无机材料学报 ›› 2026, Vol. 41 ›› Issue (3): 359-369.DOI: 10.15541/jim20250275 CSTR: 32189.14.10.15541/jim20250275

张韵铂( ), 王兵(

), 王兵( ), 李威, 宋曲之, 杜贻昂, 王应德

), 李威, 宋曲之, 杜贻昂, 王应德

收稿日期:2025-06-30

修回日期:2025-09-10

出版日期:2025-09-11

网络出版日期:2025-09-11

通讯作者:

王 兵, 副研究员. E-mail: bingwang@nudt.edu.cn作者简介:张韵铂(1999-), 女, 博士研究生. E-mail: yunbozhangzyb@163.com

基金资助:

ZHANG Yunbo( ), WANG Bing(

), WANG Bing( ), LI Wei, SONG Quzhi, DU Yi’ang, WANG Yingde

), LI Wei, SONG Quzhi, DU Yi’ang, WANG Yingde

Received:2025-06-30

Revised:2025-09-10

Published:2025-09-11

Online:2025-09-11

Contact:

WANG Bing, associate professor. E-mail: bingwang@nudt.edu.cnAbout author:ZHANG Yunbo (1999-), female, PhD candidate. E-mail: yunbozhangzyb@163.com

Supported by:摘要:

BN陶瓷纤维因其优异的耐高温、导热和透波性能, 在高温透波及半导体领域具有广泛的应用前景。但目前制备得到的BN陶瓷纤维结晶度较低, 无法充分展现h-BN晶体结构所具有的优异性能。本工作基于BN纳米片(BNNS)作为异质成核剂能够加速基底材料结晶的机制, 采用一步球磨法制备了三种横向尺寸(0.5、2、4 μm)的氨基功能化BNNS; 再通过化学键合方式将氨基功能化的BNNS接枝至聚硼氮烷先驱体分子链中, 制备了BNNS/聚硼氮烷杂化先驱体, 最终转化为高结晶、高强度BN陶瓷纤维。本工作详细探究了BNNS横向尺寸对先驱体分子结构、理化性能及纺丝性能的影响, 探索了BNNS横向尺寸-BN陶瓷纤维微结构-BN陶瓷纤维力学性能三者间的构效关系。结果表明, 增大BNNS尺寸能够提高先驱体陶瓷产率(最高可达64.1%), 但同时会破坏先驱体熔融纺丝稳定性。研究发现, 改变BNNS尺寸能够有效调控最终陶瓷纤维晶体结构, 改善纤维力学性能。BNNS尺寸与最终BN陶瓷纤维的结晶度、晶粒尺寸及其力学性能不呈线性关系。虽然BNNS造成纤维表面凸起, 导致含2 μm BNNS的BN陶瓷纤维平均拉伸强度(0.90 GPa)略低, 但其结晶度(94%)、h-BN晶粒尺寸(12.5 nm)以及密度(2.00 g/cm3)均达到最高。0.5 μm BNNS接枝的BN陶瓷纤维因兼具较高的结晶度(90%)和光滑的纤维表面, 表现出最出色的力学强度(平均拉伸强度0.94 GPa)。本工作为后续精细化调控纤维微结构以及制备高性能BN陶瓷纤维提供了重要的参考价值。

中图分类号:

张韵铂, 王兵, 李威, 宋曲之, 杜贻昂, 王应德. BNNS/聚硼氮烷杂化先驱体转化BN纤维中的纳米片尺寸效应[J]. 无机材料学报, 2026, 41(3): 359-369.

ZHANG Yunbo, WANG Bing, LI Wei, SONG Quzhi, DU Yi’ang, WANG Yingde. Size Effect of Nanosheet on BN Fibers Derived from BNNS/Polyborazine Hybrid Precursor[J]. Journal of Inorganic Materials, 2026, 41(3): 359-369.

