无机材料学报 ›› 2025, Vol. 40 ›› Issue (10): 1145-1152.DOI: 10.15541/jim20250078 CSTR: 32189.14.jim20250078

李正浩1,2( ), 李婧鸣1,2, 章玉祥1,2, 袁波1,2, 张凯1,2, 朱向东1,2(

), 李婧鸣1,2, 章玉祥1,2, 袁波1,2, 张凯1,2, 朱向东1,2( )

)

收稿日期:2025-02-23

修回日期:2025-03-25

出版日期:2025-10-20

网络出版日期:2025-04-15

通讯作者:

朱向东, 研究员. E-mail: zhu_xd1973@scu.edu.cn作者简介:李正浩(2000-), 男, 硕士研究生. E-mail: 2022223100034@stu.scu.edu.cn

基金资助:

LI Zhenghao1,2( ), LI Jingming1,2, ZHANG Yuxiang1,2, YUAN Bo1,2, ZHANG Kai1,2, ZHU Xiangdong1,2(

), LI Jingming1,2, ZHANG Yuxiang1,2, YUAN Bo1,2, ZHANG Kai1,2, ZHU Xiangdong1,2( )

)

Received:2025-02-23

Revised:2025-03-25

Published:2025-10-20

Online:2025-04-15

Contact:

ZHU Xiangdong, professor. E-mail: zhu_xd1973@scu.edu.cnAbout author:LI Zhenghao (2000-), male, Master candidate. E-mail: 2022223100034@stu.scu.edu.cn

Supported by:摘要:

碳纤维/聚醚醚酮(Carbon Fiber Polyetheretherketone, CF/PEEK)在骨修复领域已得到了广泛应用, 但生物惰性致使其骨整合性较弱, 极大地影响了临床应用的长期稳定性和骨修复效果。本研究基于无机纳米粒子液相自组装策略, 在CF/PEEK表面构筑了锰掺杂纳米羟基磷灰石(Mn/nHA)涂层, 以期改善其生物活性和骨整合性。实验结果表明, Mn/nHA和nHA涂层均可显著改善CF/PEEK表面粗糙度和提升亲水性。体外研究发现, Mn/nHA和nHA两组涂层改性材料与大鼠骨髓间充质干细胞(BMSCs)共培养7 d后, 相对细胞存活率分别高达180%和159%, 均表现出显著的促增殖效果。此外, 茜素红染色和逆转录-聚合酶链式反应(RT-PCR)检测发现两种涂层均能增强细胞在材料表面的矿化和成骨分化能力, 且Mn/nHA涂层呈现出更强的促进作用。

中图分类号:

李正浩, 李婧鸣, 章玉祥, 袁波, 张凯, 朱向东. Mn/nHA涂层CF/PEEK复合材料的制备及体外成骨活性评价[J]. 无机材料学报, 2025, 40(10): 1145-1152.

LI Zhenghao, LI Jingming, ZHANG Yuxiang, YUAN Bo, ZHANG Kai, ZHU Xiangdong. Preparation and in vitro Osteogenic Activity Evaluation of Mn/nHA Coated CF/PEEK Composite[J]. Journal of Inorganic Materials, 2025, 40(10): 1145-1152.

