Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (7): 685-693.DOI: 10.15541/jim20180515

Special Issue: 药物载体与防护材料

• REVIEW • Next Articles

LI Hao-Geng1,2,GU Hong-Yu1,ZHANG Yu-Zhi1,2( ),SONG Li-Xin1,2(

),SONG Li-Xin1,2( ),WU Ling-Nan1,QI Zhen-Yi1,ZHANG Tao1

),WU Ling-Nan1,QI Zhen-Yi1,ZHANG Tao1

Received:2018-10-29

Revised:2018-11-29

Published:2019-07-20

Online:2019-06-26

Supported by:CLC Number:

LI Hao-Geng,GU Hong-Yu,ZHANG Yu-Zhi,SONG Li-Xin,WU Ling-Nan,QI Zhen-Yi,ZHANG Tao. Surface Protection of Polymer Materials from Atomic Oxygen: a Review[J]. Journal of Inorganic Materials, 2019, 34(7): 685-693.

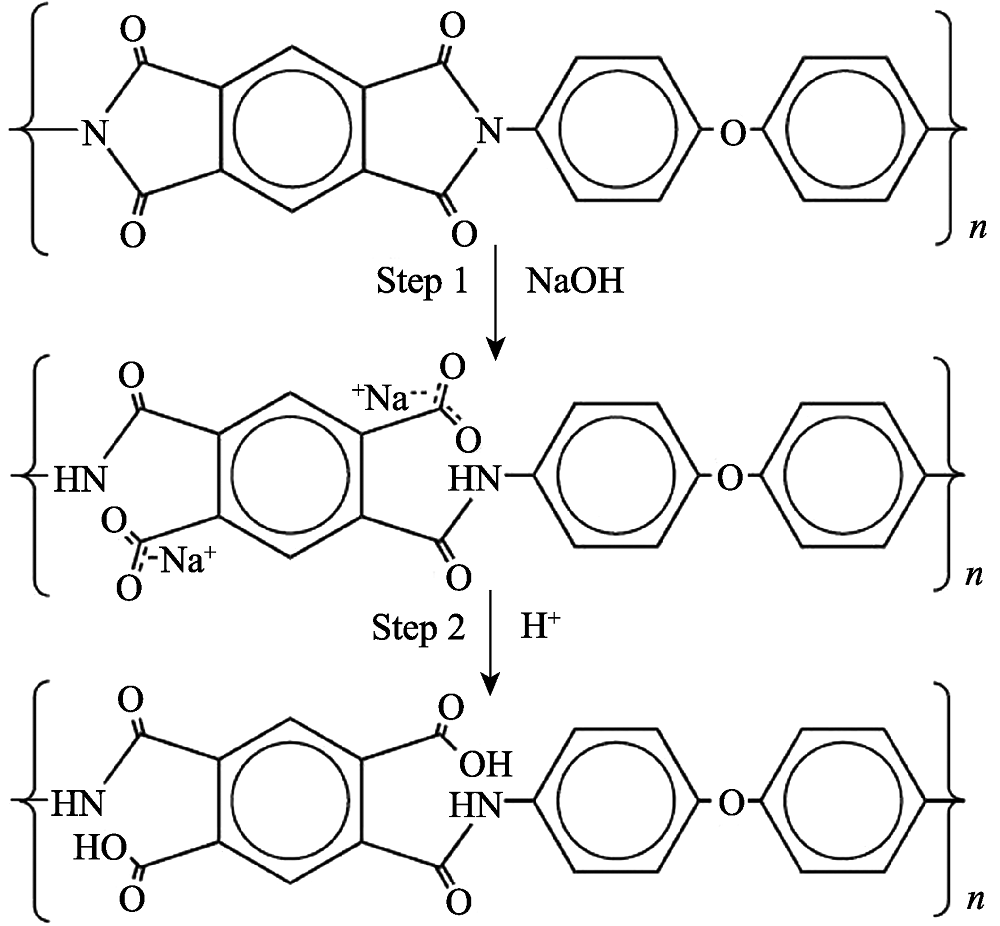

Fig. 2 PI surface modification to form polyamic acid: NaOH hydrolysis of PI (Step 1) to form sodium salt of polyamic acid followed by acidification (Step 2) to form polyamic acid[50]