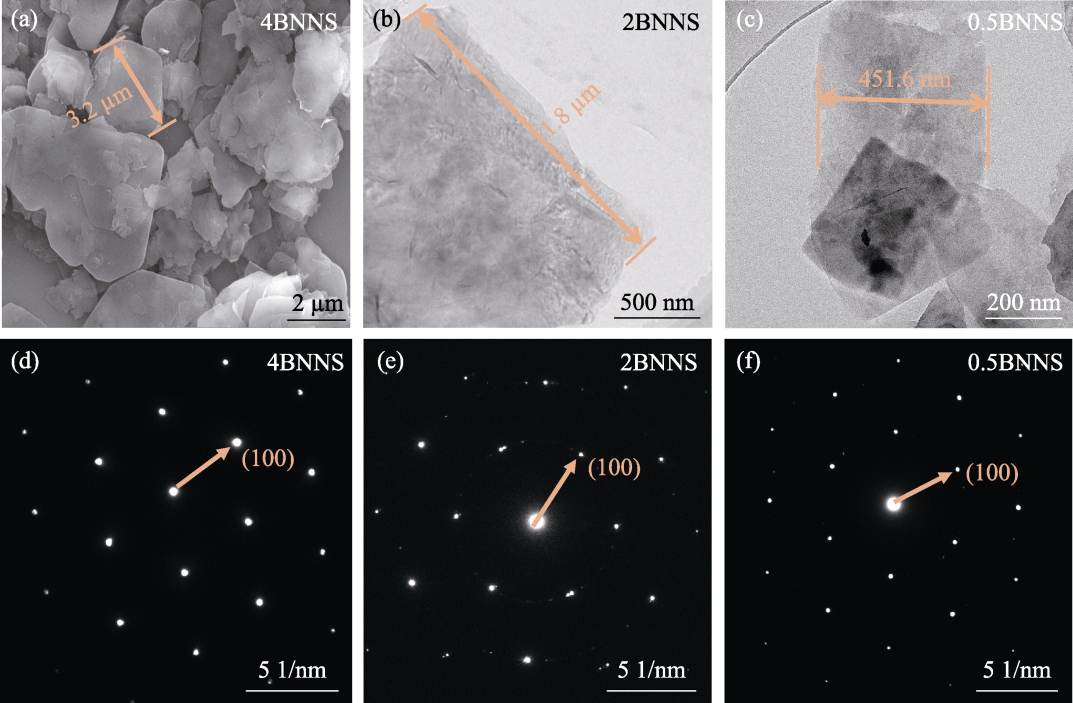

图2 不同横向尺寸BNNS的形貌及晶体结构

Fig. 2 Morphologies and crystal structures of BNNSs with different lateral sizes (a) SEM image of 4BNNS; (b, c) HRTEM images of (b) 2BNNS and (c) 0.5BNNS; (d-f) SAED patterns of 4BNNS, 2BNNS and 0.5BNNS

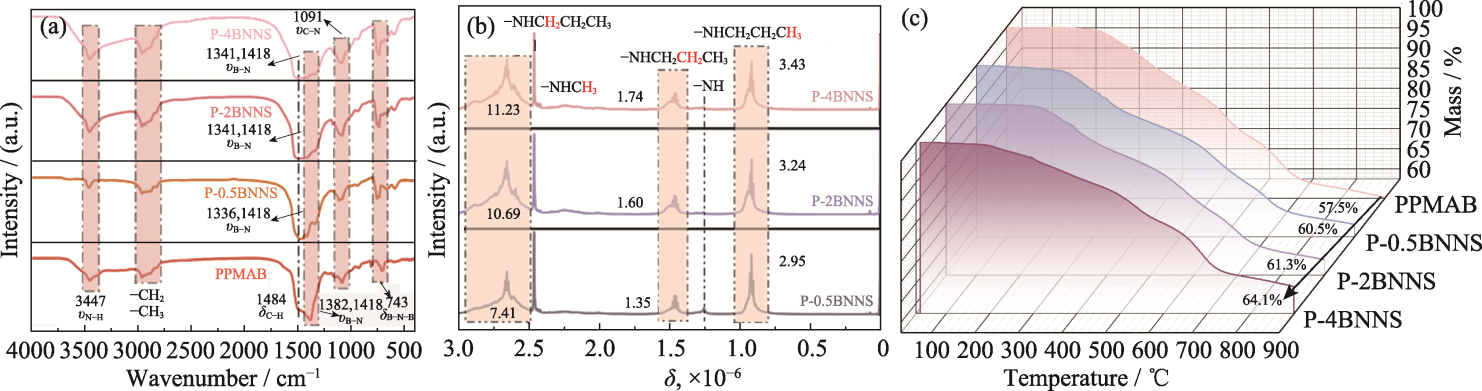

图3 不同横向尺寸BNNS接枝的P-BNNS分子结构及陶瓷产率

Fig. 3 Molecular structures and ceramic yields of P-BNNS grafted by BNNSs with different lateral sizes (a) FT-IR spectra; (b) 1H-NMR spectra; (c) Ceramic yields