| For GAPDH |

|---|

| F: 5ʹ-GGCACAGTCAAGGCTGAGAATG-3ʹ R: 5ʹ-ATGGTGGTGAAGACGCCAGTA-3ʹ |

| For BMP |

| F: 5ʹ-TGACTGGATCGTGGCACCTC-3ʹ R: 5ʹ-CAGAGTCTGCACTATGGCATGGTTA-3ʹ |

| For OPG |

| F: 5ʹ-AACCGCACCCACAACCGA-3ʹ R: 5ʹ-CACCTGAGAAGAACCCATCCG-3ʹ |

| For RUNX-2 |

| F: 5ʹ-TGGCCGGGAATGATGAGAAC-3ʹ R: 5ʹ-TTGAACCTGGCCACTTGGTT-3ʹ |

| For OCN |

| F: 5ʹ-TCTGAGTCTGACAAAGCCTTCAT-3ʹ R: 5ʹ-AAGTCCATTGTTGAGGTAGCG-3ʹ |

| For ALP |

| F: 5ʹ-CATCGCCTATCAGCTAATGCACA-3ʹ R: 5ʹ-ATGAGGTCCAGGCCATCCAG-3ʹ |

| For BSP |

| F: 5ʹ-GACCAGTTATGGCACCACGA-3ʹ R: 5ʹ-CGCAGTGTTGTACTCGTTGC-3ʹ |

表1 RT-PCR中所用引物序列

Table 1 Primers utilized for RT-PCR amplification

| For GAPDH |

|---|

| F: 5ʹ-GGCACAGTCAAGGCTGAGAATG-3ʹ R: 5ʹ-ATGGTGGTGAAGACGCCAGTA-3ʹ |

| For BMP |

