Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (7): 835-844.DOI: 10.15541/jim20230542

Special Issue: 【能源环境】氢能材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Jiaqi1( ), LI Xiaosong1, LI Xuanhe1, ZHU Xiaobing1,2(

), LI Xiaosong1, LI Xuanhe1, ZHU Xiaobing1,2( ), ZHU Aimin1

), ZHU Aimin1

Received:2023-11-24

Revised:2024-02-06

Published:2024-07-20

Online:2024-02-26

Contact:

ZHU Xiaobing, associate professor. E-mail: xzhu@dlut.edu.cnAbout author:LI Jiaqi (1999-), female, Master candidate. E-mail: lijiaqi621@mail.dlut.edu.cn

Supported by:CLC Number:

LI Jiaqi, LI Xiaosong, LI Xuanhe, ZHU Xiaobing, ZHU Aimin. Transition Metal-doped Manganese Oxide: Synthesis by Warm Plasma and Electrocatalytic Performance for Oxygen Evolution Reaction[J]. Journal of Inorganic Materials, 2024, 39(7): 835-844.

| Catalyst | Doping element content/% (in atomic) | SBET/ (m2∙g-1) | DXRD / nm | DTEM / nm |

|---|---|---|---|---|

| MnOx | - | 35.7 | 32.7 | 37.9 |

| Ni-MnOx | 1.23 | 57.5 | 27.4 | 37.5 |

| Co-MnOx | 1.41 | 51.1 | 26.9 | 20.1 |

| Fe-MnOx | 1.22 | 54.8 | 28.1 | 19.1 |

Table 1 Physicochemical parameters of MnOx, Ni-MnOx, Co-MnOx, and Fe-MnOx catalysts by ICP-OES, BET, XRD, and TEM

| Catalyst | Doping element content/% (in atomic) | SBET/ (m2∙g-1) | DXRD / nm | DTEM / nm |

