无机材料学报 ›› 2021, Vol. 36 ›› Issue (4): 418-424.DOI: 10.15541/jim20200367 CSTR: 32189.14.10.15541/jim20200367

曾建军1( ), 张魁宝1,2(

), 张魁宝1,2( ), 陈代梦1, 郭海燕1, 邓婷1, 刘奎1

), 陈代梦1, 郭海燕1, 邓婷1, 刘奎1

收稿日期:2020-07-02

修回日期:2020-09-18

出版日期:2021-04-20

网络出版日期:2020-10-30

通讯作者:

张魁宝, 研究员. E-mail: xiaobao320@163.com

作者简介:曾建军(1997-), 男, 硕士研究生. E-mail: zeng_jianjun@126.com

基金资助:

ZENG Jianjun1( ), ZHANG Kuibao1,2(

), ZHANG Kuibao1,2( ), CHEN Daimeng1, GUO Haiyan1, DENG Ting1, LIU Kui1

), CHEN Daimeng1, GUO Haiyan1, DENG Ting1, LIU Kui1

Received:2020-07-02

Revised:2020-09-18

Published:2021-04-20

Online:2020-10-30

Contact:

ZHANG Kuibao, professor. E-mail: xiaobao320@163.com

About author:ZENG Jianjun(1997-), male, Master candidate. E-mail: zeng_jianjun@126.com

Supported by:摘要:

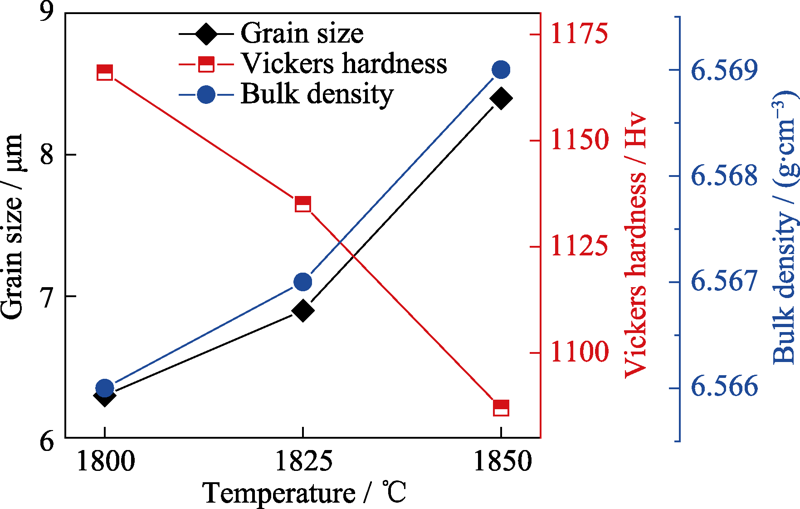

高熵陶瓷是近年来陶瓷材料研究的热点, 制备性能优异的高熵陶瓷是陶瓷材料的发展趋势。本研究采用燃烧法结合真空烧结制备出高熵透明陶瓷。测试结果显示燃烧法制备高熵(La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7粉体的平均晶粒尺寸为8 nm, 高熵粉体为无序的缺陷萤石结构。在真空炉中不同温度烧结的高熵陶瓷具有有序的烧绿石结构。烧结温度对高熵透明陶瓷的在线透过率影响不大, 最大透过率为74%(@1730 nm), 其透过率光谱中出现大量吸收峰。随着烧结温度的升高, 陶瓷的体积密度有所上升, 晶粒尺寸增大, 而维氏硬度逐渐降低。

中图分类号:

曾建军, 张魁宝, 陈代梦, 郭海燕, 邓婷, 刘奎. 真空烧结制备(La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7高熵透明陶瓷[J]. 无机材料学报, 2021, 36(4): 418-424.

ZENG Jianjun, ZHANG Kuibao, CHEN Daimeng, GUO Haiyan, DENG Ting, LIU Kui. Preparation of (La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7 High-entropy Transparent Ceramics by Vacuum Sintering[J]. Journal of Inorganic Materials, 2021, 36(4): 418-424.