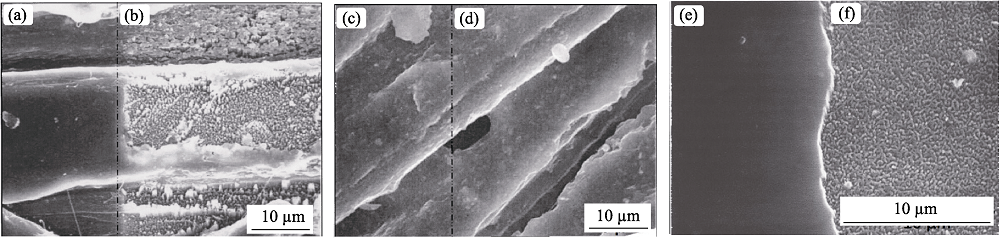

Fig. 3 SEM images of AO exposed (effective fluence ~2.0×1020atoms/cm2) samples: untreated samples[52,53] (a) masked section and (b) exposed section, images of ImplantoxTM treatment being (c) masked and (d) exposed sections, and AO exposed (e) Implantox-treated section and (f) untreated sections

| Sample | F/(×1020 O atom?cm-2) | ΔM/mg | A/cm2 | (ΔM/A)/(mg?cm-2) | E/(×10-24, cm3atom-1) |

|---|---|---|---|---|---|

| Kapton | 3.09 | 5.03 | 3.14 | 1.60 | 3.65 |

| SiOx coated PI | 3.09 | 0.17 | 3.14 | 0.05 | 0.12 |

Table 1 Erosion yield of atomic oxygen on PI samples[56]

| Sample | F/(×1020 O atom?cm-2) | ΔM/mg | A/cm2 | (ΔM/A)/(mg?cm-2) | E/(×10-24, cm3atom-1) |

|---|---|---|---|---|---|

| Kapton | 3.09 | 5.03 | 3.14 | 1.60 | 3.65 |

| SiOx coated PI | 3.09 | 0.17 | 3.14 | 0.05 | 0.12 |

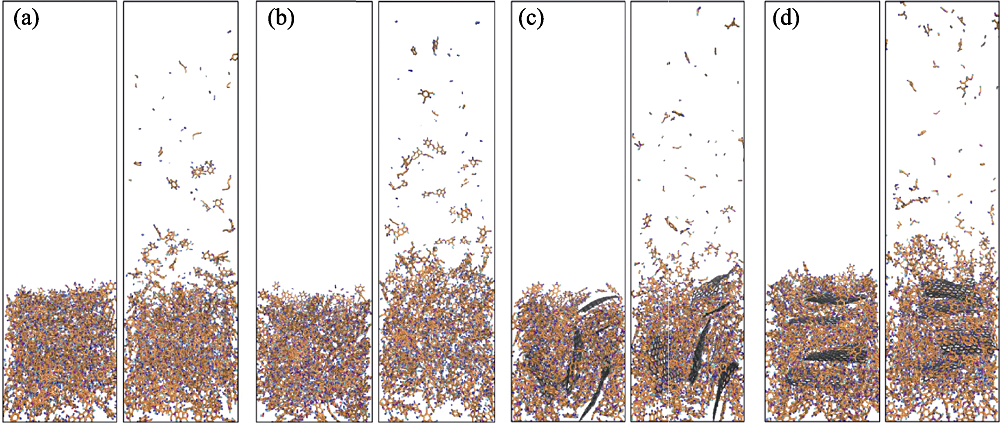

Fig. 5 Initial (left, t=0) and final (right, t=35 ps) simulation snapshots of different PI protection system under AO impact[71]:PI-grafted (a) 15wt% POSS and (b) 30wt% POSS; 15wt% graphene (c) randomly oriented and (d) aligned

| [1] |

DEVER J A, MILLER S K, SECHKAR E A , et al. Space environment exposure of polymer films on the materials international space station experiment: results from MISSE 1 and MISSE 2. High Perform. Polym., 2008,20(4/5):371-387.

DOI URL |

| [2] | ZHANG W, YI M, SHEN Z G , et al. Protection against atomic oxygen erosion of oxide coatings for spacecraft materials. Journal of Beijing University of Aeronautics and Astronautics, 2013,39(8):1074-1078. |

| [3] | LEI X F . Functional Polyimide/silicon Films: Fabrication and Properties. Xi’an: Northwestern Polytechnical University PhD thesis, 2016. |

| [4] |

LIAW D J, WANG K L, HUANG Y C , et al. Advanced polyimide materials: syntheses, physical properties and applications. Prog. Polym. Sci., 2012,37(7):907-974.