|---|---|---|---|---|

| MnOx | - | 35.7 | 32.7 | 37.9 |

| Ni-MnOx | 1.23 | 57.5 | 27.4 | 37.5 |

| Co-MnOx | 1.41 | 51.1 | 26.9 | 20.1 |

| Fe-MnOx | 1.22 | 54.8 | 28.1 | 19.1 |

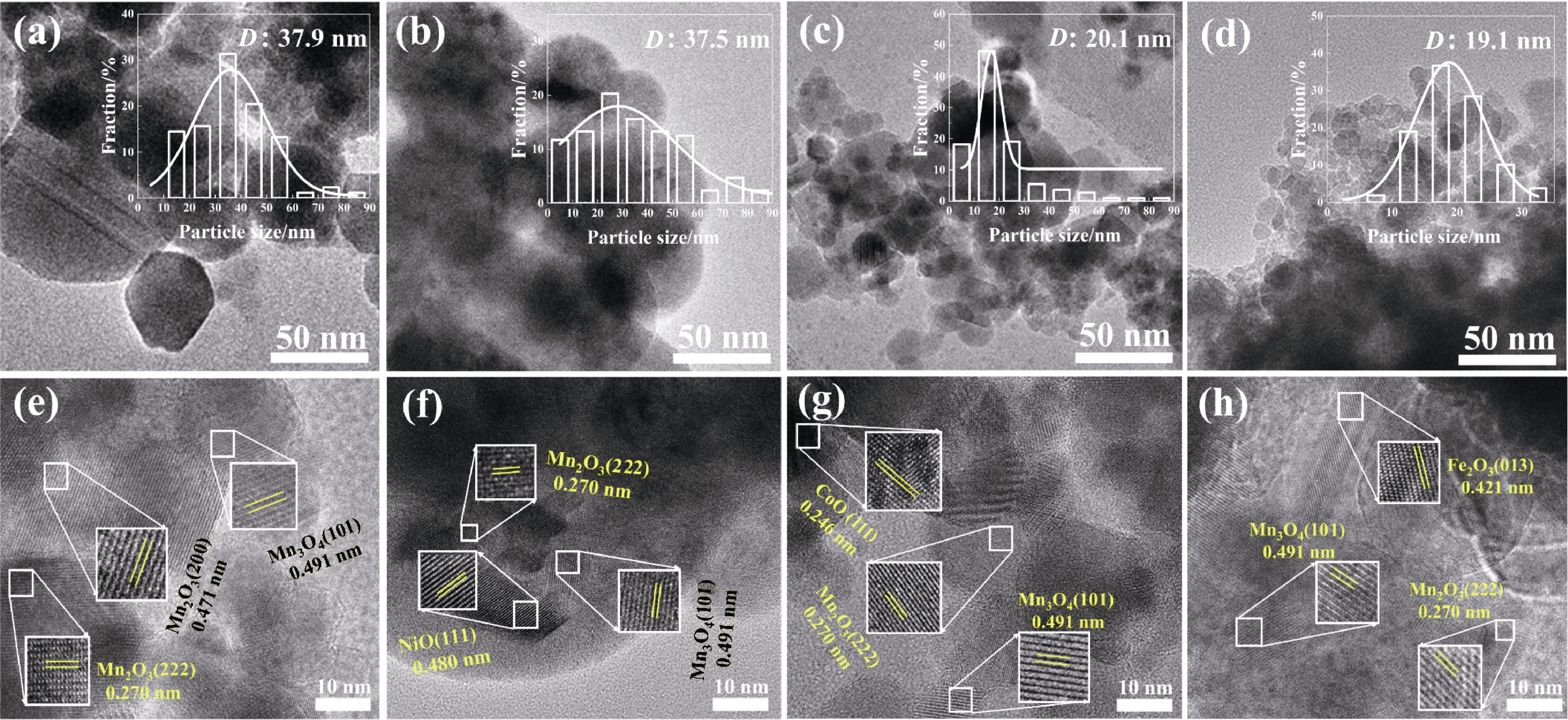

Fig. 2 (a-d) TEM and (e-h) HRTEM images of (a, e) MnOx, (b, f) Ni-MnOx, (c, g) Co-MnOx, and (d, h) Fe-MnOx catalysts with insets in (a-d) showing corresponding histograms of particle size distributions