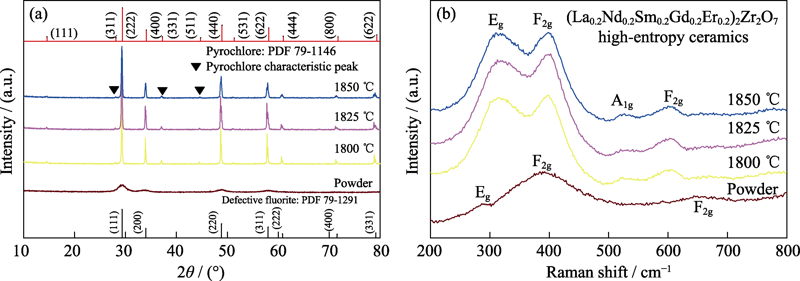

图2 煅烧粉体和不同温度烧结的高熵陶瓷的XRD图谱(a)和Raman图谱(b)

Fig. 2 XRD patterns (a) and Raman spectra (b) of calcined powder and high-entropy ceramics sintered at different temperatures

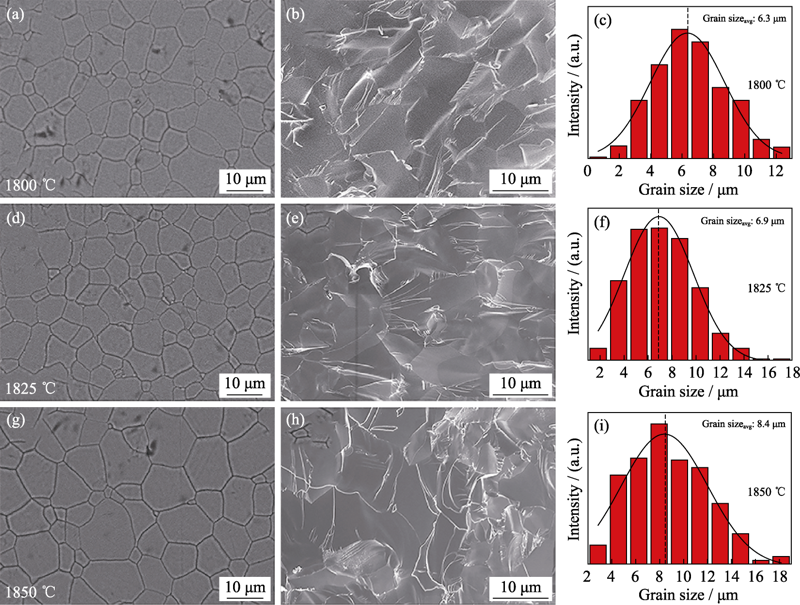

图3 高熵陶瓷的热腐蚀表面(a, d, g)和断面(b, e, h)的SEM照片及晶粒尺寸分布图(c, f, i)

Fig. 3 SEM images of final high-entropy ceramics after hot corrosion (a, d, g), SEM images of fractured final high-entropy ceramics (b, e, h), histograms of grain distribution (c, f, i) of final high-entropy ceramics

图5 不同温度烧结的高熵透明陶瓷的晶粒尺寸、维氏硬度和密度

Fig. 5 Grain sizes, Vickers hardnesses and bulk densities of high-entropy transparent ceramics sintered at different temperatures

| [1] | FU ZHENGYI, GU JUNFENG, ZOU JI, et al. Recent progress in high-entropy ceramic materials. Materials China, 2019,38(9):855-865. |

| [2] | YEH JIENWEI, CHEN SWEKAI, SUJIEN LIN, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Advanced Engineering Materials, 2004,6(5):299-303. |

| [3] | CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A, 2004,375:213-218. |

| [4] |

NIU CHANGNING, LAROSA CARLYN R, MIAO JIASHI, et al. Magnetically-driven phase transformation strengthening in high entropy alloys. Nature Communications, 2018,9(1):1363.

URL PMID |

| [5] | PRAVEEN S, KIM H S. High-entropy alloys: potential candidates for high-temperature applications-an overview. Advanced Engineering Materials, 2018,20(1):1700645. |

| [6] |

MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts. Acta Materialia, 2017,122:448-511.