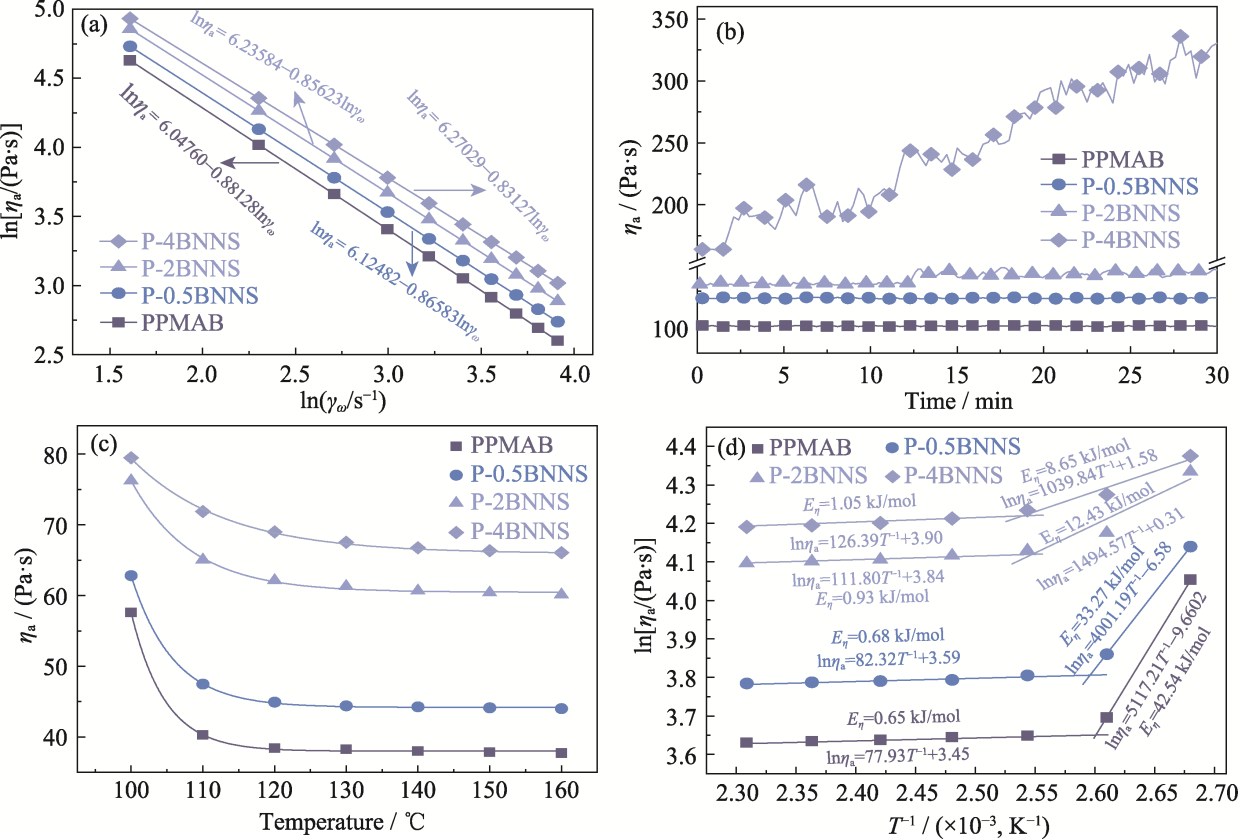

图4 PPMAB及接枝不同横向尺寸BNNS的杂化先驱体的流变性能

Fig. 4 Rheological properties of PPMAB and hybrid precursors grafted by BNNSs with different lateral sizes (a) Fitting curves of apparent viscosity (ηa) and shear rate (γω) at 140 ℃; (b) Apparent viscosity-time curves at 130 ℃; (c) Apparent viscosity-temperature curves; (d) Andrade equation fitting curves

