无机材料学报 ›› 2026, Vol. 41 ›› Issue (3): 331-339.DOI: 10.15541/jim20250258 CSTR: 32189.14.10.15541/jim20250258

郑晨1( ), 王湘宁2, 苑贺楠1, 杨嘉伟1, 李传建3(

), 王湘宁2, 苑贺楠1, 杨嘉伟1, 李传建3( ), 王华栋1(

), 王华栋1( )

)

收稿日期:2025-06-17

修回日期:2025-08-04

出版日期:2025-09-11

网络出版日期:2025-09-11

通讯作者:

王华栋, 高级工程师. E-mail: wanghuadonglq@126.com;作者简介:郑 晨(1992-), 男, 高级工程师. E-mail: zhengchen2603@163.com

ZHENG Chen1( ), WANG Xiangning2, YUAN Henan1, YANG Jiawei1, LI Chuanjian3(

), WANG Xiangning2, YUAN Henan1, YANG Jiawei1, LI Chuanjian3( ), WANG Huadong1(

), WANG Huadong1( )

)

Received:2025-06-17

Revised:2025-08-04

Published:2025-09-11

Online:2025-09-11

Contact:

WANG Huadong, senior engineer. E-mail: wanghuadonglq@126.com;About author:ZHENG Chen (1992-), male, senior engineer. E-mail:zhengchen2603@163.com

摘要:

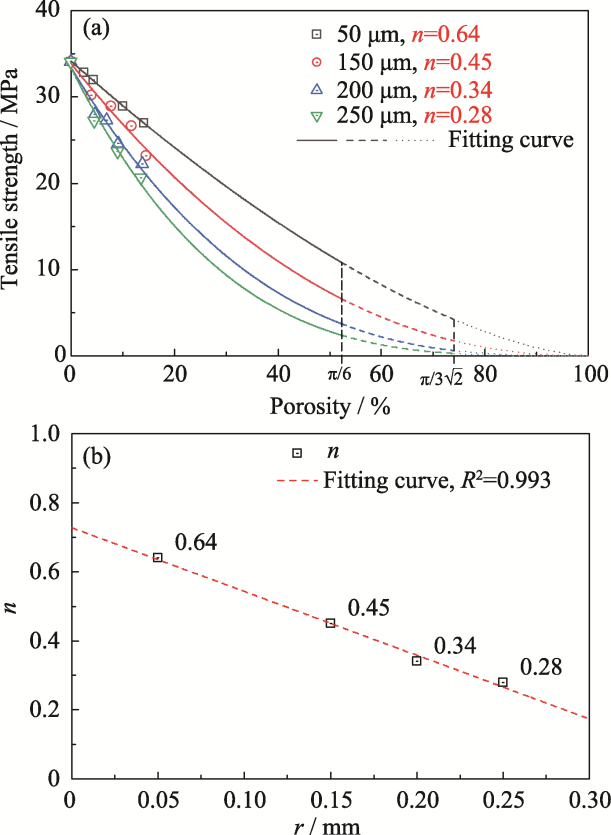

连续氧化铝纤维增强二氧化硅陶瓷基复合材料具有优异的高温抗氧化性、高强度、高韧性等特性, 作为一种军民两用材料, 广泛应用于航空、航天、能源等领域。但国内相关研究尚处于起步阶段, 对其力学性能失效机制认识不足。本研究综合溶胶-凝胶法和浆料浸渍法的工艺特点, 采用改进的液相浸渍法, 成功制备了孔隙率可调控的连续氧化铝纤维增强二氧化硅复合材料。通过多种技术手段全面表征了典型复合材料的微观形貌和成分组成, 并测试分析了不同致密程度复合材料的力学性能。结合计算机断层扫描(CT)测试获得的复合材料孔隙率, 通过模拟仿真计算, 建立了连续氧化铝纤维增强二氧化硅复合材料力学性能失效与孔隙率及孔隙尺寸的关系模型。研究结果表明, 采用改进的液相浸渍法制备的复合材料因孔隙缺陷和弱界面结合的影响, 其力学性能显著提升。同时, 随着复合材料孔隙率由2.2%增大到15.2%, 其拉伸强度由24.5 MPa降低至17.8 MPa。进一步建模仿真分析显示, 当孔隙缺陷半径为250 μm时, 孔隙率由4.5%增大至13.5%, 拉伸强度从27.2 MPa降低至20.6 MPa, 这验证了仿真模型的合理性, 揭示了拉伸强度的n次方与孔隙率呈负线性关系, 拉伸强度指数因子n与缺陷半径r呈负线性关系。本研究为连续氧化铝纤维增强二氧化硅复合材料的性能优化和实际应用提供了研究基础。

中图分类号:

郑晨, 王湘宁, 苑贺楠, 杨嘉伟, 李传建, 王华栋. 氧化铝纤维增强二氧化硅复合材料力学性能失效研究[J]. 无机材料学报, 2026, 41(3): 331-339.

