Journal of Inorganic Materials ›› 2026, Vol. 41 ›› Issue (3): 401-408.DOI: 10.15541/jim20250103

TIAN Hongwang1,2( ), LUO Longfei3, HU Chenglong1(

), LUO Longfei3, HU Chenglong1( ), YAN Meng1, PANG Shengyang1, LI Jian1, TANG Sufang1

), YAN Meng1, PANG Shengyang1, LI Jian1, TANG Sufang1

Received:2025-03-11

Revised:2025-05-19

Published:2026-03-20

Online:2025-05-22

Contact:

HU Chenglong, professor. E-mail: clhu10s@imr.ac.cnAbout author:TIAN Hongwang (1999-), male, Master candidate. E-mail: hwtian22s@imr.ac.cn

Supported by:CLC Number:

TIAN Hongwang, LUO Longfei, HU Chenglong, YAN Meng, PANG Shengyang, LI Jian, TANG Sufang. Facile Fabrication of Ceramic-resin Coatings on C/CA Composites for Oxidation Protection at Medium Temperatures[J]. Journal of Inorganic Materials, 2026, 41(3): 401-408.

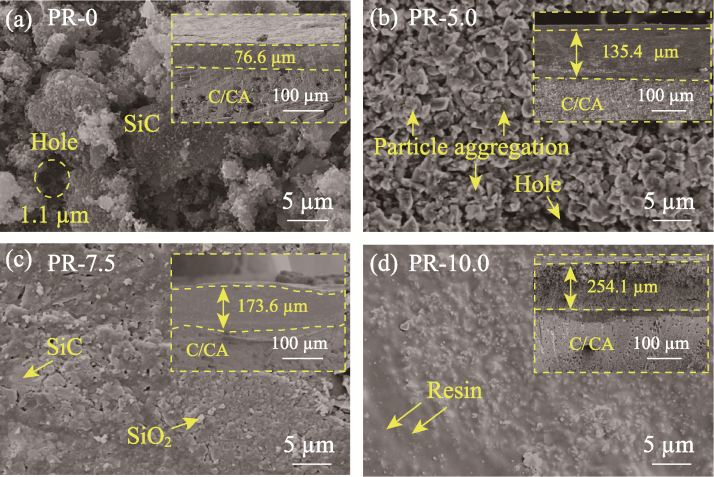

Fig. 1 Surface and cross-sectional morphologies of (a) PR-0, (b) PR-5.0, (c) PR-7.5, and (d) PR-10.0 Insets showing the corresponding cross-sectional morphologies

