Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (3): 306-312.DOI: 10.15541/jim20200364

• RESEARCH PAPER • Previous Articles Next Articles

WU Zhihong1( ), DENG Yue1, MENG Zhenzhen1, ZHANG Guoli1, ZHANG Luping1,2, WANG Yubin3

), DENG Yue1, MENG Zhenzhen1, ZHANG Guoli1, ZHANG Luping1,2, WANG Yubin3

Received:2020-07-01

Revised:2020-08-01

Published:2021-03-20

Online:2020-09-09

About author:WU Zhihong(1974-), male, PhD, associate professor. E-mail: zhihong@xauat.edu.cn

Supported by:CLC Number:

WU Zhihong, DENG Yue, MENG Zhenzhen, ZHANG Guoli, ZHANG Luping, WANG Yubin. Microwave Absorbing Properties of Novel SiC/Cf Composites Containing SiC Array Modified Coating[J]. Journal of Inorganic Materials, 2021, 36(3): 306-312.

| Composition | NaH2PO2/ ( mol·L-1) | C6H5Na3O7·2H2O/ ( mol·L-1) | NiSO4/ ( mol·L-1) | NH4Cl/ ( mol·L-1) | H2O/mL | Temperature/℃ | pH |

|---|---|---|---|---|---|---|---|

| Process conditions | 0.38 | 0.26 | 0.15 | 1.87 | 200 | (90±2) | 8-9 |

Table 1 Basic composition and process conditions of plating solution

| Composition | NaH2PO2/ ( mol·L-1) | C6H5Na3O7·2H2O/ ( mol·L-1) | NiSO4/ ( mol·L-1) | NH4Cl/ ( mol·L-1) | H2O/mL | Temperature/℃ | pH |

|---|---|---|---|---|---|---|---|

| Process conditions | 0.38 | 0.26 | 0.15 | 1.87 | 200 | (90±2) | 8-9 |

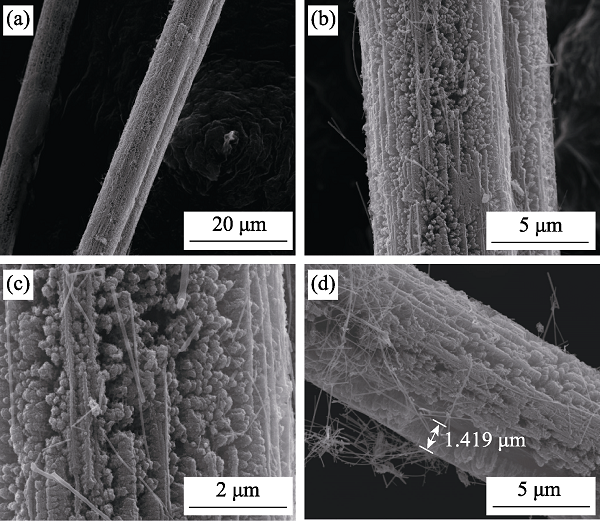

Fig. 2 SEM images of SiC/Cf composite (a) SiC tightly wrapped on the Cf; (b) SiC uniformly distributed; (c) SiC orderly arranged and insulated; (d) A few SiC nanowires distributed

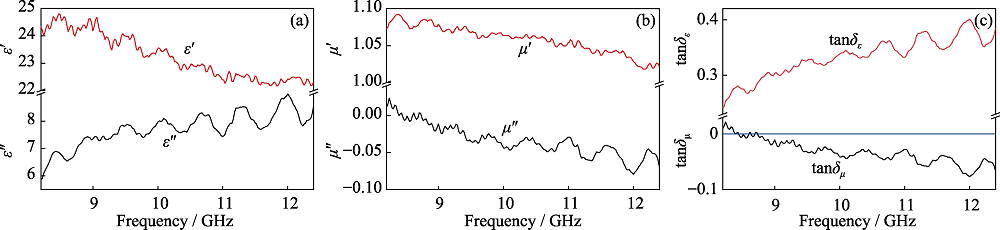

Fig. 3 Electromagnetic parameters of SiC/Cf composite (a) Real part (ε′) and imaginary part (ε″) of relative permittivity; (b) Real part (μ′) and imaginary part (μ″) of relative permeability; (c) Dielectric loss tangent (tanδε) and magnetic loss tangent (tanδμ)