| F: 5ʹ-TGACTGGATCGTGGCACCTC-3ʹ R: 5ʹ-CAGAGTCTGCACTATGGCATGGTTA-3ʹ |

| For OPG |

| F: 5ʹ-AACCGCACCCACAACCGA-3ʹ R: 5ʹ-CACCTGAGAAGAACCCATCCG-3ʹ |

| For RUNX-2 |

| F: 5ʹ-TGGCCGGGAATGATGAGAAC-3ʹ R: 5ʹ-TTGAACCTGGCCACTTGGTT-3ʹ |

| For OCN |

| F: 5ʹ-TCTGAGTCTGACAAAGCCTTCAT-3ʹ R: 5ʹ-AAGTCCATTGTTGAGGTAGCG-3ʹ |

| For ALP |

| F: 5ʹ-CATCGCCTATCAGCTAATGCACA-3ʹ R: 5ʹ-ATGAGGTCCAGGCCATCCAG-3ʹ |

| For BSP |

| F: 5ʹ-GACCAGTTATGGCACCACGA-3ʹ R: 5ʹ-CGCAGTGTTGTACTCGTTGC-3ʹ |

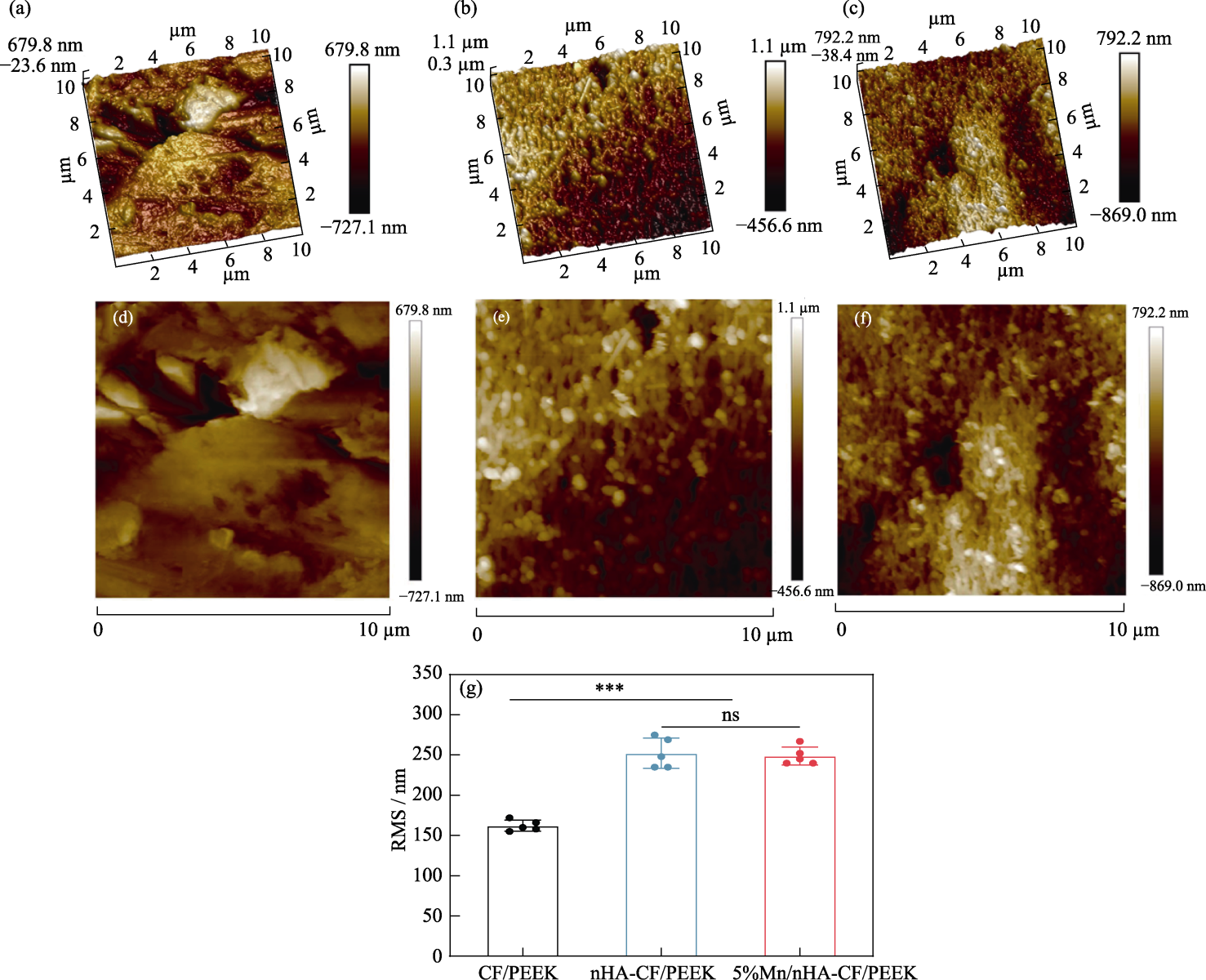

图2 CF/PEEK (a, d)、nHA-CF/PEEK (b, e)和5%Mn/nHA-CF/PEEK (c, f)表面形貌的AFM图像(a-f)和粗糙度(g)

Fig. 2 AFM images (a-f) and roughness (g) for surface topographies of CF/PEEK (a, d), nHA-CF/PEEK (b, e) and 5%Mn/ nHA-CF/PEEK (c, f) (a-c) 3D images; (d-f) 2D images; (g) Roughness

