|

|

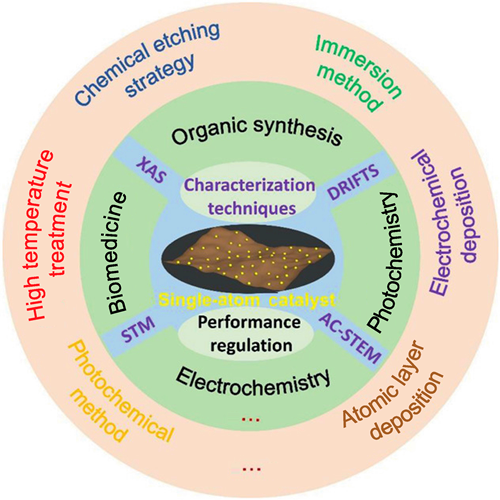

Research Progress on Preparation Methods of Single-atom Catalysts

SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing

2025 Vol. 40 (2): 113–127

Abstract

Abstract(

1644 )

HTML

HTML(

111)

PDF

PDF(7331KB)(

5399

)

Nowadays, we are facing increasingly serious energy and environmental problems, which urgently need more efficient chemical industry technologies to meet the requirements of low cost, high yield and sustainability. Developing efficient catalysts is of great significance for improving production efficiency, expanding economic benefits, optimizing energy structure, and ameliorating industrial structure. Single-atom catalysts (SACs), featuring unique properties arising from their single-atom dispersion on support surface, have demonstrated exceptional activity, selectivity and stability in energy catalysis, environmental catalysis and organic catalysis. Therefore, preparation methods and catalytic mechanisms of SACs have become a hot research topic on the international catalytic community. This review describes three strategies for preparing SACs: bottom-up synthesis, top-down synthesis and quantum dots cross-linking/self-assembly. Specifically, methods such as co-precipitation, immersion, atomic layer deposition, high-temperature atom thermal transfer, and high-temperature pyrolysis are presented in detail. These approaches precisely control the location and distribution of metal atoms, maximizing their utilization and catalytic efficiency. In addition, the challenges and development prospects faced by SACs related to stability, integrated control and industrial scalability are also summarized.

|

|

|

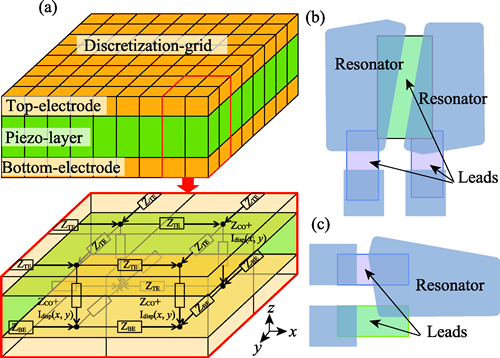

Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter

TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang

2025 Vol. 40 (2): 128–144

Abstract

Abstract(

828 )

HTML

HTML(

65)

PDF

PDF(3637KB)(

1737

)

With upgrading of communication technology and driving of 5G communication applications, the explosive number of filters required by various smart devices promoted prosperity of the filter market. However, the demanded performance also becomes increasingly stringent, including broad bandwidth, high frequency, high power capacity, miniaturization, integration, and low cost, in both academia and industry. To meet these strict requirements, the thin film bulk acoustic resonator (FBAR) filters have emerged as one of the most promising types of filters with commercial success. But currently they are still facing difficulties such as insufficient performance, complex fabrication process, relatively higher cost, and technological constraints. This paper reviews the relevant issues and key technologies in FBAR filters in three aspects: theoretical research on devices and structural optimization, preparation and optimization of high-performance piezoelectric materials, and development of novel processes and technological integration. The purpose of this paper is to delineate the trajectory of technological advancements and iterations in FBAR filters for scholars in the research field, with the expectation of providing several considerations for future research directions and pathways.

