Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (7): 687-693.DOI: 10.15541/jim20150566

• Orginal Article • Previous Articles Next Articles

YU Fang-Li1, BAI Yu2, WU Xiu-Ying3, Wang Hai-Jun4, WU Jiu-Hui1

Received:2015-11-16

Revised:2016-01-03

Published:2016-07-20

Online:2016-06-22

Supported by:CLC Number:

YU Fang-Li, BAI Yu, WU Xiu-Ying, Wang Hai-Jun, WU Jiu-Hui. Corrosion Resistance and Anti-wear Property of Nickel Based Abradable Sealing Coating Deposited by Plasma Spraying[J]. Journal of Inorganic Materials, 2016, 31(7): 687-693.

| Material | Product mark | Composition/wt% | Density/ (g·cm-3) |

|---|---|---|---|

| Ni-C | M 307 | Ni75-C25 | 3.2 |

| NiCrAl-BN | M 301 | Ni60Cr14Al-BN5.5 | 4.4 |

Table 1 Materials for abradable seal coating[12]

| Material | Product mark | Composition/wt% | Density/ (g·cm-3) |

|---|---|---|---|

| Ni-C | M 307 | Ni75-C25 | 3.2 |

| NiCrAl-BN | M 301 | Ni60Cr14Al-BN5.5 | 4.4 |

| Parameters | Ni-C | NiCrAl-BN |

|---|---|---|

| Current /A | 200 | 320 |

| Voltage /V | 90 | 90 |

| Primary gas, Ar /(m3·h-1) | 2.8 | 2.8 |

| Carrier gas flow rate /(L·min-1) | 10 | 10 |

| Carrier gas pressure / MPa | 0.8 | 0.8 |

| Powder feed rate /(g·min-1) | 40 | 48 |

Table 2 Spray parameters

| Parameters | Ni-C | NiCrAl-BN |

|---|---|---|

| Current /A | 200 | 320 |

| Voltage /V | 90 | 90 |

| Primary gas, Ar /(m3·h-1) | 2.8 | 2.8 |

| Carrier gas flow rate /(L·min-1) | 10 | 10 |

| Carrier gas pressure / MPa | 0.8 | 0.8 |

| Powder feed rate /(g·min-1) | 40 | 48 |

| Parameters | Value |

|---|---|

| Distance /mm | 100 |

| Pressure /MPa | 0.3 |

| Compressed air flow rate /(m3·h-1) | 3 |

| Inner diameter of nozzle / mm | 3.6 |

| Length of nozzle /mm | 22 |

| Particle size of abrasive particles-Brown alumina | 100# |

Table 3 Parameters for erosive wear test

| Parameters | Value |

|---|---|

| Distance /mm | 100 |

| Pressure /MPa | 0.3 |

| Compressed air flow rate /(m3·h-1) | 3 |

| Inner diameter of nozzle / mm | 3.6 |

| Length of nozzle /mm | 22 |

| Particle size of abrasive particles-Brown alumina | 100# |

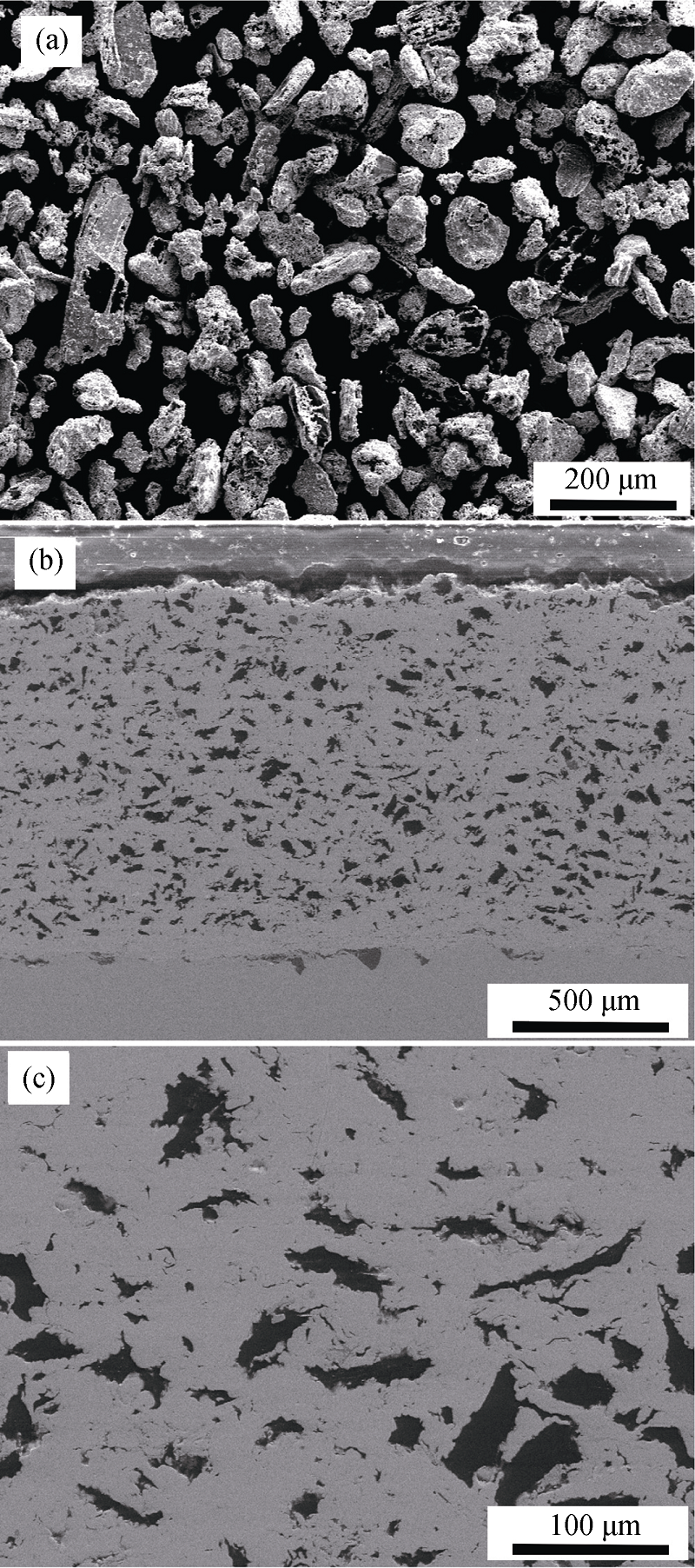

Fig. 3 Ni-C feedstock powder and cross-sectional images of Ni-C as-sprayed coating(a) Feedstock powder; (b) Whole image of coating;; (c) Detailed image of coating

