Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (3): 303-309.DOI: 10.15541/jim20220633

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Yicun1( ), LIU Xuedong1, HAO Xiaobin1, DAI Bing1(

), LIU Xuedong1, HAO Xiaobin1, DAI Bing1( ), LYU Jilei2, ZHU Jiaqi1

), LYU Jilei2, ZHU Jiaqi1

Received:2022-10-27

Revised:2022-12-18

Published:2023-03-20

Online:2023-01-11

Contact:

DAI Bing, professor. E-mail: daibinghit@vip.126.comAbout author:LI Yicun (1996-), male, PhD candidate. E-mail: 741624995@qq.com

Supported by:CLC Number:

LI Yicun, LIU Xuedong, HAO Xiaobin, DAI Bing, LYU Jilei, ZHU Jiaqi. Rapid Growth of Single Crystal Diamond at High Energy Density by Plasma Focusing[J]. Journal of Inorganic Materials, 2023, 38(3): 303-309.

| Sample | Substrate type | N2 concentration/ (μL·L-1) | Growth rate/ (μm·h-1) |

|---|---|---|---|

| S1 | molybdenum disk | 0 | 9.5 |

| S2 | focusing structure | 0 | 32.2 |

| S3 | molybdenum disk | 300 | 20.1 |

| S4 | focusing structure | 300 | 97.5 |

Table 1 Conditions for the growth experiment of single crystal diamond samples

| Sample | Substrate type | N2 concentration/ (μL·L-1) | Growth rate/ (μm·h-1) |

|---|---|---|---|

| S1 | molybdenum disk | 0 | 9.5 |

| S2 | focusing structure | 0 | 32.2 |

| S3 | molybdenum disk | 300 | 20.1 |

| S4 | focusing structure | 300 | 97.5 |

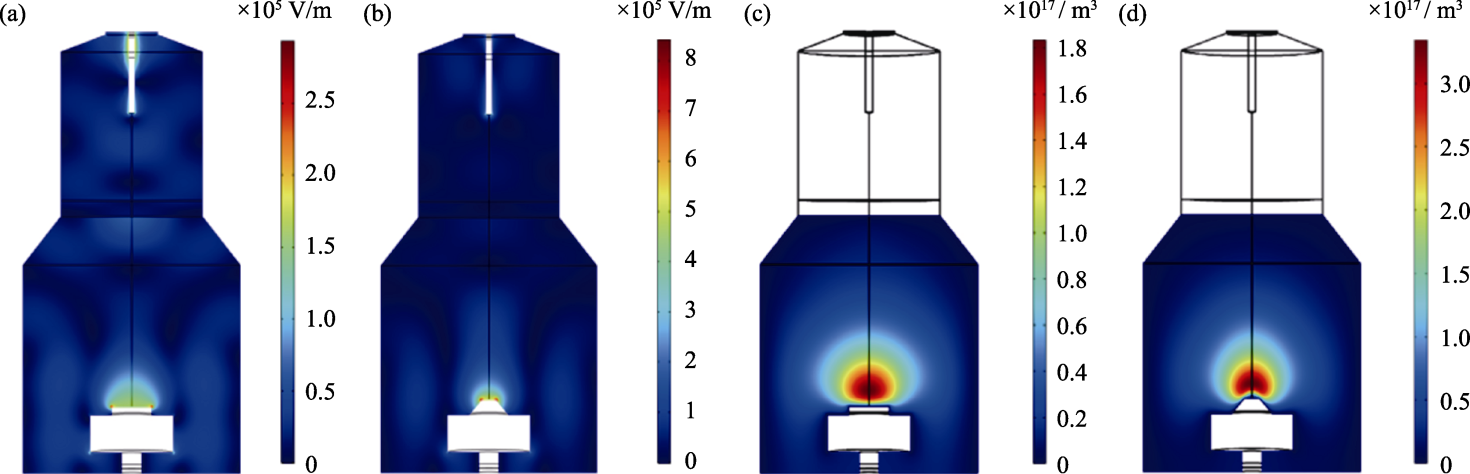

Fig. 1 Simulation results of the distribution of electric field and electron density in the reaction chamber at 3500 W and 18 kPa (a) Electric field distribution with molybdenum disk; (b) Electric field distribution with focusing structure; (c) Electron density distribution with molybdenum disk; (d) Electron density distribution with focusing structure

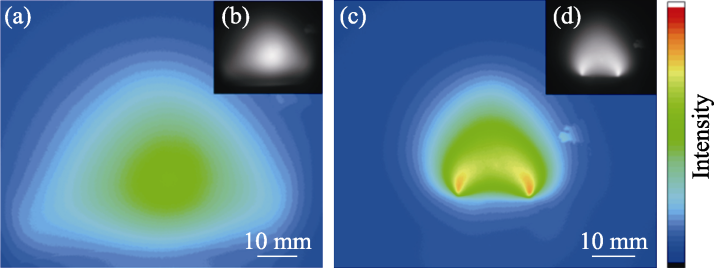

Fig. 2 Observation maps of plasma under two conditions (MW power 3500 W, pressure 18 kPa, with Hα filter) (a, b) Molybdenum disk condition; (c, d) Focusing structure condition; (a, c) are the light intensity contour plots of observation maps (b, d)

