Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (12): 1405-1412.DOI: 10.15541/jim20230164

Special Issue: 【信息功能】功能晶体(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Yicun1( ), HAO Xiaobin1, DAI Bing1(

), HAO Xiaobin1, DAI Bing1( ), WEN Dongyue1, ZHU Jiaqi1, GENG Fangjuan1, YUE Weiping2, LIN Weiqun2(

), WEN Dongyue1, ZHU Jiaqi1, GENG Fangjuan1, YUE Weiping2, LIN Weiqun2( )

)

Received:2023-04-04

Revised:2023-05-23

Published:2023-08-31

Online:2023-08-31

Contact:

DAI Bing, professor. E-mail: daibinghit@vip.126.com;About author:LI Yicun (1996-), male, PhD candidate. E-mail: 741624995@qq.com

Supported by:CLC Number:

LI Yicun, HAO Xiaobin, DAI Bing, WEN Dongyue, ZHU Jiaqi, GENG Fangjuan, YUE Weiping, LIN Weiqun. Optimization Design of MPCVD Single Crystal Diamond Growth Based on Plasma Diagnostics[J]. Journal of Inorganic Materials, 2023, 38(12): 1405-1412.

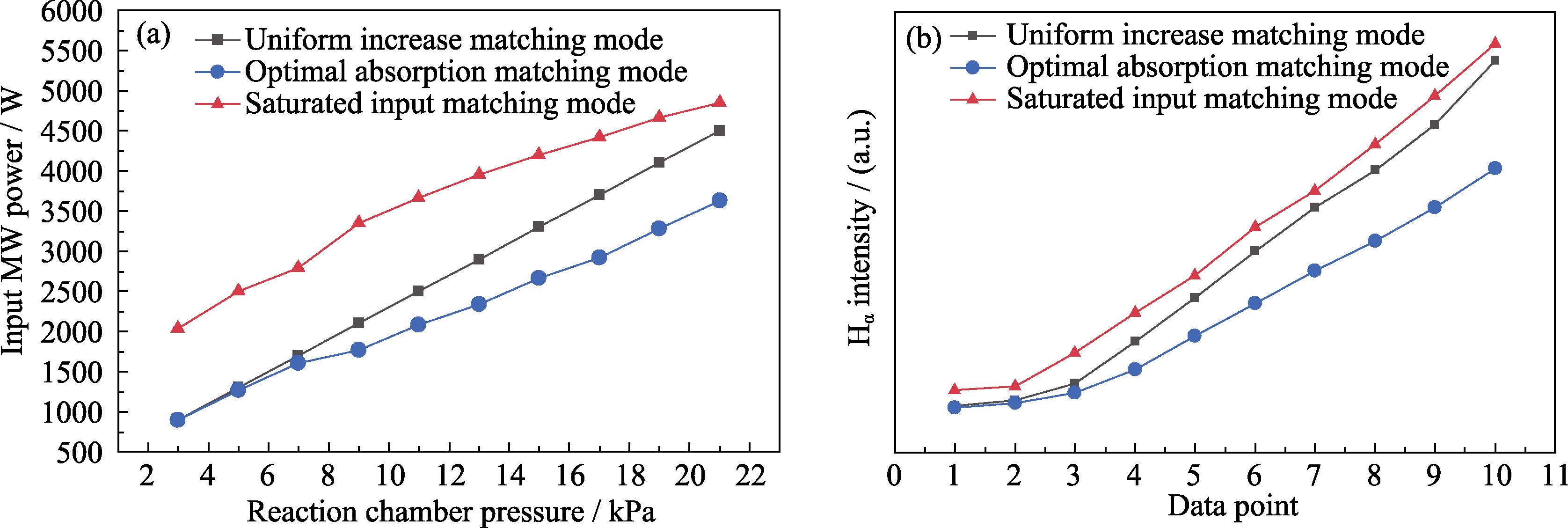

Fig. 2 Pressure-microwave power parameter curves (a) and Hα intensity of plasma central region (b) under three matching modes The abscissa in (b) corresponds to the 10 parameter observation points in (a)

