Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (2): 177-183.DOI: 10.15541/jim20240292

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Wei( ), XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song(

), XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song( )

)

Received:2024-06-17

Revised:2024-09-09

Published:2025-02-20

Online:2024-09-23

Contact:

WANG Song, professor. E-mail: wangs_0731@163.comAbout author:LI Wei (1979-), male, associate professor. E-mail: liwei79@nudt.edu.cn

Supported by:CLC Number:

LI Wei, XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song. Preparation and Performance of Sintered SiC Fiber-bonded Ceramics[J]. Journal of Inorganic Materials, 2025, 40(2): 177-183.

| Sample | Composition/% (in atom) | C/Si | |||

|---|---|---|---|---|---|

| Si | C | O | Al | ||

| SiC(Al) fiber | 47.70 | 51.50 | 0.30 | <1.00 | 1.08 |

Table 1 Chemical composition of SiC(Al) fiber

| Sample | Composition/% (in atom) | C/Si | |||

|---|---|---|---|---|---|

| Si | C | O | Al | ||

| SiC(Al) fiber | 47.70 | 51.50 | 0.30 | <1.00 | 1.08 |

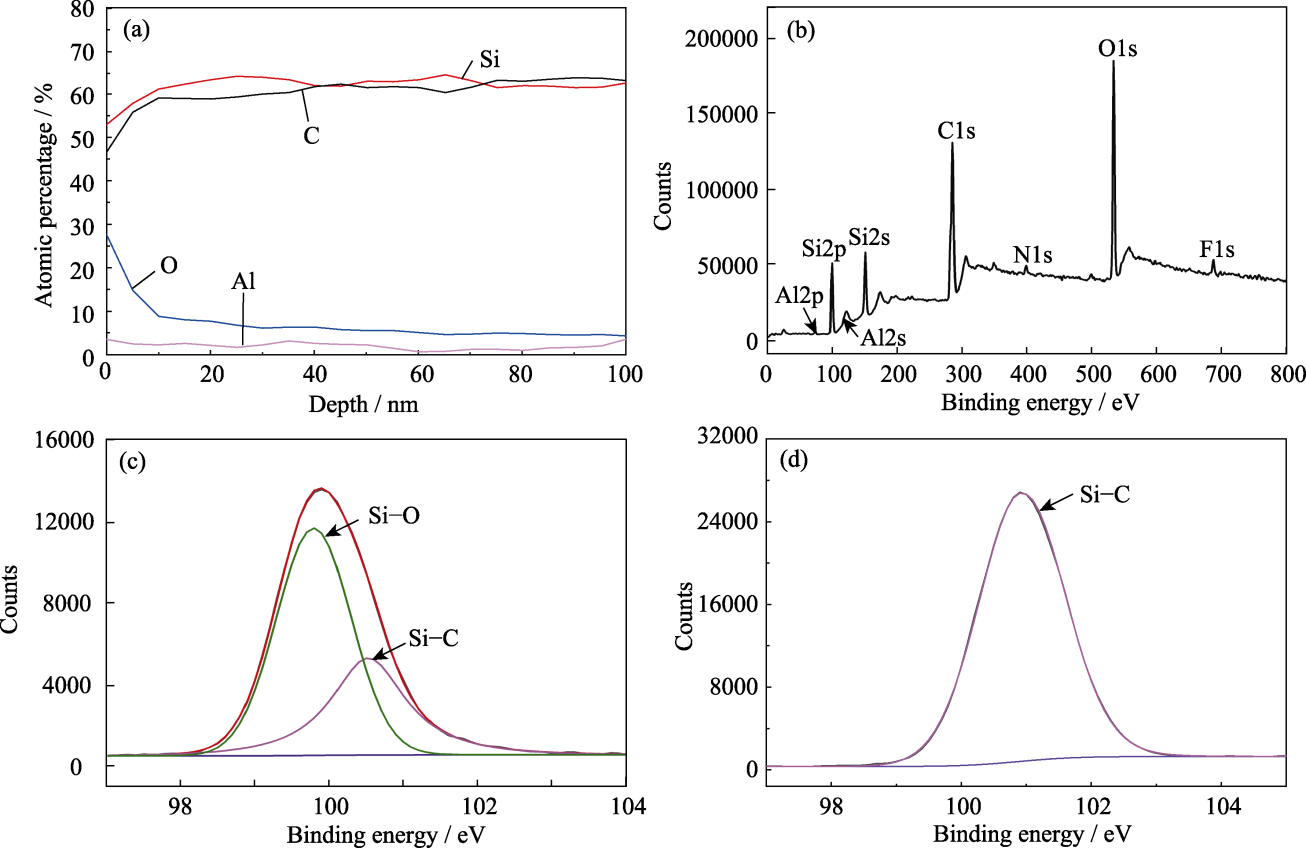

Fig. 1 Chemical composition of SiC(Al) fiber (a) AES depth profile; (b) Total XPS spectra of surface; (c, d) Si2p XPS spectra of SiC(Al) fiber (c) before and (d) after etching