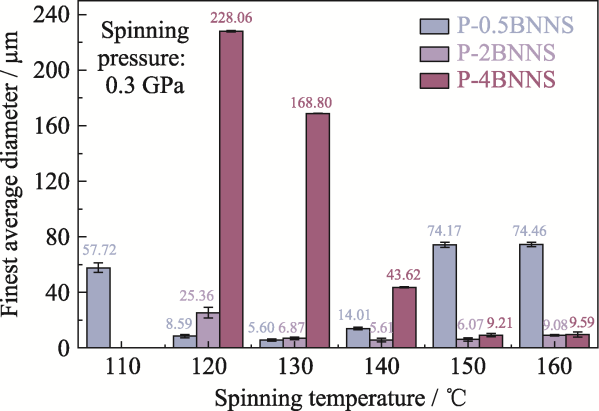

图5 0.3 GPa下P-4BNNS、P-2BNNS、P-0.5BNNS所纺原纤维在不同纺丝温度下的平均直径

Fig. 5 Average diameters of green fibers spun by P-4BNNS, P-2BNNS and P-0.5BNNS at different spinning temperatures and 0.3 GPa Colorful figure is available on website

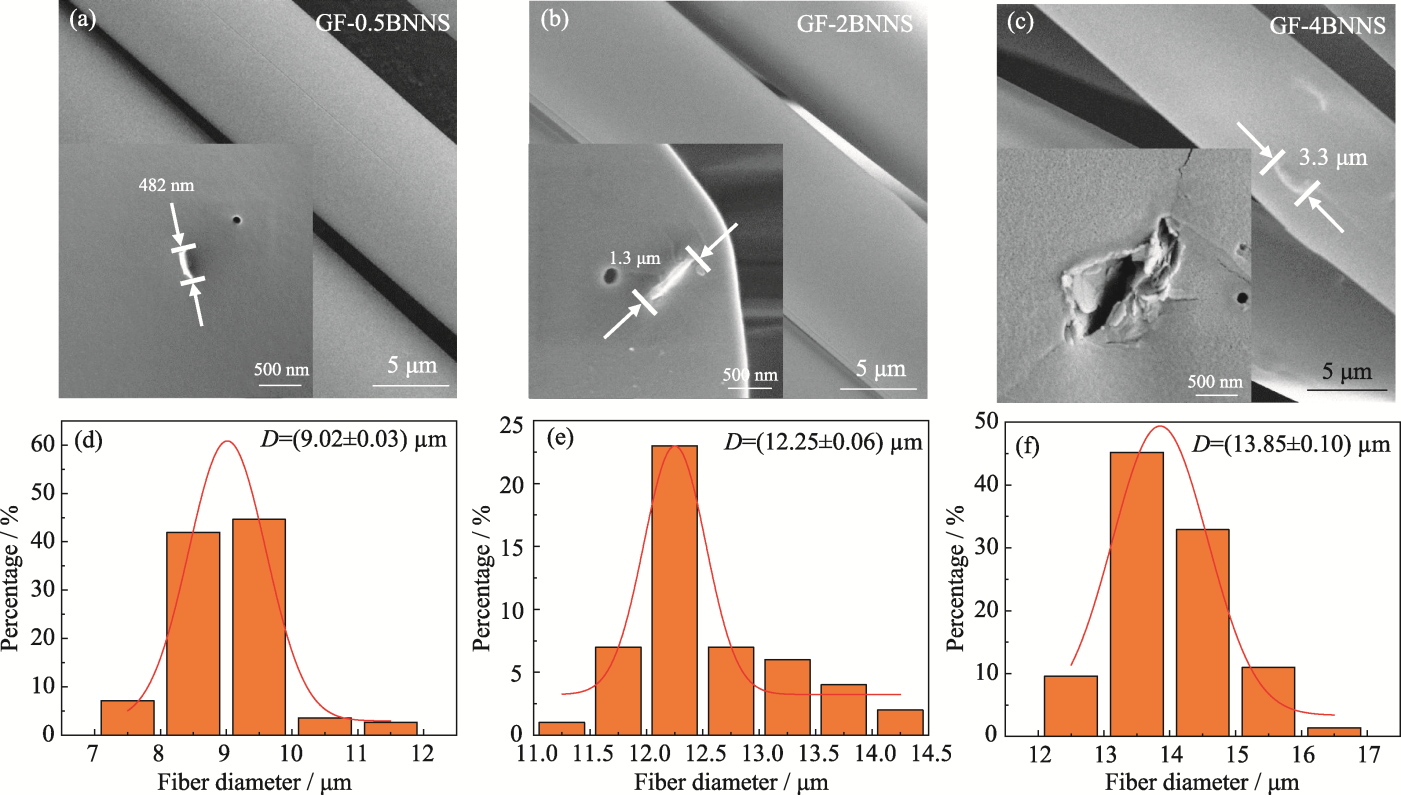

图6 三种杂化先驱体所纺原纤维的微观形貌及直径尺寸分布

Fig. 6 Morphologies and corresponding diameter distributions of green fibers spun by three hybrid precursors (a-c) SEM images; (d-f) Diameter distributions