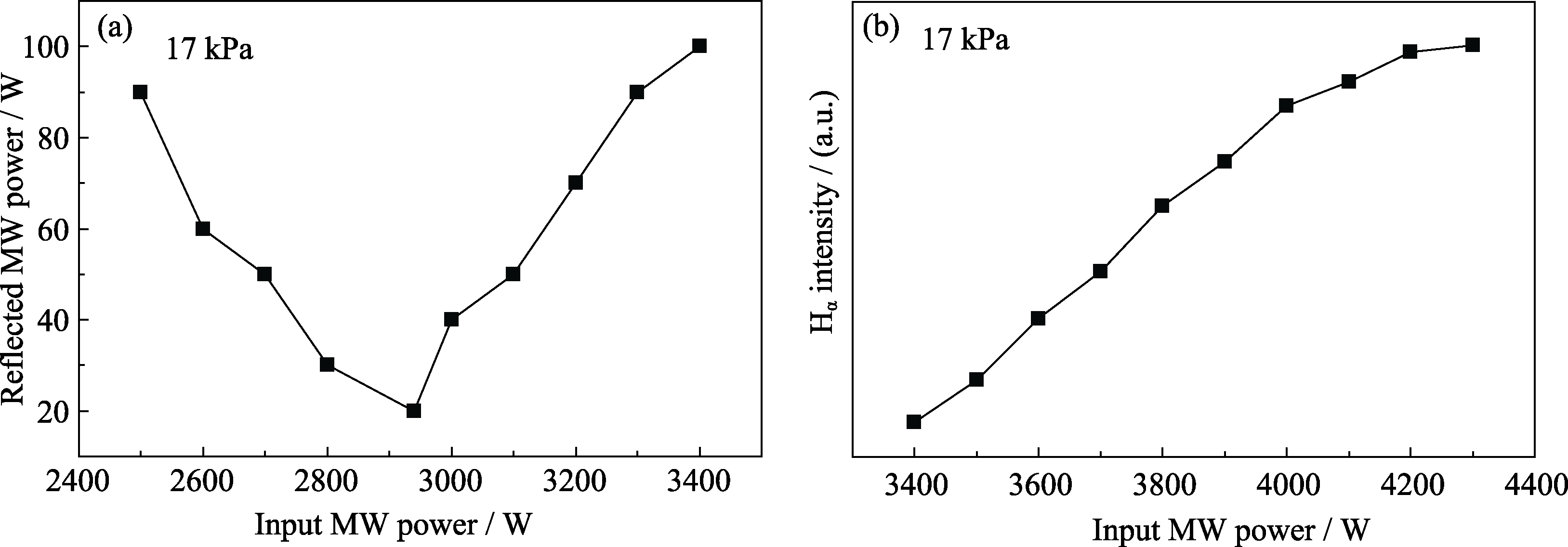

Fig. 3 At a certain pressure, change of reflected power (a) and change of Hα intensity (b) with input power The data at 17 kPa are selected for display, and the variation trend is similar under the other pressures

