无机材料学报 ›› 2023, Vol. 38 ›› Issue (10): 1133-1148.DOI: 10.15541/jim20230070 CSTR: 32189.14.10.15541/jim20230070

所属专题: 【制备方法】3D打印(202506)

收稿日期:2023-02-13

修回日期:2023-05-12

出版日期:2023-10-20

网络出版日期:2023-05-24

通讯作者:

冯 坚, 研究员. E-mail: fengj@nudt.edu.cn作者简介:王鲁凯(1993-), 男, 博士研究生. E-mail: wanglukai18@nudt.edu.cn

基金资助:

WANG Lukai( ), FENG Junzong, JIANG Yonggang, LI Liangjun, FENG Jian(

), FENG Junzong, JIANG Yonggang, LI Liangjun, FENG Jian( )

)

Received:2023-02-13

Revised:2023-05-12

Published:2023-10-20

Online:2023-05-24

Contact:

FENG Jian, professor. E-mail: fengj@nudt.edu.cnAbout author:WANG Lukai (1993-), male, PhD candidate. E-mail: wanglukai18@nudt.edu.cn

Supported by:摘要:

陶瓷基多孔结构既继承致密陶瓷材料耐高温、电绝缘、化学稳定的优异性能, 又兼具多孔结构低密度、高比表面积、低热导率的独特优势, 已被广泛应用于隔热、骨组织工程、过滤及污染物清除、电子元器件等领域。但是, 陶瓷基多孔结构的传统成孔方法在宏观尺度创造复杂几何外形与微纳尺度调控孔结构形态方面仍面临巨大挑战。近几十年来, 研究人员一直致力于创新陶瓷基多孔结构的加工成型方法, 以直写3D打印为代表的增材制造技术成为当前研究的热点, 并迅速发展出一系列成熟理论与创新方法。本文首先概述了陶瓷基多孔结构的传统成孔方法与增材制造成孔方法, 进一步详细介绍了直写组装成孔工艺过程, 主要包括假塑性墨水配方、固化策略、干燥及后处理, 分析了传统成孔方法与直写3D打印二者的组合技术在构筑陶瓷基多级孔结构方面的可行性, 总结了直写3D打印技术在制造复杂陶瓷基多孔结构领域的新观点、新进展和新发现, 最后结合陶瓷基多孔结构实际应用现状对直写3D技术的未来发展与挑战进行了展望。

中图分类号:

王鲁凯, 冯军宗, 姜勇刚, 李良军, 冯坚. 直写3D打印陶瓷基多孔结构的研究进展[J]. 无机材料学报, 2023, 38(10): 1133-1148.

WANG Lukai, FENG Junzong, JIANG Yonggang, LI Liangjun, FENG Jian. Direct-ink-writing 3D Printing of Ceramic-based Porous Structures: a Review[J]. Journal of Inorganic Materials, 2023, 38(10): 1133-1148.

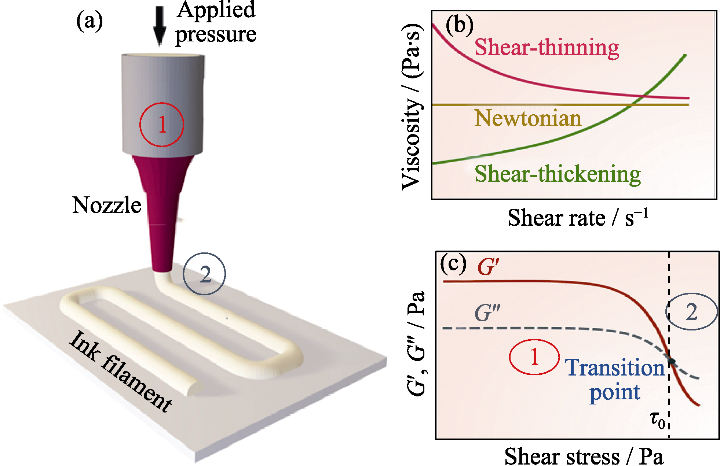

图2 直写3D打印技术

Fig. 2 Direct-ink-writing 3D printing technology (a) Schematic illustration of the ink extrusion process[29]; (b, c) Rheological behavior of pseudoplastic inks[28]

|

表1 代表性陶瓷基多孔结构的孔结构特征和墨水配方的流变性能及其打印参数

Table 1 Pore structure characteristics of representative ceramic-based porous structures and rheological properties and printing parameters of ink formulations

|

图3 陶瓷基墨水的固化方法

Fig. 3 Solidification strategies of ceramic-based inks (a) Solution-assisted solidification[61,63]; (b) Temperature-induced solidification[42,50]; (c) Light-based solidification[79]

图5 组合直接发泡法的直写3D打印技术

Fig. 5 Direct-ink-writing 3D printing technology integrated with direct foaming methods (a, b) Process schematic diagram of direct foam writing for porous ceramic-based structures[40]; (c-h) Morphologies of honeycomb ceramic with hierarchical pore structures[95]

图6 组合冷冻浇筑法的直写3D打印技术及其所制备的多级孔氧化铝支架[70]

Fig. 6 Direct-ink-writing 3D printing technology integrated with freezing casting method and its hierarchical porous alumina scaffold[70] (a) Schematic illustration of the printing process; (b) Microscopic morphology of hierarchical pore structures