DOI URL |

| [7] | YEH J. Recent progress in high-entropy alloys. Annales De Chimie-Science Des Materiaux, 2006,31(6):633-648. |

| [8] |

CHUANG MINGHAO, TSAI MINGHUNG, WANG WOEIREN, et al. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Materialia, 2011,59(16):6308-6317.

DOI URL |

| [9] |

LI ZHIMING, PRADEEP K G, DENG YUN, et al. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature, 2016,534(7606):227-230.

URL PMID |

| [10] | BUTLER T M, ALFANO J P, MARTENS R L, et al. High-temperature oxidation behavior of Al-Co-Cr-Ni-(Fe or Si) multicomponent high-entropy alloys. JOM, 2014,67(1):246-259. |

| [11] | ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015,6(1):8485. |

| [12] | CHELLALI M R, SARKAR A, NANDAM S H, et al. On the homogeneity of high entropy oxides: an investigation at the atomic scale. Scripta Materialia, 2019,166:58-63. |

| [13] | LEI ZHIFENG, LIU XIONGJUN, WANG HUI, et al. Development of advanced materials via entropy engineering. Scripta Materialia, 2019,165:164-169. |

| [14] | JIANG SICONG, HU TAO, GILD JOSHUA, et al. A new class of high-entropy perovskite oxides. Scripta Materialia, 2018,142:116-120. |

| [15] | DJENADIC R, SARKAR A, CLEMENS O, et al. Multicomponent equiatomic rare earth oxides. Materials Research Letters, 2016,5(2):102-109. |

| [16] | BRAIC V, VLADESCU A, BALACEANU M, et al. Nanostructured multi-element (TiZrNbHfTa)N and (TiZrNbHfTa)C hard coatings. Surface and Coatings Technology, 2012,211:117-121. |

| [17] | JIN T, SANG X, UNOCIC R R, et al. Mechanochemical-assisted synthesis of high-entropy metal nitride via a soft urea strategy. Advanced Materials, 2018,30(23):1707512. |

| [18] | WEI XIAO-FENG, LIU JI-XUAN, LI FEI, et al. High entropy carbide ceramics from different starting materials. Journal of the European Ceramic Society, 2019,39:2989-2994. |

| [19] | YAN XUELIANG, CONSTANTIN LOIC, LU YONGFENG, et al. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. Journal of the American Ceramic Society, 2018,101(10):4486-4491. |

| [20] | GILD J, BRAUN J, KAUFMANN K, et al. A high-entropy silicide: (Mo0.2Nb0.2Ta0.2Ti0.2W0.2)Si2. Journal of Materiomics, 2019,5(3):337-343. |

| [21] | MAYRHOFER P H, KIRNBAUER A, ERTELTHALER P, et al. High-entropy ceramic thin films; a case study on transition metal diborides. Scripta Materialia, 2018,149:93-97. |

| [22] | LIU DA, WEN TONGQI, YE BEILIN, et al. Synthesis of superfine high-entropy metal diboride powders. Scripta Materialia, 2019,167:110-114. |

| [23] | SUBRAMANIAN M A, ARAVAMUDAN G, RAO G V. Oxide pyrochlores—a review. Progress in Solid State Chemistry, 1983,15(2):55-143. |

| [24] | TROJAN P J, ZYCH E, KOSIŃSKA M. Fabrication and spectroscopic properties of nanocrystalline La2Hf2O7: Pr. Radiation Measurements, 2010,45(3):432-434. |

| [25] | WHITTLE K R, CRANSWICK L M D, REDFERN S A T, et al. Lanthanum pyrochlores and the effect of yttrium addition in the systems La2-xYxZr2O7 and La2-xYxHf2O7. Journal of Solid State Chemistry, 2009,182(3):442-450. |

| [26] | WANG ZHENGJUAN, ZHOU GUOHONG, JIANG DANYU, et al. Recent development of A2B2O7 system transparent ceramics. Journal of Advanced Ceramics, 2018,7(4):289-306. |