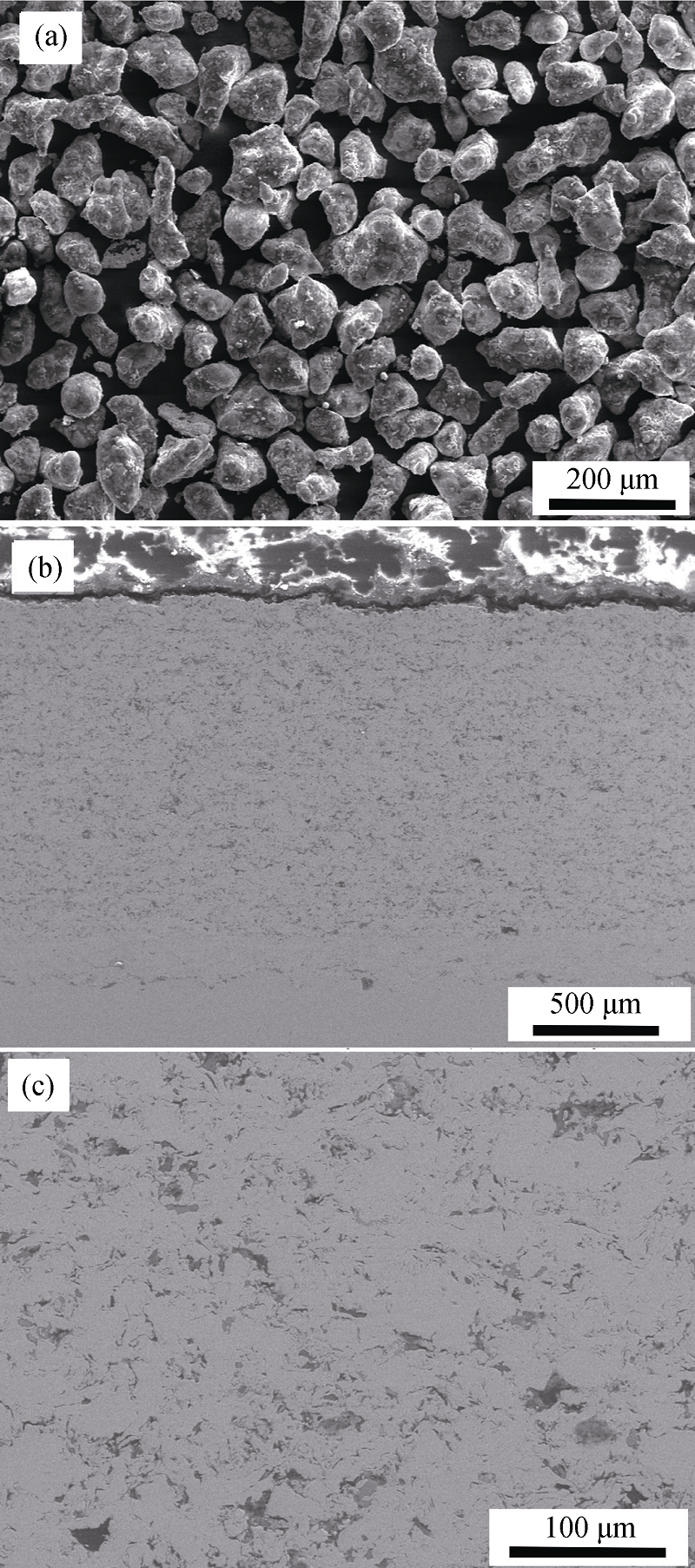

Fig. 4 NiCrAl-BN feedstock powder and cross-sectional images of NiCrAl-BN coating(a) Feedstock powder; (b) Whole image of coating; (c) Detailed image of coating

| [1] | DELEBARRE C, WAGNER V, PARIS J Y, et al.An experimental study of the high speed interaction between a labyrinth seal and an abradable coating in a turbo-engine application.Wear, 2014, 316: 109-118. |

| [2] | MA XIAO, MATTHEWS A.Evaluation of abradable seal coating mechanical properties.Wear, 2009, 267: 1501-1510. |

| [3] | MA XIAO, MATTHEWS A.Investigation of abradable seal coating performance using scratch testing. Surface & Coatings Technology, 2007, 202: 1214-1220. |

| [4] | CAO YU-XIA, LIU WEI, DU LING-ZHONG, et al.Preparation and property of Al/hBN plasma sprayed abradable sealing coating.Rare Metal Materials and Engineering, 2012, 41(S2): 813-816. |

| [5] | XU CUN-GUAN, DU LING-ZHONG, ZHANG WEI-GANG, et al.Salt spray corrosion of Ni/Graphite abradable sealing coatings,Journal of Aeronautical Materials, 2010, 30(4):53-58. |

| [6] | XU CUN-GUAN, DU LING-ZHONG, YANG BIN, et al.Study on salt spray corrosion of Ni-graphite abradable coating with 80Ni20Al and 96NiCr-4Al as bonding layers.Surface & Coatings Technology, 2011, 205: 4154-4161. |

| [7] | LEI BING, LI MAN, ZHAO ZHONG-XING, et al.Corrosion mechanism of an Al-BN abradable seal coating system in chloride solution.Corrosion Science, 2014, 79: 198-205. |

| [8] | XU CUN-GUAN, DU LING-ZHONG, YANG BIN, et al.The effect of Al content on the galvanic corrosion behaviour of coupled Ni/graphite and Ni-Al coatings.Corrosion Science, 2011, 53: 2066-2074. |