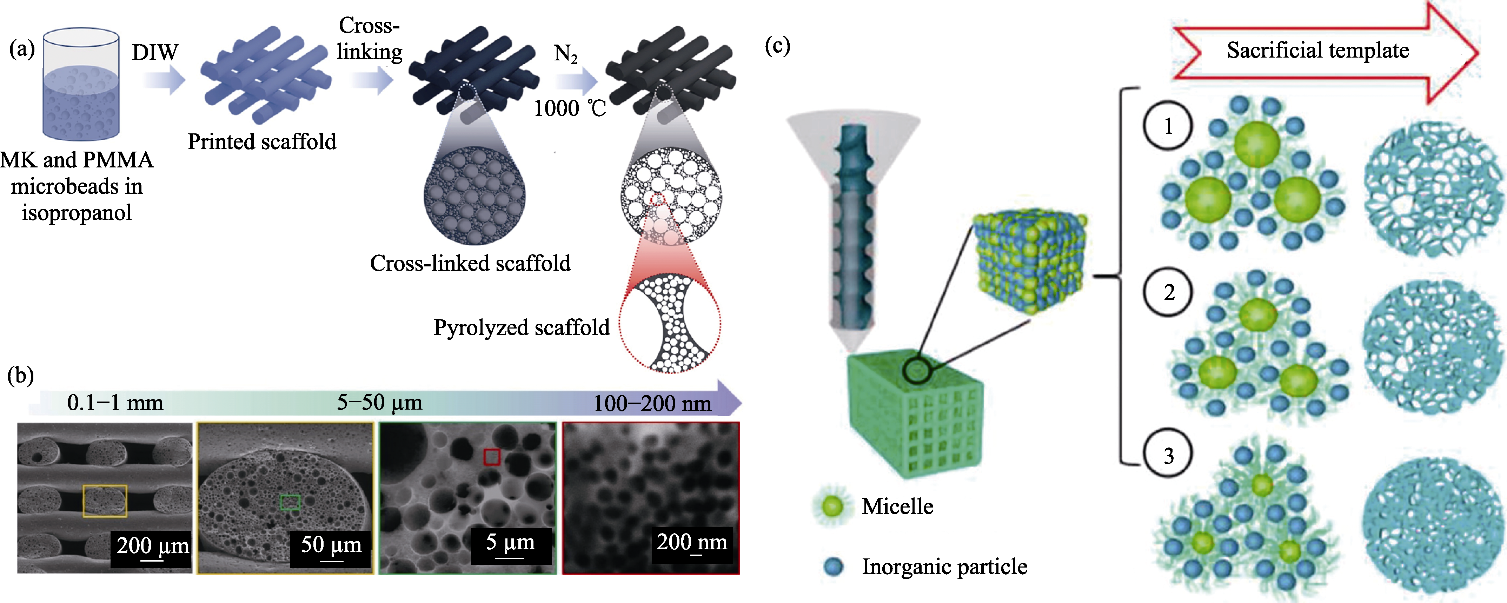

图7 组合牺牲模板法的直写3D打印技术

Fig. 7 Direct-ink-writing 3D printing technology integrated with sacrificial template method (a, b) Flow chart of preparation of hierarchical porous SiOC ceramic structures[53]; (c) Three sacrificial template methods for 3D-printed ceramics[104]