DOI URL |

| [5] | XIONG Y Q, XIE S P . Measurement methods of atomic oxygen concentration. Journal of Transducer Technology, 1999,18(3):8-12. |

| [6] |

SEMONIN D M, BRUNSVOLD A L, MINTON T K . Erosion of Kapton H® by hyperthermal atomic oxygen. J. Spacer. Rockets, 2006,43(2):421-425.

DOI URL |

| [7] | SONG M M . Study on Erosion Effect of Atomic Oygen on Polyimide and Its Protective Technology in LEO Environment. Nanchang: Jiangxi Science and Technology Normal University Master Thesis, 2012. |

| [8] | WANG C B . Study on the Degradation Behavior of Organic/Inorganic Protective Materials in Atomic Oxygen Environment. Changchun: Jilin University Master Thesis, 2017. |

| [9] | SILVERMAN E M . NASA Contrator Report 4661, Part 1. Space Environmental Effects on Spacecraft: LEO Materials Selection Guide, part 1, N96-10860, Virginia: NASA, 1995. |

| [10] |

TIAN C, CHENG L F, LUAN X G . Degradation behaviour of C/C composites by atomic oxygen irradiation. Journal of Inorganic Materials, 2013,28(8):853-858.

DOI URL |

| [11] |

HOOSHANGI Z, FEGHHI S A H, SAEEDZADEH R . The effects of low earth orbit atomic oxygen on the properties of polytetraflu- oroethylene. Acta Astronaut., 2016,119:233-240.

DOI URL |

| [12] |

DE GROH K K, BANKS B A . Atomic-oxygen undercutting of long duration exposure facility atomized-Kapton multilayer insulation. J. Spacer. Rockets, 1994,31(4):656-664.

DOI URL |

| [13] |

SHIMAMURA H, NAKAMURA T . Mechanical properties degradation of polyimide films irradiated by atomic oxygen. Polym. Degrad. Stabil., 2009,94(9):1389-1396.

DOI URL |

| [14] | DE GROH K K, BANKS B A, MITCHELL G G , et al. NASA STI Pprogram. MISSE 6 Stressed Polymers Experiment Atomic Oxygen Erosion Data, NASA/TM—2013-217847,Ohio: NASA, 2013. |

| [15] | BANKS B A, DILL G C, LOFTUS R J , et al. NASA STI Program. Comparison of Hyperthermal Ground Laboratory Atomic Oxygen Erosion Yields with Those in Low Earth Orbit, NASA/TM—2013-216613,Ohio: NASA, 2013. |

| [16] | BANKS B A, MILLER S K . NASA STI Program. Effects of Sample Holder Rdge Geometry on Atomic Oxygen Erosion Yield of Pyrolytic Graphite Exposed in Low Earth Orbit, NASA/TM—2018-219910,Ohio: NASA, 2018. |

| [17] | QING F L, CAO W Z . Mechanical Property Improvement of Novel AO Resistance PI Thin Films and the synthesis of Wide Width Films. China Space Science Society Space Materials Specialized Committee 2009 Academic Exchange Proceedings, 2009. |

| [18] | JI H W . Synthesis and Atomic Oxygen Erosion Resistance Property of PPO-containing Polyimide Films. Changchun: Jilin University Master Thesis, 2014. |

| [19] | WEI J H, GANG Z X, MING L Q , et al. Atomic oxygen resistant phosphorus-containing copolyimides derived from bis [4-(3-aminophenoxy) phenyl] phenylphosphine oxide. Sci. SerB., 2014,56(6):788-798. |

| [20] |

XIAO F, WANG K, ZHAN M . Atomic oxygen erosion resistance of polyimide/ZrO2 hybrid films. Appl. Surf. Sci., 2010,256(24):7384-7388.

DOI URL |

| [21] |

LÜ M, WANG Q, WANG T , et al. Effects of atomic oxygen exposure on the tribological performance of ZrO2-reinforced polyimide nanocomposites for low earth orbit space applications. Compos. Pt. B-Eng., 2015,77:215-222.

DOI URL |

| [22] |

LI G, WANG L, NI H , et al. Polyhedral oligomeric silsesquioxane (POSS) polymers and copolymers: a review. J. Inorg. Organomet. Polym., 2001,11(3):123-154.

DOI URL |

| [23] | MINTON T K, WRIGHT M E, TOMCZAK S J , et al. Atomic oxygen effects on POSS polyimides in low earth orbit. ACS Appl. Mater. Interfaces, 2012,4(2):492-502. |

| [24] |

LEI X F, QIAO M T, TIAN L D , et al. Improved space survivability of polyhedral oligomeric silsesquioxane (POSS) polyimides fabricated via novel POSS-diamine. Corros. Sci., 2015,90:223-238.