|

|

|

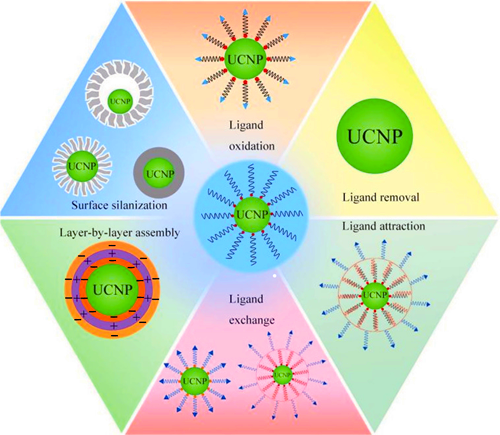

Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging

HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu

2025 Vol. 40 (2): 145–158

Abstract

Abstract(

709 )

HTML

HTML(

34)

PDF

PDF(9597KB)(

2736

)

Early diagnosis of tumor is a key factor for efficient diagnosis and treatment of cancer. Fluorescence imaging technology, particularly utilizing near-infrared (NIR) light, has shown promising potential in the biomedical field, specifically in the early detection of cancer. NIR light has minimal absorption and scattering in biological tissues, allowing for high-quality imaging with high resolution and signal-to-noise ratio. Realization of high-quality NIR fluorescence imaging relies on excellent fluorescent probes. Upconversion nanoparticles (UCNPs), excited by NIR light, have soared in fluorescence imaging due to their favorable characteristics such as low toxicity, narrow-band emission, tunable emission, long fluorescence lifetime, good stability, and high quantum yield. This article summarizes the basic principles, synthesis methods, and modification/decoration techniques of upconversion fluorescent probes, mainly expounds on several typical imaging modes of rare earth doped upconversion fluorescent probes and their latest research progress in tumor visualization, and prospects the further application research on the integration of diagnosis and treatment.

|

|

|

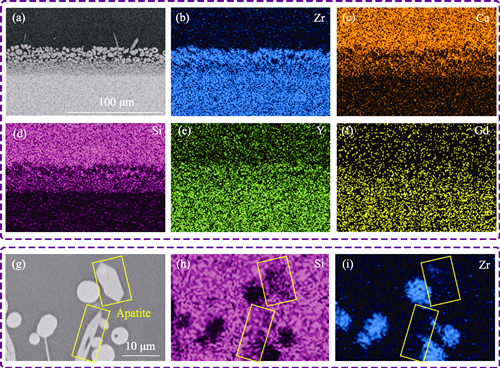

Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance

FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao

2025 Vol. 40 (2): 159–167

Abstract

Abstract(

626 )

HTML

HTML(

69)

PDF

PDF(11774KB)(

507

)

Rare-earth zirconates (REZs) have attracted attention in the field of thermal barrier materials because they are more resistant to calcium-magnesium-aluminum-silicon oxide (CMAS) corrosion than yttria stabilized zirconia (YSZ). High-entropy design of zirconates is an effective method to enhance CMAS corrosion resistance, but currently the ability of its corrosion resistance still does not meet the growing requirement. In this work, a solid-state reaction technique was used to synthesize high-entropy rare-earth zirconate (HE-REZ) (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 powder with a single-phased defect fluorite structure, and pressureless sintering (PLS) combined with cold isostatic pressing (CIP) technique was used to efficiently prepare bulk samples. The phase composition, microstructure, element distribution, thermal and mechanical properties were studied, focusing on the CMAS corrosion resistance. According to the results, under the same CMAS corrosion environment at 1300 ℃, the corrosion depth of HE-REZ with a relative density of 98.6% is only 2.6% of 7YSZ and 22.6% of Gd2Zr2O7 (GZO). The synergistic effect of zirconates' chemical inertness and high-entropy materials' sluggish diffusion accounts for this exceptional corrosion resistance. The obtained HE-REZ shows higher hardness and Young's modulus, larger coefficient of linear expansion, and lower thermal conductivity than ever, making its mechanical and thermal properties superior to GZO. All these outcomes demonstrate the good application potential of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 in the field of thermal barrier materials.