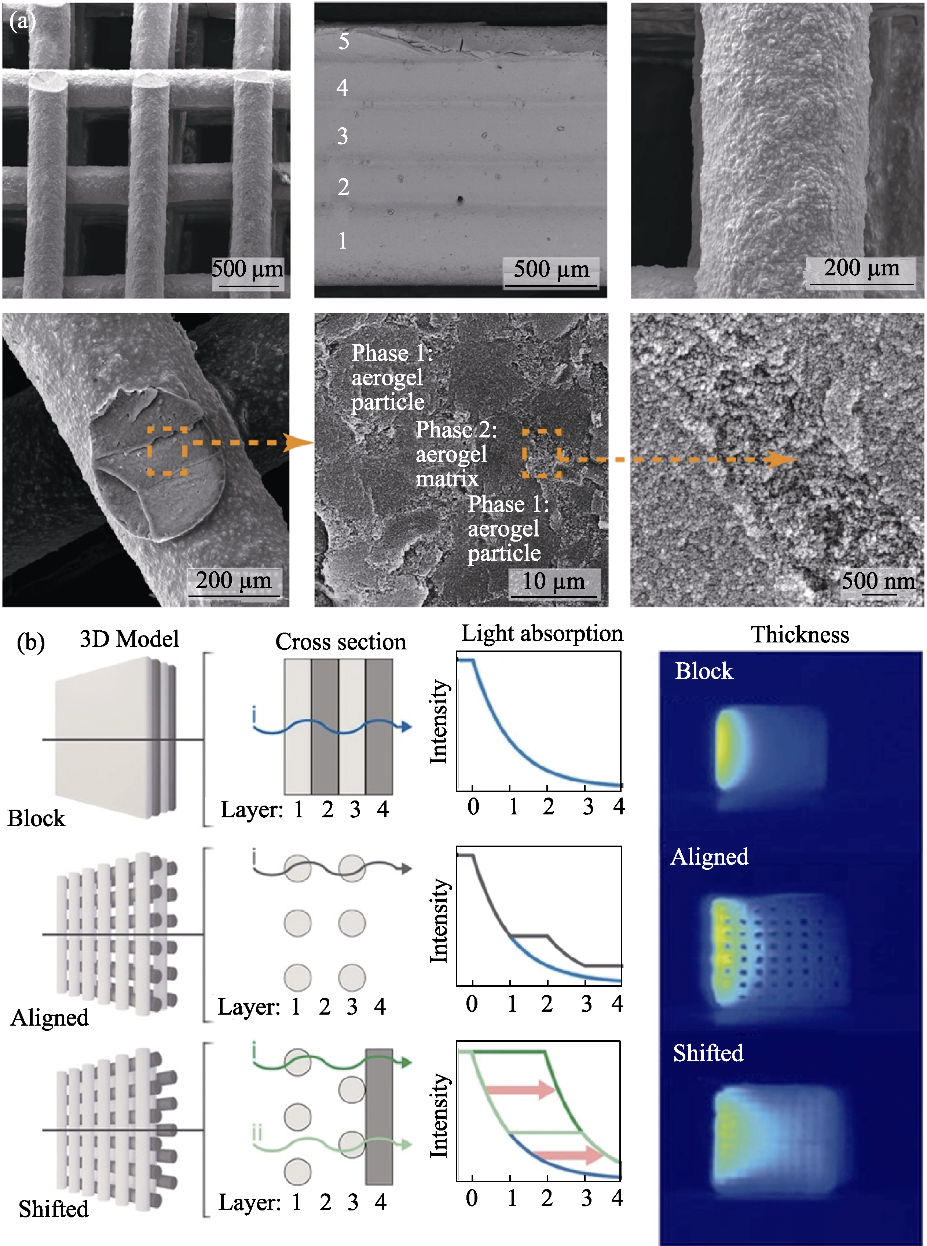

图8 组合溶胶-凝胶法的直写3D打印技术

Fig. 8 Direct-ink-writing 3D printing technology integrated with Sol-Gel method (a) Morphologies of hierarchical pore structures of SiO2 aerogels[105]; (b) TiO2 aerogel scaffolds with different hierarchical pore structures[61]

图9 3D打印纳米孔陶瓷基气凝胶的隔热应用

Fig. 9 3D-printed nanoporous ceramic-based aerogels for thermal insulation applications (a, b) Thermal shielding demonstration of 3D-printed Al2O3-SiO2 aerogels[42]; (c, d) 3D-printed SiO2 aerogels for miniaturized thermal insulation applications[105]

图11 3D打印多级孔结构过滤器用于污水净化[115]

Fig. 11 3D-printed filters with hierarchical pore structures for sewage purification[115] (a) Direct-write assembly process; (b) Pollutant decomposition mechanism

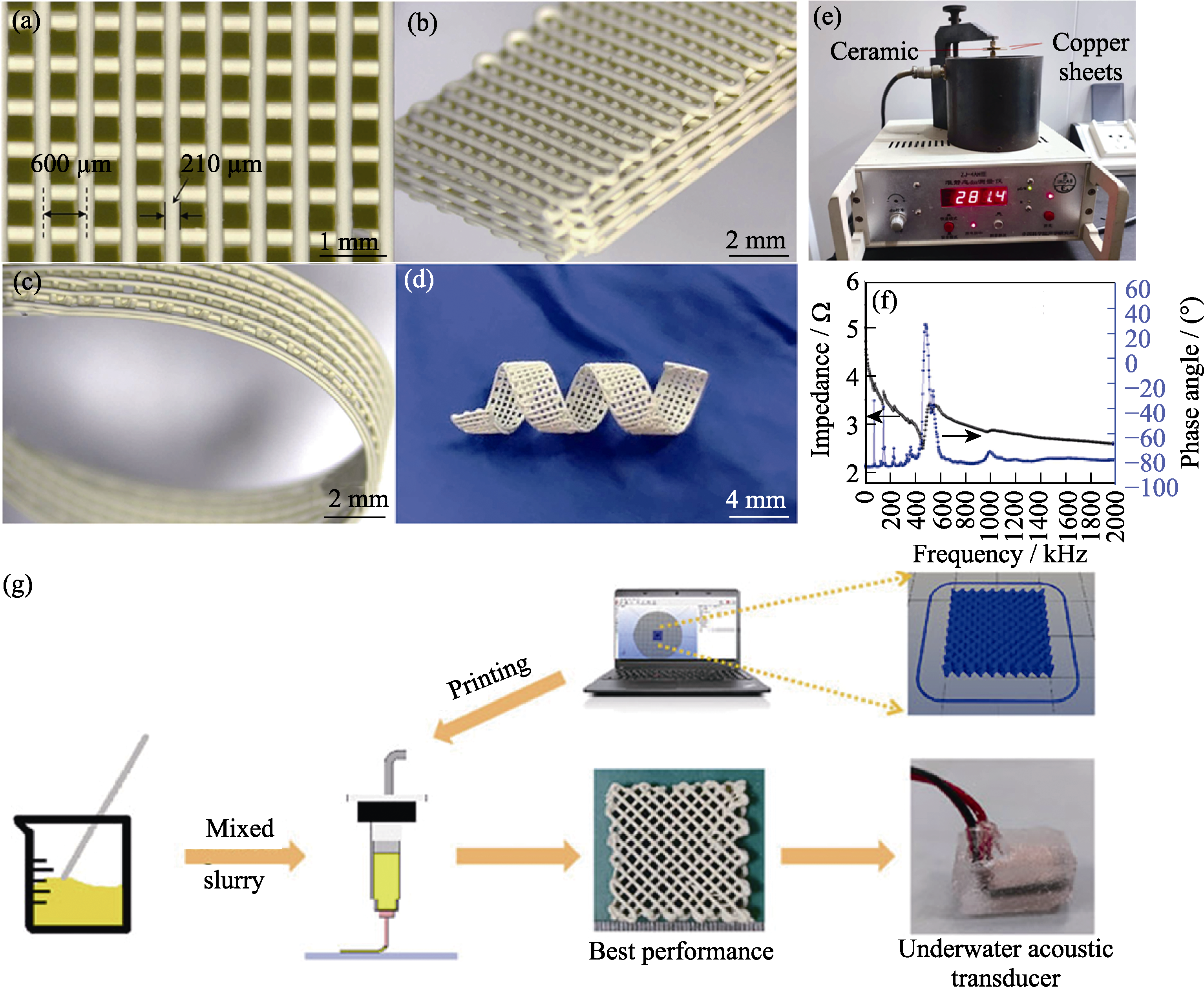

图12 3D打印多孔压电陶瓷的结构、性能及其应用

Fig. 12 Structures, performances, and applications of 3D-printed porous piezoelectric ceramics (a-f) Printed structures and performance characterizations [51]; (g) Direct-ink-writing 3D printing processes of lead zirconate titanate piezoelectric ceramics[121]

| [1] |

OHJI T, FUKUSHIMA M. Macro-porous ceramics: processing and properties. International Materials Reviews, 2012, 57(2): 115.

