Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (4): 399-406.DOI: 10.15541/jim20190360

Special Issue: 结构陶瓷论文精选(二)

• REVIEW • Next Articles

BAO Yiwang1,2,SUN Yi2,KUANG Fenghua1,LI Yueming2,WAN Detian1,2

Received:2019-07-17

Revised:2019-08-18

Published:2020-04-20

Online:2019-09-18

Supported by:CLC Number:

BAO Yiwang,SUN Yi,KUANG Fenghua,LI Yueming,WAN Detian. Development and Prospects of High Strength Pre-stressed Ceramics[J]. Journal of Inorganic Materials, 2020, 35(4): 399-406.

| Content of fiber | 28vol% | 32vol% | 43vol% | 55vol% |

|---|---|---|---|---|

| Density /(g·cm-3) | (2.69±0.01) | (2.55±0.02) | (2.44±0.04) | (2.27±0.03) |

| Open porosity/ % | (2.47±0.09) | (2.95±0.01) | (4.31±0.04) | (4.85±0.03) |

| Bending stress/MPa | (198±37) | (259±43) | (325±35) | (500±11) |

Table 1 Mechanical properties of composites with different fiber contents[36]

| Content of fiber | 28vol% | 32vol% | 43vol% | 55vol% |

|---|---|---|---|---|

| Density /(g·cm-3) | (2.69±0.01) | (2.55±0.02) | (2.44±0.04) | (2.27±0.03) |

| Open porosity/ % | (2.47±0.09) | (2.95±0.01) | (4.31±0.04) | (4.85±0.03) |

| Bending stress/MPa | (198±37) | (259±43) | (325±35) | (500±11) |

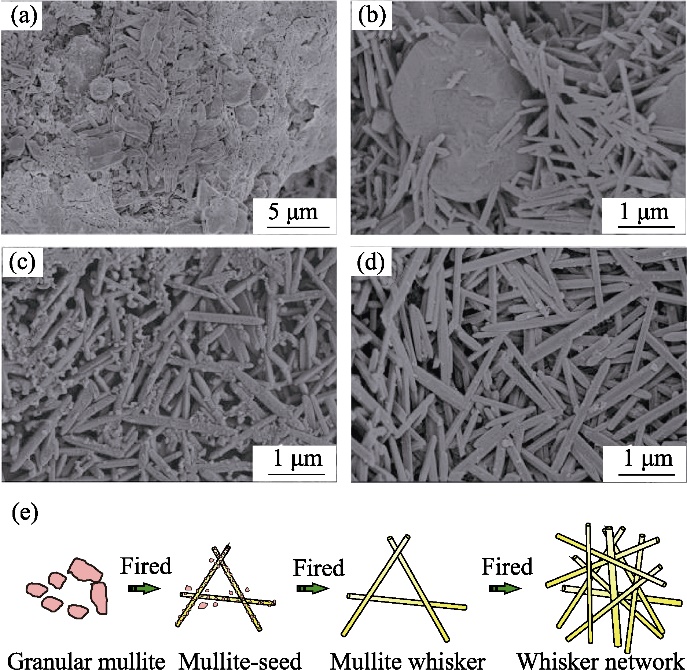

Fig. 2 SEM photomicrographs of different compositions (a-d) and formation process of the mullite whisker network (e)[37] (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4