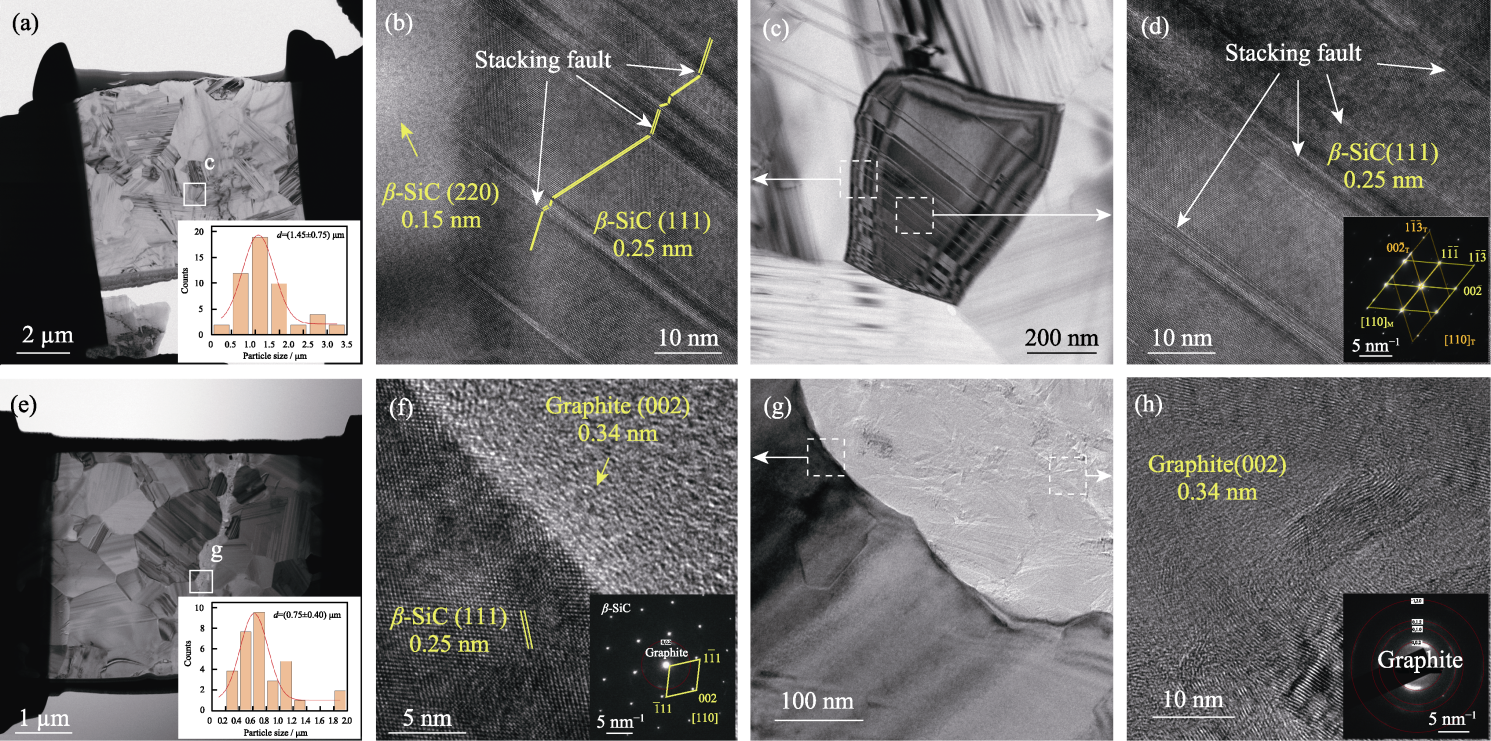

Fig. 6 (a, c, e, g) TEM and (b, d, f, h) HRTEM images of (a-d) SiC(Al) FBC and (e-h) iG/SiC(Al) FBC with insets in (a, e) showing corresponding distributions of crystal diameters and insets in (d, f, h) showing selected area electron diffraction (SAED) patterns