DOI URL |

| [2] |

SCIAMANNA V, NAIT-ALI B, GONON M. Mechanical properties and thermal conductivity of porous alumina ceramics obtained from particle stabilized foams. Ceramics International, 2015, 41(2): 2599.

DOI URL |

| [3] |

HA J H, LEE S, CHOI J R, et al. Development of a carbon-coated reticulated porous alumina material with tailored structural properties for potential radar-absorption applications. Ceramics International, 2017, 43(18): 16924.

DOI URL |

| [4] | GUO Z, ZHOU C. Recent advances in ink-based additive manufacturing for porous structures. Additive Manufacturing, 2021, 48: 102405. |

| [5] | MENDES M A, GOETZE P, TALUKDAR P, et al. Measurement and simplified numerical prediction of effective thermal conductivity of open-cell ceramic foams at high temperature. International Journal of Heat and Mass Transfer, 2016, 102: 396. |

| [6] |

HU F, WU S, SUN Y. Hollow-structured materials for thermal insulation. Advanced Materials, 2019, 31(38): 1801001.

DOI URL |

| [7] |

MORGAN K Y, SKLAVIADIS D, TOCHKA Z L, et al. Multi- material tissue engineering scaffold with hierarchical pore architecture. Advanced Functional Materials, 2016, 26(32): 5873.

DOI URL |

| [8] |

ZENG D, WU J, KENNEDY J F. Application of a chitosan flocculant to water treatment. Carbohydrate Polymers, 2008, 71(1): 135.

DOI URL |

| [9] | MIDDELKOOP V, SLATER T, FLOREA M, et al. Next frontiers in cleaner synthesis: 3D printed graphene-supported CeZrLa mixed- oxide nanocatalyst for CO2 utilisation and direct propylene carbonate production. Journal of Cleaner Production, 2019, 214: 606. |

| [10] |

FARAHANI H, WAGIRAN R, HAMIDON M N. Humidity sensors principle, mechanism, and fabrication technologies: a comprehensive review. Sensors, 2014, 14(5): 7881.

DOI PMID |

| [11] |

CAO J, DONG X, LI L, et al. Recycling of waste fly ash for production of porous mullite ceramic membrane supports with increased porosity. Journal of the European Ceramic Society, 2014, 34(13): 3181.

DOI URL |

| [12] |

AKHTAR F, ANDERSSON L, OGUNWUMI S, et al. Structuring adsorbents and catalysts by processing of porous powders. Journal of the European Ceramic Society, 2014, 34(7): 1643.

DOI URL |

| [13] |

DONG L H, ZHANG H J, ZHANG J, et al. Carbon nanotube modified sepiolite porous ceramics for high-efficient oil/water separation. Journal of Inorganic Materials, 2020, 35(6): 689.

DOI |

| [14] |

MURPHY S V, ATALA A. 3D bioprinting of tissues and organs. Nature Biotechnology, 2014, 32(8): 773.

DOI PMID |

| [15] |

FUKUSHIMA M, ZHOU Y, MIYAZAKI H, et al. Microstructural characterization of porous silicon carbide membrane support with and without alumina additive. Journal of the American Ceramic Society, 2006, 89(5): 1523.

DOI URL |

| [16] |

LI F, KANG Z, HUANG X, et al. Preparation of zirconium carbide foam by direct foaming method. Journal of the European Ceramic Society, 2014, 34(15): 3513.

DOI URL |

| [17] | LI F, LIANG M, MA X F, et al. Preparation and characterization of stoichiometric zirconium carbide foams by direct foaming of zirconia sols. Journal of Porous Materials, 2015, 22: 493. |

| [18] | HEDAYAT N, DU Y, ILKHANI H. Review on fabrication techniques for porous electrodes of solid oxide fuel cells by sacrificial template methods. Renewable and Sustainable Energy Reviews, 2017, 77: 1221. |

| [19] |

SCHELM K, ABREU MORALES E, SCHEFFLER M. Mechanical and surface-chemical properties of polymer derived ceramic replica foams. Materials, 2019, 12(11): 1870.

DOI URL |

| [20] | 王世界, 尹艺程, 邱鑫, 等. 超高温多孔陶瓷的制备、性能及应用研究进展. 材料导报, 2022, 36(12): 57. |

| [21] |

DORCHEH A S, ABBASI M. Silica aerogel; synthesis, properties and characterization. Journal of Materials Processing Technology, 2008, 199(1/2/3): 10.

DOI URL |

| [22] | GURAV J L, JUNG I K, PARK H H, et al. Silica aerogel: synthesis and applications. Journal of Nanomaterials, 2010, 2010: 409310. |

| [23] |

LIU R, XU T, WANG C A. A review of fabrication strategies and applications of porous ceramics prepared by freeze-casting method. Ceramics International, 2016, 42(2): 2907.

DOI URL |

| [24] |

STUDART A R, GONZENBACH U T, TERVOORT E, et al. Processing routes to macroporous ceramics: a review. Journal of the American Ceramic Society, 2006, 89(6): 1771.

DOI URL |

| [25] |

LASGORCEIX M, CHAMPION E, CHARTIER T. Shaping by microstereolithography and sintering of macro-micro-porous silicon substituted hydroxyapatite. Journal of the European Ceramic Society, 2016, 36(4): 1091.

DOI URL |

| [26] |

TETIK H, WANG Y, SUN X, et al. Additive manufacturing of 3D aerogels and porous scaffolds: a review. Advanced Functional Materials, 2021, 31(45): 2103410.