| [27] | SU S J, DING Y, SHU X Y, et al. Nd and Ce simultaneous substitution driven structure modifications in Gd2-xNdxZr2-yCeyO7, Journal of the European Ceramic Society, 2014,35(6):1847-1853. |

| [28] | LI FEI, ZHOU LIN, LIU JIXUAN, et al. High-entropy pyrochlores with low thermal conductivity for thermal barrier coating materials. Journal of Advanced Ceramics, 2019,8(4):576-582. |

| [29] | HE ZONGSHENG, ZHANG KUIBAO, XUE JIALI, et al. Self-propagation high-temperature synthesis of Sm-doped pyrochlores ceramic form and its aqueous durability. Materials Reports, 2018,32(32):247-250. |

| [30] |

SICKAFUS K E, MINERVINI L, GRIMES R W, et al. Radiation tolerance of complex oxides. Science, 2000,289:748-751.

URL PMID |

| [31] |

EL-ATWANI O, LI N, LI M, et al. Outstanding radiation resistance of tungsten-based high-entropy alloys. Science Advances, 2019,5(3):eaav2002.

URL PMID |

| [32] | KAREER A, WAITE J C, LI B, et al. Low activation, refractory, high entropy alloys for nuclear applications, Journal of Nuclear Materials, 2019,526:151744. |

| [33] | JI YAMING, JIANG DANYU, FEN TAO, et al. Fabrication of transparent La2Hf2O7 ceramics from combustion synthesized powders. Materials Research Bulletin, 2005,40(3):553-559. |

| [34] | ZHAO WENWEN, ZHANG KUIBAO, LI WEIWEI, et al. Fabrication and optical properties of transparent LaErZr2O7 ceramic with high excess contents of La and Er. Ceramics International, 2019,45(9):11717-11722. |

| [35] | WANG ZHENGJUAN, ZHOU GUOHONG, QIN XIANPENG, et al. Fabrication and phase transition of La2-xLuxZr2O7 transparent ceramics. Journal of the European Ceramic Society, 2014,34(15):3951-3958. |

| [36] | WANG ZHENGJUAN, ZHOU GUOHONG, ZHANG FANG, et al. Fabrication and properties of La2-xGdxHf2O7 transparent ceramics. Journal of Luminescence, 2016,169:612-615. |

| [37] | YI HAILAN, ZOU XIAOQING, YANG YAN, et al. Fabrication of highly transmitting LaGdHf2O7 ceramics. Journal of the American Ceramic Society, 2011,94(12):4120-4122. |

| [38] | ZHOU GUOHONG, WANG ZHENGJUAN, ZHOU BOZHU, et al. Fabrication of transparent Y2Hf2O7 ceramics via vacuum sintering. Optical Materials, 2013,35(4):774-777. |

| [39] | HU Y L, BAI L H, TONG Y G, et al. First-principle calculation investigation of NbMoTaW based refractory high entropy alloys. Journal of Alloys and Compounds, 2020,827:153963. |

| [40] | ZHANG GUANGRAN, MILISAVLJEVIC IVA, ZYCH EUGENIUSZ, et al. High-entropy sesquioxide X2O3 upconversion transparent ceramics. Scripta Materialia, 2020,186:19-23. |

| [41] | CHEN XIANQIANG, WU YIQUAN. High-entropy transparent fluoride laser ceramics. Journal of the American Ceramic Society, 2019,103(2):750-756. |

| [42] | ZHANG KUIBAO, LI WEIWEI, ZENG JIANJUN, et al. Preparation of (La0.2Nd0.2Sm0.2Gd0.2Yb0.2)2Zr2O7 high-entropy transparent ceramic using combustion synthesized nanopowder. Journal of Alloys and Compounds, 2020,817(15):153328. |

| [43] | LI WEIWEI, ZHANG KUIBAO, ZHAO WENWEN, et al. Vacuum sintering and optical properties of Gd2-xNdxZr2O7 transparent ceramics using combustion synthesized nanopowders. Optical Materials, 2020,100:109622. |

| [44] | LI WEIWEI, ZHANG KUIBAO, XIE DAYAN, et al. Characterizations of vacuum sintered Gd2Zr2O7 transparent ceramics using combustion synthesized nanopowder. Journal of the European Ceramic Society, 2020,40(4):1665-1670. |

| [45] |

LEE Y H, SHEU H S, DENG J P, et al. Preparation and fluorite- pyrochlore phase transformation in Gd2Zr2O7. Journal of Alloys and Compounds, 2009,487:595-598.