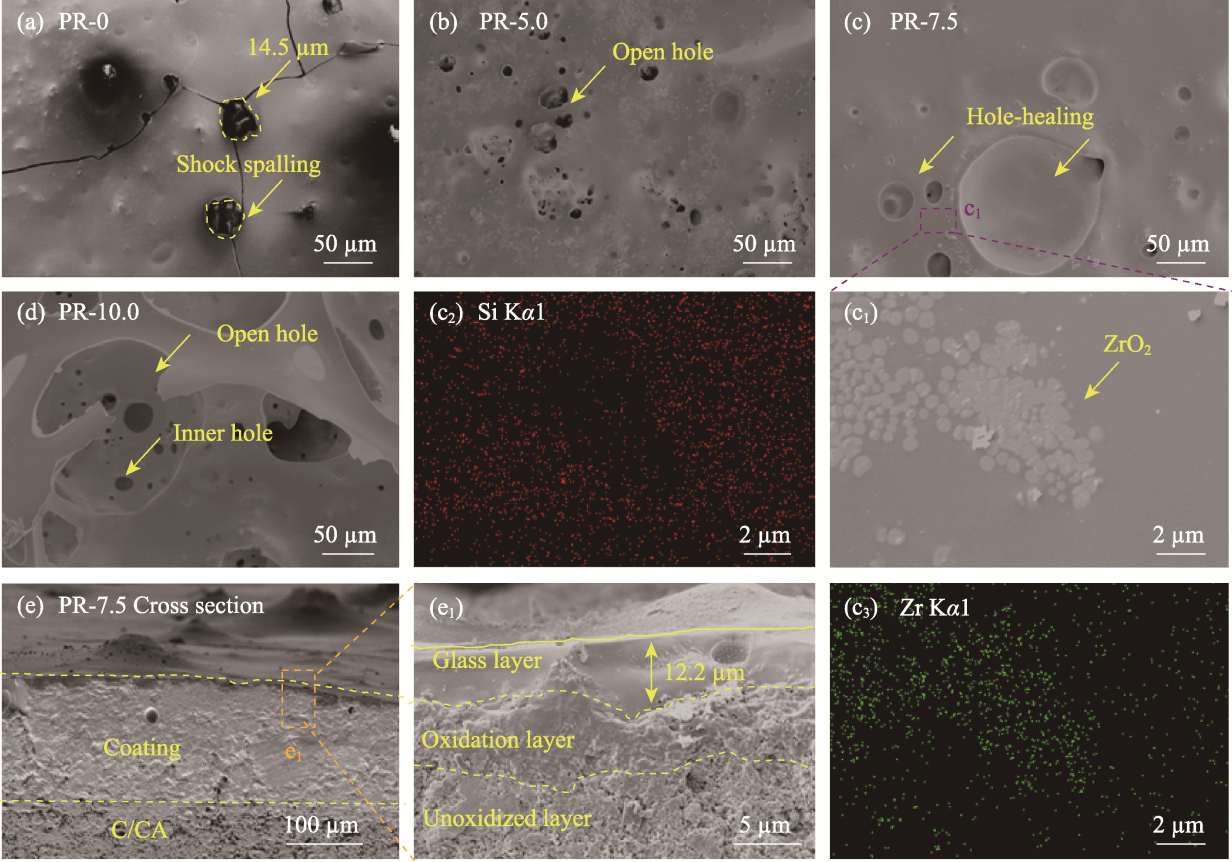

Fig. 3 (a-d) Surface morphologies of PR-0, PR-5.0, PR-7.5, and PR-10.0 after thermal shock; (c1-c3) Surface microstructures under high magnification and corresponding elemental analyses; (e, e1) Cross-sectional morphologies of PR-7.5

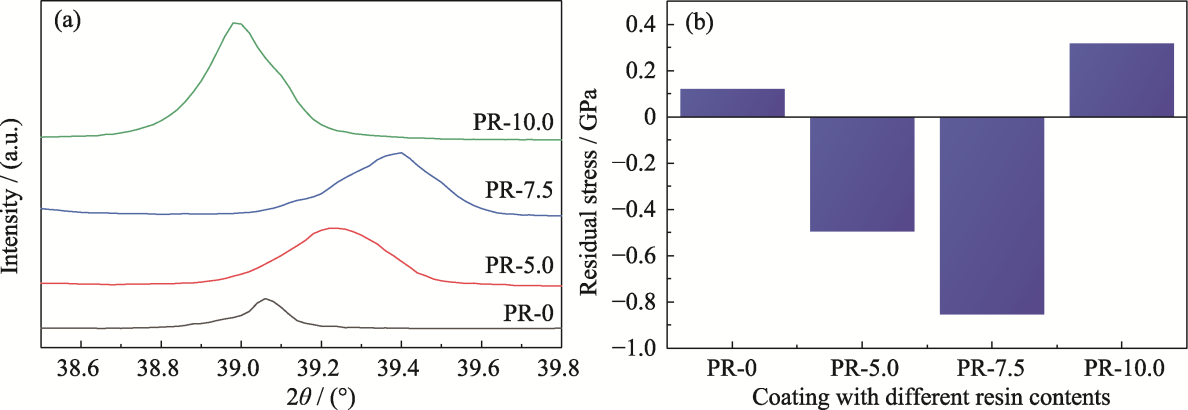

Fig. 4 (a) XRD patterns near 2θ=39° of different coatings, and (b) residual stress of the coating calculated according to the shift of diffraction peaks in (a)