DOI URL |

| [27] |

HWA L C, RAJOO S, NOOR A M, et al. Recent advances in 3D printing of porous ceramics: a review. Current Opinion in Solid State and Materials Science, 2017, 21(6): 323.

DOI URL |

| [28] |

FENG J, SU B L, XIA H, et al. Printed aerogels: chemistry, processing, and applications. Chemical Society Reviews, 2021, 50(6): 3842.

DOI PMID |

| [29] |

SAADI M, MAGUIRE A, POTTACKAL N T, et al. Direct ink writing: a 3D printing technology for diverse materials. Advanced Materials, 2022, 34(28): 2108855.

DOI URL |

| [30] |

ZHANG F, LI Z, XU M, et al. A review of 3D printed porous ceramics. Journal of the European Ceramic Society, 2022, 42(8): 3351.

DOI URL |

| [31] | 刘岩松, 李文博, 刘永胜, 等. 3D打印陶瓷铸型研究与应用进展. 材料工程, 2022, 50(7): 18. |

| [32] |

POPOV V, EVSEEV A, IVANOV A, et al. Laser stereolithography and supercritical fluid processing for custom-designed implant fabrication. Journal of Materials Science: Materials in Medicine, 2004, 15(2): 123.

DOI URL |

| [33] | MANÇANARES C G, DE S. ZANCUL E, CAVALCANTE DA SILVA J, et al. Additive manufacturing process selection based on parts’ selection criteria. The International Journal of Advanced Manufacturing Technology, 2015, 80: 1007. |

| [34] |

LIU S, MO L, BI G, et al. DLP 3D printing porous β-tricalcium phosphate scaffold by the use of acrylate/ceramic composite slurry. Ceramics International, 2021, 47(15): 21108.

DOI URL |

| [35] |

PROVIN C, MONNERET S. Complex ceramic-polymer composite microparts made by microstereolithography. IEEE Transactions on Electronics Packaging Manufacturing, 2002, 25(1): 59.

DOI URL |

| [36] | ZHANG B, PEI X, SONG P, et al. Porous bioceramics produced by inkjet 3D printing: effect of printing ink formulation on the ceramic macro and micro porous architectures control. Composites Part B: Engineering, 2018, 155: 112. |

| [37] |

HOLMAN R K, UHLAND S A, CIMA M J, et al. Surface adsorption effects in the inkjet printing of an aqueous polymer solution on a porous oxide ceramic substrate. Journal of Colloid and Interface Science, 2002, 247(2): 266.

PMID |

| [38] | RABINSKIY L, RIPETSKY A, SITNIKOV S, et al.Fabrication of porous silicon nitride ceramics using binder jetting technology. IOP Conference Series: Materials Science and Engineering, 2016: 012023. |

| [39] |

MUNIZ N O, VECHIETTI F A, DOS SANTOS L A L. Influence of several binders on the mechanical properties of alumina parts manufactured by 3D inkjet printing. Materials Research Express, 2019, 6(11): 115341.

DOI URL |

| [40] |

MINAS C, CARNELLI D, TERVOORT E, et al. 3D printing of emulsions and foams into hierarchical porous ceramics. Advanced Materials, 2016, 28(45): 9993.

DOI URL |

| [41] |

JIN H, YANG Z, LI H, et al. Fabrication of Si2N2O ceramic foam by combination of direct ink writing and biological foaming techniques. Advanced Engineering Materials, 2020, 22(4): 1901541.

DOI URL |

| [42] |

WANG L, FENG J, LUO Y, et al. Versatile thermal-solidifying direct-write assembly towards heat-resistant 3D-printed ceramic aerogels for thermal insulation. Small Methods, 2022, 6(5): 2200045.

DOI URL |

| [43] |

LEWIS J A. Direct ink writing of 3D functional materials. Advanced Functional Materials, 2006, 16(17): 2193.

DOI URL |

| [44] |

LEWIS J A, SMAY J E, STUECKER J, et al. Direct ink writing of three-dimensional ceramic structures. Journal of the American Ceramic Society, 2006, 89(12): 3599.

DOI URL |

| [45] |

CESARANO J, GRIECO S. Robocasting: a new technique for the freeform fabrication of near-net-shape ceramics. Materials Technology, 1997, 12(3/4): 98.

DOI URL |

| [46] |

NEUMANN T V, DICKEY M D. Liquid metal direct write and 3D printing: a review. Advanced Materials Technologies, 2020, 5(9): 2000070.

DOI URL |

| [47] |

LIU N, SUN X, CHEN Z, et al. Direct ink writing of dense alumina ceramics prepared by rapid sintering. Ceramics International, 2022, 48(20): 30767.

DOI URL |

| [48] | LIU Q, ZHAI W. Hierarchical porous ceramics with distinctive microstructures by emulsion-based direct ink writing. ACS Applied Materials & Interfaces, 2022, 14(28): 32196. |

| [49] | ROOPAVATH U K, MALFERRARI S, VAN HAVER A, et al. Optimization of extrusion based ceramic 3D printing process for complex bony designs. Materials & Design, 2019, 162: 263. |

| [50] | WANG L, FENG J, LUO Y, et al. Three-dimensional-printed silica aerogels for thermal insulation by directly writing temperature- induced solidifiable inks. ACS Applied Materials & Interfaces, 2021, 13(34): 40964. |

| [51] |

LI Z, LI J, LUO H, et al. Direct ink writing of 3D piezoelectric ceramics with complex unsupported structures. Journal of the European Ceramic Society, 2022, 42(9): 3841.