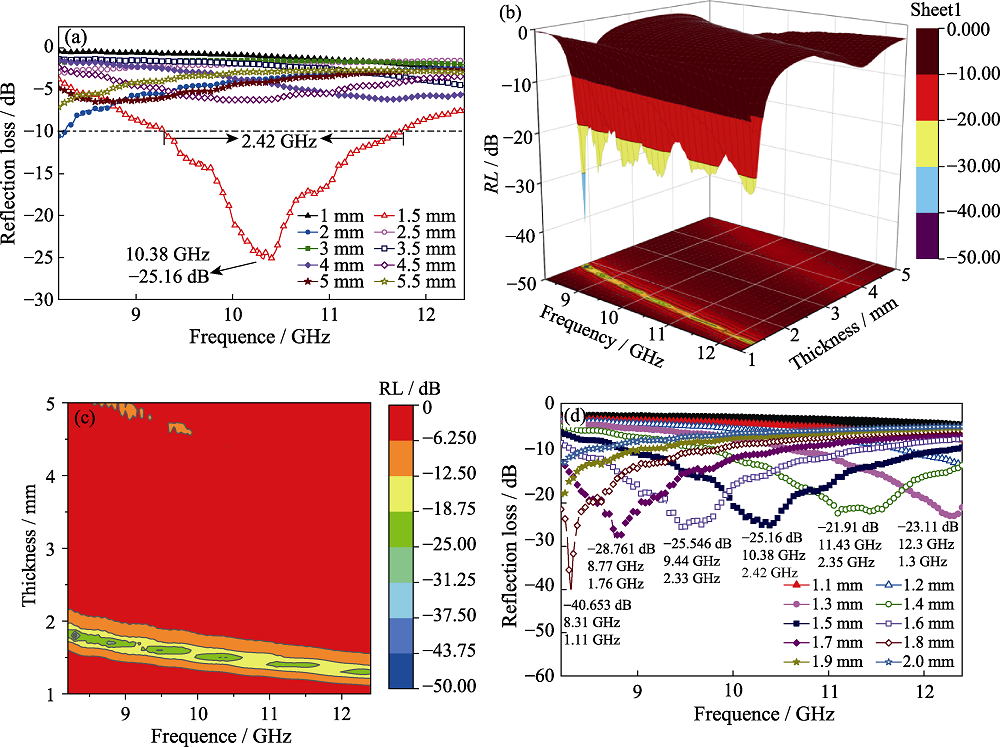

Fig. 5 RL diagrams of SiC/Cf composite material RL value (a), 3D display RL value (b) and 3D RL value projection (c) with a thickness of 1-5.5 mm; RL value with thickness of 1.1-2.0 mm (d)

| Absorbent material | Thickness/mm | RLmin/dB | Frequency/GHz | Effective absorption bandwidth/GHz | Ref. |

|---|---|---|---|---|---|

| SiCNW | 3.00 | -17.40 | 11.20 | 2.50 | [29] |

| SiCNW/Cf | 2.00 | -21.50 | 7.70 | 2.40 | [30] |

| SiCNW-Cf/LAS | 3.00 | -37.80 | 7.20 | <2.00 | [31] |

| ZnO/Cf | 4.35 | -33.00 | - | 5.10 | [32] |

| NiZn ferrite/BC | 2.00 | -11.00 | - | - | [33] |

| HPC/Fe3O4 | 5.50 | -20.10 | 11.76 | ~2.00 | [34] |

| SiC/Cf | 1.50 | -25.16 | 10.38 | 2.42 | This work |

| 1.80 | -40.66 | 8.31 | 1.11 | This work |

Table 2 Comparison between SiC/Cf composite and other similar structural materials

| Absorbent material | Thickness/mm | RLmin/dB | Frequency/GHz | Effective absorption bandwidth/GHz | Ref. |