ZHENG Chen, WANG Xiangning, YUAN Henan, YANG Jiawei, LI Chuanjian, WANG Huadong. Mechanical Property Failure of Alumina Fiber Reinforced Silica Composite[J]. Journal of Inorganic Materials, 2026, 41(3): 331-339.

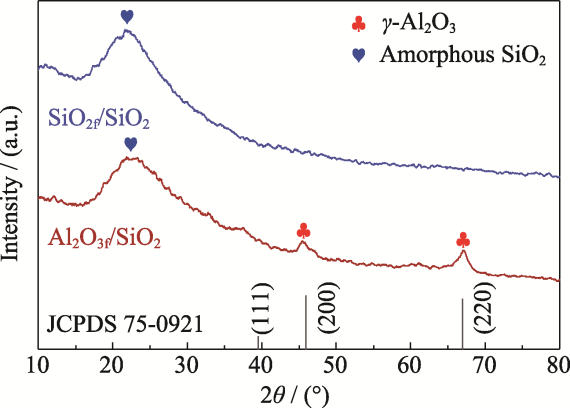

图3 氧化铝纤维增强二氧化硅复合材料样品和石英纤维增强二氧化硅复合材料的XRD图谱

Fig. 3 XRD patterns of alumina fiber reinforced silica composite and quartz fiber reinforced silica composite

| Parameter | Value |

|---|---|

| Thermal conductivity/(W·m-1·K-1) | 0.644 (300 ℃) |

| Average linear expansion coefficient/K-1 | 5.26×10-6 (RT-800 ℃) |

表1 氧化铝纤维增强二氧化硅复合材料样品的基本热学性能

Table 1 Basic thermal properties of alumina fiber reinforced silica composite

| Parameter | Value |

|---|---|

| Thermal conductivity/(W·m-1·K-1) | 0.644 (300 ℃) |

| Average linear expansion coefficient/K-1 | 5.26×10-6 (RT-800 ℃) |

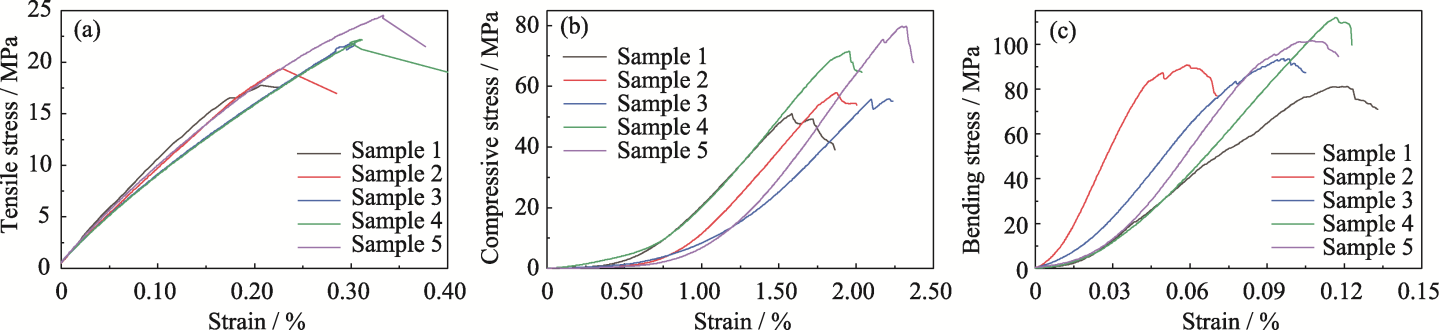

图5 氧化铝纤维增强二氧化硅复合材料样品的力学性能测试结果

Fig. 5 Mechanical property test results of alumina fiber reinforced silica composite (a) Tensile stress-strain curves; (b) Compressive stress-strain curves; (c) Bending stress-strain curves Colorful figures are available on website