Fig. 11 (a) Load-displacement curves during the flexural strength test and (b) residual bending strength of iG/SiC(Al) FBC after 100 h oxidation at different temperatures

| [1] | YIN F, RAO A G. Performance analysis of an aero engine with inter-stage turbine burner. The Aeronautical Journal, 2017, 121(1245): 1605. |

| [2] | SRINIVAS G, RAGHUNANDANA K, SATISH SHENOY B. Recent developments in turbomachinery component materials and manufacturing challenges for aero engine applications. IOP Conference Series: Materials Science and Engineering, 2018, 314: 012012. |

| [3] | LIN Z M. The current development and future trends of fighter engines. Aeroengine, 2006, 32(1): 1. |

| [4] | BERGS T, GRÜNEBAUM T, FRICKE K, et al. Life cycle assessment for milling of Ti-and Ni-based alloy aero engine components. Procedia CIRP, 2021, 98: 625. |

| [5] | WANG X G, LIU J L, JIN T, et al. Tensile behaviors and deformation mechanisms of a nickel-base single crystal superalloy at different temperatures. Materials Science and Engineering: A, 2014, 598: 154. |

| [6] |

ZHANG G, ZHANG Y, ZHENG L, et al. Research progress in powder metallurgy superalloys and manufacturing technologies for aero-engine application. Acta Metallurgica Sinica, 2019, 55(9): 1133.

DOI |

| [7] | FAN X, YIN X. Progress in research and development on matrix modification of continuous fiber-reinforced silicon carbide matrix composites. Advanced Composites and Hybrid Materials, 2018, 1: 685. |

| [8] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8): 804.

DOI PMID |

| [9] | KARADIMAS G, SALONITIS K. Ceramic matrix composites for aero engine applications--a review. Applied Sciences, 2023, 13(5): 3017. |

| [10] | KATOH Y, SNEAD L L, HENAGER J C H, et al. Current status and recent research achievements in SiC/SiC composites. Journal of Nuclear Materials, 2014, 455(1/2/3): 387. |

| [11] | DICARLO J A, YUN H M, MORSCHER G N, et al. SiC/SiC composites for 1200 ℃ and above//BANSAL N P. Handbook of ceramic composites. Boston: Springer US, 2005: 77-98. |

| [12] | LUTHRA K L, CORMAN G S. Melt infiltrated (MI) SiC/SiC composites for gas turbine applications//KRENKEL W, NASLAIN R, SCHNEIDER H. High temperature ceramic matrix composites. Ohio: Wiley-American Ceramic Society, 2001: 744-753. |

| [13] | 武安华, 曹文斌, 马芳, 等. SiC的固相热压烧结. 北京科技大学学报, 2000, 22(4): 328. |

| [14] | ISHIKAWA T, KAJII S, MATSUNAGA K, et al. A tough, thermally conductive silicon carbide composite with high strength up to 1600 ℃ in air. Science, 1998, 282(5392): 1295. |

| [15] | HO C Y, TSAI S C, LIN H T, et al. Microstructural investigation of Si-ion-irradiated single crystal 3C-SiC and SA-Tyrannohex SiC fiber-bonded composite at high temperatures. Journal of Nuclear Materials, 2013, 443(1/2/3): 1. |

| [16] | XU Z M, YU Y P, WANG S, et al. Research progress of SiC fiber-bonded ceramics. Journal of Material Engineering, 2023, 51(8): 23. |

| [17] | VERA M C, MARTÍNEZ-FERNÁNDEZ J, SINGH M, et al. Strength and thermal shock resistance of Si-Al-C-O and Si-Ti-C-O fiber-bonded ceramics. International Journal of Applied Ceramic Technology, 2022, 19(2): 1126. |

| [18] | GOU Y, WANG H, JIAN K. Formation of carbon-rich layer on the surface of SiC fiber by sintering under vacuum for superior mechanical and thermal properties. Journal of the European Ceramic Society, 2017, 37(3): 907. |

| [19] | ZHANG Y, CHEN J, YAN D, et al. Conversion of silicon carbide fibers to continuous graphene fibers by vacuum annealing. Carbon, 2021, 182: 435. |

| [20] | 王堋人. SA型SiC纤维烧结致密化机理及高温性能研究. 长沙: 国防科技大学博士学位论文, 2020. |

| [21] | YAMAMOTO H, BABA Y, SASAKI T A. Electronic structures of N2+ and O2+ ion-implanted Si (100). Surface and Interface Analysis, 1995, 23(6): 381. |

| [22] | KAJII S, MATSUNAGA K, SATO M, et al. Mechanical behavior of SiC-Polycrystalline fiber-bonded-cermics. 28th International Conference on Advanced Ceramics and Composites B:Ceramic Engineering and Science Proceedings, Hoboken, 2004, 25: 43-48. |