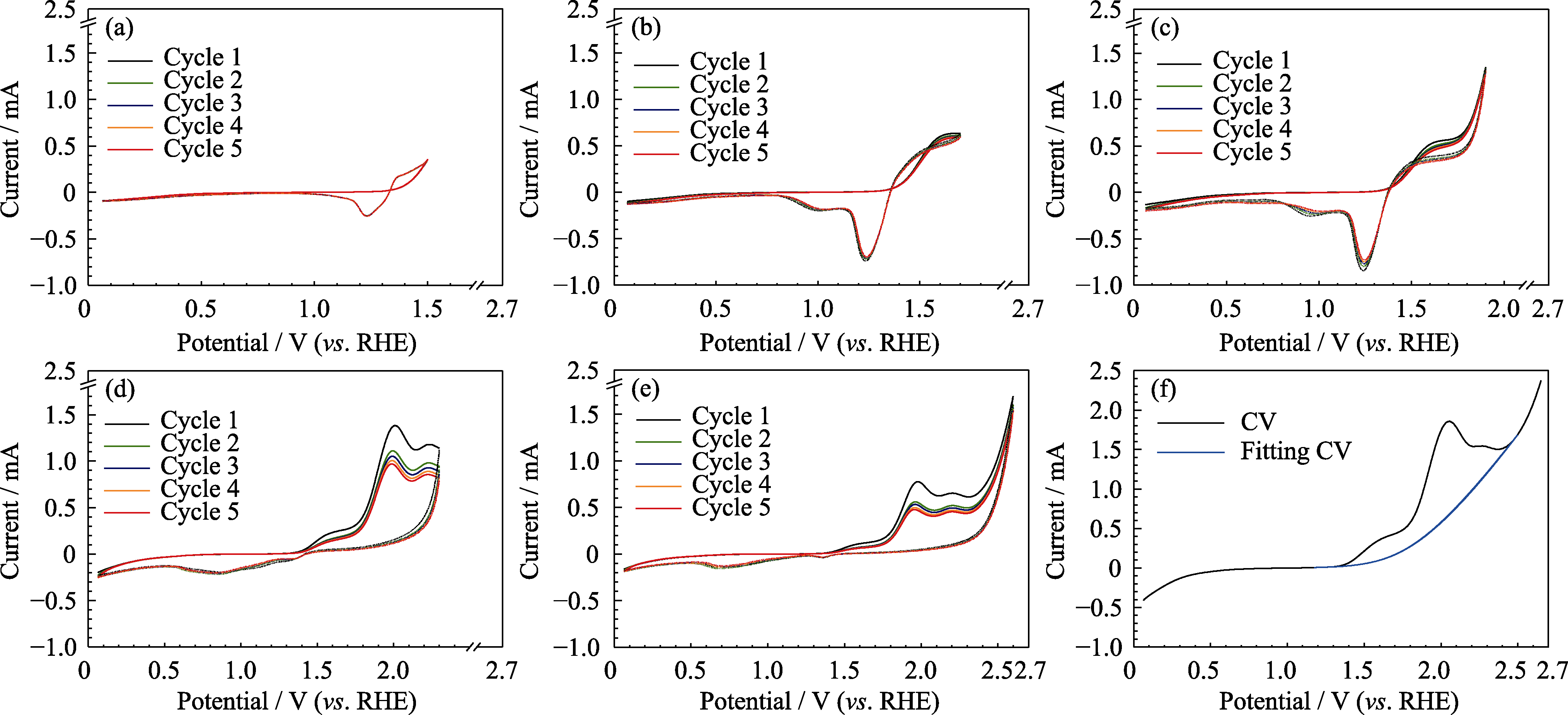

Fig. 5 Cyclic voltammetric curves of MnOx catalysts synthesized by gliding arc warm plasma at ending potentials of (a) 1.5, (b) 1.7, (c) 1.9, (d) 2.3, and (e) 2.6 V, and (f) the comparison between the measured CV curve and the fitting curve educed by Bulter-Volmer equation (simple version) Colorful figures are available on website