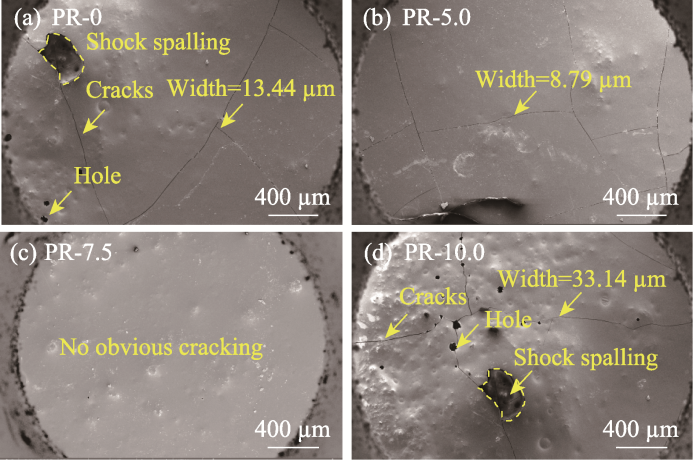

Fig. S3 Macroscopic surface morphologies of the different coatings after thermal shock from 1200 ℃ to room temperature (a) PR-0; (b) PR-5.0; (c) PR-7.5; (d) PR-10.0

| Temperature/℃ | Sample | a/(×10-2, min-1) | b | R2 | k/(×10-3, s-1) | lnk |

|---|---|---|---|---|---|---|

| 800 | PR-0 | 43.45 | -4.305 | 0.9974 | 7.2417 | -4.9279 |

| PR-5.0 | 35.9 | 8.9301 | 0.9996 | 5.9833 | -5.1188 | |

| PR-7.5 | 17.42 | -1.3518 | 0.9974 | 2.9033 | -5.8419 | |

| PR-10.0 | 40.84 | 8.8932 | 0.9948 | 6.8067 | -4.9899 | |

| 1000 | PR-0 | 66.32 | -4.2528 | 0.9999 | 11.0533 | -4.5050 |

| PR-5.0 | 8.75 | 0.9611 | 0.9611 | 1.4583 | -6.5305 | |

| PR-7.5 | 5.15 | 0.8934 | 0.8934 | 0.8583 | -7.0605 | |

| PR-10.0 | 18.68 | 5.5384 | 0.9951 | 3.1133 | -5.7721 | |

| 1200 | PR-0 | 81.66 | -9.239 | 0.9996 | 13.61 | -4.2970 |

| PR-5.0 | 10.72 | 6.0556 | 0.8625 | 1.7867 | -6.3274 | |

| PR-7.5 | 2.37 | 0.0858 | 0.9112 | 0.395 | -7.8366 | |

| PR-10.0 | 35.01 | 3.0509 | 0.9928 | 5.835 | -5.1439 |

Table S1 Fitting results of oxidation kinetics equation parameters of PR-0, PR-5.0, PR-7.5, and PR-10.0 at 800, 1000 and 1200 ℃