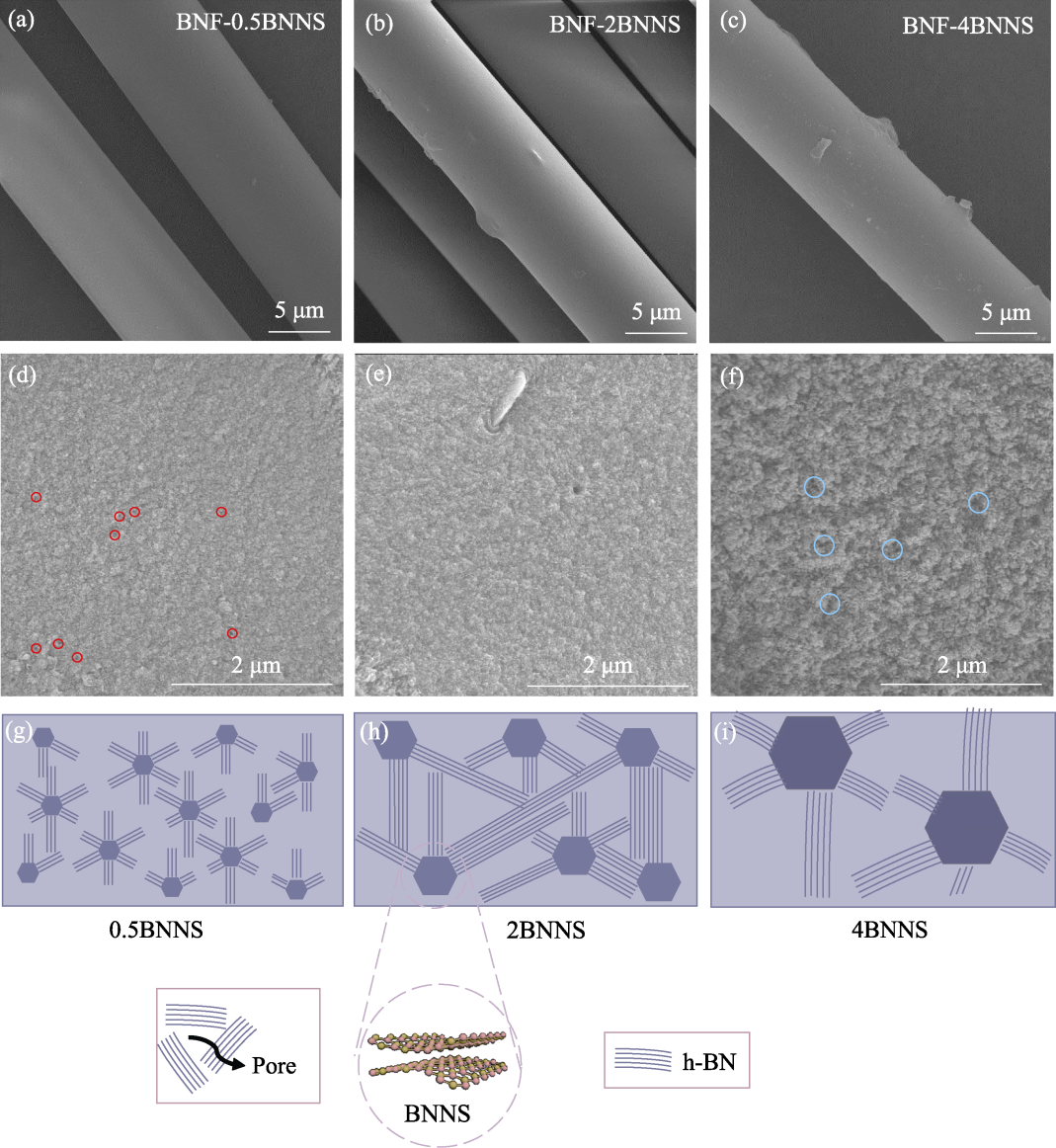

图7 相同条件下不同杂化先驱体制备BN陶瓷纤维的表面及截面形貌及不同横向尺寸BNNS诱导纤维内部晶粒排列示意图

Fig. 7 Surface and cross-section morphologies of BN ceramic fibers derived from different hybrid precursors under the same conditions and schematic diagrams of internal grain arrangement induced by BNNSs with different lateral sizes (a-f) BN ceramic fibers derived from (a, d) P-0.5BNNS, (b, e) P-2BNNS and (c, f) P-4BNNS; (g-i) Schematics of the relationship between BNNS size and crystal structure of BN ceramic fibers