DOI URL |

| [52] | TROKSA A L, ESHELMAN H V, CHANDRASEKARAN S, et al. 3D-printed nanoporous ceramics: tunable feedstock for direct ink write and projection microstereolithography. Materials & Design, 2021, 198: 109337. |

| [53] | HUANG K, ELSAYED H, FRANCHIN G, et al. 3D printing of polymer-derived SiOC with hierarchical and tunable porosity. Additive Manufacturing, 2020, 36: 101549. |

| [54] |

YARAHMADI M, ROA J, ZHANG J, et al. Micromechanical properties of yttria-doped zirconia ceramics manufactured by direct ink writing. Journal of the European Ceramic Society, 2022, 43(7): 2884.

DOI URL |

| [55] |

YARAHMADI M, BARCELONA P, FARGAS G, et al. Optimization of the ceramic ink used in direct ink writing through rheological properties characterization of zirconia-based ceramic materials. Ceramics International, 2022, 48(4): 4775.

DOI URL |

| [56] |

ÁLVAREZ F, CIFUENTES A, SERRANO I, et al. Optimization of the sintering thermal treatment and the ceramic ink used in direct ink writing of α-Al2O3: characterization and catalytic application. Journal of the European Ceramic Society, 2022, 42(6): 2921.

DOI URL |

| [57] |

MA S, LIU X, FU S, et al. Direct ink writing of porous SiC ceramics with geopolymer as binder. Journal of the European Ceramic Society, 2022, 42(15): 6815.

DOI URL |

| [58] | SCHAFFNER M, FABER J A, PIANEGONDA L, et al. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nature Communications, 2018, 9: 878. |

| [59] | M’BARKI A, BOCQUET L, STEVENSON A. Linking rheology and printability for dense and strong ceramics by direct ink writing. Scientific Reports, 2017, 7: 6017. |

| [60] |

SMAY J E, CESARANO J, LEWIS J A. Colloidal inks for directed assembly of 3-D periodic structures. Langmuir, 2002, 18(14): 5429.

DOI URL |

| [61] |

REBBER M, TROMMLER M, LOKTEVA I, et al. Additive-free, gelled nanoinks as a 3D printing toolbox for hierarchically structured bulk aerogels. Advanced Functional Materials, 2022, 32(19): 2112914.

DOI URL |

| [62] |

HE P, TANG X, CHEN L, et al. Patterned carbon nitride-based hybrid aerogel membranes via 3D printing for broadband solar wastewater remediation. Advanced Functional Materials, 2018, 28(29): 1801121.

DOI URL |

| [63] | OLIVEIRA R L, ALVES A P, BARBOSA L, et al. 3D printing of bioactive glass S53P4/sodium alginate sintering-free scaffolds. Bioprinting, 2022, 27: e00226. |

| [64] |

MENSHUTINA N, ABRAMOV A, TSYGANKOV P, et al. Extrusion-based 3D printing for highly porous alginate materials production. Gels, 2021, 7(3): 92.

DOI URL |

| [65] | SUN H, HU C, ZHOU C, et al. 3D printing of calcium phosphate scaffolds with controlled release of antibacterial functions for jaw bone repair. Materials & Design, 2020, 189: 108540. |

| [66] |

LIU G, YAN Y. Research progress of porous ceramics produced by freeze casting technique. Journal of Inorganic Materials, 2014, 29(6): 571.

DOI |

| [67] | 刘晓光, 薛文东, 李妍, 等. 快速冷冻干燥法制备多孔氧化硅陶瓷. 人工晶体学报, 2016, 45(1): 35. |

| [68] |

RENTERIA A, DIAZ J A, HE B, et al. Particle size influence on material properties of BaTiO3 ceramics fabricated using freeze- form extrusion 3D printing. Materials Research Express, 2019, 6(11): 115211.

DOI URL |

| [69] |

LI F, ZHAO L, DANG W, et al. Pore structure and thermal oxidation curing behavior of porous polymer derived ceramics with superhigh porosity fabricated by freeze casting. Ceramics International, 2021, 47(22): 31114.

DOI URL |

| [70] |

MOON Y W, CHOI I J, KOH Y H, et al. Porous alumina ceramic scaffolds with biomimetic macro/micro-porous structure using three- dimensional (3-D) ceramic/camphene-based extrusion. Ceramics International, 2015, 41(9): 12371.

DOI URL |

| [71] |

YOON B H, CHOI W Y, KIM H E, et al. Aligned porous alumina ceramics with high compressive strengths for bone tissue engineering. Scripta Materialia, 2008, 58(7): 537.

DOI URL |

| [72] |

CHEN R, WANG C A, HUANG Y, et al. Ceramics with special porous structures fabricated by freeze-gelcasting: using tert-butyl alcohol as a template. Journal of the American Ceramic Society, 2007, 90(11): 3478.

DOI URL |

| [73] |

TOMECKOVA V, HALLORAN J W. Porous ceramics by photopolymerization with terpene-acrylate vehicles. Journal of the American Ceramic Society, 2012, 95(12): 3763.

DOI URL |

| [74] |

SOFIE S W, DOGAN F. Freeze casting of aqueous alumina slurries with glycerol. Journal of the American Ceramic Society, 2001, 84(7): 1459.

DOI URL |

| [75] |

DE HAZAN Y, THÄNERT M, TRUNEC M, et al. Robotic deposition of 3D nanocomposite and ceramic fiber architectures via UV curable colloidal inks. Journal of the European Ceramic Society, 2012, 32(6): 1187.

DOI URL |

| [76] |

MAENG W Y, JEON J W, LEE J B, et al. Photocurable ceramic/ monomer feedstocks containing terpene crystals as sublimable porogen for UV curing-assisted 3D plotting. Journal of the European Ceramic Society, 2020, 40(9): 3469.

DOI URL |

| [77] |

MAENG W Y, LEE J B, KOH Y H, et al. Innovative in situ photocuring-assisted 3D plotting technique for complex-shaped ceramic architectures with high shape retention. Ceramics International, 2019, 45(7): 8440.