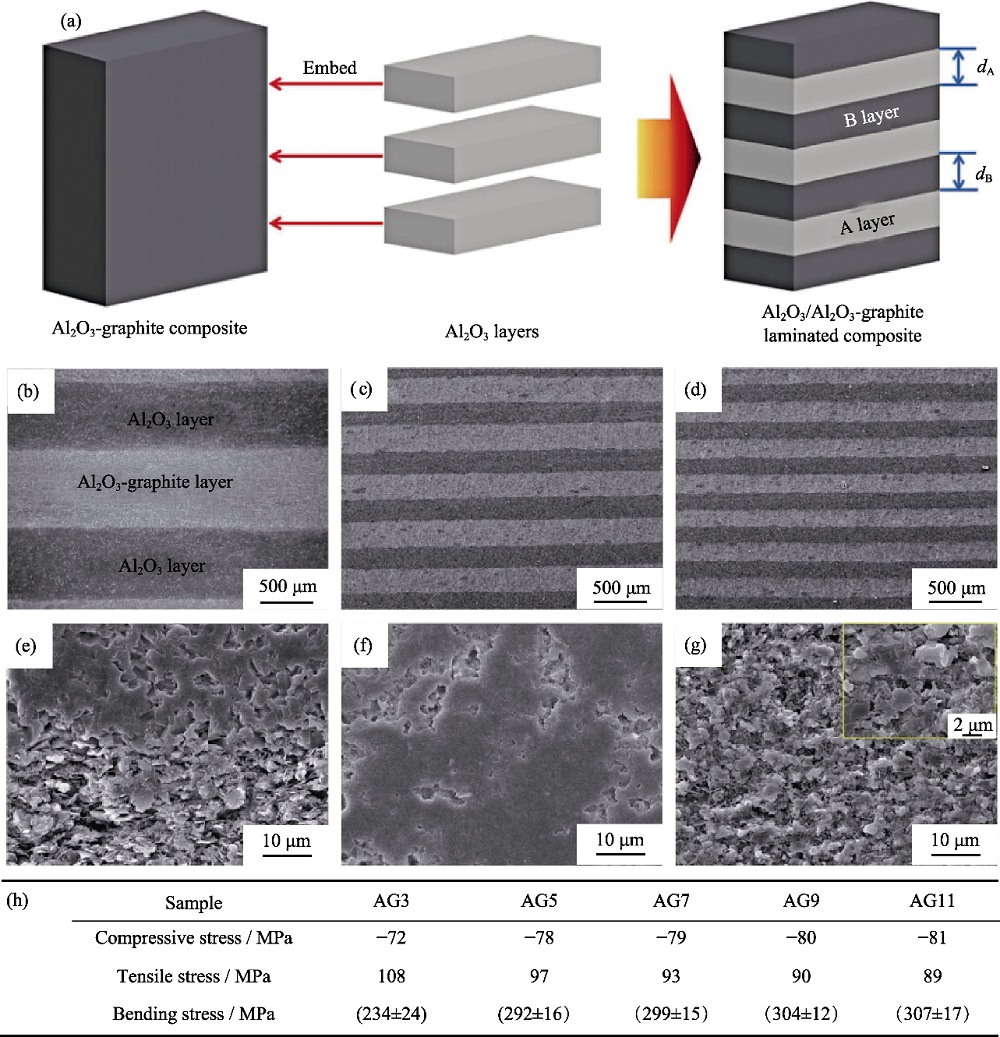

Fig. 4 Schematic diagram of the laminated composites (a), microstructures of different structural composites (b-g) and mechanical properties of different laminate samples (h)[47] (b) AG3; (c)AG7; (d) AG11; (e) Interface of composite; (f) Microscopic structure of Al2O3 layer; (g) Microscopic structure of Al2O3-graphite layer