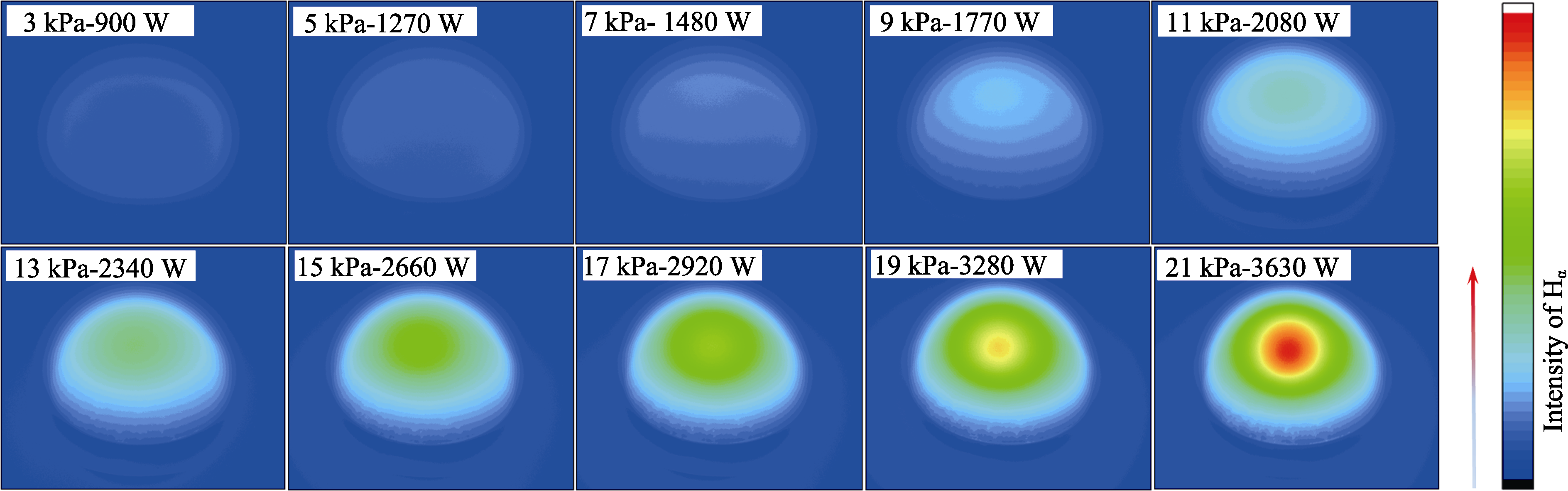

Fig. 4 Atomic hydrogen concentration distributions in plasma at various observation parameter points under optimal absorption matching mode with similar distribution pattern changes in other modes