| Temperature/℃ | Sample | a/(×10-2, min-1) | b | R2 | k/(×10-3, s-1) | lnk |

|---|---|---|---|---|---|---|

| 800 | PR-0 | 43.45 | -4.305 | 0.9974 | 7.2417 | -4.9279 |

| PR-5.0 | 35.9 | 8.9301 | 0.9996 | 5.9833 | -5.1188 | |

| PR-7.5 | 17.42 | -1.3518 | 0.9974 | 2.9033 | -5.8419 | |

| PR-10.0 | 40.84 | 8.8932 | 0.9948 | 6.8067 | -4.9899 | |

| 1000 | PR-0 | 66.32 | -4.2528 | 0.9999 | 11.0533 | -4.5050 |

| PR-5.0 | 8.75 | 0.9611 | 0.9611 | 1.4583 | -6.5305 | |

| PR-7.5 | 5.15 | 0.8934 | 0.8934 | 0.8583 | -7.0605 | |

| PR-10.0 | 18.68 | 5.5384 | 0.9951 | 3.1133 | -5.7721 | |

| 1200 | PR-0 | 81.66 | -9.239 | 0.9996 | 13.61 | -4.2970 |

| PR-5.0 | 10.72 | 6.0556 | 0.8625 | 1.7867 | -6.3274 | |

| PR-7.5 | 2.37 | 0.0858 | 0.9112 | 0.395 | -7.8366 | |

| PR-10.0 | 35.01 | 3.0509 | 0.9928 | 5.835 | -5.1439 |

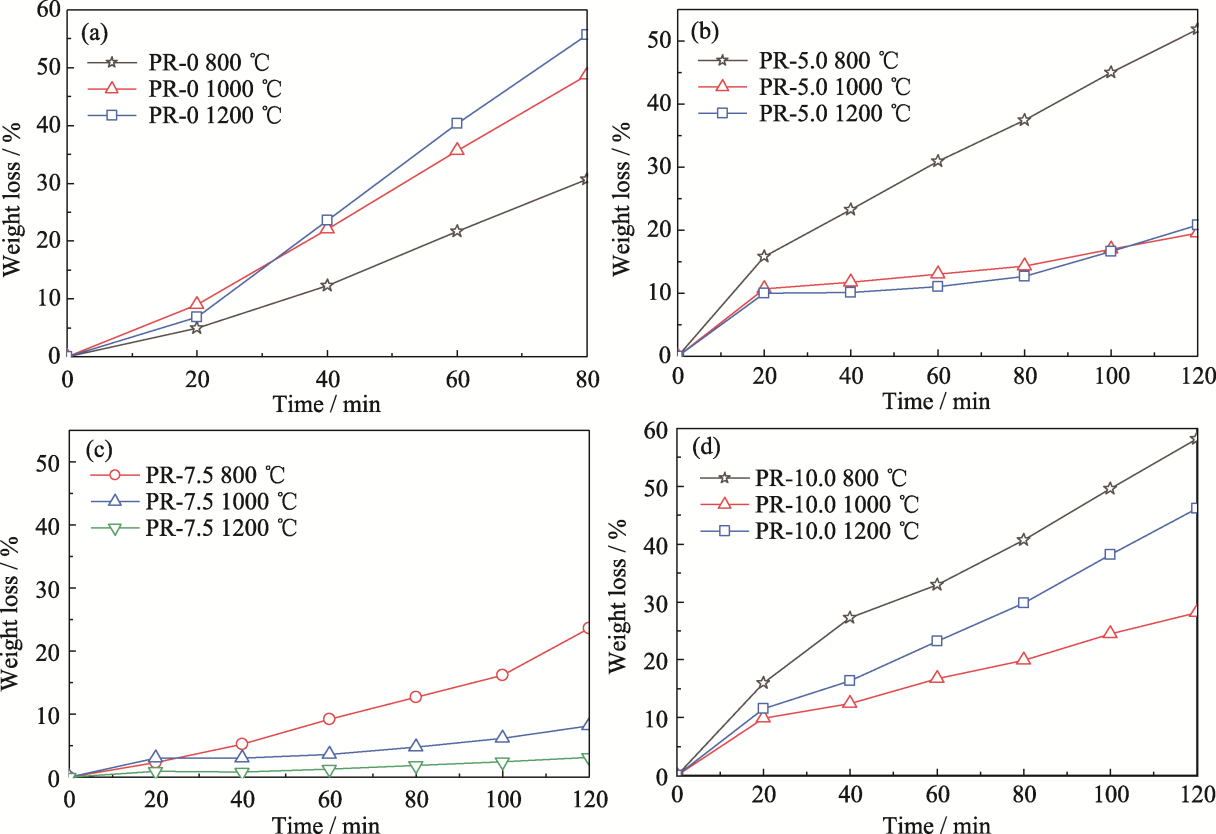

Fig. S6 Weight loss of the C/CA with different coatings under oxidation tests in the temperature range of 800-1200 ℃ (a) PR-0; (b) PR-5.0; (c) PR-7.5; (d) PR-10.0

| [1] | LEVENTIS N, SOTIRIOU-LEVENTIS C, ZHANG G, et al. Nanoengineering strong silica aerogels. Nano Lett., 2002, 2: 957. |

| [2] | PIERRE A C, PAJONK G M. Chemistry of aerogels and their applications. Chem. Rev., 2002, 102: 4243. |

| [3] | ZHANG W, HU C, LI J, et al. Insight into the origin of oxidation behaviors of carbon fiber reinforced carbon aerogel composites with different porous skeletons. Carbon, 2023, 209: 118008. |

| [4] | YANG D, DONG S, HONG C, et al. Preparation, modification, and coating for carbon-bonded carbon fiber composites: a review. Ceram. Int., 2022, 48: 14935. |