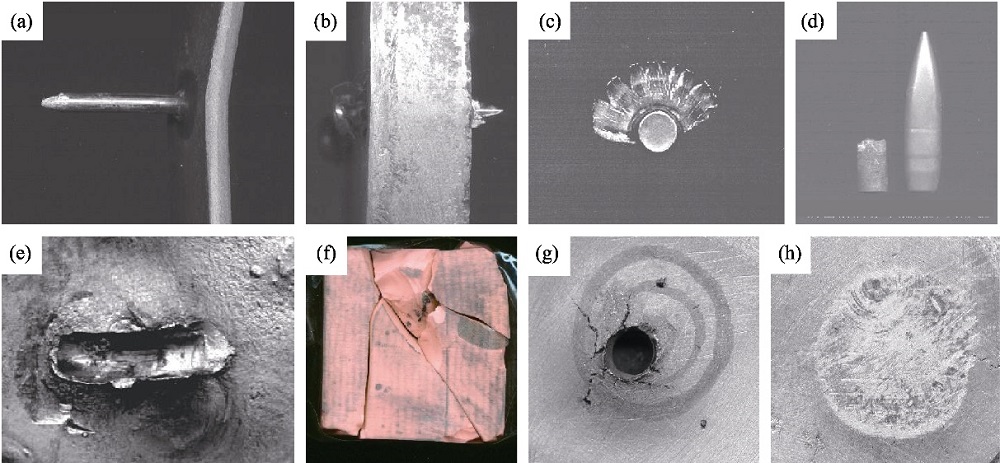

Fig. 5 Comparisons of impact resistance and armor piercing resistance between pre-stressed and unpre-stressed ceramics[50] (a) Test of impact resistance performance with the nail gun, which could penetrate the steel plate with a thickness of 6 mm; (b) 30 mm-thick aluminum alloy plate penetrated by nail gun; (c) Mushroom-shaped fragments of pre-stressed composite materials fired by ordinary rifle bullets; (d) Morphologies of the armor-piercing incendiary bullets before and after firing at pre-stressed composite materials; (e) Morphology of aluminum alloy pre-stressed ceramics after shooting; (f) Unpre-stressed ceramic materials being crushed and penetrated after shooting; (g) Frontal morphology of pre-stressed composite materials fired by armor-piercing incendiary bullets; (h) Reverse morphology of the pr-estressed composite materials fired by armor-piercing incendiary bullets, which could not penetrate the pre-stressed composite ceramics

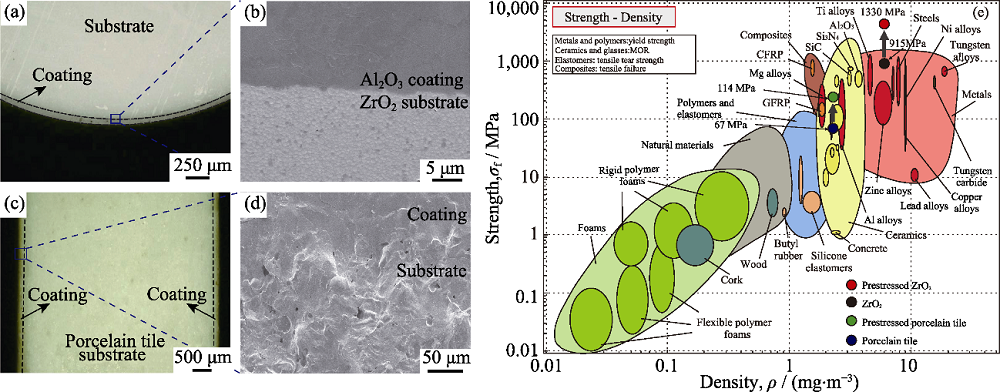

Fig. 7 Pre-stressed ceramics samples(a, c), SEM images(b, d)[51] and Ashby diagram(e)[52] (a, b) Pre-stressed structural ceramics; (c, d) Pre-stressed architectural ceramics

| [1] | KRSTIC Z . Silicon nitride: the engineering material of the future. J. Mater. Sci., 2012,47(2):535-552. |

| [2] | LAUNEY M E, RITCHIE R O . On the fracture toughness of advanced materials. Adv. Mater., 2009,21(21):2103-2110. |

| [3] | GUO J K . Stress design of ceramic grain boundary. J. Inorg. Mater., 1995,1(10):27-31. |

| [4] | GOHARDANI A S, GOHARDANI O . Ceramic engine considerations for future aerospace propulsion. Aircr. Eng. Aerosp. Tec., 2012,84(2):75-86. |

| [5] | GARVIE R C, HANNINK R H, PASCOE R T . Ceramic steel? Nature, 1975,258(5537):703-704. |

| [6] | JOHNSTON R D, CHIPMAN R D, KNAPP W J . Prestressed ceramics as a structural material. J. Am. Ceram. Soc., 1953,36(4):121-126. |

| [7] | GREEN D J . Crack arrest and multiple cracking in glass through the use of designed residual stress profiles. Science, 1999,283(5406):1295-1297. |

| [8] | WONDRACZEK L, MAURO J C, ECKERT J , et al. Towards ultrastrong glasses. Adv. Mater., 2011,23(39):4578-4586. |

| [9] | INSLEY R H, BARCZAK V J . Thermal conditioning of polycrystalline alumina ceramics. J. Am. Ceram. Soc., 2006,47(1):1-4. |

| [10] | CHEN L, WANG A, XIANGBO S , et al. Effect of surface heat transfer coefficient gradient on thermal shock failure of ceramic materials under rapid cooling condition. Ceram. Int., 2018,44:8992-8999. |