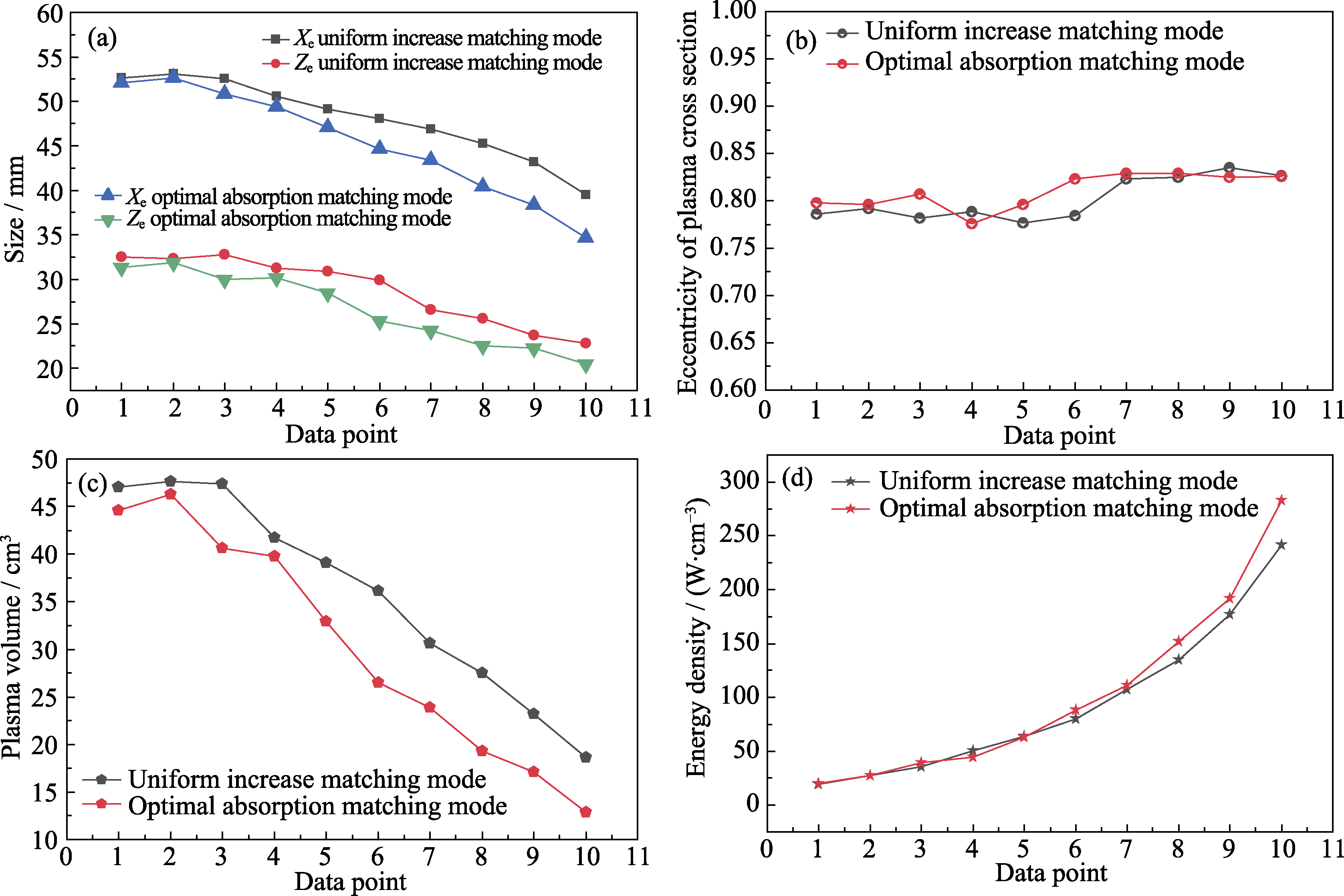

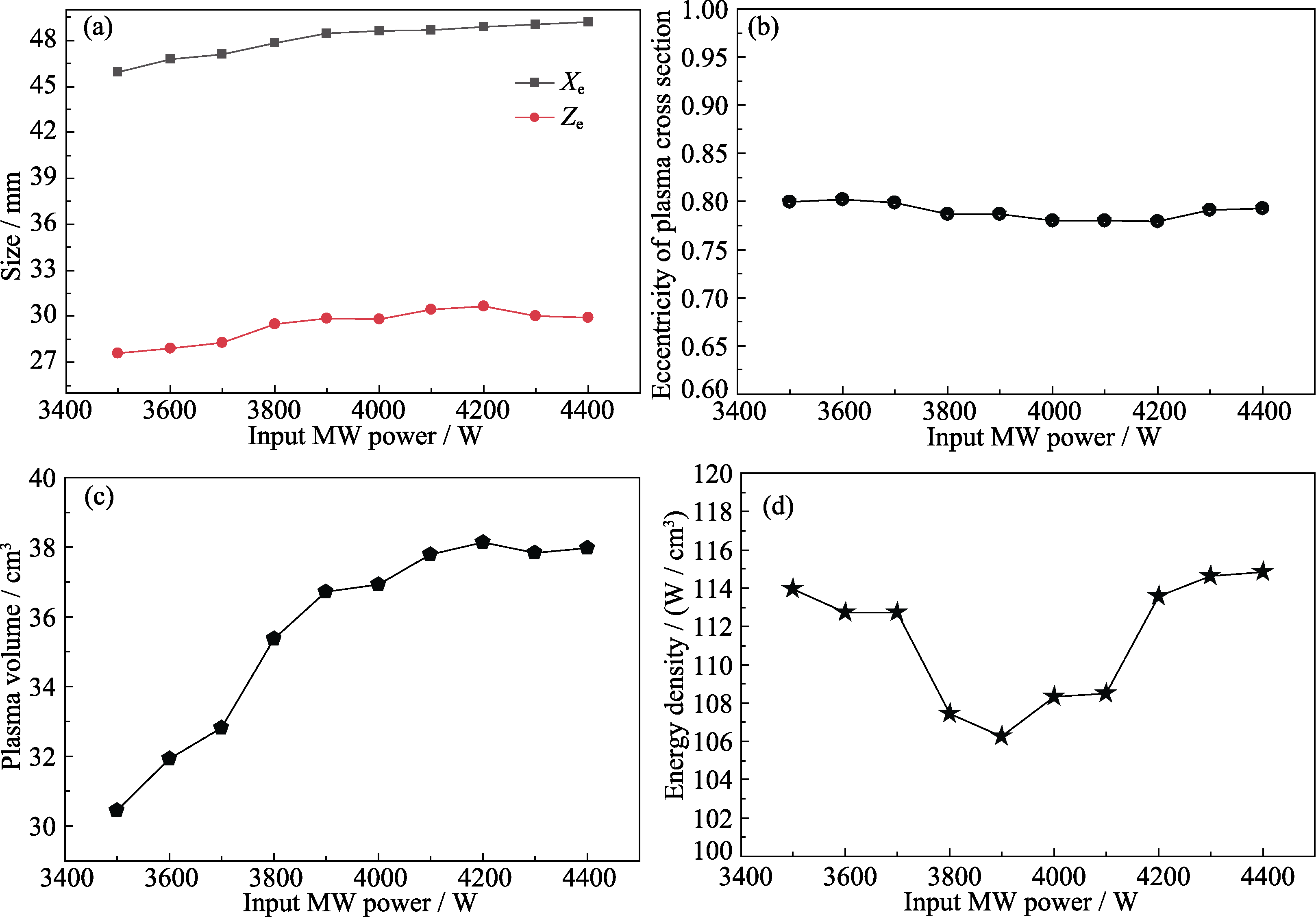

Fig. 5 Quantitative analysis of plasma in uniform increase and optimal absorption matching mode (a) Sizes of major axis and minor axis; (b) Eccentricity; (c) Volume; (d) Energy density

Fig. 6 Changes in plasma major axis and minor axis (a), eccentricity (b), volume (c), and energy density (d) with input power under constant pressure with data at 16 kPa showing the selected display, and variation trends being similar under different pressures

Fig. 7 Prediction map of MPCVD single crystal diamond growth process HITLH-2450M system, seed at 0.5 mm in thickness, under the conditions of 20 ℃ water-cooling, 9-17 kPa pressure, and 1600-4200 W microwave power

| Parameter | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|

| Preset growth temperature/℃ | 850 | 850 | 850 |

| Preset major axis/mm | 48 | 42 | 53 |

| Predicted pressure- microwave power | 14.2 kPa- 3140 W | 15.6 kPa- 2600 W | 12.8 kPa- 3500 W |

| Actual growth temperature/℃ | 867 | 860 | 835 |

| Actual major axis/mm | 47.5 | 41.2 | 52.8 |

| Energy density/ (W·cm-3) | 121.3 | 148.5 | 115.2 |

| Growth rate/(μm·h-1) | 8.5 | 8.9 | 8.2 |

Table 1 Parameter points selection based on the predicted map and growth parameters of actual single crystal diamond

| Parameter | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|

| Preset growth temperature/℃ | 850 | 850 | 850 |

| Preset major axis/mm | 48 | 42 | 53 |

| Predicted pressure- microwave power | 14.2 kPa- 3140 W | 15.6 kPa- 2600 W | 12.8 kPa- 3500 W |