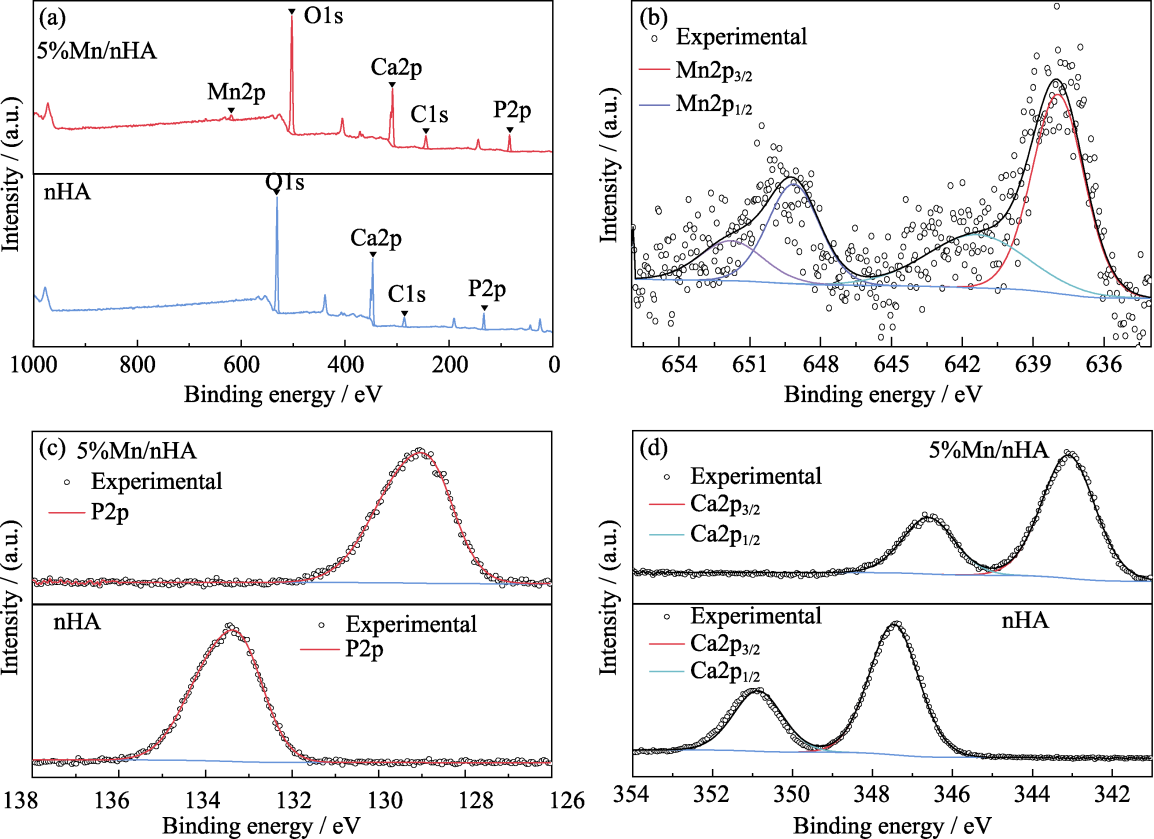

图6 CF/PEEK表面nHA和5%Mn/nHA涂层样品的XPS谱图

Fig. 6 XPS spectra of nHA and 5%Mn/nHA coated on CF/PEKK samples (a) XPS full spectra; (b) Mn, (c) P and (d) Ca element valence analyses

| Sample | O/% | Ca/% | P/% | Mn/% |

|---|---|---|---|---|

| nHA | 63.96±2.55 | 21.38±1.24 | 14.67±1.22 | - |

| 5%Mn/nHA | 69.41±3.15 | 17.05±1.74 | 12.36±1.24 | 1.18±0.15 |

表2 材料表面涂层的元素组成(原子分数)

Table 2 Elemental composition of the surface coating (in atom)

| Sample | O/% | Ca/% | P/% | Mn/% |

|---|---|---|---|---|

| nHA | 63.96±2.55 | 21.38±1.24 | 14.67±1.22 | - |

| 5%Mn/nHA | 69.41±3.15 | 17.05±1.74 | 12.36±1.24 | 1.18±0.15 |

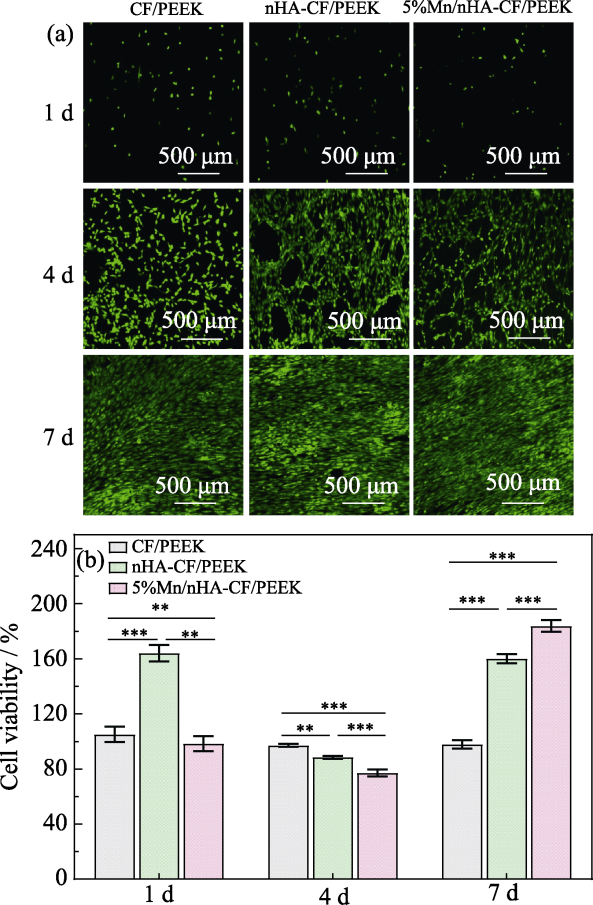

图7 在CF/PEEK、nHA-CF/PEEK及5%Mn/nHA-CF/PEEK表面培养1、4和7 d的BMSCs增殖情况

Fig. 7 BMSCs growth and proliferation on CF/PEEK, nHA-CF/PEEK and 5%Mn/nHA-CF/PEEK after culturing for 1, 4 and 7 d (a) CLSM images; (b) MTT analysis. Colorful figures are available on website