| [11] | BARBI S, MUGONI C, MONTORSI M , et al. Chemical hardening of glazed porcelain tiles. J. Am. Ceram. Soc., 2019,102:2853-2862. |

| [12] | SHAN Z, LIU J, SHI F , et al. A new strengthening theory for improving the fracture strength of lithium disilicate glass-ceramics by introducing Rb or Cs ions. J. Non-Cryst. Solids, 2018,481:479-485. |

| [13] | RICHERSON D W, DEKKER M . Modern ceramic engineering, process, processing and use in design. New York, 2nd edition revised , 1992: 21-33. |

| [14] | GRIFFITH A A . The phenomena of rupture and flow in solids. Phil. Trans., 1921,221(2):163-198. |

| [15] | 关振铎, 张中太, 焦金生 . 无机材料物理性能. 北京: 清华大学出版社, 1992: 92-93. |

| [16] | MESSING G L, STEVENSON A J . Toward pore-free ceramics. Science, 2008,322(5900):383-384. |

| [17] | ALFORD N M, BIRCHALL J D, KENDALL K . High-strength ceramics through colloidal control to remove defects. Nature, 1987,330(6143):51-53. |

| [18] | WANG W, FU Z, WANG H , et al. Influence of hot pressing sintering temperature and time on microstructure and mechanical properties of TiB2 ceramics. J. Eur. Ceram. Soc., 2002,22(7):1045-1049. |

| [19] | HUANG Y H, JIANG D L, ZHANG X F , et al. Enhancing toughness and strength of SiC ceramics with reduced graphene oxide by HP sintering. J. Eur. Ceram. Soc., 2018,38(13):4329-4337. |

| [20] | HAN Y, LI S, ZHU T , et al. An oscillatory pressure sintering of zirconia powder: densification trajectories and mechanical properties. J. Am. Ceram. Soc., 2018,101(5):1824-1829. |

| [21] | LI S, XIE Z P, XUE W J . Microstructure and mechanical properties of zirconia ceramics consolidated by a novel oscillatory pressure sintering. Ceram. Int., 2015,41(8):10281-10286. |

| [22] | LI S, XIE Z P . Preparation of zirconia ceramics with high density and fine grains by oscillatory pressure sintering. J. Inorg. Mater., 2016,31(2):207-212. |

| [23] | ZHU T, XIE Z, HAN Y , et al. Improved mechanical properties of Al2O3-25vol% SiCw composites prepared by oscillatory pressure sintering. Ceram. Int., 2017,43:15437-15441. |

| [24] | FURUKAWA, IWAHASHI, HORITA,et al. Structural evolution and the Hall-Petch relationship in an Al-Mg-Li-Zr alloy with ultra-fine grain size. Acta Mater., 1997,45(11):4751-4757. |

| [25] | HIRATA Y, SUZUE N, MATSUNAGA N , et al. Particle size effect of starting SiC on processing, microstructures and mechanical properties of liquid phase-sintered SiC. J. Eur. Ceram. Soc., 2010,30(9):1945-1954. |

| [26] | 刘维良, 喻佑华 . 先进陶瓷工艺学. 武汉: 武汉理工大学出版社, 2004: 636-664. |

| [27] | ZhAN G D, KUNTZ J D, WAN J , et al. Single-wall carbon nanotubes as attractive toughening agents in alumina-based nanocomposites. Nat. Mater., 2003,2(1):38-42. |

| [28] | PADTURE N P . Multifunctional composites of ceramics and single walled carbon nanotubes. Adv. Mater., 2010,21(17):1767-1770. |

| [29] | OSTEEN K G, BRUNER K L, ONG D , et al. Single-crystal SiC nanowires with a thin carbon coating for stronger and tougher ceramic composites. Adv. Mater., 2010,17(12):1519-1523. |

| [30] | ZHANG L, BEN Y, WU J , et al. Alumina assisted grain refinement and physical performance enhancement of yttria transparent ceramics by two-step sintering. Mat. Sci. Eng. A, 2017,684:466-469. |

| [31] | FISHER E S, MANGHNANI M H, WANG J F , et al. Elastic properties of Al2O3 and Si3N4 matrix composites with SiC whisker reinforcement. J. Am. Ceram. Soc., 1992,75(4):908-914. |