| [9] | WANG HAI-JUN, XIE ZHAO-QIAN, GUO YONG-MING, et al.Characteristic of high efficiency supersonic plasma spraying particles and coatings.China Surface Engineering, 2010, 23(3):84-88. |

| [10] | BAI Y, HAN Z H, LI H Q, et al.Structure-property differences between supersonic and conventional atmospheric plasma sprayed zirconia thermal barrier coatings,Surface & Coatings Technology, 2011, 205: 3833-3839. |

| [11] | WANG GANG, TENG BAI-QIU, WANG ZHI-HONG, et al.The development of abradable coatings for aero engine.Thermal Spray Technology, 2012, 4(1): 20-23. |

| [12] | YI MAO-ZHONG, ZHANG XIAN-LONG, ZHENG JI-HONG, et al.Development of abradable seal coatings and their performance evaluation.Aeronautical Manufacturing Technology, 1998, 3: 3-5. |

| [13] | WANG HAI-JUN, CAI JIANG, HAN ZHI-HAI.Study on erosion wear of WC-Co coatings prepared by supersonic plasma spray and HVOF spray.Journal of Materials Engineering, 2005, 4: 50-54. |

| [14] | MATTHEWS S, JAMES B, HYLAND M.The role of microstructure in the mechanism of high velocity erosion of Cr3C2-NiCr thermal spray coatings: Part 1-As-sprayed coatings.Surface and Coatings Technology, 2009, 203: 1086-1093. |

| [15] | MATTHEWS S, JAMES B, HYLAND M.The role of microstructure in the mechanism of high velocity erosion of Cr3C2-NiCr thermal spray coatings: Part 2 - Heat treated coatings.Surface and Coatings Technology, 2009, 203: 1094-1100. |

| [16] | YI MAO-ZHONG, ZHANG XIAN-LONG, HE JIA-WEN.Relationship between erosion wear resistance of abradable seal coating & experimental parameters.Aviation Engineering and Mainienance, 1999, 2: 16-18. |