DOI URL |

| [25] |

LI X, AL-OSTAZ A, JARADAT M , et al. Substantially enhanced durability of polyhedral oligomeric silsequioxane-polyimide nanocomposites against atomic oxygen erosion. Eur. Polym. J., 2017,92:233-249.

DOI URL |

| [26] | TOMCZAK S J, MARCHANT D, SVEIDA S , et al. Properties and improved space survivability of POSS (polyhedral oligomeric silsesquioxane) polyimides. MRS Online Proc. Libr., 2004,851. |

| [27] |

BRUNSVOLD A L, MINTON T K, GOUZMAN I , et al. An investigation of the resistance of polyhedral oligomeric silsesquioxane polyimide to atomic-oxygen attack. High Perform. Polym., 2004,16(2):303-318.

DOI URL |

| [28] |

VERKER R, GROSSMAN E, GOUZMAN I , et al. POSS-polyimide nanocomposite films: simulated hypervelocity space debris and atomic oxygen effects. High Perform. Polym., 2008,20(4/5):475-491.

DOI URL |

| [29] |

VERKER R, GROSSMAN E, ELIAZ N . Erosion of POSS-polyimide films under hypervelocity impact and atomic oxygen: the role of mechanical properties at elevated temperatures. Acta Mater., 2009,57(4):1112-1119.

DOI URL |

| [30] |

FANG G, LI H, LIU J , et al. Intrinsically atomic-oxygen-resistant POSS-containing polyimide aerogels: synthesis and characterization. Chem. Lett., 2015,44(8):1083-1085.

DOI URL |

| [31] |

LEI X, QIAO M, TIAN L , et al. Evolution of surface chemistry and morphology of hyperbranched polysiloxane polyimides in simulated atomic oxygen environment. Corros. Sci., 2015,98:560-572.

DOI URL |

| [32] |

LIU Y Z, SUN Y, ZENG F L , et al. Characterization and analysis on atomic oxygen resistance of POSS/PVDF composites. Appl. Surf. Sci., 2014,320:908-913.

DOI URL |

| [33] |

LEI X F, CHEN Y, ZHANG H P , et al. Space survivable polyimides with excellent optical transparency and self-healing properties derived from hyperbranched polysiloxane. ACS Appl. Mater.Interfaces, 2013,5(20):10207-10220.

DOI URL |

| [34] | DUO S W, SONG M M, LIU T Z , et al. SiO2 Coatings Prepared by Sol-Gel Process Protecting Silver from Atomic Oxygen Erosion. Applied Mechanics and Materials. Switzerland: Trans Tech Publications, 2012: 3044-3047. |

| [35] |

HEIMANN R B, KLEIMAN J I, LITOCSKY E , et al. High-pressure cold gas dynamic (CGD)-sprayed alumina-reinforced aluminum coatings for potential application as space construction material. Surf. Coat. Technol., 2014,252:113-119.

DOI URL |

| [36] |

GOUZMAN I, GIRSHEVITZ O, GROSSMAN E , et al. Thin film oxide barrier layers: protection of Kapton from space environment by liquid phase deposition of titanium oxide. ACS Appl. Mater.Interfaces, 2010,2(7):1835-1843.

DOI URL |

| [37] |

QI H, QIAN Y, XU J , et al. Studies on atomic oxygen erosion resistance of deposited Mg-alloy coating on Kapton. Corros. Sci., 2017,124:56-62.

DOI URL |

| [38] |

QI H, QIAN Y, XU J , et al. An AZ31 magnesium alloy coating for protecting polyimide from erosion-corrosion by atomic oxygen. Corros. Sci., 2018,138:170-177.

DOI URL |

| [39] |

ERDOĞAN S, KÖYTEPE S, SECKIN T , et al. V2O5-polyimide hybrid material: synthesis, characterization, and sulfur removal properties in fuels. Clean Technol. Environ.Policy, 2014,16(3):619-628.

DOI URL |

| [40] |

CHEN L, LIU L, DU Y , et al. Processing and characterization of ZnO nanowire-grown PBO fibers with simultaneously enhanced interfacial and atomic oxygen resistance properties. RSC Adv., 2014,4(104):59869-59876.

DOI URL |

| [41] |

GOTLIB-VAINSTEIN K, GOUZMAN I, GIRSHEVITZ O , et al. Liquid phase deposition of a space-durable, antistatic SnO2 coating on Kapton. ACS Appl. Mater.Interfaces, 2015,7(6):3539-3546.