| [32] | KHODAEIA M, YAGHOBIZADEHB O, ALHOSSEINI S H N ,et al. The effect of oxide, carbide, nitride and boride additives on properties of pressureless sintered SiC: a review. J. Eur. Ceram. Soc., 2019,39(7):2215-2231. |

| [33] | KUMAR S, SAIRAM K, SONBER J K , et al. Hot-pressing of MoSi2, reinforced B4C composites. Ceram. Int., 2014,40(10):16099-16105. |

| [34] | YU H, CHEN Y, GUO X , et al. Study on mechanical properties of hot pressing sintered mullite-ZrO2 composites with finite element method. Ceram. Int., 2018,44(7):7509-7514. |

| [35] | GUO X, YANG H, ZHANG L , et al. Sintering behavior, microstructure and mechanical properties of silicon carbide ceramics containing different nano-TiN additive. Ceram. Int., 2010,36(1):161-165. |

| [36] | DING Y, DONG S, ZHOU Q , et al. Preparation of C/SiC composites by hot pressing, using different C fiber content as reinforcement. J. Am. Ceram. Soc., 2006,89(4):1447-1449. |

| [37] | CHEN X, LI T, REN Q , et al. Mullite whisker network reinforced ceramic with high strength and lightweight. J. Alloy Compd., 2017,700:37-42. |

| [38] | 李国平 . 预应力混凝土结构设计原理. 北京: 人民交通出版社, 2000: 1-10. |

| [39] | NAWY E . Reinforced concrete: a fundamental approach. Prentice-Hall, 2nd edition revised, 1996: 1-15. |

| [40] | MAURO J C, PHILIP C S, VAUGHN D J , et al. Glass science in the united states: current status and future directions. Int. J. Appl. Glass. Sci., 2014,5(1):2-15. |

| [41] | OLCOTT J S . Chemical strengthening of glass. Science, 1963,140(3572):1189-1193. |

| [42] | CHAUDHRI M M, LIANGYI C . The catastrophic failure of thermally tempered glass caused by small-particle impact. Nature, 1986,320(6057):48-50. |

| [43] | 包亦望, 郑元善, 苏盛彪 , 等. 预应力陶瓷及其抗冲击与穿甲性能. 材料导报, 2000,14:110-112. |

| [44] | AURELIO I L, DORNELES L S, MAY L G . Extended glaze firing on ceramics for hard machining: crack healing, residual stresses, optical and microstructural aspects. Dent Mater., 2017,33(2):226-240. |

| [45] | SHAN Z, LIU J, LIU M , et al. Surface strengthening of lithium disilicate glass-ceramic by ion-exchange using Rb, Cs nitrates. Ceram. Int., 2018,44:12466-12471. |

| [46] | DAL BÓ M, DOMINGUINI L, ZIMMER A , et al. Chemical tempering of porcelain tiles. Ceram. Int., 2016,42:15199-15202. |

| [47] | SONG J, YANG H, BERMEJO R , et al. Enhanced thermal shock response of Al2O3-graphite composites through a layered architectural design. J. Am. Ceram. Soc., 2019,102:3673-3684. |

| [48] | QIAN S, LIU F, MA M , et al. Mechanical strength enhancement of low temperature co-fired multilayer ceramic substrates by introducing residual stress. Ceram. Int., 2019,45(8):10982-10990. |

| [49] | BAO Y, SU S, YANG J , et al. Pre-stressed ceramics and improvement of impact resistance. Mater. Lett., 2002,57(2):518-524. |

| [50] | 包亦望 . 先进陶瓷力学性能评价方法与技术. 北京: 中国建材工业出版社, 2017: 140-187. |

| [51] | BAO Y, KUANG F, SUN Y , et al. A simple way to make pre-stressed ceramics with high strength. J. Materiomics., 2019,5:657-662. |

| [52] | ASHBY, M F . Materials Selection in Mechanical Design. Oxford, 4th edition revised, 2011: 60-68. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | WANG Zhixiang, CHEN Ying, PANG Qingyang, LI Xin, WANG Genshui. Sintering Behaviour and Dielectric Properties of MnCO3-doped MgO-based Ceramics [J]. Journal of Inorganic Materials, 2025, 40(1): 97-103. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||