| [23] | CORMAN G S, LUTHRA K L. Silicon melt infiltrated ceramic composites (HiPerComp™)//BANSAL N P. Handbook of ceramic composites. Boston: Springer US, 2005: 99-115. |

| [24] | ZHANG J, ZHANG Y, WANG Y, et al. Long-term oxidation performance of SiCf/SiC composites at 1200 ℃ in air atmosphere manufactured by PIP and hybrid CVI/PIP techniques. Ceramics International, 2024, 50(7): 10259. |

| [1] | CHEN Bin, REN Ke, WANG Yiguang. Evolution of Mechanical Properties of Mini-SiCf/SiC Composites at High Temperatures over a Long Period of Time [J]. Journal of Inorganic Materials, 2025, 40(9): 971-980. |

| [2] | GOU Yanzi, KANG Weifeng, WANG Pengren. Influence of Sintering Conditions on Preparation of Nearly Stoichiometric SiC Fibers with Highly Crystalline Microstructure [J]. Journal of Inorganic Materials, 2025, 40(4): 405-414. |

| [3] | GOU Yanzi, KANG Weifeng, ZHANG Qingyu. Preparation of Nearly Stoichiometric SiC(Ti) Fibers with Highly Crystalline Microstructure from Polytitanocarbosilane [J]. Journal of Inorganic Materials, 2024, 39(12): 1377-1383. |

| [4] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [5] | WANG Yuanjie, PEI Xueliang, LI Haoyi, XU Xin, HE Liu, HUANG Zhengren, HUANG Qing. Crosslinking of Active Polycarbosilane Initiated by Free Radical and Its Application in the Preparation of SiC Fibers [J]. Journal of Inorganic Materials, 2021, 36(9): 967-973. |

| [6] | WANG Xi,WANG Kejie,BAI Hui,SONG Zhuolin,WANG Bo,ZHANG Chengyu. Creep Properties and Damage Mechanisms of 2D-SiCf/SiC Composites Prepared by CVI [J]. Journal of Inorganic Materials, 2020, 35(7): 817-821. |

| [7] | WANG Pengren, GOU Yanzi, WANG Hao. Third Generation SiC Fibers for Nuclear Applications [J]. Journal of Inorganic Materials, 2020, 35(5): 525-531. |

| [8] | Han-Qing YU, Zhi-Jun DONG, Guan-Ming YUAN, Ye CONG, Xuan-Ke LI, Yong-Ming LUO. Boron-carbon doped Silicon Carbide Fibers: Preparation and Property [J]. Journal of Inorganic Materials, 2019, 34(5): 493-501. |

| [9] | SHI Xu-Guo, LI Ming-Yuan, MA Wei-Gang, ZHOU Xin-Gui, ZHANG Xing. Experimental Study on Thermal Transport Property of KD-II SiC Fiber [J]. Journal of Inorganic Materials, 2018, 33(7): 756-760. |

| [10] | WANG Guo-Dong, SONG Yong-Cai. Enhancing Mechanical Property of SiC Fiber by Decreasing Fiber Diameter through a Modified Melt-spinning Process [J]. Journal of Inorganic Materials, 2018, 33(7): 721-727. |

| [11] | MU Yang, DENG Jia-Xin, LI Hao, ZHOU Wan-Cheng. Comparison of High-temperature Dielectric and Microwave Absorbing Property of Two Continuous SiC Fibers [J]. Journal of Inorganic Materials, 2018, 33(4): 427-433. |

| [12] | ZUO Ya-Zhuo, LI Hong, WANG Shao-Lei, YANG Min, REN Mu-Su, SUN Jin-Liang. Ablation Behavior of (C-SiC)f/C Composites [J]. Journal of Inorganic Materials, 2017, 32(11): 1141-1146. |

| [13] | CAO Shi-Yi, WANG Jun, WANG Hao, WANG Xiao-Zhou. Influence of Free Carbon Elimination on Microstructure and Property of SiC Fibers [J]. Journal of Inorganic Materials, 2016, 31(5): 529-534. |

| [14] | YUAN Qin, SONG Yong-Cai. Research and Development of Continuous SiC Fibers and SiCf/SiC Composities [J]. Journal of Inorganic Materials, 2016, 31(11): 1157-1165. |

| [15] | MAO Jin-Yuan, LIU Min, MAO Jie, DENG Chun-Min, ZENG De-Chang, XU Lin. Oxidation-resistance of ZrB2-MoSi2 Composite Coatings Prepared by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2015, 30(3): 282-286. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||