DOI URL |

| [42] |

OUYANG Q, WANG W, FU Q , et al. Atomic oxygen irradiation resistance of transparent conductive oxide thin films. Thin Solid Films, 2017,623:31-39.

DOI URL |

| [43] |

HUANG Y, LÜ S, TIAN X , et al. Interface analysis of inorganic films on polyimide with atomic oxygen exposure. Surf. Coat. Technol., 2013,216:121-126.

DOI URL |

| [44] |

WANG W, LI C, ZHANG J , et al. Effects of atomic oxygen treatment on structures, morphologies and electrical properties of ZnO: Al films. Appl. Surf. Sci., 2010,256(14):4527-4532.

DOI URL |

| [45] |

CHAVERZ R, IONESCU E, BALAN C , et al. Effect of ambient atmosphere on crosslinking of polysilazanes.[J]. Appl. Polym. Sci., 2011,119(2):794-802.

DOI URL |

| [46] | LI S, ZHANG Y . Effect of synthesis temperature on structure and ceramization process of polyaluminasilazanes. Chinese Journal of Inorganic Chemistry, 2011,27(5):943-950. |

| [47] | CHANG Y C, LIU T Z, ZHANG H , et al. Protection of Kapton from Atomic-oxygen Erosion Using a Polysilazane Coating. LIU H W, WANG G, ZHANG G W. Material Science, Civil Engineering and Architecture Science, Mechanical Engineering and Manufacturing Technology II. Switzerland: Trans. Tech. Publications, 2014,651:65-68. |

| [48] |

DUO S, CHANG Y C, LIU T , et al. Atomic oxygen erosion resistance of polysiloxane/POSS hybrid coatings on Kapton. Phys.Procedia, 2013,50:337-342.

DOI URL |

| [49] |

KLEIMAN J I . Surface modification technologies for durable space polymers. MRS Bull., 2010,35(1):55-65.

DOI URL |

| [50] | ISKANDEROVA Z A, KLEIMAN J I, GUDIMENKO Y , et al. Surface Modification of Polymers and Carbon-based Materials by ion Implantation and Oxidative Conversion:U.S., 5,683,757.1997 -11-4. |

| [51] | GUDIMENKO Y, KLEIMAN J I, COOL G R , et al. Modification of Subsurface Region of Polymers and Carbon-based Materials:U.S., 5,948,484. 1999 -9-7. |

| [52] | GUDIMENKO Y, NG R, KLEIMAN J , et al. Photosil™ Surface Modification Treatment of Polymer-based Space Materials and External Space Components. KLEIMAN J, ISKANDEROVA Z A. Protection of Materials and Structures from Space Environment. U.S.: Kluwer Academic Publishers, 2004: 419-434. |

| [53] | ISKANDEROVA Z A, KLEIMAN J I, GUDIMENKO Y , et al. Research Aspects of Scaling-up Implantox Technology for Protection of Polymers in Space by Ion Implantation. Protection of Space Materials from the Space Environment. Dordrecht: Springer, 2001: 145-163. |

| [54] | GU H Y . Surface Activation and Silanization of Polyimide. Shanghai: Shanghai Institute of Ceramics PhD Thesis, 2015. |

| [55] |

SHU M, LI Z, MAN Y , et al. Surface modification of poly (4, 4°-oxydiphenylene pyromellitimide)(Kapton) by alkali solution and its applications to atomic oxygen protective coating. Corros. Sci., 2016,112:418-425.

DOI URL |

| [56] |

LIU K, MU H, SHU M , et al. Improved adhesion between SnO2/SiO2 coating and polyimide film and its applications to atomic oxygen protection. Colloids Surf.A, 2017,529:356-362.

DOI URL |

| [57] | WANG D, GAO Z M, LI Z H , et al. Analysis of erosion effect of environmental factors on polyimide films and coatings. Surface Technology, 2018,47(1):123-128. |

| [58] |

ISKANDEROVA Z A, KLEIMAN J I, GUDIMENKO Y , et al. Influence of content and structure of hydrocarbon polymers on erosion by atomic oxygen. J. Spacer.Rockets, 1995,32(5):878-884.

DOI URL |

| [59] |

XIE Y, GAO Y, QIN X , et al. Preparation and properties of atomic oxygen protective films deposited on Kapton by solvothermal and Sol-Gel methods. Surf. Coat. Technol., 2012,206(21):4384-4388.