| [5] | ZHANG S, MA Y, SURESH L, et al. Carbon nanotube reinforced strong carbon matrix composites. ACS Nano, 2020, 14: 9282. |

| [6] | YAN M, HU C, LI J, et al. An unusual carbon-ceramic composite with gradients in composition and porosity delivering outstanding thermal protection performance up to 1900 ℃. Adv. Funct. Mater., 2022, 32: 2204133. |

| [7] | YAN M, HU C, LI J, et al. Construction of a ceramic coating with low residual stress on C/CA composites for thermal protection at ultra-high temperatures. Compos. B Eng., 2023, 266: 110970. |

| [8] | XU L, LI X, NI L, et al. Ablation behavior of functional gradient ceramic coating for porous carbon-bonded carbon fiber composites. Corros. Sci., 2018, 142: 145. |

| [9] | LI X, FENG J, WU X, et al. Ablation resistance of C/C-SiCO nanoporous ceramic composites with TaSi2-MoSi2-ZrB2-borosilicate glass coating. Process. Appl. Ceram., 2023, 17: 384. |

| [10] | XU B, AN Y, WANG P, et al. Microstructure and ablation behavior of double anti-oxidation protection for carbon-bonded carbon fiber composites. Ceram. Int., 2017, 43: 783. |

| [11] | MA J, LI J, GUO P, et al. Tailoring microstructures of carbon fiber reinforced carbon aerogel-like matrix composites by carbonization to modulate their mechanical properties and thermal conductivities. Carbon, 2022, 196: 807. |

| [12] | LI J, GUO P, HU C, et al. Fabrication of large aerogel-like carbon/ carbon composites with excellent load-bearing capacity and thermal-insulating performance at 1800 ℃. ACS Nano, 2022, 16: 6565. |

| [13] | CHEN Z, CUI X, WANG X, et al. Novel high-entropy (La0.35Gd0.35Y0.35Sm0.35Yb0.6)Zr2O7 thermal barrier coatings: thermal cycling performance and failure behavior. Ceram. Int., 2024, 50(24): 54716. |

| [14] | GABB T P, ROGERS R B, NESBITT J A, et al. Influences of processing and fatigue cycling on residual stresses in a NiCrY-coated powder metallurgy disk superalloy. J. Mater. Eng. Perform., 2017, 26: 5237. |

| [15] | TAO S, YANG J, SHAO F, et al. Atmospheric plasma sprayed thick thermal barrier coatings: microstructure, thermal shock behaviors and failure mechanism. Eng. Fail. Anal., 2022, 131: 105819. |

| [16] | DEWANGAN B, CHAKLADAR N D. Modelling of residual stress during curing of a polymer under autoclave conditions and experimental validation. Comput. Mater. Sci., 2024, 241: 113038. |

| [17] | O’MASTA M R, BUI P P, LARSON N M, et al. Reinforcement induced microcracking during the conversion of polymer-derived ceramics. Acta Mater., 2024, 275: 120053. |

| [18] | VAZ R F, GARFIAS A, ALBALADEJO V, et al. How increasing cold spray coatings thickness affects their residual stress and properties. Surf. Coat. Technol., 2024, 485: 130867. |

| [19] | LIU P, ZHANG X, XUE Y, et al. A novel B2O3/B4C-modified composite adhesive with wide operative temperature range for alumina fiber fabric bonding. Ceram. Int., 2021, 47: 6643. |

| [20] | ZHU S, XU Y, LIU R, et al. Preparation of high-temperature antioxidant coatings on tantalum-based surfaces by atmospheric plasma spraying and their microstructural characterization. Surf. Coat. Technol., 2025, 501: 131928. |

| [21] | CONNELLY A J, TRAVIS K P, HAND R J, et al. Composition-structure relationships in simplified nuclear waste glasses: 2. The effect of ZrO2 additions. J. Am. Ceram. Soc., 2011, 94: 137. |

| [1] | QI Fang, LIU Hui, WU Zhengmin, LU Yi, WU Wenwen, WANG Zhen. Matrix/Interface/Fiber Integrated Oxidation Mechanism of Mini-SiCf/BN/SiC in Water-oxygen Environment at 1100 ℃ [J]. Journal of Inorganic Materials, 2026, 41(3): 340-348. |