|

|

|

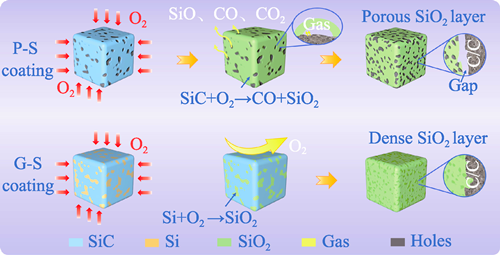

Thermal Shock and Ablation Resistance of SiC Coating Repaired by Gaseous Silicon Infiltration

HOU Jiaqi, CHEN Ruicong, ZENG Yaoying, ZHOU Lei, ZHANG Jiaping, FU Qiangang

2025 Vol. 40 (2): 168–176

Abstract

Abstract(

583 )

HTML

HTML(

44)

PDF

PDF(15988KB)(

266

)

Integrity and denseness of coatings significantly influence their performance. Scrapping and re-preparation of defective or damaged coatings not only lead to material waste but also prolong preparation time. To address the challenge of cost-effectiveness, repairing the coating to restore its protective capability is obviously essential. However, there is rare literature touched effective repairing method for porous SiC ceramic coatings. In this study, a straightforward and cost-effective gaseous silicon infiltration method was employed to repair defects in porous SiC coating prepared by pack cementation. Comparison experiments on thermal shock and ablation resistance of the coating were carried out before and after repair. Results demonstrated that the repaired coating exhibited robust adhesion to its substrate after 15 thermal cycles from room temperature to 1773 K, with a mass loss rate reduction of 97.05% in contrast to the pack cementation SiC coating. After ablation for 30 s, carbon fibers located in the center area of the repaired coating were successfully coated with SiO2, without naked exposure or damage. The mass and thickness loss rates were reduced by 97.02% and 67.99%, respectively. All above results indicated that thermal shock and ablation resistance of the repaired coating were enhanced, which can be attributed to the increased densification and the reduction of defects in the repaired coating. Therefore, silicon, introduced through gaseous silicon infiltration, is more easily oxidized at elevated temperature to form SiO2, which effectively heals defects and obstructs oxygen penetration, thereby preventing further oxidative damage to the substrate. This study provides a novel coating repair strategy with good economy and feasibility, constructs a new approach to effectively repair defects and damages of coatings, and enhances their service stability and durability.

|

|

|

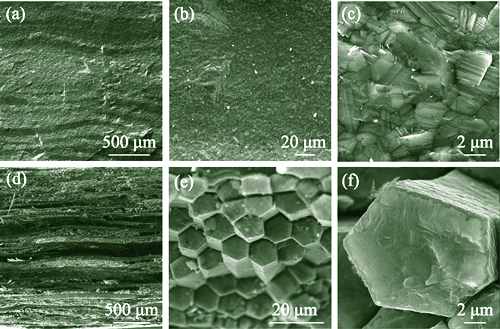

Preparation and Performance of Sintered SiC Fiber-bonded Ceramics

LI Wei, XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song

2025 Vol. 40 (2): 177–183

Abstract

Abstract(

669 )

HTML

HTML(

25)

PDF

PDF(3909KB)(

559

)