| Actual growth temperature/℃ | 867 | 860 | 835 |

| Actual major axis/mm | 47.5 | 41.2 | 52.8 |

| Energy density/ (W·cm-3) | 121.3 | 148.5 | 115.2 |

| Growth rate/(μm·h-1) | 8.5 | 8.9 | 8.2 |

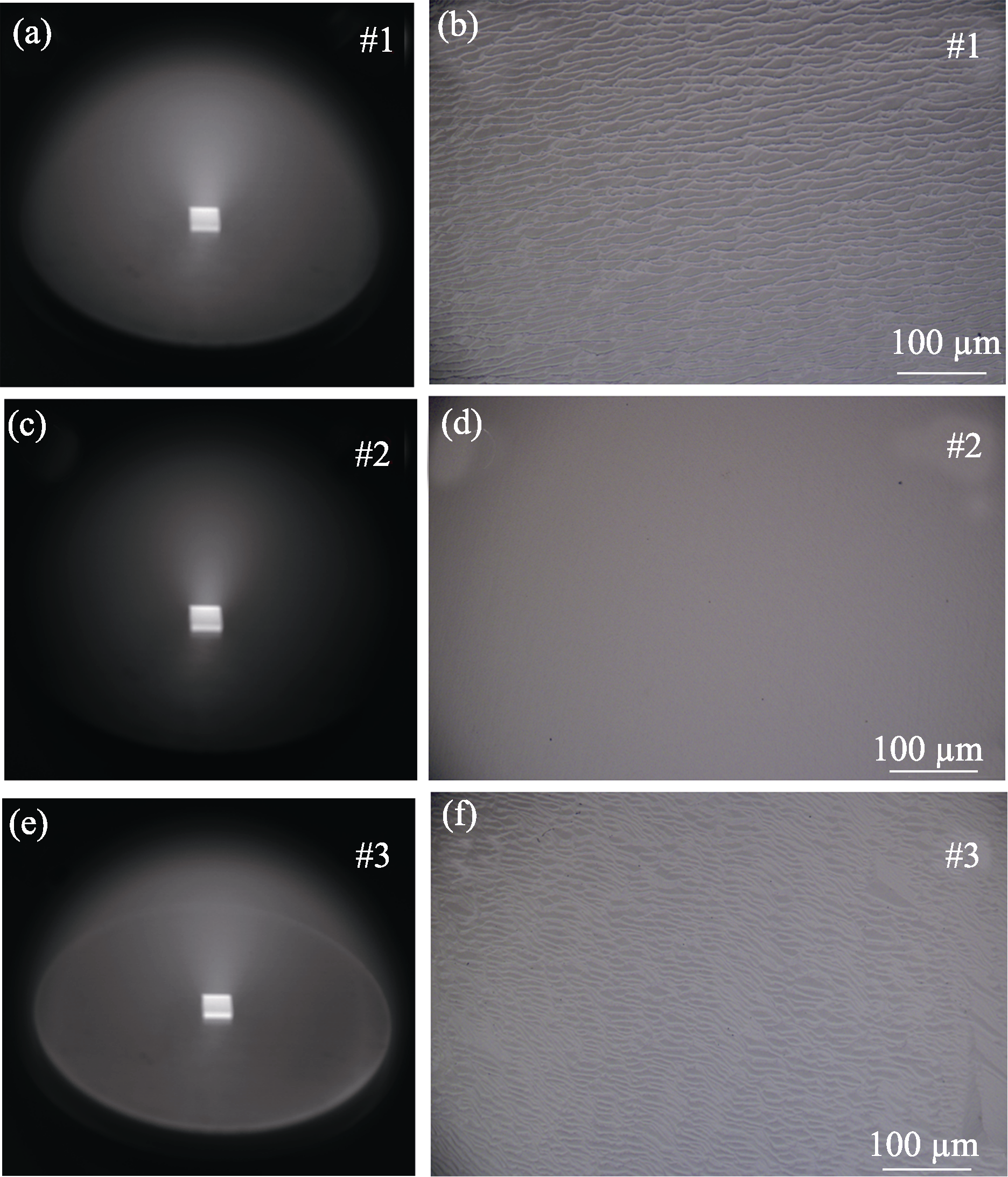

Fig. 8 Photos of plasma growth environment of three samples (with Hα filter) and the surface optical micrographs after 10 h of growth (a, b) Sample 1; (c, d) Sample 2; (e, f) Sample 3

| [1] | ARNAULT J, SAADA S, RALCHENKO V. CVD grown single crystal diamond: a review. Physica Status Solidi (RRL)-Rapid Research Letters, 2022, 16: 2100354. |

| [2] | ZHENG Y, CHENGMING L I, LIU J, et al. Chemical vapor deposited diamond with versatile grades: from gemstone to quantum electronics. Frontiers of Materials Science, 2022, 16: 220590. |

| [3] | LIU K, ZHANG S, RALCHENKO V, et al. Tailoring of typical color centers in diamond for photonics. Advanced Materials, 2021, 33: 2000891. |

| [4] | LIU K, ZHANG S, LIU B J, et al. Investigating the energetic band diagrams of oxygen-terminated CVD grown e6 electronic grade diamond. Carbon, 2020, 169: 440. |

| [5] |

MOKUNO Y, CHAYAHARA A, YAMADA H. Synthesis of large single crystal diamond plates by high rate homoepitaxial growth using microwave plasma CVD and lift-off process. Diamond and Related Materials, 2008, 17(4/5): 415.