DOI URL |

| [60] | BANKS B A, DE GROH K K, AUER B M , et al. LDEF. Monte Carlo Modeling of Atomic Oxygen Attack of Polymers with Protective Coatings on LDEF. N93-28282,Ohio: NASA , 1993: 1137-1150. |

| [61] | WEAVER A B, KULAKHMETOY M, ALEXEENKO A A . Consistent atomic oxygen model for firect dimulation monte carlo below 1000 kelvin. J. Thermophys.Heat Transfer, 2016: 689-694. |

| [62] |

LIU Y, LI G . Numerical simulation on atomic oxygen undercutting of Kapton film in low earth orbit. Acta Astronaut., 2010,67(3/4):388-395.

DOI URL |

| [63] |

HUANG Y, TIAN X, LÜ S , et al. An undercutting model of atomic oxygen for multilayer silica/alumina films fabricated by plasma immersion implantation and deposition on polyimide. Appl. Surf. Sci., 2011,257(21):9158-9163.

DOI URL |

| [64] | BANKS B A, DE GROH K K, KNEUBEL C A . NASA STI Program. Comparison of the Results of MISSE 6 Atomic Oxygen Erosion Yields of Layered Kapton H Films with Monte Carlo Computational Predictions, NASA/TM—2014-218411,Ohio: NASA, 2014. |

| [65] | DUO S W, LI M S, ZHANG Y M . Erosion theoretical and predictive models of atomic oxygen for space materials in low earth orbit. |

| Chinese Journal of Materials Reaserch, 2003,17(2):113-121. | |

| [66] |

LEE C H, CHEN L W . Reactive probability of atomic oxygen with material surfaces in low earth orbit. J. Spacecr.Rockets, 2000,37(2):252-256.

DOI URL |

| [67] |

LIU T, SUN Q, MENG J , et al. Degradation modeling of satellite thermal control coatings in a low earth orbit environment. Sol.Energy, 2016,139:467-474.

DOI URL |

| [68] |

CHEN L, LI Z, LEE C H , et al. Unified model for low-earth- orbital atomic-oxygen and atomic-oxygen/ultraviolet induced erosion of polymeric materials. Aerosp. Sci. Technol., 2016,53:194-206.

DOI URL |

| [69] |

VAN DUIN A C T, DASGUPTA S, LORANT F , et al. ReaxFF: a reactive force field for hydrocarbons. J. Phys. Chem. A, 2001,105(41):9396-9409.

DOI URL |

| [70] |

RAHNAMOUN A, VAN DUIN A C T . Reactive molecular dynamics simulation on the disintegration of Kapton, POSS polyimide, amorphous silica, and teflon during atomic oxygen impact using the reaxff reactive force-field method. J. Phys. Chem. A, 2014,118(15):2780-2787.

DOI URL |

| [71] |

RAHMANI F, NOURANIAN S, LI X , et al. Reactive molecular simulation of the damage mitigation efficacy of POSS-, graphene-, and carbon nanotube-loaded polyimide coatings exposed to atomic oxygen bombardment. ACS Appl. Mater. Interfaces, 2017,9(14):12802-12811.

DOI URL |

| [72] |

ZENG F, PENG C, LIU Y , et al. Reactive molecular dynamics simulations on the disintegration of PVDF, FP-POSS, and their composite during atomic oxygen impact. J. Phys. Chem. A, 2015,119(30):8359-8368.

DOI URL |

| [73] | GINDULYTE A, MASSA L, BANKS B A , et al. Degradation of Polymers by O (3 P) in Low Earth Orbit. Protection of Materials and Structures from Space Environment. Dordrecht: Springer, 2004: 299-306. |

| [74] |

ZHANG H, REN S, PU J , et al. Barrier mechanism of multilayers graphene coated copper against atomic oxygen irradiation. Appl. Surf. Sci., 2018,444:28-35.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | SUN Jing, LI Xiang, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Effect of Lauric Acid Modifier on the Hydrolysis Resistance of Aluminum Nitride Powders [J]. Journal of Inorganic Materials, 2025, 40(7): 826-832. |

| [3] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [4] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [5] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [6] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [7] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [8] | GUO Ziyu, ZHU Yunzhou, WANG Li, CHEN Jian, LI Hong, HUANG Zhengren. Effect of Zn2+ Catalyst on Microporous Structure of Porous Carbon Prepared from Phenolic Resin/Ethylene Glycol [J]. Journal of Inorganic Materials, 2025, 40(5): 466-472. |

| [9] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [10] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [11] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [12] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [13] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [14] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [15] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||