SiC fiber-bonded ceramics (FBCs), representing a novel class of SiC materials, synthesized via direct sintering of SiC fibers and characterized by lack of a matrix phase, porosity below 3% and fiber volume fraction exceeding 90%, exhibit remarkable properties, including high-temperature resistance, high strength, and robust resistance to oxidation and irradiation. Consequently, they are a promising contender for future aero-engine and advanced nuclear energy applications. Herein, SiC(Al) FBCs were prepared by pre-treating the fibers to form in-situ graphite (iG) layers on their surface, followed by direct sintering the fibers using a hot-press sintering process. Then, macroscopic/microscopic structures, mechanical properties and oxidative properties of the fibers and bulk ceramics were characterized. The results show that pre-treatment of SiC(Al) fibers leads to forming a 300-400 nm thick carbon layer, adhering well to the fibers. Density of the hot-press sintered iG/SiC(Al) FBCs is 3.15 g/cm3, with a porosity of only 0.52%. Meanwhile, the matrix is completely dense, the fibers are deformed in a new form of hexagonal prisms, and the well-defined interfaces are present between the fibers. Furthermore, bending strength, fracture toughness, and work of fracture of the bulk ceramics are 320 MPa, 9.5 MPa·m1/2 and 1169 J·m-2, respectively. After oxidation at 1500 and 1600 ℃ for 100 h in air, the retention rates of the flexural strength remain as high as 86% and 72%, respectively, while maintaining a quasi-plastic fracture mode.

|

|

|

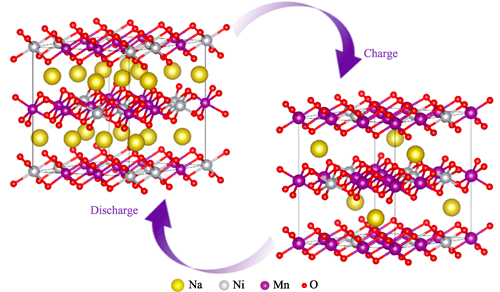

Inhibition of P2-O2 Phase Transition for P2-Na2/3Ni1/3Mn2/3O2 as Cathode of Sodium-ion Battery via Synergetic Substitution of Cu and Mg

ZHU Zhijie, SHEN Mingyuan, WU Tao, LI Wencui

2025 Vol. 40 (2): 184–195

Abstract

Abstract(

742 )

HTML

HTML(

43)

PDF

PDF(8401KB)(

3818

)

The research of sodium-ion batteries (SIBs) is of great significance for development of new energy and energy storage methods. As cathode material, P2-type layered oxide material Na2/3Ni1/3Mn2/3O2 has attracted wide attention due to its excellent capacity and high working voltage. However, it suffers from undesired P2-O2 phase transition, which leads to a drastic change in volume and rapid capacity decay. Here, a P2-Na0.67Ni0.18Cu0.10Mg0.05Mn0.67O2 (NCMM-10-05) cathode was synthesized through solid-state method with synergetic substitution of Cu and Mg. The results indicated that the incorporation of Cu and Mg suppressed irreversible P2-O2 phase transition when charging to high voltage and initialized OP4 phase formation, which improved reversible stability of structure. Thus the as-obtained material exhibited excellent electrochemical performance, which delivered an initial discharge capacity of 113 mAh·g-1 in the voltage range of 2.00-4.35 V (vs. Na+/Na), a reversible capacity of 64.1 mAh·g-1 at 8C (1C=100 mA·g-1), and a capacity retention of 88.9% after 200 cycles at 1C. The effect of Cu and Mg synergetic substitution on the structure and electrochemical properties of P2-type layered oxides was explored, and the specific roles played by Cu and Mg in the structural evolution were further investigated by in situ X-ray diffraction (XRD) analysis and density functional theory (DFT) calculations. This work provides a new insight into the rational design of highly stable cathode materials with rapid Na+ transport capability for SIBs.

|

|

|

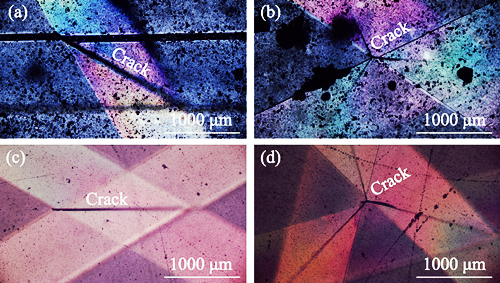

Twinning Defects in Near-stoichiometric Lithium Niobate Single Crystals

HAO Yongxin, SUN Jun, YANG Jinfeng, ZHAO Chencheng, LIU Ziqi, LI Qinglian, XU Jingjun