DOI URL |

| [6] | YAN C S, VOHRA Y K, MAO H K et al. Very high growth rate chemical vapor deposition of single-crystal diamond. Proceedings of the National Academy of Sciences of the United States of America, 2002, 99(20): 12523. |

| [7] | MUEHLE M, ASMUSSEN J, BECKER M F, et al. Extending microwave plasma assisted CVD SCD growth to pressures of 400 Torr. Diamond and Related Materials, 2017, 79: 150. |

| [8] | LIANG Q, CHIN C Y, LAI J, et al. Enhanced growth of high quality single crystal diamond by microwave plasma assisted chemical vapor deposition at high gas pressures. Applied Physics Letters, 2009, 94(2): 12523. |

| [9] |

ACHARD J, TALLAIRE A, SUSSMANN R, et al. The control of growth parameters in the synthesis of high-quality single crystalline diamond by CVD. Journal of Crystal Growth, 2005, 284(3/4): 396.

DOI URL |

| [10] |

TALLAIRE A, ACHARD J, SILVA F, et al. Homoepitaxial deposition of high-quality thick diamond films: effect of growth parameters. Diamond and Related Materials, 2005, 14(3): 249.

DOI URL |

| [11] | SILVA F, ACHARD J, BRINZA O, et al. High quality, large surface area, homoepitaxial MPACVD diamond growth. Diamond & Related Materials, 2009, 18(5): 683. |

| [12] | GICQUEL A, SILVA F, ROND C, et al. Ultrafast deposition of diamond by plasma-enhanced CVD. Comprehensive Hard Materials, 2014, 3: 217. |

| [13] |

YAMADA H, CHAYAHARA A, MOKUNO Y, et al. Modeling and numerical analyses of microwave plasmas for optimizations of a reactor design and its operating conditions. Diamond and Related Materials, 2005, 14(11): 1776.

DOI URL |

| [14] | YAMADA H, CHAYAHARA A, MOKUNO Y. Simplified description of microwave plasma discharge for chemical vapor deposition of diamond. Journal of Applied Physics, 2007, 101: 063302. |

| [15] | SU J J, LI Y F, LI X L, et al. A novel microwave plasma reactor with a unique structure for chemical vapor deposition of diamond films. Diamond and Related Materials, 2014, 42: 28. |

| [16] | FÜNER M, WILD C, KOIDL P. Simulation and development of optimized microwave plasma reactors for diamond deposition. Surface & Coatings Technology, 1999, 116-119: 853. |

| [17] | LI Y F, SU J J, LIU Y Q, et al. Design of a new TM021 mode cavity type MPCVD reactor for diamond film deposition. Diamond and Related Materials, 2014, 44: 88. |

| [18] |

SILVA F, HASSOUNI K, BONNIN X, et al. Microwave engineering of plasma-assisted CVD reactors for diamond deposition. Journal of Physics Condensed Matter, 2009, 21(36): 364202.

DOI URL |

| [19] | BOLSHAKOV A P, RALCHENKO V G, SHU G Y, et al. Single crystal diamond growth by MPCVD at subatmospheric pressures. Materials Today Communications, 2020, 25: 101635. |

| [20] | GICQUEL A, DERKAOUI N, ROND C, et al. Quantitative analysis of diamond deposition reactor efficiency. Chemical Physics, 2012, 398: 239. |

| [21] | LOBAEV M A, BOGDANOV S A, RADISHEV D B, et al. Method of power density determination in microwave discharge, sustained in hydrogen-methane gas mixture. Diamond & Related Materials, 2016, 66: 177. |

| [22] | BUSHUEV E V, YUROV V YU, BOLSHAKOV A P, et al. Express in situ measurement of epitaxial CVD diamond film growth kinetics. Diamond and Related Materials, 2017, 72: 61. |

| [23] |

ACHARD J, SILVA F, BRINZA O, et al. Coupled effect of nitrogen addition and surface temperature on the morphology and the kinetics of thick CVD diamond single crystals. Diamond and Related Materials, 2007, 16(4-7): 685.