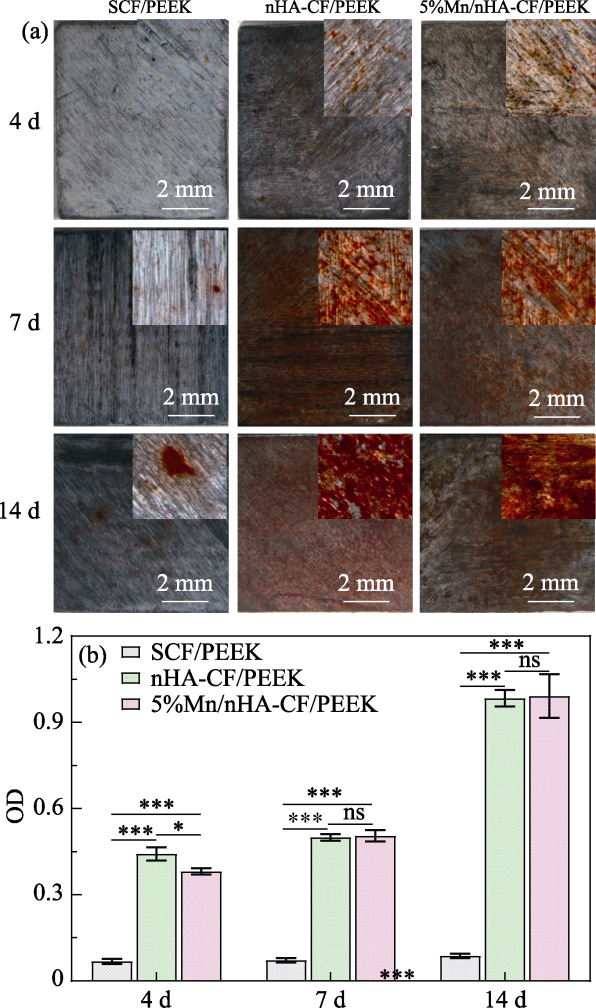

图8 在SCF/PEEK、nHA-CF/PEEK及5%Mn/nHA- CF/PEEK表面培养4、7和14 d的BMSCs矿化能力

Fig. 8 BMSCs mineralization ability on SCF/PEEK, nHA-CF/ PEEK and 5%Mn/nHA-CF/PEEK after culturing for 4, 7 and 14 d (a) Alizarin red stained images; (b) Semi-quantitative analysis. Colorful figures are available on website