|---|---|---|---|---|---|

| SiCNW | 3.00 | -17.40 | 11.20 | 2.50 | [29] |

| SiCNW/Cf | 2.00 | -21.50 | 7.70 | 2.40 | [30] |

| SiCNW-Cf/LAS | 3.00 | -37.80 | 7.20 | <2.00 | [31] |

| ZnO/Cf | 4.35 | -33.00 | - | 5.10 | [32] |

| NiZn ferrite/BC | 2.00 | -11.00 | - | - | [33] |

| HPC/Fe3O4 | 5.50 | -20.10 | 11.76 | ~2.00 | [34] |

| SiC/Cf | 1.50 | -25.16 | 10.38 | 2.42 | This work |

| 1.80 | -40.66 | 8.31 | 1.11 | This work |

| [1] | YE X L, CHEN Z F, AI S F, et al. Novel three-dimensional SiC/ melamine-derived carbon foam-reinforced SiO2 aerogel composite with low dielectric loss and high impedance matching ratio. ACS Sustainable Chemistry & Engineering, 2019,7(2):2774-2783. |

| [2] | 赵灵智, 胡社军, 李伟善 , 等. 吸波材料的吸波原理及其研究进展. 现代防御技术, 2007(1):27-31. |

| [3] | LIANG X H, ZHANG X M, LIU W, et al. A simple hydrothermal process to grow MoS2 nanosheets with excellent dielectric loss and microwave absorption performance. Journal of Materials Chemistry C, 2016,4(28):6816-6821. |

| [4] | JIANG Y, CHEN Y, LIU Y J, et al. Lightweight spongy bone-like graphene@SiC aerogel composites for high-performance microwave absorption. Chemical Engineering Journal, 2018,337:522-531. |

| [5] | QIU J, WU X Y, QIU T T. High electromagnetic wave absorbing performance of activated hollow carbon fibers decorated with CNTs and Ni nanoparticles. Ceramics International, 2016,42(4):5278-5285. |

| [6] | 武志红, 李妤婕, 张聪 , 等. 竹炭/SiC复合材料结构及其吸波性能. 硅酸盐学报, 2018,46(1):150-155. |

| [7] | 刘丹莉, 刘平安, 杨青松 , 等. 吸波材料的研究现状及其发展趋势. 材料导报, 2013(17):77-81. |

| [8] | LI W W, CHEN M J, ZENG Z H, et al. Broadband composite radar absorbing structures with resistive frequency selective surface: optimal design, manufacturing and characterization. Composites Science and Technology, 2017,145:10-14. |

| [9] | CHOI W, KIM C. Broadband microwave-absorbing honeycomb structure with novel design concept. Composites Part B-Engineering, 2015,83:14-20. |

| [10] | LI W C, LI C S, LIN L H, et al. All-dielectric radar absorbing array metamaterial based on silicon carbide/carbon foam material. Journal of Alloys and Compounds, 2019 ( 781):883-891. |

| [11] |

YE W, SUN Q L, ZHANG G Y. Effect of heat treatment conditions on properties of carbon-fiber-based electromagnetic-wave-absorbing composites. Ceramics International, 2019,45(4):5093-5099.

DOI URL |

| [12] | ADEBAYO L L, SOLEIMANI H, YAHYA N, et al. Recent advances in the development of Fe3O4-BASED microwave absorbing materials. Ceramics International, 2020,46(2):1249-1268. |

| [13] | LIU Y, ZHANG Z Q, XIAO S T, et al. Preparation and properties of cobalt oxides coated carbon fibers as microwave-absorbing materials. Applied Surface Science, 2011,257(17):7678-7683. |

| [14] | SONG Z M, LIU X F, SUN X, et al. Alginate-templated synthesis of CoFe/carbon fiber composite and the effect of hierarchically porous structure on electromagnetic wave absorption performance. Carbon, 2019,151:36-45. |

| [15] | CHEN X G, YE Y, CHENG J P. Recent progress in electromagnetic wave absorbers, Journal of Inorganic Materials, 2011,26(5):449-457. |

| [16] | 吕晓艳, 田玉平, 魏云 , 等. 镍/碳纳米纤维复合物的制备及其吸波性能. 化学研究, 2016,27(6):756-759. |

| [17] | WU R B, YANG Z H, FU M S, et al. In-situ growth of SiC nanowire arrays on carbon fibers and their microwave absorption properties. Journal of Alloys & Compounds, 2016,687:833-838. |

