Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (2): 168-176.DOI: 10.15541/jim20240287

Special Issue: 【结构材料】热障与环境障涂层(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

HOU Jiaqi1( ), CHEN Ruicong1, ZENG Yaoying1, ZHOU Lei2, ZHANG Jiaping1(

), CHEN Ruicong1, ZENG Yaoying1, ZHOU Lei2, ZHANG Jiaping1( ), FU Qiangang1

), FU Qiangang1

Received:2024-06-12

Revised:2024-07-25

Published:2025-02-20

Online:2024-09-02

Contact:

ZHANG Jiaping, professor. E-mail: zhangjiaping@nwpu.edu.cnAbout author:HOU Jiaqi (1999-), female, PhD candidate. E-mail: houjiaqi@mail.nwpu.edu.cn

Supported by:CLC Number:

HOU Jiaqi, CHEN Ruicong, ZENG Yaoying, ZHOU Lei, ZHANG Jiaping, FU Qiangang. Thermal Shock and Ablation Resistance of SiC Coating Repaired by Gaseous Silicon Infiltration[J]. Journal of Inorganic Materials, 2025, 40(2): 168-176.

Fig. 3 Phase composition and morphologies of the coatings (a) XRD pattern, (b, c) surface and (d) cross-section morphologies for P-S coating;(e) XRD pattern, (f) surface morphology, (g) EDS analysis of Spot 1 and (h) cross-section morphology for G-S coating

| Sample | Density/(g·cm-3) | Porosity/% |

|---|---|---|

| P-S | 1.80 | 7.31 |

| G-S | 1.87 | 3.92 |

Table 1 Densities and porosities of coating samples

| Sample | Density/(g·cm-3) | Porosity/% |

|---|---|---|

| P-S | 1.80 | 7.31 |

| G-S | 1.87 | 3.92 |

Fig. 5 Morphologies of coating samples after thermal shock test (a) Macroscopic, (b, c) surface and (d) cross-section morphologies for P-S coating sample; (e) Macroscopic, (f, g) surface and (h) cross-section morphologies for G-S coating sample

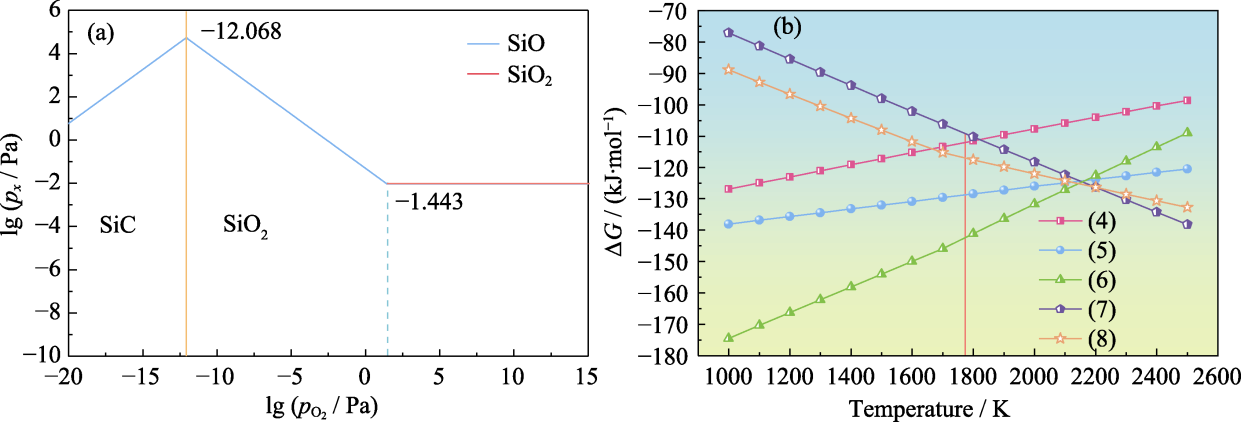

Fig. 6 Variations of vapor pressure of main oxidation products for coatings with partial pressure of oxygen (a) and Gibbs free energy of oxidation reaction with temperature (b) Colorful figures are available on website