DOI URL |

| [46] | GLERUP M, NIELSEN O F, POULSEN F W. The structural transformation from the pyrochlore structure, A2B2O7, to the fluorite structure, AO2, studied by raman spectroscopy and defect chemistry modeling. Journal of Solid State Chemistry, 2001,160(1):25-32. |

| [47] | ZOU XIAOQING, ZHOU GUOHONG, YI HAILAN, et al. Fabrication of transparent Y2Hf2O7 ceramic from combustion synthesized powders. Journal of Inorganic Materials, 2011,26:929-932. |

| [48] | GUPTA S K, REGHUKUMAR C, SUDARSHAN K, et al. Orange-red emitting Gd2Zr2O7:Sm3+: structure-property correlation, optical properties and defect spectroscopy . Journal of Physics and Chemistry of Solids, 2018,116:360-366. |

| [49] | TROJAN-PIEGZA J, BRITES C D S, RAMALHO J F C B. et al. La0.4Gd1.6Zr2O7:0.1%Pr transparent sintered ceramic-a wide-range luminescence thermometer. Journal of Materials Chemistry C, 2020,8:7005-7011. |

| [1] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [2] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [3] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [4] | 樊文楷, 杨潇, 李宏华, 李永, 李江涛. 无压烧结制备(Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7高熵陶瓷及其高温抗CMAS腐蚀性能[J]. 无机材料学报, 2025, 40(2): 159-167. |

| [5] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [6] | 鲍伟超, 郭晓杰, 辛晓婷, 彭湃, 王新刚, 刘吉轩, 张国军, 许钫钫. 在碳化物陶瓷中构筑金属原子层分相共生结构[J]. 无机材料学报, 2025, 40(1): 17-22. |

| [7] | 李刘媛, 黄开明, 赵秀艺, 刘会超, 王超. RE-Si-Al-O玻璃相对高熵稀土双硅酸盐微结构及耐CMAS腐蚀性能的影响[J]. 无机材料学报, 2024, 39(7): 793-802. |

| [8] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [9] | 刘国昂, 王海龙, 方成, 黄飞龙, 杨欢. B4C含量对(Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C陶瓷力学性能及抗氧化性能的影响[J]. 无机材料学报, 2024, 39(6): 697-706. |

| [10] | 张睿, 张侃, 袁梦雅, 谷鑫磊, 郑伟涛. 氮空位调控晶格畸变度强化(NbMoTaW)Nx薄膜的力学性质和耐磨损性[J]. 无机材料学报, 2024, 39(6): 715-725. |

| [11] | 吕朝阳, 徐勇, 杨久延, 涂广升, 涂兵田, 王皓. MgF2助剂对MgAl1.9Ga0.1O4透明陶瓷的制备与光学性能的影响[J]. 无机材料学报, 2024, 39(5): 531-538. |

| [12] | 张文宇, 郭瑞华, 岳全鑫, 黄雅荣, 张国芳, 关丽丽. 高熵磷化物双功能催化剂的制备及高效电解水性能[J]. 无机材料学报, 2024, 39(11): 1265-1274. |

| [13] | 郭凌翔, 唐颖, 黄世伟, 肖博澜, 夏东浩, 孙佳. C/C复合材料高熵氧化物涂层抗烧蚀性能[J]. 无机材料学报, 2024, 39(1): 61-70. |

| [14] | 郭天民, 董江波, 陈正鹏, 饶睦敏, 李明飞, 李田, 凌意瀚. 中温固体氧化物燃料电池的高熵双钙钛矿阴极材料: 兼容性与活性研究[J]. 无机材料学报, 2023, 38(6): 693-700. |

| [15] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||