| [18] | ZHOU W, LONG L, XIAO P, et al. Silicon carbide nano-fibers in-situ grown on carbon fibers for enhanced microwave absorption properties. Ceramics International, 2017,43(7):5628-5634. |

| [19] | WU Z H, ZHENG H K, ZHANG G L, et al. Synthesis of diameter- fluctuating silicon carbide nanowires for excellent microwave absorption. Materials Chemistry and Physics, 2020,244:122648. |

| [20] | FU M, ZHU Z, ZHOU Y, et al. Multifunctional pompon flower- like nickel ferrites as novel pseudocapacitive electrode materials and advanced absorbing materials. Ceramics International, 2020,46(1):850-856. |

| [21] | LIANG C Y, WANG Z J. Eggplant-derived SiC aerogels with high- performance electromagnetic wave absorption and thermal insulation properties. Chemical Engineering Journal, 2019,373:598-605. |

| [22] | DUAN Y, LIU Z, JING H, et al. Novel microwave dielectric response of Ni/Co-doped manganese dioxides and their microwave absorbing properties. Journal of Materials Chemistry, 2012,22(35):18291-18299. |

| [23] | DONG S, ZHANG X H, HU P T, et al. Biomass-derived carbon and polypyrrole addition on SiC whiskers for enhancement of electromagnetic wave absorption. Chemical Engineering Journal, 2019,359:882-893. |

| [24] | HU P, DONG S, LI X, et al. A low-cost strategy to synthesize MnO nanorods anchored on 3D biomass-derived carbon with superior microwave absorption properties. Journal of Materials Chemistry C, 2019,7(30):9219-9228. |

| [25] | ZHANG X J, LI S, WANG S W, et al. Self-supported construction of three-dimensional MoS2 hierarchical nanospheres with tunable high-performance microwave absorption in broadband. Journal of Physical Chemistry C, 2016,120(38):22019-22027. |

| [26] | LIANG H S, LIU J L, ZHANG Y, et al. Ultra-thin broccoli-like SCFs@TiO2 one-dimensional electromagnetic wave absorbing material. Composites Part B Engineering, 2019,178:107507. |

| [27] |

NING M Q, LU M M, LI J B, et al. Two-dimensional nanosheets of MoS2: a promising material with high dielectric properties and microwave absorption performance. Nanoscale, 2015,7(38):15734-15740.

DOI URL PMID |

| [28] | ZHOU X F, JIA Z R, FENG A L, et al. Synthesis of fish skin- derived 3D carbon foams with broadened bandwidth and excellent electromagnetic wave absorption performance. Carbon, 2019,152:827-836. |

| [29] | WU R B, ZHOU K, YANG Z H, et al. Molten-salt-mediated synthesis of SiC nanowires for microwave absorption applications. CrystEngComm, 2013,15(3):570-576. |

| [30] | ZHANG W D, ZHANG X, WU H J, et al. Impact of morphology and dielectric property on the microwave absorbing performance of MoS2-based materials. Journal of Alloys and Compounds, 2018,751:34-42. |

| [31] | XIA L, ZHANG X Y, YANG Y N, et al. Enhanced electromagnetic wave absorption properties of laminated SiCNW-Cf/lithium-aluminum- silicate (LAS) composites. Journal of Alloys and Compounds, 2018,748:154-162. |

| [32] | WANG X X, YU M X, ZHANG W, et al. Synthesis and microwave absorption properties of graphene/nickel composite materials. Applied Physics A, 2015,118(3):1053-1058. |

| [33] | WU K H, TING T H, LIU C I, et al. Electromagnetic and microwave absorbing properties of Ni0.5Zn0.5Fe2O4/bamboo charcoal core-shell nanocomposites. Composites Science and Technology, 2008,68(1):132-139. |

| [34] | LIU Z, LV Y X, FANG J Y, et al. A new method for an efficient porous carbon/Fe3O4 composite based electromagnetic wave absorber derived from a specially designed polyimide. Composites Part B-engineering, 2018,155:148-155. |

| [35] |

LIU L L, ZHANG S, YAN F, et al. Three-dimensional hierarchical MoS2 nanosheets/ultralong N-doped carbon nanotubes as high- performance electromagnetic wave absorbing material. ACS Applied Materials & Interfaces, 2018,10(16):14108-14115.