Fig. S4 Cyclic voltammetry of MnOx catalyst synthesized by gliding arc warm plasma at ending potentials of (a) 1.3, (b) 1.4, (c) 1.6, (d) 1.8, (e) 2.0, (f) 2.1, (g) 2.2, (h) 2.4, and (i) 2.5V

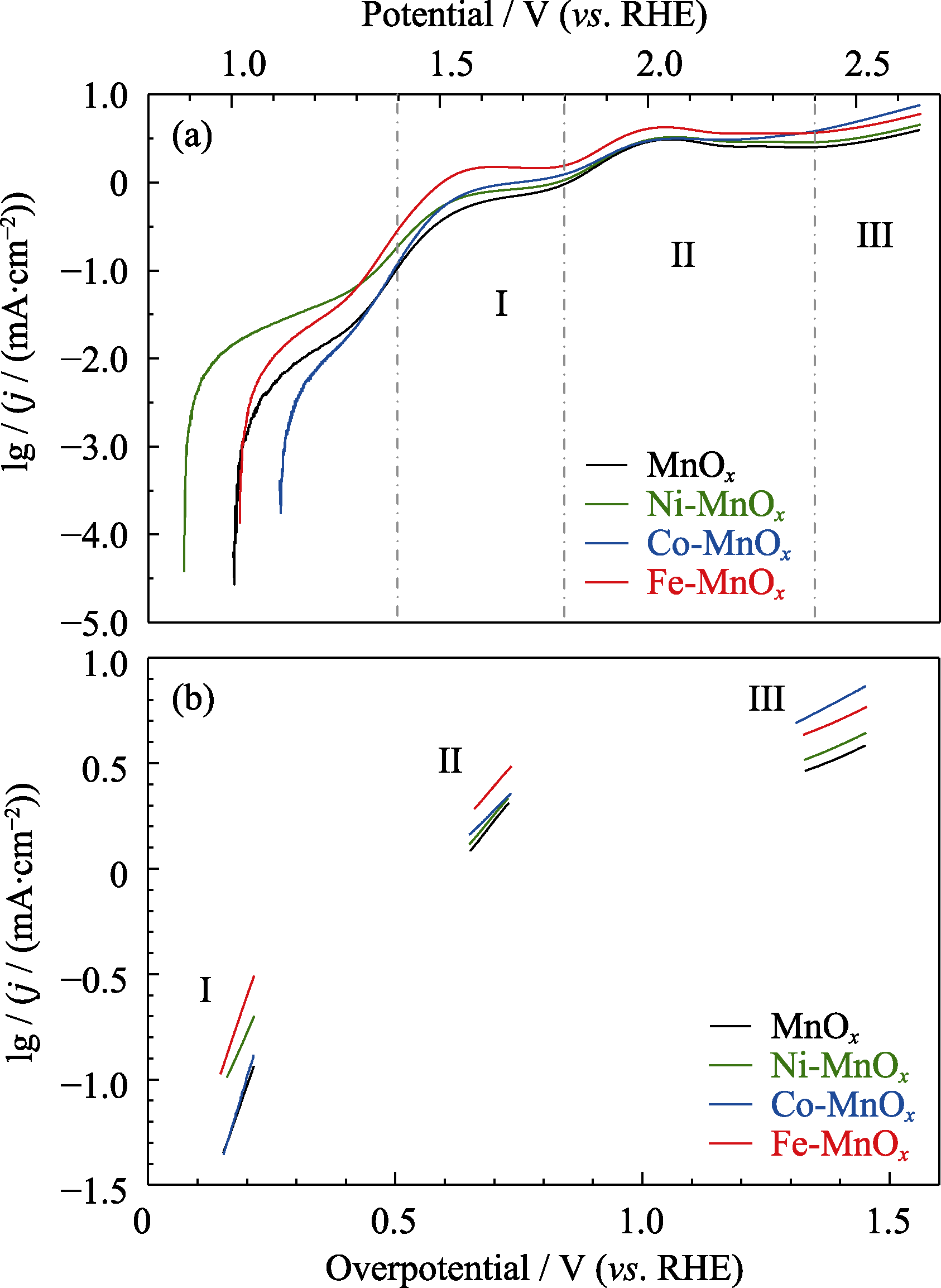

Fig. 6 (a) lgj-E curves and (b) Tafel-type plots of MnOx, Ni-MnOx, Co-MnOx, and Fe-MnOx catalysts The data is derivative from Fig. 4; Colorful figures are available on website