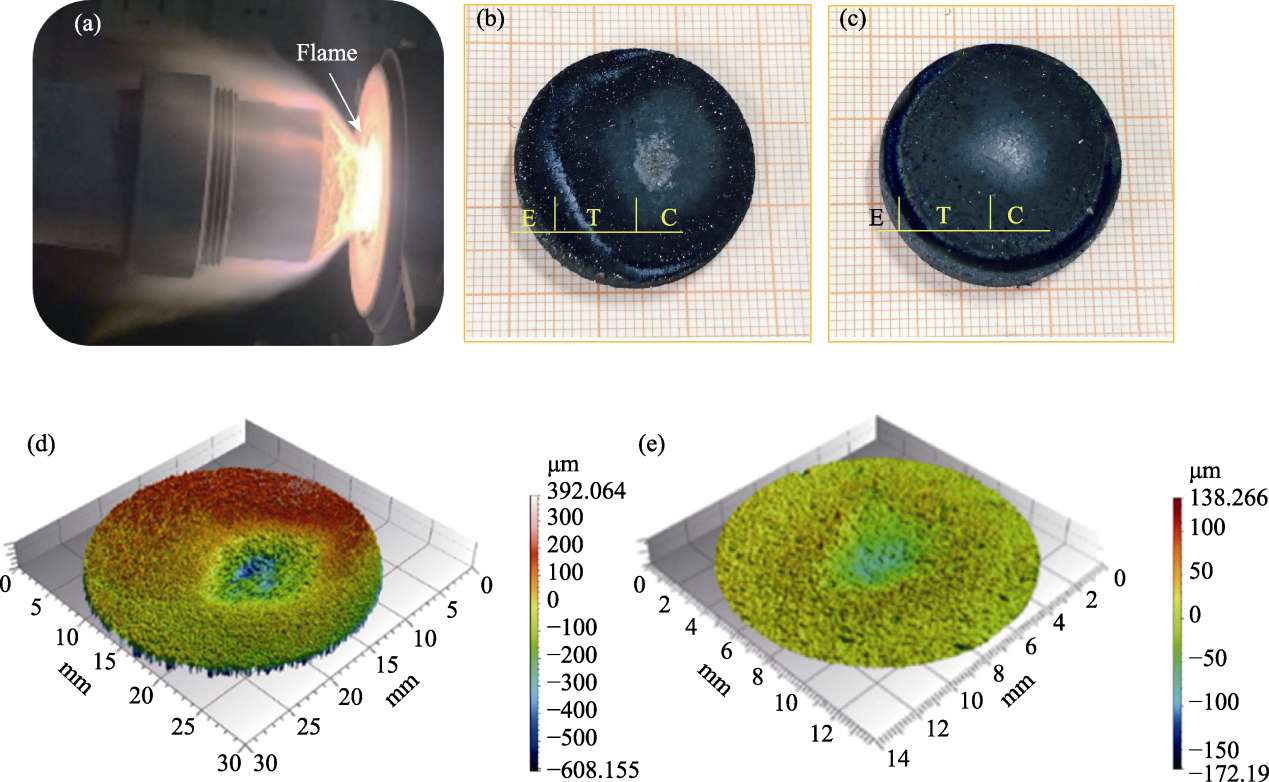

Fig. 8 Macroscopic morphology and 3D profile of the coating samples (a) Image of the process of ablation; (b, c) Macroscopic morphologies of (b) P-S and (c) G-S coating samples; (d, e) 3D profiles of (d) P-S and (e) G-S coating samples. Colorful figures are available on website

Fig. 9 (a) Variation curves of coating surface temperature with time, (b) mass and thickness loss rates, and (c, d) XRD patterns of P-S (c) and G-S (d) coating samples

Fig. 10 Surface morphologies and EDS analyses of C region in coatings after ablation (a, b) Surface morphology of P-S coating; (c) EDS analysis of Spot 2 in Fig. (a); (d, e) Surface morphology of G-S coating; (f) EDS analysis of Spot 3 in Fig. (e)