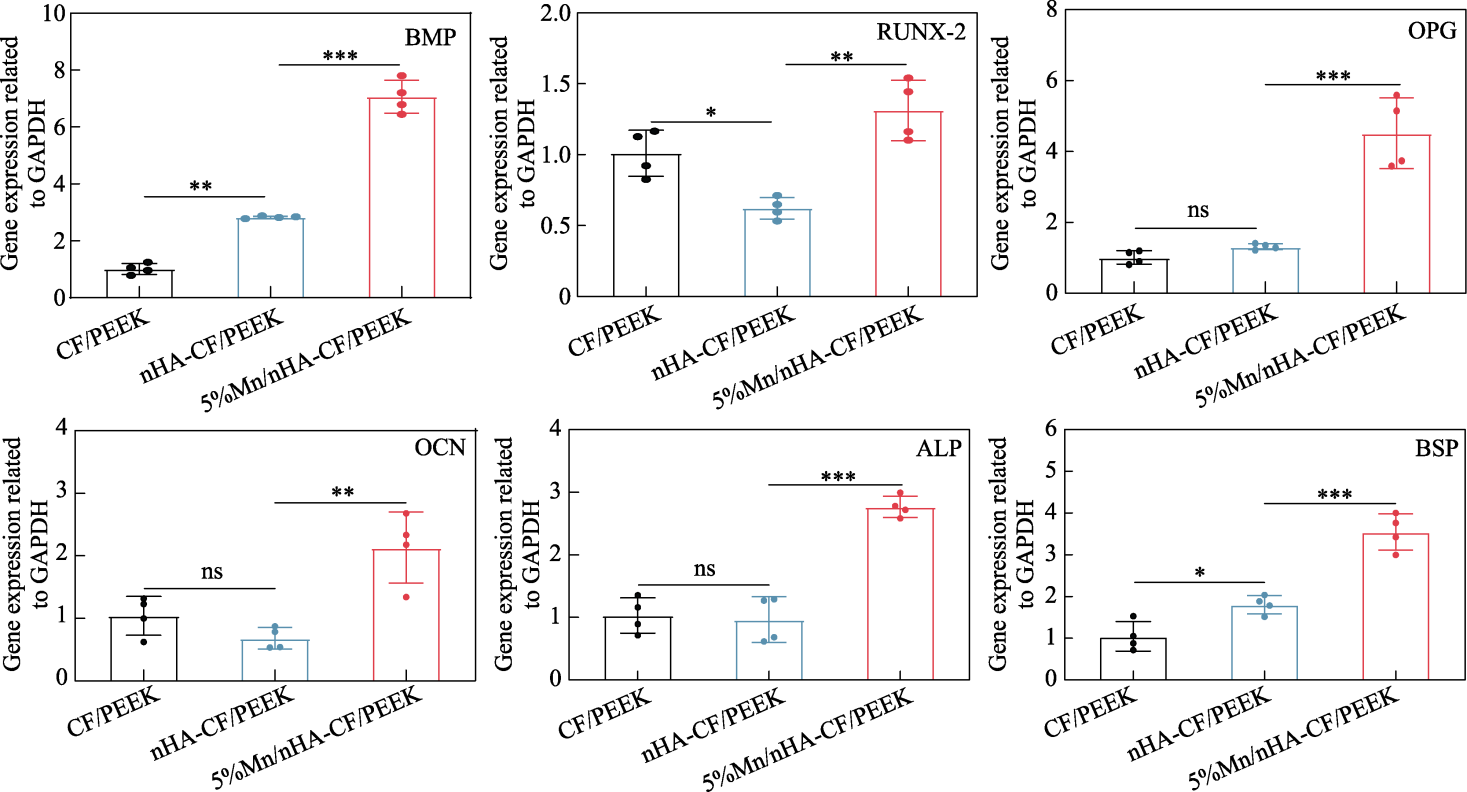

图9 BMSCs在CF/PEEK、nHA-CF/PEEK及5%Mn/nHA-CF/PEEK表面培养4 d的成骨相关基因表达

Fig. 9 Osteogenic gene expressions of BMSCs cultured on CF/PEEK, nHA-CF/PEEK and 5%Mn/nHA-CF/PEEK for 4 d

| [1] | ZHENG W, WU D, ZHANG Y, et al. Multifunctional modifications of polyetheretherketone implants for bone repair: a comprehensive review. Biomaterials Advances, 2023, 154: 213607. |

| [2] | CHEN J, CAO G, LI L, et al. Modification of polyether ether ketone for the repairing of bone defects. Biomedical Materials, 2022, 17(4): 042001. |

| [3] | LONG J R, KALANI M A, GOULDING K A, et al. Carbon- fiber-reinforced polyetheretherketone orthopedic implants in musculoskeletal and spinal tumors: imaging and clinical features. Skeletal Radiology, 2023, 52(3): 393. |

| [4] | ZHAO S, DONG W, WANG Y, et al. Chemical modification strategy to improve biological activity of carbon fiber-reinforced poly(ether ether ketone) implants. ACS Applied Polymer Materials, 2023, 5(8): 6607. |

| [5] | YAMANE Y, YABUTSUKA T, TAKAOKA Y, et al. Surface modification of carbon fiber-polyetheretherketone composite to impart bioactivity by using apatite nuclei. Materials, 2021, 14(21): 6691. |

| [6] | UEMATSU H, ARATAMA T, YAMAGUCHI A, et al. Influence of polyetheretherketone radicals on interfacial interaction with carbon fiber and crystal formation of polyetheretherketone at the interphase. Surfaces and Interfaces, 2024, 49: 104409. |

| [7] | HASSAN E A M, ELAGIB T H H, MEMON H, et al. Surface modification of carbon fibers by grafting PEEK-NH2 for improving interfacial adhesion with polyetheretherketone. Materials, 2019, 12(5): 778. |

| [8] | LEE S, JEON I S, JHO J Y. Mechanical properties of polyetheretherketone composites with surface-modified hydroxyapatite nanofibers and carbon fibers. Macromolecular Research, 2022, 30(4): 261. |

| [9] | HA S W, ECKERT K L, WINTERMANTEL E, et al. NaOH treatment of vacuum-plasma-sprayed titanium on carbon fibre- reinforced poly(etheretherketone). Journal of Materials Science: Materials in Medicine, 1997, 8(12): 881. |

| [10] | KONTOGIANNI G I, COELHO C, GAUTHIER R, et al. Osteogenic potential of nano-hydroxyapatite and strontium-substituted nano- hydroxyapatite. Nanomaterials, 2023, 13(12): 1881. |

| [11] | WAN Z, BAI X, WANG X, et al. MGP high-expressing MSCs orchestrate the osteoimmune microenvironment of collagen/ nanohydroxyapatite-mediated bone regeneration. Advanced Science, 2024, 11(23): e2308986. |