DOI URL |

| [78] |

JONHSON W, XU X, BIAN K, et al. 3D-printed hierarchical ceramic architectures for ultrafast emulsion treatment and simultaneous oil-water filtration. ACS Materials Letters, 2022, 4(4): 740.

DOI URL |

| [79] | JONHSON W, XU X, ZHANG D, et al. Fabrication of 3D-printed ceramic structures for portable solar desalination devices. ACS Applied Materials & Interfaces, 2021, 13(19): 23220. |

| [80] | WANG L, FENG J, JIANG Y, et al. Ultraviolet-assisted direct- write printing strategy towards polyorganosiloxane-based aerogels with freeform geometry and outstanding thermal insulation performance. Chemical Engineering Journal, 2022, 455: 140818. |

| [81] | XU X, YANG J, JONHSON W, et al. Additive manufacturing solidification methodologies for ink formulation. Additive Manufacturing, 2022, 56: 102939. |

| [82] | 孟继智, 李娟娟, 石友昌, 等. SiO2气凝胶干燥技术的研究进展. 化工科技, 2016, 24(2): 73. |

| [83] |

FU R, ZHENG B, LIU J, et al. The fabrication and characterization of carbon aerogels by gelation and supercritical drying in isopropanol. Advanced Functional Materials, 2003, 13(7): 558.

DOI URL |

| [84] | GARCÍA-GONZÁLEZ C A, CAMINO-REY M, ALNAIEF M, et al. Supercritical drying of aerogels using CO2: effect of extraction time on the end material textural properties. The Journal of Supercritical Fluids, 2012, 66: 297. |

| [85] | 王鲁凯.双交联聚有机硅氧烷气凝胶的制备及其性能研究. 长沙: 国防科技大学硕士学位论文, 2019. |

| [86] |

LI Z, XU M, WANG J, et al. Recent advances in cryogenic 3D printing technologies. Advanced Engineering Materials, 2022, 24(10): 2200245.

DOI URL |

| [87] | SIMóN-HERRERO C, CAMINERO-HUERTAS S, ROMERO A, et al. Effects of freeze-drying conditions on aerogel properties. Journal of Materials Science, 2016, 51: 8977. |

| [88] | OIKONOMOPOULOU V P, KROKIDA M K, KARATHANOS V T. The influence of freeze drying conditions on microstructural changes of food products. Procedia Food Science, 2011, 1: 647. |

| [89] |

GUO Z, AN L, LAKSHMANAN S, et al. Additive manufacturing of porous ceramics with foaming agent. Journal of Manufacturing Science and Engineering, 2022, 144(2): 021010.

DOI URL |

| [90] |

DEE P, TAN S, LE FERRAND H. Fabrication of microstructured calcium phosphate ceramics scaffolds by material extrusion-based 3D printing approach. International Journal of Bioprinting, 2022, 8(2): 551.

DOI PMID |

| [91] |

JIN H, YANG Z, ZHONG J, et al. Mechanical and dielectric properties of 3D printed highly porous ceramics fabricated via stable and durable gel ink. Journal of the European Ceramic Society, 2019, 39(15): 4680.

DOI URL |

| [92] |

SESSO M L, SLATER S, THORNTON J, et al. Direct ink writing of hierarchical porous ultra-high temperature ceramics (ZrB2). Journal of the American Ceramic Society, 2021, 104(10): 4977.

DOI URL |

| [93] |

PUTZ F, SCHERER S, OBER M, et al. 3D printing of hierarchical porous silica and α-quartz. Advanced Materials Technologies, 2018, 3(7): 1800060.

DOI URL |

| [94] |

KEMP J W, HMEIDAT N S, COMPTON B G. Boron nitride- reinforced polysilazane-derived ceramic composites via direct-ink writing. Journal of the American Ceramic Society, 2020, 103(8): 4043.

DOI URL |

| [95] |

MUTH J T, DIXON P G, WOISH L, et al. Architected cellular ceramics with tailored stiffness via direct foam writing. Proceedings of the National Academy of Sciences, 2017, 114(8): 1832.

DOI URL |

| [96] |

CHAN S S, SESSO M L, FRANKS G V. Direct ink writing of hierarchical porous alumina-stabilized emulsions: rheology and printability. Journal of the American Ceramic Society, 2020, 103(10): 5554.

DOI URL |

| [97] |

ALENI A H, KRETZSCHMAR N, JANSSON A, et al. 3D printing of dense and porous TiO2 structures. Ceramics International, 2020, 46(10): 16725.

DOI URL |

| [98] |

REN B, LIU J, WANG Y, et al. Hierarchical cellular scaffolds fabricated via direct foam writing using gelled colloidal particle- stabilized foams as the ink. Journal of the American Ceramic Society, 2019, 102(11): 6498.

DOI URL |

| [99] |

ZHANG X, HUO W, LIU J, et al. 3D printing boehmite gel foams into lightweight porous ceramics with hierarchical pore structure. Journal of the European Ceramic Society, 2020, 40(3): 930.

DOI URL |

| [100] |

ZHANG G, CHEN H, YANG S, et al. Frozen slurry-based laminated object manufacturing to fabricate porous ceramic with oriented lamellar structure. Journal of the European Ceramic Society, 2018, 38(11): 4014.

DOI URL |

| [101] |

WANG H, LI X D, YU J S, et al. Fabrication and characterization of ordered macroporous PMS-derived SiC from a sacrificial template method. Journal of Materials Chemistry, 2004, 14(9): 1383.

DOI URL |

| [102] | WANG H, SUNG I, LI X, et al. Fabrication of porous SiC ceramics with special morphologies by sacrificing template method. Journal of Porous Materials, 2004, 11: 265. |

| [103] |

KUMAR B M, KIM Y W. Processing of polysiloxane-derived porous ceramics: a review. Science and Technology of Advanced Materials, 2010, 11(4): 044303.