DOI URL |

| [24] | WANG X, DUAN P, CAO Z, et al. Homoepitaxy growth of single crystal diamond under 300 torr pressure in the MPCVD system. Materials, 2019, 12: 3953. |

| [25] | MUCHNIKOV A B, VIKHAREV A L, GORBACHEV A M, et al. Homoepitaxial single crystal diamond growth at different gas pressures and MPACVD reactor configurations. Diamond and Related Materials, 2010, 19(5/6): 43. |

| [1] | YU Leyangyang, ZHAO Fangxia, ZHANG Shuxin, XU Yixiang, NIU Yaran, ZHANG Zhenzhong, ZHENG Xuebin. Preparation of High-entropy Boride Powders for Plasma Spraying by Inductive Plasma Spheroidization [J]. Journal of Inorganic Materials, 2025, 40(7): 808-816. |

| [2] | LIANG Ruihui, ZHONG Xin, HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin. High-temperature Water Vapor Corrosion Behaviors of Environmental Barrier Coatings with Yb2O3-modified Silicon Bond Layer [J]. Journal of Inorganic Materials, 2025, 40(4): 425-432. |

| [3] | MA Wen, SHEN Zhe, LIU Qi, GAO Yuanming, BAI Yu, LI Rongxing. Preparation of Y2O3 Coating by Suspension Plasma Spraying and Its Resistance to Plasma Etching [J]. Journal of Inorganic Materials, 2024, 39(8): 929-936. |

| [4] | LI Jiaqi, LI Xiaosong, LI Xuanhe, ZHU Xiaobing, ZHU Aimin. Transition Metal-doped Manganese Oxide: Synthesis by Warm Plasma and Electrocatalytic Performance for Oxygen Evolution Reaction [J]. Journal of Inorganic Materials, 2024, 39(7): 835-844. |

| [5] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [6] | LU Hao, XU Shengrui, HUANG Yong, CHEN Xing, XU Shuang, LIU Xu, WANG Xinhao, GAO Yuan, ZHANG Yachao, DUAN Xiaoling, ZHANG Jincheng, HAO Yue. Epitaxy Single Crystal GaN on AlN Prepared by Plasma-enhanced Atomic Layer Deposition [J]. Journal of Inorganic Materials, 2024, 39(5): 547-553. |

| [7] | YANG Zhiliang, YANG Ao, LIU Peng, CHEN Liangxian, AN Kang, WEI Junjun, LIU Jinlong, WU Lishu, LI Chengming. Preparation of 3-inch Diamond Film on Silicon Substrate for Thermal Management [J]. Journal of Inorganic Materials, 2024, 39(3): 283-290. |

| [8] | LI Junsheng, ZENG Liang, LIU Rongjun, WANG Yanfei, WAN Fan, LI Duan. Functional Strontium Tantalum Oxynitride Ceramics: Efficient Synthesis, Densification and Dielectric Performance [J]. Journal of Inorganic Materials, 2023, 38(8): 885-892. |

| [9] | QIU Haiyang, MIAO Guangtan, LI Hui, LUAN Qi, LIU Guoxia, SHAN Fukai. Effect of Plasma Treatment on the Long-term Plasticity of Synaptic Transistor [J]. Journal of Inorganic Materials, 2023, 38(4): 406-412. |

| [10] | LI Yicun, LIU Xuedong, HAO Xiaobin, DAI Bing, LYU Jilei, ZHU Jiaqi. Rapid Growth of Single Crystal Diamond at High Energy Density by Plasma Focusing [J]. Journal of Inorganic Materials, 2023, 38(3): 303-309. |

| [11] | PAN Yangyang, LIANG Bo, HONG Du, QI Zhixiang, NIU Yaran, ZHENG Xuebin. High Temperature Long-term Service Performance of TiAlCrY/YSZ Coating on TiAl Alloy [J]. Journal of Inorganic Materials, 2023, 38(1): 105-112. |

| [12] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| [13] | WAN Peng, LI Mian, HUANG Qing. Molten Salt Assisted Synthesis of Dy3Si2C2 Coated SiC Powders and Sintering Behavior of SiC Ceramics [J]. Journal of Inorganic Materials, 2021, 36(1): 49-54. |

| [14] | DONG Mengyue, XU Weiwei, ZHAO Jing, DI Lanbo, ZHANG Xiuling. Ru/γ-Al2O3 and Plasma Co-activation for CO2 Methanation: Effect of Catalytic Material Preparation Method [J]. Journal of Inorganic Materials, 2020, 35(5): 567-572. |

| [15] | ZHENG Xue, JIANG Rui, LI Qian, WANG Weizhe, XU Zhimou, PENG Jing. Research on Anodic Aluminum Oxide Nanostructured LEDs [J]. Journal of Inorganic Materials, 2020, 35(5): 561-566. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||