| [12] | HUANG Z, JIANG X, ZHANG L, et al. Multifunctional manganese-based nanogels catalyze immune energy metabolism to promote bone repair. Composites Part B: Engineering, 2025, 291: 112005. |

| [13] | TASKOZHINA G, BATYROVA G, UMAROVA G, et al. The manganese-bone connection: investigating the role of manganese in bone health. Journal of Clinical Medicine, 2024, 13(16): 4679. |

| [14] | PARK J W, TSUTSUMI Y, PARK E K. Osteogenic differentiation of human mesenchymal stem cells modulated by surface manganese chemistry in SLA titanium implants. BioMed Research International, 2022, 2022(1): 5339090. |

| [15] | SETTLE E A, MRAZ F R, DOUGLAS C R, et al. Effect of diet and manganese level on growth, perosis and 54Mn uptake in chicks. The Journal of Nutrition, 1969, 97(1): 141. |

| [16] | ZHANG K, QI C, CAI K. Manganese-based tumor immunotherapy. Advanced Materials, 2023, 35(19): e2205409. |

| [17] |

HAASE H. Innate immune cells speak manganese. Immunity, 2018, 48(4): 616.

DOI PMID |

| [18] |

WANG C, GUAN Y, LV M, et al. Manganese increases the sensitivity of the cGAS-STING pathway for double-stranded DNA and is required for the host defense against DNA viruses. Immunity, 2018, 48(4): 675.

DOI PMID |

| [19] | ZHANG R, WANG C, GUAN Y, et al. Manganese salts function as potent adjuvants. Cellular & Molecular Immunology, 2021, 18(5): 1222. |

| [20] | LUN W, WANG H, LI M, et al. Fabrication of MnO2-modified decellularized tendon membrane for enhancing tendon repair. Advanced Healthcare Materials, 2025, 14(1): e2402584. |

| [21] | RAY S, YAXLEY G M, MILLER L A, et al. Monazite saturation in carbonatite melts at crustal and upper mantle conditions. Geochimica et Cosmochimica Acta, 2025, 393: 1. |

| [22] | SILINGARDI F, SALAMANNA F, ESPAÑOL M, et al. Regulation of osteogenesis and angiogenesis by cobalt, manganese and strontium doped apatitic materials for functional bone tissue regeneration. Biomaterials Advances, 2024, 163: 213968. |

| [23] | GUO Y, SUN Q, WU F G, et al. Polyphenol-containing nanoparticles: synthesis, properties, and therapeutic delivery. Advanced Materials, 2021, 33(22): 2007356. |

| [24] | ZUO W, HUANG M R, SCHMITZ F, et al. Probing electrostatic and hydrophobic associative interactions in cells. The Journal of Physical Chemistry B, 2024, 128(44): 10861. |

| [25] | NAGAR H, SHARMA S. Role of surface functional groups in the adsorption behavior of microcystin-LR on graphene surfaces. Chemosphere, 2025, 374: 144169. |

| [26] |

ZHOU Z, ZHANG L, LI J, et al. Polyelectrolyte-calcium complexes as a pre-precursor induce biomimetic mineralization of collagen. Nanoscale, 2021, 13(2): 953.

DOI PMID |

| [27] | PAN P, HU Y, WANG C, et al. Abalone shells bioenhanced carboxymethyl chitosan/collagen/PLGA bionic hybrid scaffolds achieving biomineralization and osteogenesis for bone regeneration. International Journal of Biological Macromolecules, 2024, 279: 135018. |

| [28] | AVERY D, MORANDINI L, SHEAKLEY L S, et al. Canonical Wnt signaling enhances pro-inflammatory response to titanium by macrophages. Biomaterials, 2022, 289: 121797. |

| [29] | VROMAN L. Effect of absorbed proteins on the wettability of hydrophilic and hydrophobic solids. Nature, 1962, 196(4583): 476. |

| [30] | NGUYEN T T, JANG Y S, KIM Y K, et al. Osteogenesis-related gene expression and guided bone regeneration of a strontium- doped calcium-phosphate-coated titanium mesh. ACS Biomaterials Science & Engineering, 2019, 5(12): 6715. |

| [31] | YANG S, NING G, HOU Y, et al. Myoneurin regulates BMP signaling by competing with Ppm1a for Smad binding. iScience, 2022, 25(6): 104495. |