2025 Vol. 40 (2): 196–204

Abstract

Abstract(

469 )

HTML

HTML(

21)

PDF

PDF(12074KB)(

335

)

Lithium niobate (LN) single crystals have emerged as one of the most valuable materials for integrated photonics materials due to their exceptional properties, including non-linear and electro-optical effects. Compared to congruent lithium niobate (CLN) crystals, near-stoichiometric lithium niobate (nSLN) crystals exhibit more pronounced non-linear and electro-optical properties, offering higher application value. nSLN crystals with high compositional uniformity can be prepared using a vapor transport equilibration method. However, large-size LN single crystals are highly susceptible to twinning defects and wafer cracks during diffusion processing. Here, large size nSLN single crystals were prepared using the vapor transport equilibration method to address the aforementioned defects and cracking. The twinning defects within wafers after diffusion processing were characterized, the mechanisms of twinning formation were analyzed, the wafer placement method to produce complete 4-inch (100 nm) and 6-inch (153 nm) wafers was modified, and the composition and transmittance of wafers were tested. Results indicate that composition of the wafers is at least 49.94% (in mole), approaching stoichiometric ratio, and their transmittance is greater than 71% across the 600-3300 nm range. Both Z-cut and X-cut wafers prepared by vapor transport equilibration method exhibited twinning defects. However, cracks were observed when twinning defects intersected on Z-cut wafers, whereas no cracks were present on X-cut wafers. The twinning planes on both Z-cut and X-cut wafers were depending on , which they were identified as deformation twins. According to the mechanism of deformation twin formation, the non-uniform deformation of lithium-rich materials is identified as the primary driving force beneath the twin formation. Ultimately, it was proposed to mitigate twin activation by modifying the diffusion treatment process, thereby increasing the yields of 4-inch (100 nm) and 6-inch (153 nm) nSLN wafers.

|

|

|

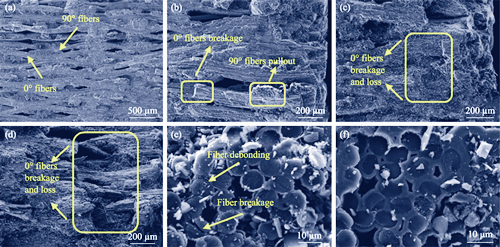

2D Plain and 3D Needle-punched C/SiC Composites: Low-velocity Impact Damage Behavior and Failure Mechanism

LUAN Xingang, HE Dianwei, TU Jianyong, CHENG Laifei

2025 Vol. 40 (2): 205–214

Abstract

Abstract(

465 )

HTML

HTML(

47)

PDF

PDF(9735KB)(

560

)

Continuous carbon fiber reinforced silicon carbide (C/SiC) composites are often subjected to low-velocity impacts when utilized as structural materials for thermal protection. However, research on in-plane impact damage and multiple impact damage of C/SiC composites is limited. To investigate the in-plane impact damage behavior of C/SiC composites, a drop-weight impact test method was developed for strip samples, and these results were subsequently compared with those of C/SiC composite plates. Results show that the in-plane impact behavior of C/SiC strip samples is similar to that of C/SiC composite plates. Variation of the impact load with displacement is characterized by three stages: a nearly linear stage, a severe load drop stage, and a rebound stage where displacement occurs after the impact energy exceeds its peak value. Impact damage behavior under single and multiple impacts on 2D plain and 3D needled C/SiC composites was investigated at different impact energies and durations. Crack propagation in C/SiC composites was studied by computerized tomography (CT) technique. In the 2D plain C/SiC composite, load propagation between layers is hindered during impact, leading to delamination and 90° fiber brittle fracture. The crack length perpendicular to the impact direction increases with impact energy increases, resulting in more serious 0° fiber fracture and a larger area of fiber loss. In the 3D needled C/SiC composite, load propagates between the layers during impact through the connection of needled fibers. The fibers continue to provide substantial structural support, with notable instances of fiber pull-off and debonding. Consequently, the impact resistance is superior to that of 2D plain C/SiC composite. When the 3D needled C/SiC composite undergoes two successive impacts of 1.5 J, the energy absorption efficiency of the second impact is significantly lower, accompanied by a smaller impact displacement. Moreover, the total energy absorption efficiency of these two impacts of 1.5 J is lower than that of a single 3.0 J impact.