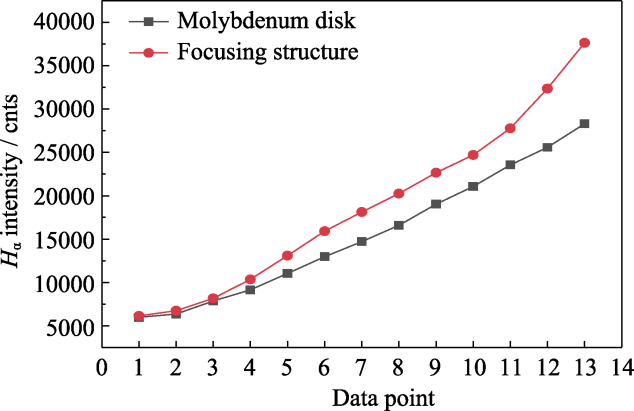

Fig. 3 Hα (656 nm) intensity of plasma under different power and pressure conditions Data points in the horizontal axis represent different power-pressure parameters. Data point 1 is the initial parameter (900 W-5 kPa), and then the power and pressure of each data point increase by 200 W and 1 kPa successively until the final growth conditions (3500 W-18 kPa)

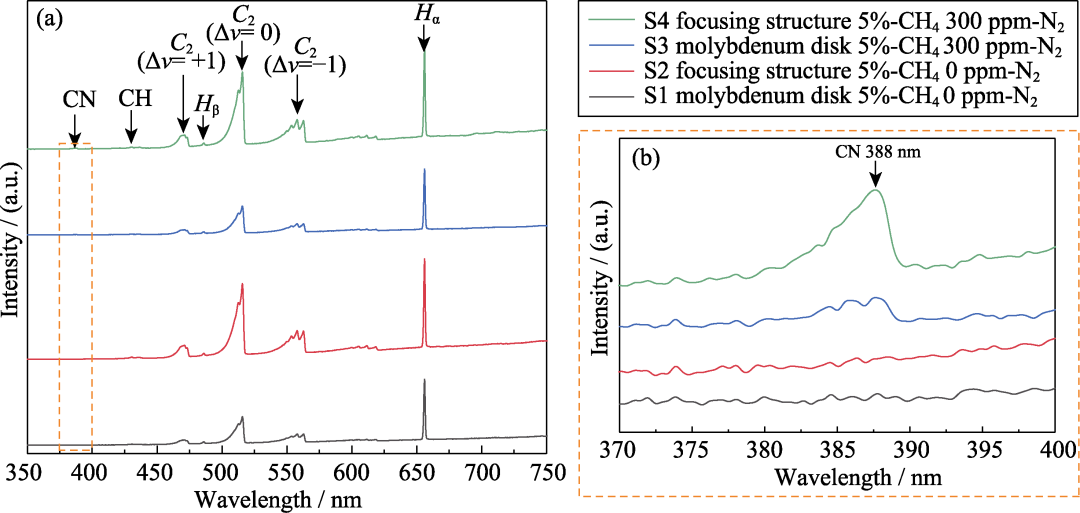

Fig. 5 OE spectra during growth of different samples (a) OE spectra of sample S1, S2, S3 and S4 during the growth experiments; (b) Magnified OE spectra around the CN (388 nm) band; 1 ppm=1 μL/L; Colorful figures are available on website

| [1] |

ARNAULT J, SAADA S, RALCHENKO V. Chemical vapor deposition single-crystal diamond: a review. Physica Status Solidi (RRL)-Rapid Research Letters, 2022, 16: 2100354.

DOI URL |

| [2] |

LIU K, ZHANG S, RALCHENKO V, et al. Tailoring of typical color centers in diamond for photonics. Advanced Materials, 2020, 33: 2000891.

DOI URL |

| [3] | WILLIAMS R J, KITZLER O, BAI Z, et al. High power diamond Raman lasers. IEEE Journal of Selected Topics in Quantum Electronics, 2018, 24(5): 1602214. |

| [4] | LIU B J, DAI B, LIU K, et al. Alpha-voltaic battery on diamond Schottky barrier diode. Diamond &Related Materials, 2018, 87: 35. |

| [5] |

LIU K, ZHANG S, LIU B J, et al. Investigating the energetic band diagrams of oxygen-terminated CVD grown e6 electronic grade diamond. Carbon, 2020, 169: 440.

DOI URL |

| [6] |

LIU K, ZHANG S, LIU B J, et al. Impact of positive space charge depletion layer on negatively charged and neutral centers in gold-diamond Schottky junction. Carbon, 2019, 153: 381.