Fig. 11 Surface morphologies and EDS analyses of T and E regions in coatings after ablation (a) Surface morphology of T region, (b) EDS analysis of Spot 4, (c) surface morphology of E region and (d) EDS analysis of Spot 5 for P-S coating; (e) Surface morphology of T region, (f) EDS analysis of Spot 6, (g) surface morphology of E region and (h) EDS analysis of Spot 7 for G-S coating

| [1] | OPEKA M, TALMY I, ZAYKOSKI J. Oxidation-based materials selection for 2000 ℃+hypersonic aerosurfaces: theoretical considerations and historical experience. Journal of Materials Science, 2004, 39: 5887. |

| [2] | ZHANG X, WANG Y, CHENG Y, et al. Research progress on ultra-high temperature ceramic composites. Journal of Inorganic Materials, 2024, 39(6): 571. |

| [3] | DU H. Research progress on integrated thermal management and key technology of hypersonic vehicles. Equipment Environmental Engineering, 2023, 20(1): 43. |

| [4] | LI C, CROSKY A. The effect of carbon fabric treatment on delamination of 2D-C/C composites. Composites Science and Technology, 2006, 66(15): 2633. |

| [5] | FRIEDRICH C, GADOW R, SPEICHER M. Protective multilayer coatings for carbon-carbon composites. Surface and Coatings Technology, 2002, 151: 405. |

| [6] | LI J, LUO R. Study of the mechanical properties of carbon nanofiber reinforced carbon/carbon composites. Composites Part A: Applied Science & Manufacturing, 2008, 39(11): 1700. |

| [7] | 王海军, 王齐华, 顾秀娟. 碳/碳复合材料抗氧化行为的研究进展. 材料科学与工程学报, 2003, 21(1): 117. |

| [8] | FU Q, ZHANG P, ZHUANG L, et al. Micro/nano multiscale reinforcing strategies toward extreme high-temperature applications: take carbon/carbon composites and their coatings as the examples. Journal of Materials Science & Technology, 2022, 96: 31. |

| [9] | 褚衍辉, 付前刚, 李贺军, 等. 炭/炭复合材料高温防氧化陶瓷涂层的研究新进展. 材料工程, 2010, 86: 86. |

| [10] | JIN X, FAN X, LU C, et al. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites. Journal of the European Ceramic Society, 2018, 38(1): 1. |

| [11] | ZHOU L, FU Q, HU D, et al. Oxidation protective SiC-Si coating for carbon/carbon composites by gaseous silicon infiltration and pack cementation: a comparative investigation. Journal of the European Ceramic Society, 2021, 41(1): 194. |

| [12] | XIN Y, HUANG Q, SU Z, et al. A double layer nanostructure SiC coating for anti-oxidation protection of carbon/carbon composites prepared by chemical vapor reaction and chemical vapor deposition. Ceramics International, 2013, 39(5): 5053. |

| [13] | ZHAO Z, LI K, LI W, et al. Preparation, ablation behavior and mechanism of C/C-ZrC-SiC and C/C-SiC composites. Ceramics International, 2018, 44(7): 7481. |

| [14] | FU Q, LI H, SHI X, et al. Silicon carbide coating to protect carbon/carbon composites against oxidation. Scripta Materialia, 2005, 52(9): 923. |

| [15] | ZHU X, ZHANG Y, SU Y, et al. SiC-Si coating with micro-pores to protect carbon/carbon composites against oxidation. Journal of the European Ceramic Society, 2021, 41(1): 114. |

| [16] | SONG S, YIN J, ZHU Y, et al. Optical coating on Cf/SiC composites via aqueous slurry painting and reaction bonding. Journal of Inorganic Materials, 2017, 32(2): 210. |

| [17] | YANG Z, YIN Z, ZHAO Z, et al. Microstructure and properties of SiO2-based ceramic cores with ball-shaped powders by the preceramic polymer technique in N2 atmosphere. Materials Chemistry and Physics, 2020, 243: 122609. |

| [18] | PAVESE M, FINO P, BADINI C, et al. HfB2/SiC as a protective coating for 2D Cf/SiC composites: effect of high temperature oxidation on mechanical properties. Surface and Coatings Technology, 2008, 202(10): 2059. |