| [32] | YANG X, ZHANG D, LIU G, et al. Bioinspired from mussel and salivary acquired pellicle: a universal dual-functional polypeptide coating for implant materials. Materials Today Chemistry, 2019, 14: 100205. |

| [33] | WANG H, LIN C C, ZHANG X R, et al. Mussel-inspired polydopamine coating: a general strategy to enhance osteogenic differentiation and osseointegration for diverse implants. ACS Applied Materials & Interfaces, 2019, 11(7): 7615. |

| [1] | 闫共芹, 王晨, 蓝春波, 洪雨昕, 叶维超, 付向辉. Al掺杂P2型Na0.8Ni0.33Mn0.67-xAlxO2钠离子电池正极材料的制备与电化学性能[J]. 无机材料学报, 2025, 40(9): 1005-1012. |

| [2] | 安然, 林锶, 郭世刚, 张冲, 祝顺, 韩颖超. 铁掺杂纳米羟基磷灰石的制备及紫外吸收性能研究[J]. 无机材料学报, 2025, 40(5): 457-465. |

| [3] | 李承瑜, 丁自友, 韩颖超. 锰掺杂纳米羟基磷灰石的体外抗菌-促成骨性能研究[J]. 无机材料学报, 2024, 39(3): 313-320. |

| [4] | 王艳莉, 钱心怡, 沈春银, 詹亮. 石墨烯基介孔锰铈氧化物催化剂: 制备和低温催化还原NO[J]. 无机材料学报, 2024, 39(1): 81-89. |

| [5] | 孟波, 肖刚, 王秀丽, 涂江平, 谷长栋. 离子热合成锰基氧化物及其可逆储热性能[J]. 无机材料学报, 2023, 38(7): 793-799. |

| [6] | 刘妍, 张宇帆, 王茜蔓, 李婷, 马文婷, 杨富巍, 陈靓, 赵东月, 严小琴. 基于羟基磷灰石材料的风化脆弱骨质文物加固保护研究[J]. 无机材料学报, 2023, 38(11): 1345-1354. |

| [7] | 施吉翔, 翟东, 朱敏, 朱钰方. 生物活性玻璃-二氧化锰复合支架的制备与表征[J]. 无机材料学报, 2022, 37(4): 427-435. |

| [8] | 陈亚玲, 舒松, 王劭鑫, 李建军. Mn-HAP基低温SCR催化剂的制备及抗硫中毒性能[J]. 无机材料学报, 2022, 37(10): 1065-1072. |

| [9] | 朱雨桐, 谭佩洁, 林海, 朱向东, 张兴栋. 可注射透明质酸/羟基磷灰石复合材料: 制备、理化性能和细胞相容性[J]. 无机材料学报, 2021, 36(9): 981-990. |

| [10] | 林子扬, 常宇辰, 吴章凡, 包荣, 林文庆, 王德平. 不同模拟体液对硼硅酸盐生物活性玻璃基骨水泥矿化性能的影响[J]. 无机材料学报, 2021, 36(7): 745-752. |

| [11] | 吴永豪, 李向锋, 朱向东, 张兴栋. 高强度羟基磷灰石纳米陶瓷的构建及其促成骨细胞活性研究[J]. 无机材料学报, 2021, 36(5): 552-560. |

| [12] | 宋可可, 黄浩, 鲁梦婕, 杨安春, 翁杰, 段可. 水热制备锌、硅、镁、铁等元素掺杂羟基磷灰石及其表征[J]. 无机材料学报, 2021, 36(10): 1091-1096. |

| [13] | 邵悦婷, 朱英杰, 董丽颖, 蔡安勇. 羟基磷灰石超长纳米线/植物纤维纳米复合“宣纸”及其防霉性能[J]. 无机材料学报, 2021, 36(1): 107-112. |

| [14] | 柏祥涛,班丽卿,庄卫东. 高镍三元正极材料的包覆与掺杂改性研究进展[J]. 无机材料学报, 2020, 35(9): 972-986. |

| [15] | 李雪渊,王宏刚,田柱,朱建辉,刘影,贾兰,尤东江,李向明,康利涛. 一种用于长寿命水系锌锰电池的海藻酸钠/二氧化硅准凝胶复合电解质[J]. 无机材料学报, 2020, 35(8): 909-915. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||