| Catalyst | Potential/V | Slope/ (mV∙dec-1) | Starting Tafel (E, i)/(V, mA) |

|---|---|---|---|

| MnOx | 1.27-1.75I | 153 | (1.33, 0.02) |

| 1.75-2.42II | 359 | (1.82, 0.64) | |

| 2.42-2.65III | 893 | (2.55, 1.86) | |

| Ni-MnOx | 1.27-1.74I | 186 | (1.33, 0.51) |

| 1.74-2.42II | 356 | (1.82, 0.71) | |

| 2.42-2.65III | 879 | (2.52, 1.98) | |

| Co-MnOx | 1.27-1.74I | 131 | (1.31, 0.18) |

| 1.74-2.26II | 423 | (1.82, 0.80) | |

| 2.26-2.65III | 806 | (2.44, 2.41) | |

| Fe-MnOx | 1.25-1.74I | 144 | (1.30, 0.04) |

| 1.74-2.36II | 363 | (1.82, 1.03) | |

| 2.36-2.65III | 874 | (2.50, 2.52) |

Table S1 Electrochemical performances for MnOx, Ni-MnOx, Co-MnOx, and Fe-MnOx catalysts from Fig. 6

| Catalyst | Potential/V | Slope/ (mV∙dec-1) | Starting Tafel (E, i)/(V, mA) |

|---|---|---|---|

| MnOx | 1.27-1.75I | 153 | (1.33, 0.02) |

| 1.75-2.42II | 359 | (1.82, 0.64) | |

| 2.42-2.65III | 893 | (2.55, 1.86) | |

| Ni-MnOx | 1.27-1.74I | 186 | (1.33, 0.51) |

| 1.74-2.42II | 356 | (1.82, 0.71) | |

| 2.42-2.65III | 879 | (2.52, 1.98) | |

| Co-MnOx | 1.27-1.74I | 131 | (1.31, 0.18) |

| 1.74-2.26II | 423 | (1.82, 0.80) | |

| 2.26-2.65III | 806 | (2.44, 2.41) | |

| Fe-MnOx | 1.25-1.74I | 144 | (1.30, 0.04) |

| 1.74-2.36II | 363 | (1.82, 1.03) | |

| 2.36-2.65III | 874 | (2.50, 2.52) |

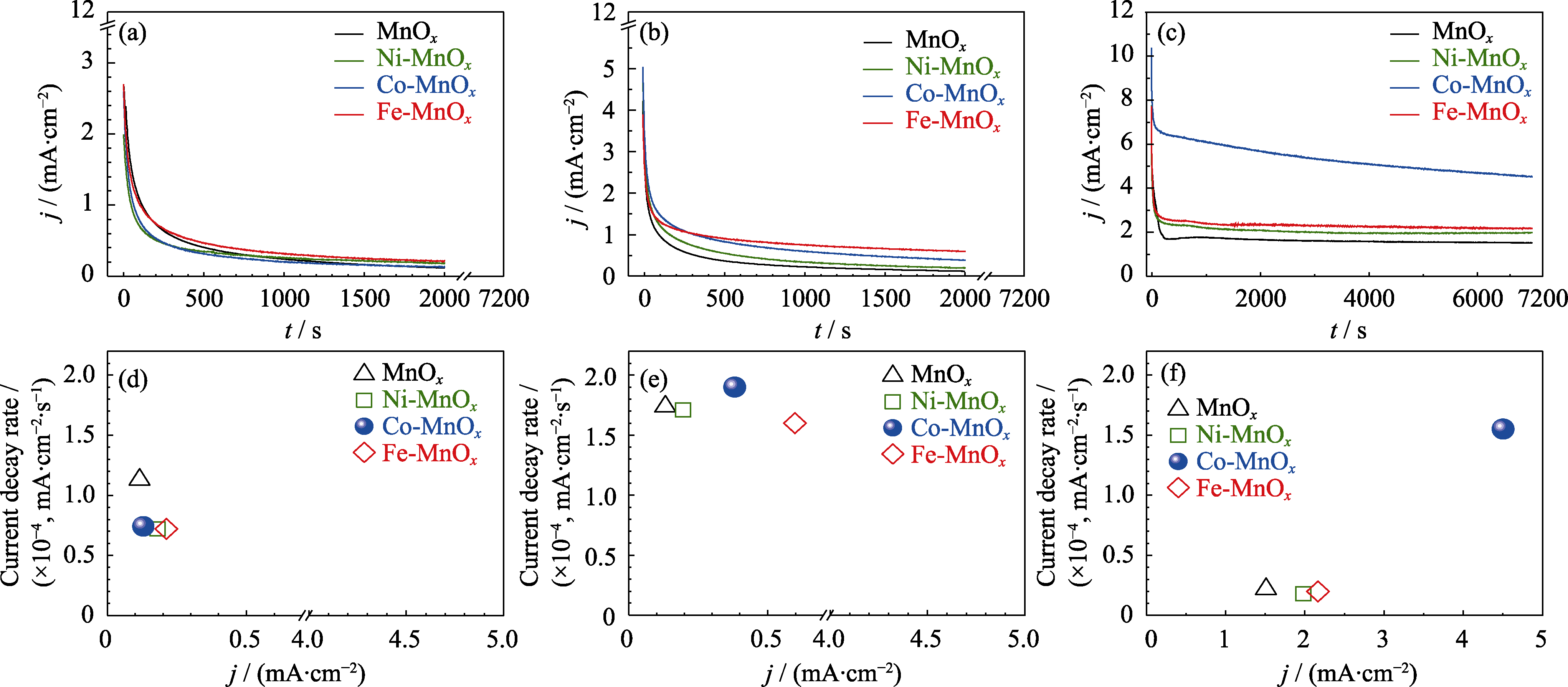

Fig. 8 (a-c) Current density-time (j-t) dependence of stability tests, and (d-f) relationship between current decay rate and ending current density on MnOx, Ni-MnOx, Co-MnOx, and Fe-MnOx catalysts at (a, d) 1.5, (b, e) 1.9 and (c, f) 2.5 V Colorful figures are available on website