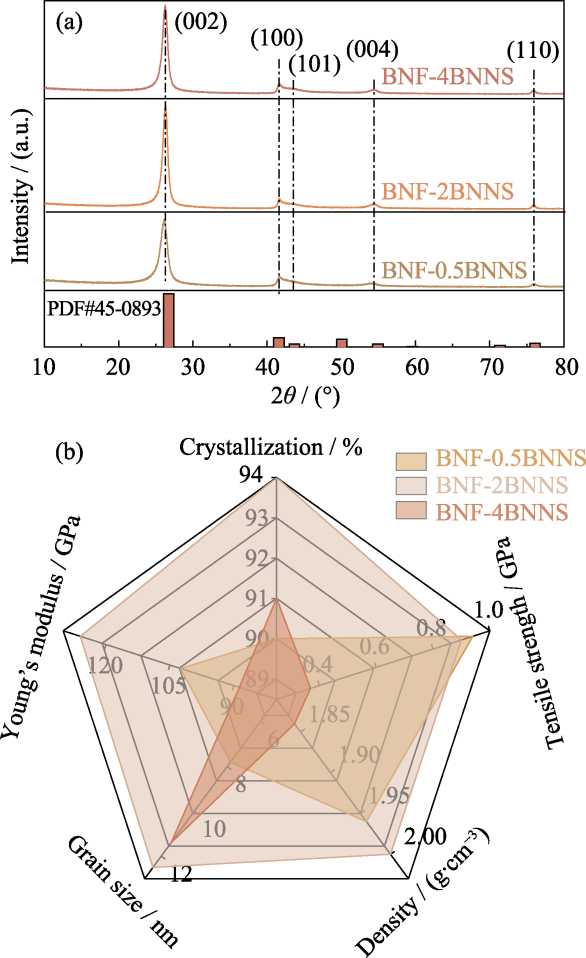

图8 接枝不同横向尺寸BNNS的BN陶瓷纤维的晶体结构及力学性能

Fig. 8 Crystal structures and mechanical properties of BN ceramic fibers grafted by BNNSs with different lateral sizes (a) XRD patterns; (b) Radar chart of crystallinity, grain size, mechanical strength and density. Colorful figures are available on website

| Sample | Crystallinity/% | Grain size/nm | I(002)/I(100) | Density/(g·cm-3) | Tensile strength/GPa | Young’s modulus/GPa |

|---|---|---|---|---|---|---|

| BNF-0.5BNNS | 90 | 7.8 | 5.86 | 1.96 | 0.94 | 102.5 |

| BNF-2BNNS | 94 | 12.5 | 8.97 | 2.00 | 0.90 | 126.0 |

| BNF-4BNNS | 91 | 11.4 | 7.67 | 1.84 | 0.37 | 88.7 |

表S1 接枝不同横向尺寸BNNS的BN陶瓷纤维晶体结构及力学性能

Table S1 Crystal structures and mechanical properties of BN ceramic fibers grafted by BNNS with different lateral sizes

| Sample | Crystallinity/% | Grain size/nm | I(002)/I(100) | Density/(g·cm-3) | Tensile strength/GPa | Young’s modulus/GPa |

|---|---|---|---|---|---|---|

| BNF-0.5BNNS | 90 | 7.8 | 5.86 | 1.96 | 0.94 | 102.5 |

| BNF-2BNNS | 94 | 12.5 | 8.97 | 2.00 | 0.90 | 126.0 |

| BNF-4BNNS | 91 | 11.4 | 7.67 | 1.84 | 0.37 | 88.7 |

| Sample | Shape parameter (β) | Scale parameter (η)/GPa |

|---|---|---|

| BNF-0.5BNNS | 4.92 | 1.05 |

| BNF-2BNNS | 4.69 | 0.99 |

| BNF-4BNNS | 5.50 | 0.42 |

表S2 三种BN陶瓷纤维拉伸强度的双参数Weibull方程参数

Table S2 Two-parameter Weibull equation of tensile strength for three BN ceramic fibers