| [19] | HUANG J, ZENG X, LI H, et al. Influence of the preparation temperature on the phase, microstructure and anti-oxidation property of a SiC coating for C/C composites. Carbon, 2004, 42(8/9): 1517. |

| [20] | ZHANG P, ZHANG Y, CHEN G, et al. High-temperature oxidation behavior of CVD-SiC ceramic coating in wet oxygen and structural evolution of oxidation product: experiment and first-principle calculations. Applied Surface Science, 2021, 556: 149808. |

| [21] | GOLESTANI F, ZAKERI M, RAZAVI M, et al. Microstructure and ablative properties of Si-SiC coating prepared by spark plasma sintering. Ceramics International, 2018, 44(7): 8403. |

| [22] | 张武装, 熊翔, 曾毅. 包埋法制备SiC涂层C/C复合材料及真空热处理对涂层的影响. 粉末冶金材料科学与工程, 2011, 16(2): 6. |

| [23] | ZHANG P, FU Q, CHENG C, et al. Microstructure evolution of in-situ SiC-HfB2-Si ternary coating and its corrosion behaviors at ultra-high-temperatures. Journal of the European Ceramic Society, 2021, 41(13): 6223. |

| [24] | ZHOU L, ZHANG J, HU D, et al. High temperature oxidation and ablation behaviors of HfB2-SiC/SiC coatings for carbon/carbon composites fabricated by dipping-carbonization assisted pack cementation. Journal of Materials Science & Technology, 2022, 111: 88. |

| [25] | ZHANG J, HOU J, ZHOU L, et al. TaSi2 modified HfB2-SiC coating: preparation and ablation behavior. Journal of the American Ceramic Society, 2024, 107(1): 461. |

| [26] | WANG P, LI H, SUN J, et al. The effect of HfB2 content on the oxidation and thermal shock resistance of SiC coating. Surface and Coatings Technology, 2018, 339: 124. |

| [27] | TANAY R, MANAS K, MANAB M. Thermal shock behavior of ZrB2-MoSi2-SiC Composites. Journal of Alloys and Compounds, 2022, 9924: 166443. |

| [28] | ARTHUR H, VICTOR L. Volatility diagrams for silica, silicon nitride, and silicon carbide and their application to high-temperature decomposition and oxidation. Journal of the American Ceramic Society, 1990, 73(10): 2785. |

| [29] | WANG W, FU Q. Recovery in oxidation behavior of damaged SiC-ZrB2/SiC coating of carbon/carbon composites. Journal of Materiomics, 2023, 9(3): 541. |

| [30] | DU J, YU G, JIA Y, et al. Ultra-high temperature ablation behaviour of 2.5D SiC/SiC under an oxy-acetylene torch. Corrosion Science, 2022, 201: 110263. |

| [31] | ZHANG J, QU J, FU Q. Ablation behavior of nose-shaped HfB2- SiC modified carbon/carbon composites exposed to oxyacetylene torch. Corrosion Science, 2019, 151: 87. |

| [32] | 王首豪. ZrC改性C/C-SiC复合材料高温性能及影响机理研究. 大连: 大连理工大学博士学位论文, 2020: 97. |

| [33] | YU Y, HAN Z, CHENG Y, et al. Ablation behavior of 3D PyC-Cf/ SiHfBOC composites under an oxyacetylene torch environment above 2000 ℃. Ceramics International, 2024, 50(9): 14011. |

| [34] | ZHOU H, ZHANG X, GAO L, et al. Ablation properties of ZrB2- SiC ultra-high temperature ceramic coatings. Journal of Inorganic Materials, 2013, 28(3): 256. |

| [35] | ZHEN Q, LI Z, HU P, et al. A glass-ceramic coating with self- healing capability and high infrared emissivity for carbon/carbon composites. Corrosion Science, 2018, 141: 81. |

| [36] | LI J, ZHAN Y, WANG H, et al. Long-life ablation resistance ZrB2-SiC-TiSi2 ceramic coating for SiC coated C/C composites under oxidizing environments up to 2200 K. Journal of Alloys and Compounds, 2020, 824: 153934. |