| [17] | YI MAO-ZHONG, HUANG BAI-YUN, HE JIA-WEN.Erosion wear behaviour and model of abradable seal coating.Wear, 2002, 252: 9-15. |

| [18] | LIU WEI, ZHOU KUI, DU LING-ZHONG, et al.Frictional wear resistance and erosion resistance of abradable seal coating.Thermal Spray. Technology, 2012, 4(4):34-41. |

| [19] | CHEN BAI-MING, BI QIN-LING, YANG JUN, et al.Tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composites.Tribology International, 2008, 41: 1145-1152. |

| [20] | LI JIAN-LIANG, XIONG DANG-SHENG, Tribological behavior of graphite-containing nickel-based composite as function of temperature, load and counterface.Wear, 2009, 266: 360-367. |

| [1] | WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment [J]. Journal of Inorganic Materials, 2025, 40(7): 799-807. |

| [2] | LIANG Ruihui, ZHONG Xin, HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin. High-temperature Water Vapor Corrosion Behaviors of Environmental Barrier Coatings with Yb2O3-modified Silicon Bond Layer [J]. Journal of Inorganic Materials, 2025, 40(4): 425-432. |

| [3] | FAN Wenkai, YANG Xiao, LI Honghua, LI Yong, LI Jiangtao. Pressureless Sintering of (Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7 High-entropy Ceramic and Its High Temperature CMAS Corrosion Resistance [J]. Journal of Inorganic Materials, 2025, 40(2): 159-167. |

| [4] | FAN Wugang, CAO Xiong, ZHOU Xiang, LI Ling, ZHAO Guannan, ZHANG Zhaoquan. Anticorrosion Performance of 8YSZ Ceramics in Simulated Aqueous Environment of Pressurized Water Reactor [J]. Journal of Inorganic Materials, 2024, 39(7): 803-809. |

| [5] | LI Liuyuan, HUANG Kaiming, ZHAO Xiuyi, LIU Huichao, WANG Chao. Influence of RE-Si-Al-O Glass Phase on Microstructure and CMAS Corrosion Resistance of High Entropy Rare Earth Disilicates [J]. Journal of Inorganic Materials, 2024, 39(7): 793-802. |

| [6] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [7] | FAN Dong, ZHONG Xin, WANG Yawen, ZHANG Zhenzhong, NIU Yaran, LI Qilian, ZHANG Le, ZHENG Xuebin. Corrosion Behavior and Mechanism of Aluminum-rich CMAS on Rare-earth Silicate Environmental Barrier Coatings: [J]. Journal of Inorganic Materials, 2023, 38(5): 544-552. |

| [8] | LUO Shuwen, MA Mingsheng, LIU Feng, LIU Zhifu. Corrosion Behavior and Mechanism of LTCC Materials in Ca-B-Si System [J]. Journal of Inorganic Materials, 2023, 38(5): 553-560. |

| [9] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| [10] | WANG Hongda, FENG Qian, YOU Xiao, ZHOU Haijun, HU Jianbao, KAN Yanmei, CHEN Xiaowu, DONG Shaoming. Microstructure and Corrosion Behavior of Brazed Joints of SiC/SiC Composites and Hastelloy N Alloy Using Cu-Ni Alloy [J]. Journal of Inorganic Materials, 2022, 37(4): 452-458. |

| [11] | LIU Pingping, ZHONG Xin, ZHANG Le, LI Hong, NIU Yaran, ZHANG Xiangyu, LI Qilian, ZHENG Xuebin. Molten Salt Corrosion Behaviors and Mechanisms of Ytterbium Silicate Environmental Barrier Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1267-1274. |

| [12] | ZHANG Zhigang,LU Xiaotong,LIU Jinli. NiFe2O4 Ceramic U-shaped Sleeve Prepared by Slip Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2020, 35(6): 661-668. |

| [13] | DING Jianxiang,HUANG Peiyan,ZHA Yuhui,WANG Dandan,ZHANG Peigen,TIAN Wubian,SUN Zhengming. High-purity Ti2AlC Powder: Preparation and Application in Ag-based Electrical Contact Materials [J]. Journal of Inorganic Materials, 2020, 35(6): 729-734. |

| [14] | WANG Zhihu,ZHANG Jumei,BAI Lijing,ZHANG Guojun. Mg(OH)2 Film on Micro-arc Oxidation Ceramic Coating of AZ31 Magnesium Alloy: Preparation and Corrosion Resistance [J]. Journal of Inorganic Materials, 2020, 35(6): 709-716. |

| [15] | TANG Shuai,ZHANG Wentai,QIAN Junyu,XIAN Peng,MO Xiaoshan,HUANG Nan,WAN Guojiang. Long-term in Vitro Corrosion Behavior of Zinc in Ringer’s Solution [J]. Journal of Inorganic Materials, 2020, 35(4): 461-468. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||