DOI URL PMID |

| [36] | ZHAO H, CHENG Y, LV H, et al. Achieving sustainable ultralight electromagnetic absorber from flour by turning surface morphology of nanoporous carbon. ACS Sustainable Chemistry & Engineering, 2018,6(11):15850-15857. |

| [37] |

QIU X, WANG L X, ZHU H L, et al. Lightweight and efficient microwave absorbing materials based on walnut shell-derived nano-porous carbon. Nanoscale, 2017,9(22):7408-7418.

DOI URL PMID |

| [1] | TAN Bowen, GENG Shuanglong, ZHANG Kai, ZHENG Bailin. Composition-gradient Design of Silicon Electrodes to Mitigate Mechanochemical Coupling Degradation [J]. Journal of Inorganic Materials, 2025, 40(7): 772-780. |

| [2] | ZHOU Houlin, SONG Zhiqing, TIAN Guo, GAO Xingsen. Effects of Growth Conditions on the Formation of Self-assembly Grown Topological Domain in BiFeO3 Nanoislands [J]. Journal of Inorganic Materials, 2025, 40(6): 667-674. |

| [3] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [4] | GOU Yanzi, KANG Weifeng, WANG Pengren. Influence of Sintering Conditions on Preparation of Nearly Stoichiometric SiC Fibers with Highly Crystalline Microstructure [J]. Journal of Inorganic Materials, 2025, 40(4): 405-414. |

| [5] | MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites [J]. Journal of Inorganic Materials, 2025, 40(3): 323-328. |

| [6] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [7] | HOU Jiaqi, CHEN Ruicong, ZENG Yaoying, ZHOU Lei, ZHANG Jiaping, FU Qiangang. Thermal Shock and Ablation Resistance of SiC Coating Repaired by Gaseous Silicon Infiltration [J]. Journal of Inorganic Materials, 2025, 40(2): 168-176. |

| [8] | LI Wei, XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song. Preparation and Performance of Sintered SiC Fiber-bonded Ceramics [J]. Journal of Inorganic Materials, 2025, 40(2): 177-183. |

| [9] | ZHANG Li, GUAN Haoyang, ZHENG Qining, HONG Zhiliang, WANG Jiaxuan, XING Ning, LI Mei, LIU Yongsheng, ZHANG Chengyu. Creep Properties and Damage Mechanisms of SiCf/SiC-SiYBC Prepared by Melt Infiltration [J]. Journal of Inorganic Materials, 2025, 40(1): 23-30. |

| [10] | QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment [J]. Journal of Inorganic Materials, 2024, 39(8): 920-928. |

| [11] | TAN Min, CHEN Xiaowu, YANG Jinshan, ZHANG Xiangyu, KAN Yanmei, ZHOU Haijun, XUE Yudong, DONG Shaoming. Microstructure and Oxidation Behavior of ZrB2-SiC Ceramics Fabricated by Tape Casting and Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2024, 39(8): 955-964. |

| [12] | WANG Kanglong, YIN Jie, CHEN Xiao, WANG Li, LIU Xuejian, HUANG Zhengren. Effect of Particle Grading on Properties of Silicon Carbide Ceramics Prepared by Selective Laser Sintering Printing Combined with Solid-phase Sintering at Atmospheric Pressure [J]. Journal of Inorganic Materials, 2024, 39(7): 754-760. |

| [13] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [14] | WU Xiaochen, ZHENG Ruixiao, LI Lu, MA Haolin, ZHAO Peihang, MA Chaoli. Research Progress on In-situ Monitoring of Damage Behavior of SiCf/SiC Ceramic Matrix Composites at High Temperature Environments [J]. Journal of Inorganic Materials, 2024, 39(6): 609-622. |

| [15] | SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian. Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis [J]. Journal of Inorganic Materials, 2024, 39(6): 726-732. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||