|

|

|

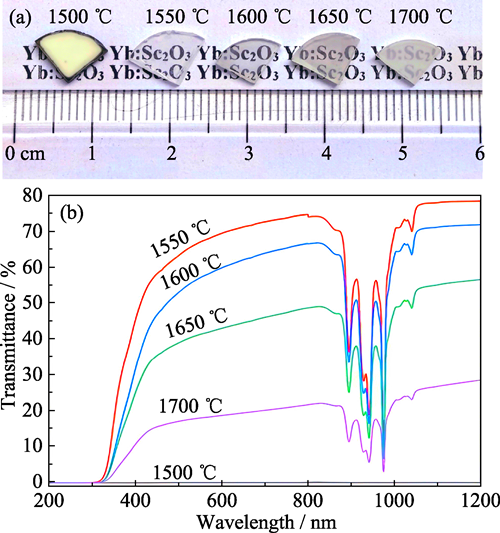

Yb:Sc2O3 Transparent Ceramics Fabricated from Co-precipitated Nano-powders: Microstructure and Optical Property

YE Junhao, ZHOU Zhenzhen, HU Chen, WANG Yanbin, JING Yanqiu, LI Tingsong, CHENG Ziqiu, WU Junlin, IVANOV Maxim, HRENIAK Dariusz, LI Jiang

2025 Vol. 40 (2): 215–224

Abstract

Abstract(

553 )

HTML

HTML(

27)

PDF

PDF(1582KB)(

824

)

Sc2O3, as a host for solid-state laser gain materials, has advantage of high thermal conductivity and easy matching with activating ions, which is promising in high-power laser applications. Currently, Yb-doped Sc2O3 ceramics have been fabricated at very high sintering temperatures, but their optical quality and sintering process still need further improvement. In this work, 5%Yb:Sc2O3 (in mass) nano-powders were obtained by co-precipitation, and then transparent ceramics were fabricated by vacuum pre-sintering and hot isostatic pressing (HIP) post-treatment. The cubic Yb:Sc2O3 nano-powders with good dispersity and an average crystallite of 29 nm were obtained. Influence of pre-sintering temperatures (1500-1700 ℃) on densification process, microstructure changes, and optical transmittance of Yb:Sc2O3 ceramics was detected. Experimental data revealed that all samples have a uniform microstructure, while the average grain sizes increase with the increase of the sintering temperatures. Impressively, the optimum in-line transmittance of Yb:Sc2O3 ceramics, pre-sintered at 1550 ℃ after HIP post-treatment, reaches 78.1% (theoretical value of 80%) at 1100 nm. Spectroscopic properties of the Yb:Sc2O3 ceramics reveal that the minimum population inversion parameter β2 and the luminescence decay time of 5%Yb:Sc2O3 ceramics are 0.041 and 0.49 ms, respectively, which demonstrate that the optical quality of the Yb:Sc2O3 has been improved. Meanwhile, their best vacuum sintering temperature can be controlled down to a lower temperature (1550 ℃). In conclusion, Yb:Sc2O3 nano-powders are successfully synthesized by co-precipitation method, and good optical quality transparent ceramics are fabricated by vacuum pre-sintering at 1550 ℃and HIP post-treatment.

|

|