| [1] | XIAO Xiaolin, WANG Yuxiang, GU Peiyang, ZHU Zhenrong, SUN Yong. Advances in Regulation of Damaged Skin Regeneration by Two-dimensional Inorganic Materials [J]. Journal of Inorganic Materials, 2025, 40(8): 860-870. |

| [2] | YU Yiping, XIAO Peng, ZHAO Changhao, XU Mengdi, YAO Lidong, LI Wei, WANG Song. Ablation Behavior of High-temperature Laminated Ta/Ta0.5Hf0.5C Cermets under High-frequency Plasma Wind Tunnel Test [J]. Journal of Inorganic Materials, 2025, 40(7): 790-798. |

| [3] | CHEN Xi, YUAN Yuan, TAN Yeqiang, LIU Changsheng. Strategic Study on the Development of Inorganic Non-metallic Biomaterials [J]. Journal of Inorganic Materials, 2025, 40(5): 449-456. |

| [4] | LIN Yuanwei, JING Zhao, CHEN Hetuo, LI Jiaheng, QIN Xianpeng, ZHOU Guohong, WANG Shiwei. Ablative Properties of SiCp Doped Cf/Li2O-Al2O3-SiO2 Composites [J]. Journal of Inorganic Materials, 2025, 40(10): 1153-1162. |

| [5] | LI Xiaoxuan, FU Qiangang, WEN Zihao, YANG Jinshan, NI Dewei, ZHANG Jie, CHENG Yuan, LIU Yuxuan, CHU Yanhui, CAI Feiyan, WANG Jingyang, ZHANG Xinghong. Research Progress on Ultra-high Temperature Ceramic Structural Materials for Extreme Environments [J]. Journal of Inorganic Materials, 2025, 40(10): 1045-1078. |

| [6] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| [7] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [8] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| [9] | ZHENG Bin, KANG Kai, ZHANG Qing, YE Fang, XIE Jing, JIA Yan, SUN Guodong, CHENG Laifei. Preparation and Thermal Stability of Ti3SiC2 Ceramics by Polymer Derived Ceramics Method [J]. Journal of Inorganic Materials, 2024, 39(6): 733-740. |

| [10] | ZHANG Xinghong, WANG Yiming, CHENG Yuan, DONG Shun, HU Ping. Research Progress on Ultra-high Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(6): 571-590. |

| [11] | GUO Xiaoyang, ZHANG Xiaolin, JIANG Yan, TIAN Yuan, GENG Zhi. Ti-doped Hf(Zr)B2-SiC Anti-ablation Coatings: Preparation and Ablation Resistance Mechanism [J]. Journal of Inorganic Materials, 2024, 39(12): 1357-1366. |

| [12] | YOU Bojie, LI Bo, LI Xuqin, MA Xuehan, ZHANG Yi, CHENG Laifei. Thermal Shock Damage and In-plane Shear Performance Degradation of 2D SiCf/SiC at Medium Temperature [J]. Journal of Inorganic Materials, 2024, 39(12): 1367-1376. |

| [13] | WANG Bo, CAI Delong, ZHU Qishuai, LI Daxin, YANG Zhihua, DUAN Xiaoming, LI Yanan, WANG Xuan, JIA Dechang, ZHOU Yu. Mechanical Properties and Thermal Shock Resistance of SrAl2Si2O8 Reinforced BN Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(10): 1182-1188. |

| [14] | GUO Lingxiang, TANG Ying, HUANG Shiwei, XIAO Bolan, XIA Donghao, SUN Jia. Ablation Resistance of High-entropy Oxide Coatings on C/C Composites [J]. Journal of Inorganic Materials, 2024, 39(1): 61-70. |

| [15] | CAI Jia, ZHAO Fangxia, FAN Dong, HUANG Liping, NIU Yaran, ZHENG Xuebin, ZHANG Zhenzhong. Pyrolysis Behavior and Laser Ablation Resistance of PCS in Polycarbosilane Composite Coatings [J]. Journal of Inorganic Materials, 2023, 38(11): 1271-1280. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||