ C, FIGUEIREDO F M, MIRANZO P, et al. Graphene nanoplatelet/silicon nitride composites with high electrical conductivity. Carbon, 2012, 50(10): 3607-3615. |

| [36] | RAMIREZ C, GARZÓN L, MIRANZO P, et al. Electrical conductivity maps in graphene nanoplatelet/silicon nitride composites using conducting scanning force microscopy. Carbon, 2011, 49(12): 3873-3880. |

| [37] | RAMÍRZE C, VEGA-DIAZ S M, FIGUEIREDO F M, et al. Synthesis of conducting graphene/Si3N4 composites by spark plasma sintering. Carbon, 3013, 57: 425-432. |

| [38] | RAMIREZ C, OSENDI M I. Characterzation of graphene nanoplateles-Si3N4 composites by Raman spectroscopy. Journal of the European Ceramic Society, 2013, 33(3): 471-477. |

| [39] | MIRANZO P, GARCÍA E, RAMÍREZ C, et al. Anisotropic thermal conductivity of silicon nitride ceramics containing carbon nanostructures. Journal of the European Ceramic Society, 2012, 32(8): 1847-1854. |

| [40] | MIRANZO P, GARCÍA E, RAMÍREZ C, et al. In situ processing of electrically conducting graphene/SiC nanocomposites. Journal of the European Ceramic Society, 2013, 33(10): 1665-1674. |

| [41] | YADHUKULAKRISHNAN G B, KARUMURI S, RAHMAN A, et al. Spark plasma sintering of graphene reinforced zirconium diboride ultra- high temperature ceramic composites. Ceramics International, 2013, 39(6): 6637-6649. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | YU Leyangyang, ZHAO Fangxia, ZHANG Shuxin, XU Yixiang, NIU Yaran, ZHANG Zhenzhong, ZHENG Xuebin. Preparation of High-entropy Boride Powders for Plasma Spraying by Inductive Plasma Spheroidization [J]. Journal of Inorganic Materials, 2025, 40(7): 808-816. |

| [3] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [4] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [5] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [6] | ZHANG Jiawei, CHEN Ning, CHENG Yuan, WANG Bo, ZHU Jianguo, JIN Cheng. Electrical Properties of Bismuth Layered Piezoelectric Bi4Ti3O12 Ceramics with A/B-site Doping [J]. Journal of Inorganic Materials, 2025, 40(6): 690-696. |

| [7] | TANG Ying, LI Jie, XIANG Huaicheng, FANG Weishuang, LIN Huixing, YANG Junfeng, FANG Liang. Rattling Effect: A New Mechanism Affecting the Resonant Frequency Temperature Coefficient of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 656-666. |

| [8] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [9] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [10] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [11] | ZHOU Yangyang, ZHANG Yanyan, YU Ziyi, FU Zhengqian, XU Fangfang, LIANG Ruihong, ZHOU Zhiyong. Enhancement of Piezoelectric Properties in CaBi4Ti4O15-based Ceramics through Bi3+ Self-doping Strategy [J]. Journal of Inorganic Materials, 2025, 40(6): 719-728. |

| [12] | YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid [J]. Journal of Inorganic Materials, 2025, 40(6): 711-718. |

| [13] | HUANG Zipeng, JIA Wenxiao, LI Lingxia. Crystal Structure and Terahertz Dielectric Properties of (Ti0.5W0.5)5+ Doped MgNb2O6 Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 647-655. |

| [14] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [15] | YIN Changzhi, CHENG Mingfei, LEI Weicheng, CAI Yiyang, SONG Xiaoqiang, FU Ming, LÜ Wenzhong, LEI Wen. Effect of Ga3+ Doping on Crystal Structure Evolution and Microwave Dielectric Properties of SrAl2Si2O8 Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 704-710. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||