| Sample | Shape parameter (β) | Scale parameter (η)/GPa |

|---|---|---|

| BNF-0.5BNNS | 4.92 | 1.05 |

| BNF-2BNNS | 4.69 | 0.99 |

| BNF-4BNNS | 5.50 | 0.42 |

| [1] | NACLERIO A E E, KIDAMBI P R R. A review of scalable hexagonal boron nitride (h-BN) synthesis for present and future applications. Advanced Materials, 2023, 35(6): 2207374. |

| [2] | WANG B, CAI D, ZHU Q, et al. Mechanical properties and thermal shock resistance of SrAl2Si2O8 reinforced BN ceramic composites. Journal of Inorganic Materials, 2024, 39(10): 1182. |

| [3] | AN L, YU Y, CAI Q, et al. Hexagonal boron nitride nanosheets: preparation, heat transport property and application as thermally conductive fillers. Progress in Materials Science, 2023, 138: 101154. |

| [4] | LIN S, YE F, MA J, et al. Fabrication and properties of porous boron nitride/silicon oxynitride ceramic composites via gas pressure sintering. Materials & Design, 2015, 87: 272. |

| [5] | LIAO P, HE H, GUO H, et al. Highly thermally conductive boron nitride fiber. ACS Nano, 2025, 19(16): 16043. |

| [6] | WANG Z, GE M, YU S, et al. Microstructures and properties of polymer-derived hexagonal boron nitride fibers with initial gradient oxygen contents. Materials Characterization, 2024, 207: 113503. |

| [7] | ZOU C, GUO S, ZHOU X. Mechanical property and fracture behavior of borazine-derived bulk boron nitride ceramics reinforced with chopped Si3N4 fiber. Journal of Materials Engineering and Performance, 2025, 34(6): 4821. |

| [8] | MIELE P, BERNARD S, CORNU D, et al. Recent developments in polymer-derived ceramic fibers (PDCFs): preparation, properties and applications-a review. Soft Materials, 2007, 4(2/3/4): 249. |

| [9] | DENG C, SONG Y, WANG Y, et al. Synthesis of polymeric precursor for boron nitride through substitution reaction of methylamine/dimethylamine. Acta Chimica Sinica, 2010, 68(12): 1217. |

| [10] | HOSSAIN A, SOUVIGNET T, INNIS N R, et al. Two-step ALD process for non-oxide ceramic deposition: the example of boron nitride. Journal of Physics: Materials, 2024, 7(3): 035006. |

| [11] | TOURY B, MIELE P, CORNU D, et al. Boron nitride fibers prepared from symmetric and asymmetric alkylaminoborazines. Advanced Functional Materials, 2002, 12(3): 228. |

| [12] | LEI Y, WANG Y, SONG Y. Atmosphere influence in the pyrolysis of poly (alkylamino)borazine for the production of BN fibers. Ceramics International, 2013, 39(6): 6847. |

| [13] | LI W, WANG J, XIE Z, et al. Synthesis and characterization of silicon-containing polyborazine to boron nitride ceramic fiber. Acta Chimica Sinica, 2011, 69(16): 1936. |

| [14] | DU Y, WANG B, MENG F, et al. Nearly stoichiometric BN fiber with high crystallinity achieved by boron trichloride assisted curing process. Journal of the American Ceramic Society, 2022, 105(1): 82. |

| [15] | LIU Y, PAN Y, YIN D, et al. Investigations on microstructure and mechanical properties of boron nitride fiber using experimental and numerical methods. Materials Today Communications, 2022, 33: 104554. |

| [16] | BERNARD S, CHASSAGNEUX F, BERTHET M P, et al. Crystallinity, crystalline quality, and microstructural ordering in boron nitride fibers. Journal of the American Ceramic Society, 2005, 88(6): 1607. |

| [17] | RAJABIFAR N, GHANEMI S, ROSTAMI A, et al. Synergistic impact of hybrid carbon nanotube and graphene on crystallinity and thermo-mechanical behavior of polymer blends. Polymer Composites, 2025, 46(2): 1416. |

| [18] | SALEHI A, RAHMATI R, KHERADMANDKEYSOMI M, et al. Carbon nanotubes embedded in nanofibrillated EPDM rubber as thermally and electronically conducting polypropylene nanocomposites for flexible electrostatic discharging. ACS Applied Nano Materials, 2025, 8(8): 3847. |

| [19] | MANDAL S, ROY D, MUKHOPADHYAY K, et al. Mechanistic insight into the role of the aspect ratio of nanofillers in the gas barrier properties of polymer nanocomposite thin films. RSC Applied Interfaces, 2024, 1(5): 977. |