| [2] | LI Zexi, LU Wenjie, WANG Chao, ZHANG Lu, LI Shuti, GAO Fangliang. Two-dimensional GaN: Preparation Based on Liquid Metal Gallium and Photoelectric Properties [J]. Journal of Inorganic Materials, 2026, 41(3): 377-384. |

| [3] | MA Xinchao, ZHI Qing, LI Wei, CHEN Mao, WANG Hailong, ZHANG Rui, ZHANG Fan, FAN Bingbing. High-temperature Oxidation Mechanism and Electromagnetic Wave Absorption Properties of Fe2AlB2 [J]. Journal of Inorganic Materials, 2026, 41(1): 45-54. |

| [4] | LIU Jiangping, GUAN Xin, TANG Zhenjie, ZHU Wenjie, LUO Yongming. Research Progress on Catalytic Oxidation of Nitrogen-containing Volatile Organic Compounds [J]. Journal of Inorganic Materials, 2025, 40(9): 933-943. |

| [5] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [6] | LI Jianjun, CHEN Fangming, ZHANG Lili, WANG Lei, ZHANG Liting, CHEN Huiwen, XUE Changguo, XU Liangji. Peroxymonosulfate Activation by CoFe2O4/MgAl-LDH Catalyst for the Boosted Degradation of Antibiotic [J]. Journal of Inorganic Materials, 2025, 40(4): 440-448. |

| [7] | LIANG Ruihui, ZHONG Xin, HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin. High-temperature Water Vapor Corrosion Behaviors of Environmental Barrier Coatings with Yb2O3-modified Silicon Bond Layer [J]. Journal of Inorganic Materials, 2025, 40(4): 425-432. |

| [8] | MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites [J]. Journal of Inorganic Materials, 2025, 40(3): 323-328. |

| [9] | HOU Jiaqi, CHEN Ruicong, ZENG Yaoying, ZHOU Lei, ZHANG Jiaping, FU Qiangang. Thermal Shock and Ablation Resistance of SiC Coating Repaired by Gaseous Silicon Infiltration [J]. Journal of Inorganic Materials, 2025, 40(2): 168-176. |

| [10] | LI Wei, XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song. Preparation and Performance of Sintered SiC Fiber-bonded Ceramics [J]. Journal of Inorganic Materials, 2025, 40(2): 177-183. |

| [11] | YI Guogang, WU Yaoying, ZU Xihong. Non-solvent and Low-temperature Preparation of Porous Silicon-carbon Anodes for Enhanced Lithium Storage [J]. Journal of Inorganic Materials, 2025, 40(12): 1379-1386. |

| [12] | AI Yizhaotong, REN Jiulong, QIANG Linya, ZHANG Xiaozhen, YANG Kai, GAO Yanfeng. Friction and Wear Properties of Al2O3-GdAlO3 (GAP) Amorphous Ceramic Coatings under High Load Capacity [J]. Journal of Inorganic Materials, 2025, 40(10): 1111-1118. |

| [13] | CAO Luhan, MENG Jia, XUE Yudong, SHENG Xiaochen, CUI Yuanyuan, LE Jun, SONG Lixin. Effect of SiC Transition Layer on Bonding Properties of MoSi2-SABB Coating on SiC/SiC Ceramic Matrix Composites [J]. Journal of Inorganic Materials, 2025, 40(10): 1119-1128. |

| [14] | LI Xiaoxuan, FU Qiangang, WEN Zihao, YANG Jinshan, NI Dewei, ZHANG Jie, CHENG Yuan, LIU Yuxuan, CHU Yanhui, CAI Feiyan, WANG Jingyang, ZHANG Xinghong. Research Progress on Ultra-high Temperature Ceramic Structural Materials for Extreme Environments [J]. Journal of Inorganic Materials, 2025, 40(10): 1045-1078. |

| [15] | ZHANG Li, GUAN Haoyang, ZHENG Qining, HONG Zhiliang, WANG Jiaxuan, XING Ning, LI Mei, LIU Yongsheng, ZHANG Chengyu. Creep Properties and Damage Mechanisms of SiCf/SiC-SiYBC Prepared by Melt Infiltration [J]. Journal of Inorganic Materials, 2025, 40(1): 23-30. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||