DOI URL |

| [104] | YANG G, GUAN R, ZHEN H, et al. Tunable size of hierarchically porous alumina ceramics based on DIW 3D printing supramolecular gel. ACS Applied Materials & Interfaces, 2022, 14(8): 10998. |

| [105] |

ZHAO S, SIQUEIRA G, DRDOVA S, et al. Additive manufacturing of silica aerogels. Nature, 2020, 584(7821): 387.

DOI |

| [106] | FARRELL E S, GANONYAN N, COOPERSTEIN I, et al. 3D- printing of ceramic aerogels by spatial photopolymerization. Applied Materials Today, 2021, 24: 101083. |

| [107] |

张伟蒙, 汪杰, 胡晶. 3D打印骨组织支架孔隙结构对支架性能影响的研究进展. 中国塑料, 2022, 36(12): 155.

DOI |

| [108] |

YU W, SUN X, MENG H, et al. 3D printed porous ceramic scaffolds for bone tissue engineering: a review. Biomaterials Science, 2017, 5(9): 1690.

DOI PMID |

| [109] |

FENG Y, ZHU S, MEI D, et al. Application of 3D printing technology in bone tissue engineering: a review. Current Drug Delivery, 2021, 18(7): 847.

DOI PMID |

| [110] | HALEEM A, JAVAID M, KHAN R H, et al. 3D printing applications in bone tissue engineering. Journal of Clinical Orthopaedics and Trauma, 2020, 11: S118. |

| [111] | KANWAR S, VIJAYAVENKATARAMAN S. Design of 3D printed scaffolds for bone tissue engineering: a review. Bioprinting, 2021, 24: e00167. |

| [112] |

SHAO H, SUN M, ZHANG F, et al. Custom repair of mandibular bone defects with 3D printed bioceramic scaffolds. Journal of Dental Research, 2018, 97(1): 68.

DOI PMID |

| [113] |

ZOCCA A, FRANCHIN G, ELSAYED H, et al. Direct ink writing of a preceramic polymer and fillers to produce hardystonite (Ca2ZnSi2O7) bioceramic scaffolds. Journal of the American Ceramic Society, 2016, 99(6): 1960.

DOI URL |

| [114] |

ELSAYED H, GARDIN C, FERRONI L, et al. Highly porous Sr/Mg-doped hardystonite bioceramics from preceramic polymers and reactive fillers: direct foaming and direct ink writing. Advanced Engineering Materials, 2019, 21(6): 1800900.

DOI URL |

| [115] | LIU D, JIANG P, LI X, et al. 3D printing of metal-organic frameworks decorated hierarchical porous ceramics for high-efficiency catalytic degradation. Chemical Engineering Journal, 2020, 397: 125392. |

| [116] | HOSLETT J, MASSARA T M, MALAMIS S, et al. Surface water filtration using granular media and membranes: a review. Science of the Total Environment, 2018, 639: 1268. |

| [117] | LI N, LU X, HE M, et al. Catalytic membrane-based oxidation- filtration systems for organic wastewater purification: a review. Journal of Hazardous Materials, 2021, 414: 125478. |

| [118] | NADAGOUDA M N, GINN M, RASTOGI V. A review of 3D printing techniques for environmental applications. Current Opinion in Chemical Engineering, 2020, 28: 173. |

| [119] |

GHOSAL P, GUPTA B, AMBEKAR R S, et al. 3D printed materials in water treatment applications. Advanced Sustainable Systems, 2022, 6(3): 2100282.

DOI URL |

| [120] | JIN Z, MEI H, LIU H, et al. High-strength, superhydrophilic/ underwater superoleophobic multifunctional ceramics for high efficiency oil-water separation and water purification. Materials Today Nano, 2022, 18: 100199. |

| [121] | LIU K, ZHANG Q, ZHOU C, et al. 4D printing of lead zirconate titanate piezoelectric composites transducer based on direct ink writing. Frontiers in Materials, 2021, 8: 659441. |

| [122] |

NAN B, ZANG J D, LU W L, et al. Recent progress on additive manufacturing of piezoelectric ceramics. Journal of Inorganic Materials, 2022, 37(6): 585.

DOI |

| [123] |

LIU K, SUN C, SHI Y S, et al. Current status and prospect of additive manufacturing piezoceramics. Journal of Inorganic Materials, 2022, 37(3): 278

DOI |

| [124] |

TUTTLE B A, SMAY J E, CESARANO J, et al. Robocast Pb (Zr0.95Ti0.05)O3 ceramic monoliths and composites. Journal of the American Ceramic Society, 2001, 84(4): 872.

DOI URL |

| [125] |

WALTON R L, BROVA M J, WATSON B H, et al. Direct writing of textured ceramics using anisotropic nozzles. Journal of the European Ceramic Society, 2021, 41(3): 1945.

DOI URL |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 余艺平, 肖鹏, 赵长浩, 徐梦迪, 姚立冬, 李伟, 王松. 耐高温层状Ta/Ta0.5Hf0.5C金属陶瓷的高频等离子体风洞烧蚀行为研究[J]. 无机材料学报, 2025, 40(7): 790-798. |

| [3] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [4] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [5] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [6] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [7] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [8] | 唐莹, 李洁, 相怀成, 方维双, 林慧兴, 杨俊峰, 方亮. Rattling效应: 一种影响微波介质陶瓷谐振频率温度系数的新机制[J]. 无机材料学报, 2025, 40(6): 656-666. |

| [9] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [10] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [11] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [12] | 周阳阳, 张艳艳, 于子怡, 傅正钱, 许钫钫, 梁瑞虹, 周志勇. 通过Bi3+自掺杂增强CaBi4Ti4O15基陶瓷压电性能[J]. 无机材料学报, 2025, 40(6): 719-728. |

| [13] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [14] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [15] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||