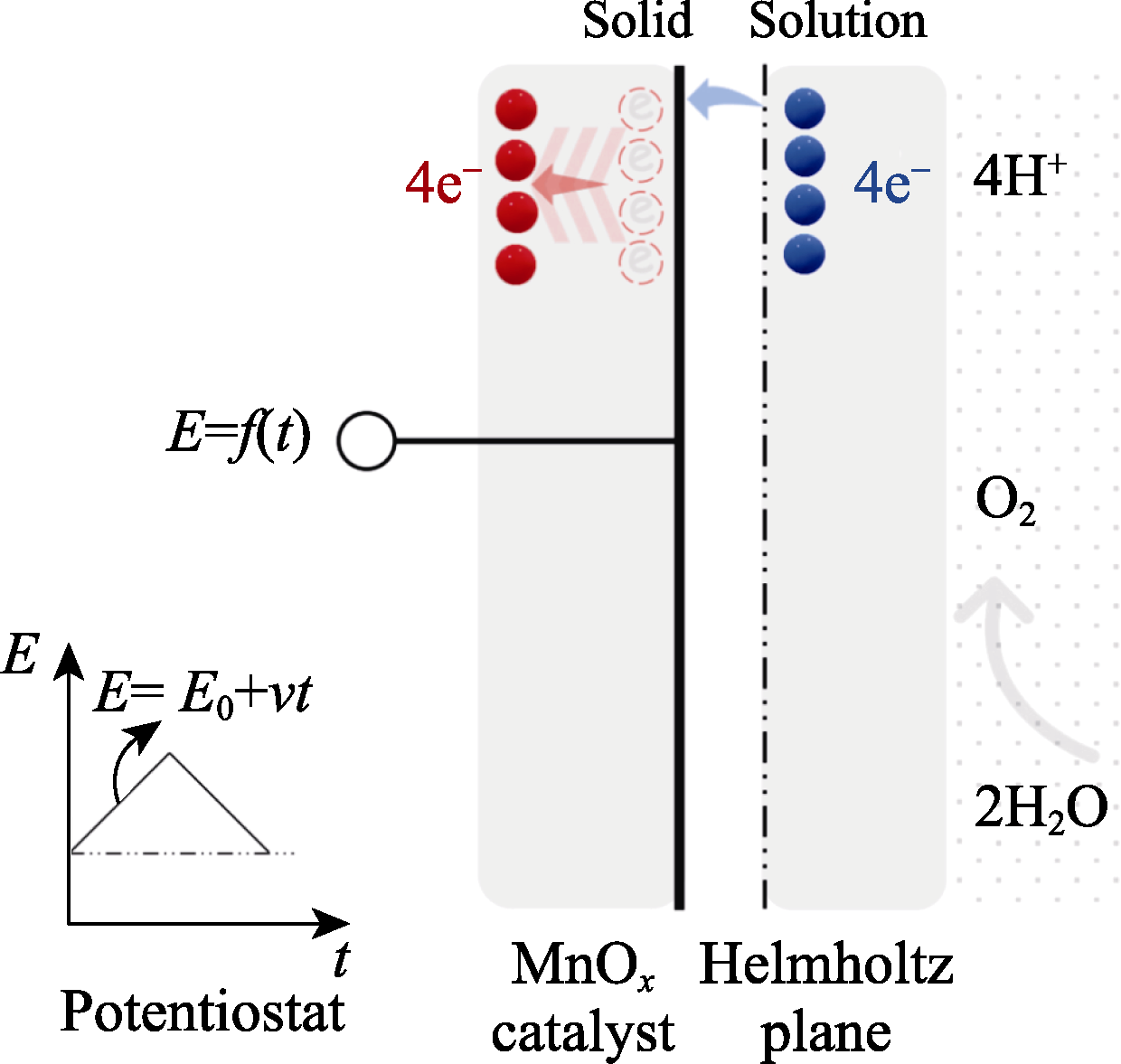

Fig. 9 Schematic double layer (of Helmholtz plane) for the featured current step Bottom left: A potentiostat that linearly loads voltage to double layer (at left side); Right: A double layer that consists of two sides of solid (MnOx catalyst) and solution

| [1] | LOISEL J, GALLEGO-SALA A V, AMESBURY M J, et al. Expert assessment of future vulnerability of the global peatland carbon sink. Nature Climate Change, 2021, 11(4): 70. |

| [2] | LAURENT A, ESPINOSA N. Environmental impacts of electricity generation at global, regional and national scales in 1980-2011: what can we learn for future energy planning? Energy & Environmental Science, 2015, 8(3): 689. |

| [3] | CHUNG D Y, LOPES P P, FARINAZZO P, et al. Dynamic stability of active sites in hydr(oxy)oxides for the oxygen evolution reaction. Nature Energy, 2020, 5(3): 222. |

| [4] | SUEN N T, HUNG, S F, QUAN Q, et al. Electrocatalysis for the oxygen evolution reaction: recent development and future perspectives. Chemical Society Reviews, 2017, 46(2): 337. |

| [5] | URSUA A, GANDIA L M, SANCHIS P. Hydrogen production from water electrolysis: current status and future trends. Proceedings of the IEEE, 2012, 100(2): 410. |

| [6] | 王新东, 刘高阳, 许军元, 等. 质子交换膜水电解析氧电催化复合材料合成、微结构调控及性能研究. 中国科学: 化学, 2014(8): 1241. |

| [7] | DALY K M, JIMENEZ-VILLEGAS S, GODWIN B, et al. A comparison of photodeposited RuOx for alkaline water electrolysis. ACS Applied Energy Materials, 2023, 6(3): 1449. |

| [8] | GONG R, LIU B, WANG X, et al. Electronic structure modulation induced by cobalt-doping and lattice-contracting on armor-like ruthenium oxide drives pH-universal oxygen evolution. Small, 2022, 19(4): 2204889. |

| [9] | ZHAO F, WEN B, NIU W, et al. Increasing iridium oxide activity for the oxygen evolution reaction with hafnium modification. Journal of the American Chemical Society, 2021, 143(38): 15616. |

| [10] | SILVA C D F, CLAUDEL F, MARTIN V, et al. Oxygen evolution reaction activity and stability benchmarks for supported and unsupported IrOx electrocatalysts. ACS Catalysis, 2021, 11(7): 4107. |

| [11] | YANG X, SUN X, GAN L Y, et al. A CoOx/FeOx heterojunction on carbon nanotubes prepared by plasma-enhanced atomic layer deposition for the highly efficient electrocatalysis of oxygen evolution reactions. Journal of Materials Chemistry A, 2020, 8(30): 15140. |

| [12] | MOYSIADOU A, HU X. Stability profiles of transition metal oxides in the oxygen evolution reaction in alkaline medium. Journal of Materials Chemistry A, 2019, 7(45): 25865. |

| [13] | WU G, CHEN W, ZHENG X, et al. Hierarchical Fe-doped NiOx nanotubes assembled from ultrathin nanosheets containing trivalent nickel for oxygen evolution reaction. Nano Energy, 2017, 38: 167. |

| [14] | WANG P, ZHANG S, WANG Z, et al. Manganese-based oxide electrocatalysts for the oxygen evolution reaction: a review. Journal of Materials Chemistry A, 2023, 11(11): 5476. |

| [15] | LI A, OOKA H, BONNET N, et al. Stable potential windows for long-term electrocatalysis by manganese oxides under acidic conditions. Angewandte Chemie International Edition, 2019, 58(15): 5054. |