DOI URL |

| [7] |

LIU K, LIU B J, ZHAO J W, et al. Application of back bias to interdigital-electrode structured diamond UV detector showing enhanced responsivity. Sensors and Actuators A: Physical, 2019, 290: 222.

DOI URL |

| [8] |

TALLAIRE A, ACHARD J, SILVA F, et al. Growth of large size diamond single crystals by plasma assisted chemical vapour deposition: recent achievements and remaining challenges. Comptes Rendus Physique, 2013, 14(2/3): 169.

DOI URL |

| [9] | SILVA F, ACHARD J, BRINZA O, et al. High quality, large surface area, homoepitaxial MPACVD diamond growth. Diamond & Related Materials, 2009, 18(5): 683. |

| [10] |

GOODWIN D G. Scaling laws for diamond chemical vapor deposition. I. Diamond surface chemistry. Journal of Applied Physics, 1993, 74(11): 6888.

DOI URL |

| [11] |

SILVA F, HASSOUNI K, BONNIN X, et al. Microwave engineering of plasma-assisted CVD reactors for diamond deposition. Journal of Physics: Condensed Matter, 2009, 21(36): 364202.

DOI URL |

| [12] |

VITTON J P, GARENNE J J, TRUCHET S. High quality homoepitaxial growth of diamond films. Diamond and Related Materials, 1993, 2(5/6/7): 713.

DOI URL |

| [13] |

WANG X, DUAN P, CAO Z, et al. Homoepitaxy growth of single crystal diamond under 300 torr pressure in the MPCVD system. Materials, 2019, 12: 3953.

DOI URL |

| [14] |

MUEHLE M, ASMUSSEN J, BECKER M F, et al. Extending microwave plasma assisted CVD SCD growth to pressures of 400 Torr. Diamond and Related Materials, 2017, 79: 150.

DOI URL |

| [15] |

BOLSHAKOV A P, RALCHENKO V G, SHU G Y, et al. Single crystal diamond growth by MPCVD at subatmospheric pressures. Materials Today Communications, 2020, 25: 101635.

DOI URL |

| [16] |

BOGDANOV S A, GORBACHEV A M, RADISHEV D B, et al. Contraction of microwave discharge in the reactor for chemical vapor deposition of diamond. Technical Physics Letters, 2019, 45(2): 89.

DOI |

| [17] | CHAYAHARA A, MOKUNO Y, et al. The effect of nitrogen addition during high-rate homoepitaxial growth of diamond by microwave plasma CVD. Diamond & Related Materials, 2004, 13: 1954. |

| [18] | YAMADA H, CHAYAHARA A, MOKUNO Y, et al. Simulation of microwave plasmas concentrated on the top surface of a diamond substrate with finite thickness. Diamond & Related Materials, 2006, 15(9): 1383. |

| [19] | YAMADA H, MOKUNO Y, CHAYAHARA A, et al. Predominant physical quantity dominating macroscopic surface shape of diamond synthesized by microwave plasma CVD. Diamond & Related Materials, 2007, 16(3): 576. |

| [20] | LOBAEV M A, BOGDANOV S A, RADISHEV D B, et al. Method of power density determination in microwave discharge, sustained in hydrogen-methane gas mixture. Diamond & Related Materials, 2016, 66: 177. |

| [21] | GICQUEL A, SILVA F, ROND C, et al. Ultrafast deposition of diamond by plasma-enhanced CVD. Comprehensive Hard Materials, 2014, 3: 217. |

| [22] |

MOKUNO Y, CHAYAHARA A, YAMADA H. Synthesis of large single crystal diamond plates by high rate homoepitaxial growth using microwave plasma CVD and lift-off process. Diamond and Related Materials, 2008, 17(4/5): 415.

DOI URL |

| [23] |

ZHANG Z, SONG Y, GOU L. Evolution of surface morphology and optical transmittance of single crystal diamond film by epitaxial growth. AIP Advances, 2019, 9(9): 095048.

DOI URL |

| [24] | MOKUNO Y, CHAYAHARA A, YAMADA H, et al. Improving purity and size of single-crystal diamond plates produced by high-rate CVD growth and lift-off process using ion implantation. Diamond & Related Materials, 2009, 18(10): 1258. |

| [25] |

ACHARD J, SILVA F, BRINZA O, et al. Coupled effect of nitrogen addition and surface temperature on the morphology and the kinetics of thick CVD diamond single crystals. Diamond and Related Materials, 2007, 16(4-7): 685.

DOI URL |

| [26] |

WU G, CHEN M H, LIAO J. The influence of recess depth and crystallographic orientation of seed sides on homoepitaxial growth of CVD single crystal diamonds. Diamond and Related Materials, 2016, 65: 144.

DOI URL |

| [1] | GUO Xiang-Xin, HUANG Shi-Ting, ZHAO Ning, CUI Zhong-Hui, FAN Wu-Gang, LI Chi-Lin, LI Hong. Rapid Development and Critical Issues of Secondary Lithium-air Batteries [J]. Journal of Inorganic Materials, 2014, 29(2): 113-123. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||