| [20] | FENG L, GUO L, CHEN Q, et al. Tailoring the geometry of silicon nitride nanofillers to simultaneously strengthen and toughen carbon/carbon composites. Journal of Materials Science & Technology, 2024, 202: 183. |

| [21] | ZHANG Y, WANG B, DU Y, et al. High crystallinity BN fiber derived from organic-inorganic hybrid BNNS/polyborazine precursor. Journal of the American Ceramic Society, 2025, 108(7): 20439. |

| [22] | DU Y, WANG B, LI W, et al. Design and synthesis of a novel spinnable polyborazine precursor with high ceramic yield via one-pot copolymerization. Journal of the American Ceramic Society, 2021, 104(11): 5509. |

| [23] | WANG G, SONG Y. Enhancing mechanical property of SiC fiber by decreasing fiber diameter through a modified melt-spinning process. Journal of Inorganic Materials, 2018, 33(7): 721. |

| [24] | ZHANG Y, CHEN J, ZHANG H, et al. Hexagonal boron nitride ceramic reinforced with a dispersed glass phase and microdomain-extruded glass fibers. Journal of the European Ceramic Society, 2025, 45(10): 117362. |

| [25] | MIELE P, TOURY B, CORNU D, et al. Borylborazines as new precursors for boron nitride fibers. Journal of Organometallic Chemistry, 2005, 690(11): 2809. |

| [26] | MIELE P, TOURY B, CHASSAGNEUX F, et al. Correlation between structural features and mechanical properties of boron nitride fibers derived from alkylaminoborazines. Journal of the European Ceramic Society, 2005, 25(2): 157. |

| [27] | WANG C, HONG C, YAN L, et al. Structural evaluation and mechanical property of boron nitride fibers during melt-drawn fabrication process. International Journal of Applied Ceramic Technology, 2018, 15(3): 660. |

| [28] | VINCENT H, CHASSAGNEUX F, VINCENT C, et al. Microtexture and structure of boron nitride fibers by transmission electron microscopy, X-ray diffraction, photoelectron spectroscopy and Raman scattering. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2003, 340(1/2): 181. |

| [29] | WANG Z, GE M, YU S, et al. Microstructural evolution of polymer-derived hexagonal boron nitride fibers under high-temperature stretching. Journal of Advanced Ceramics, 2023, 12(10): 1973. |

| [30] | GANESH R, OBAID A A, GILLESPIE J W. Experimental determination of bimodal strength distribution of S-glass fibers. Composites Part B: Engineering, 2023, 254: 110559. |

| [1] | 石金瑜, 雷一明, 王晨旭, 张洁, 王京阳. 不同化学计量碳化钛的离子辐照损伤行为研究[J]. 无机材料学报, 2026, 41(3): 322-330. |

| [2] | 郑晨, 王湘宁, 苑贺楠, 杨嘉伟, 李传建, 王华栋. 氧化铝纤维增强二氧化硅复合材料力学性能失效研究[J]. 无机材料学报, 2026, 41(3): 331-339. |

| [3] | 袁旺, 胡建宝, 周亮, 阚艳梅, 张翔宇, 董绍明. 氩气气氛热处理对Shicolon-II SiC纤维机械性能和微观结构演变的影响[J]. 无机材料学报, 2026, 41(1): 119-128. |

| [4] | 张永恒, 陈继新. 镱铝硅酸盐玻璃和SiC改性h-BN基复合材料的制备与性能研究[J]. 无机材料学报, 2026, 41(1): 37-44. |

| [5] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [6] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [7] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [8] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [9] | 赵凯旋, 刘文鹏, 丁守军, 窦仁勤, 罗建乔, 高进云, 孙贵花, 任浩, 张庆礼. 熔融法制备Nd:YLF原料及其晶体生长和性能研究[J]. 无机材料学报, 2025, 40(5): 529-535. |

| [10] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [11] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [12] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [13] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [14] | 郭佳芯, 陈美娟, 吴浩, 郑潇然, 闵楠, 田辉, 齐东丽, 李全军, 都时禹, 沈龙海. 高压下新型MAX相Zr3InC2的第一性原理研究[J]. 无机材料学报, 2025, 40(12): 1414-1424. |

| [15] | 黄建锋, 梁瑞虹, 周志勇. W/Cr共掺杂对CaBi2Nb2O9陶瓷晶体结构及电学性能的影响[J]. 无机材料学报, 2024, 39(8): 887-894. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||