| [16] | BIGIANI L, MACCATO C, ANDREU T, et al. Quasi-1D Mn2O3 nanostructures functionalized with first-row transition-metal oxides as oxygen evolution catalysts. ACS Applied Nano Materials, 2020, 3(10): 9889. |

| [17] | FUJIMOTO K, UEDA Y, INOHARA D, et al. Cobalt-doped electrolytic manganese dioxide as an efficient bifunctional catalyst for oxygen evolution/reduction reactions. Electrochimica Acta, 2020, 354: 136592. |

| [18] | MELDER J, MEBS S, LESSING F, et al. Tuning electrocatalytic water oxidation by MnOx through the incorporation of abundant metal cations. Sustainable Energy & Fuels, 2023, 7(1): 92. |

| [19] | RUSANOV V D, FRIDMAN A A, SHOLIN G V. The physics of a chemically active plasma with nonequilibrium vibrational excitation of molecules. Soviet Physics Uspekhi, 1981, 24(6): 447. |

| [20] | LIU Y F, MU J S, XU X Y, et al. Microstructure and dry-sliding wear properties of TiC-reinforced composite coating prepared by plasma-transferred arc weld-surfacing process. Materials Science and Engineering: A, 2007, 458(1/2): 366. |

| [21] | FENG Z C, LIU Y F, LI Y, et al. Microstructure and high temperature reciprocating sliding wear properties of MoSi2/TiC/γ-Ni composite coating in-situ synthesized by co-axial powder feeding plasma transferred arc cladding. Tribology International, 2019, 129: 82. |

| [22] | CESCHINI L, LANZONI E, MARTINI C, et al. Comparison of dry sliding friction and wear of Ti6Al4V alloy treated by plasma electrolytic oxidation and PVD coating. Wear, 2008, 264(1/2): 86. |

| [23] | SABATINI G, CESCHINI L, MARTINI C, et al. Improving sliding and abrasive wear behaviour of cast A356 and wrought AA7075 aluminium alloys by plasma electrolytic oxidation. Materials & Design, 2010, 31(2): 816. |

| [24] | EFREMENKO V G, CHABAK Y G, FEDUN V I, et al. Formation mechanism, microstructural features and dry-sliding behaviour of “bronze/WC carbide” composite synthesised by atmospheric pulsed-plasma deposition. Vacuum, 2021, 185: 110031. |

| [25] | ÇELIK O N. Microstructure and wear properties of WC particle reinforced composite coating on Ti6Al4V alloy produced by the plasma transferred arc method. Applied Surface Science, 2013, 274: 334. |

| [26] | FRIDMAN A, NESTER S, KENNEDY L A, et al. Gliding arc gas discharge. Progress in Energy and Combustion Science, 1999, 25(2): 211. |

| [27] | 孙进桃, 赵旭腾, 陈琪, 等. 等离子催化重整CH4/CO2中的协同效应及积碳动力学. 工程热物理学报, 2023, 44(5): 1428. |

| [28] | ZHANG S Y, LI X S, LIU J B, et al. Dimensionless factors for an alternating-current non-thermal arc plasma. Physics of Plasmas, 2016, 23(12): 120707. |

| [29] | CHEN D, QIAO M, LU Y R, et al. Preferential cation vacancies in perovskite hydroxide for the oxygen evolution reaction. Angewandte Chemie International Edition, 2018, 57(28): 8691. |

| [30] | WANG X, ZHUANG L, JIA Y, et al. Plasma-triggered synergy of exfoliation, phase transformation, and surface engineering in cobalt diselenide for enhanced water oxidation. Angewandte Chemie International Edition, 2018, 57(50): 16421. |

| [31] | XU L, JIANG Q, XIAO Z, et al. Plasma-engraved Co3O4 nanosheets with oxygen vacancies and high surface area for the oxygen evolution reaction. Angewandte Chemie International Edition, 2016, 55(17): 5277. |

| [32] | LIU S X, LI X S, ZHU X, et al. Gliding arc plasma synthesis of crystalline TiO2 nanopowders with high photocatalytic activity. Plasma Chemistry and Plasma Processing, 2013, 33(5): 827. |

| [33] | ZHU X, LI J J, LIU M T, et al. Mesoporous TiO2 electrocatalysts synthesized by gliding arc plasma for oxygen evolution reaction. Journal of Physics D: Applied Physics, 2021, 54(48): 484003. |

| [34] | ZHANG S Y, LI X S, LIU J L, et al. Plasmochemical approach to template-free synthesis of highly crystalline mesoporous TiO2 within milliseconds. ChemNanoMat, 2019, 5(4): 403. |

| [35] | ASL H Z, ROZATI S M. High-quality spray-deposited fluorine- doped tin oxide: effect of film thickness on structural, morphological, electrical, and optical properties. Applied Physics A, 2019, 125(10): 689. |

| [36] | WANG Z, XU K, RUAN S, et al. Mesoporous Co-Mn spinel oxides as efficient catalysts for low temperature propane oxidation. Catalysis Letters, 2021, 152(9): 2695. |

| [37] | HAMMER B, NORSKOV J K. Why gold is the noblest of all the metals. Nature, 1995, 376 (6537): 238. |

| [38] | DONG C, QU Z, QIN Y, et al. Revealing the highly catalytic performance of spinel CoMn2O4 for toluene oxidation: involvement and replenishment of oxygen species using in situ designed-TP techniques. ACS Catalysis, 2019, 9(8): 6698. |

| [39] | HUANG H, ZHAO Y, BAI Y, et al. Conductive metal-organic frameworks with extra metallic sites as an efficient electrocatalyst for the hydrogen evolution reaction. Advanced Science, 2020, 7(9): 2000012. |

| [40] | KISSLINGER R, RIDDELL S, SAVELA S, et al. Transparent nanoporous P-type NiO films grown directly on non-native substrates by anodization. Journal of Materials Science: Materials in Electronics, 2019, 30(12): 11327. |

| [41] | HOLM E A, FOILES S M. How grain growth stops: a mechanism for grain-growth stagnation in pure materials. Science, 2010, 328(5982): 1138. |

| [42] | NAJAFKHANI F, KHEIRI S, POURBAHARI B, et al. Recent advances in the kinetics of normal/abnormal grain growth: a review. Archives of Civil and Mechanical Engineering, 2021, 21: 1. |

| [43] | SHANNON R D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallographica Section A, 1976, 32(5): 751. |

| [44] | CHEN J, YAO M, WANG X. Investigation of transition metal ion doping behaviors on TiO2 nanoparticles. Journal of Nanoparticle Research, 2007, 10(1): 163. |

| [45] | XIONG L P, HU S, HOU J W, et al. Preparation and catalytic activity of Pt based hydrophobic catalysts adulterated with Fe series elements. Journal of Inorganic Materials, 2011, 26(1): 91. |

| [46] | LIDE D R. CRC handbook of chemistry and physics, 90th ed. Boca Raton: CRC Press, 2010: 1215. |

| [47] | LARMINIE J. Fuel cell systems explained, 2nd ed. New York: Wiley, 2003: 48. |

| [48] | BARD A J, FAULKNER L R. Electrochemical methods:fundamentals and applications, 2nd ed. New York: Wiley, 2001: 15. |

| [49] | FAN X, LIANG X, ZHAO Z, et al. Enhanced treatment performance of phenol wastewater by electrochemical reactor with MnOx/Ti membrane electrode modified with Sb-SnO2 interlayer People's Republic of China. Journal of Materials Science: Materials in Electronics, 2020, 31(21): 19044. |

| [50] | SUN Z, LIU C, LI X S, et al. Semi-transparent nanofilms of plasmonic Au/TiO2 for visible-light photocatalysis. Materials Chemistry and Physics, 2022, 280: 125773. |

| [51] | 朱晓兵, 李佳佳, 李怡宁, 等. 氧化锰电催化析氧反应及其电极界面特性. 化工学报, 2021, 72(S1): 398. |

| [1] | YUE Quanxin, GUO Ruihua, WANG Ruifen, AN Shengli, ZHANG Guofang, GUAN Lili. 3D Core-shell Structured NiMoO4@CoFe-LDH Nanorods: Performance of Efficient Oxygen Evolution Reaction and Overall Water Splitting [J]. Journal of Inorganic Materials, 2024, 39(11): 1254-1264. |

| [2] | WANG Peng, JIN Zunlong, CHEN Ningguang, LIU Yonghao. Theoretical Investigation of Mo Doped α-MnO2 Electrocatalytic Oxygen Evolution Reaction [J]. Journal of Inorganic Materials, 2022, 37(5): 541-546. |

| [3] | FU Yongsheng, BI Min, LI Chun, SUN Jingwen, WANG Xin, ZHU Junwu. Research Progress on Non-noble Metal/Nitrogen-doped Carbon Composite Materials in Electrocatalytic Oxygen Evolution Reaction [J]. Journal of Inorganic Materials, 2022, 37(2): 163-172. |

| [4] | GONG Yun, LIU Yan, GU Ping, ZHOU Xiao-Xia. Synthesis of Nano Manganese Oxide with Assistance of Ultrasonic for Removal of Low Concentration NO [J]. Journal of Inorganic Materials, 2019, 34(2): 186-192. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||