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 17.8 | 19.4 | 21.8 | 22.2 | 24.5 |

| Compressive strength/MPa | 51.0 | 58.0 | 55.9 | 71.5 | 79.8 |

| Bending strength/MPa | 81.2 | 90.6 | 93.5 | 111.9 | 101.6 |

表2 氧化铝纤维增强二氧化硅复合材料样品的力学性能

Table 2 Mechanical properties of alumina fiber reinforced silica composite

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 17.8 | 19.4 | 21.8 | 22.2 | 24.5 |

| Compressive strength/MPa | 51.0 | 58.0 | 55.9 | 71.5 | 79.8 |

| Bending strength/MPa | 81.2 | 90.6 | 93.5 | 111.9 | 101.6 |

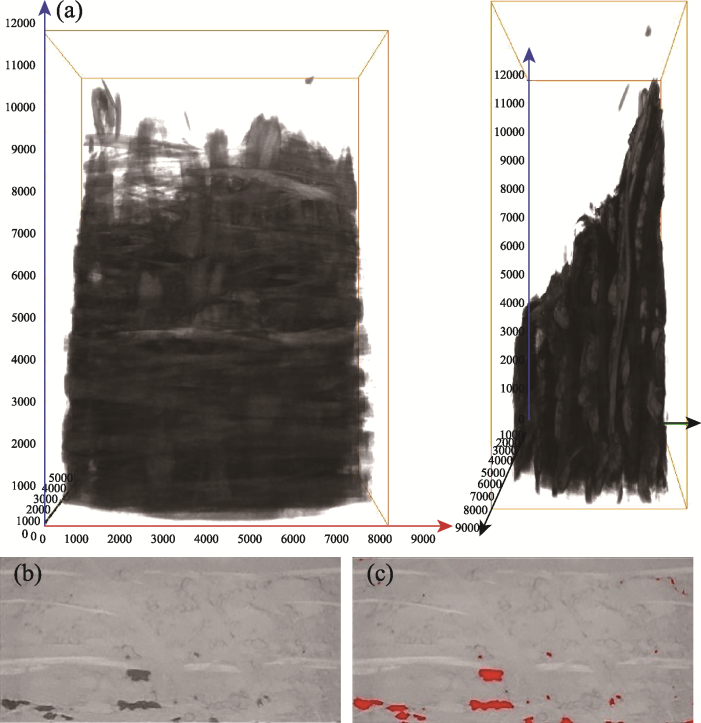

图6 拉伸断裂试样(a)不同角度的重构立体图像、(b)内部切片图像和(c)截面缺陷/孔隙率定量分析统计结果图

Fig. 6 (a) Reconstructed stereogram from different angles, (b) inner slice image and (c) quantitative statistical results of cross-sectional defect/porosity analysis of tensile fracture sample

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 17.8 | 19.4 | 21.8 | 22.2 | 24.5 |

| Porosity/% | 15.2 | 10.4 | 8.9 | 3.7 | 2.2 |

表3 氧化铝纤维增强二氧化硅复合材料拉伸试样对应的拉伸强度及孔隙率

Table 3 Tensile strengths and porosities of tensile samples of alumina fiber reinforced silica composite

| Sample | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Tensile strength/MPa | 17.8 | 19.4 | 21.8 | 22.2 | 24.5 |

| Porosity/% | 15.2 | 10.4 | 8.9 | 3.7 | 2.2 |

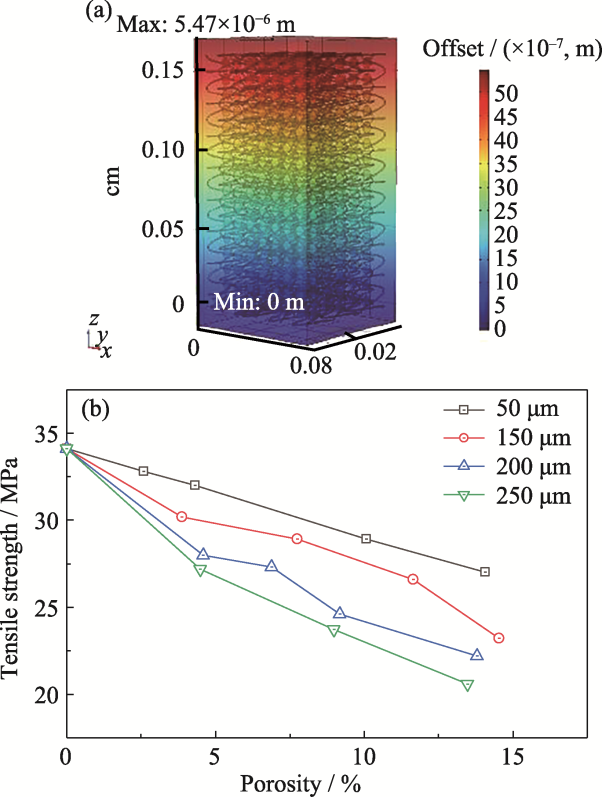

图7 (a)复合材料模型拉伸断裂时的体位移(应变)图; (b)不同孔隙缺陷半径的复合材料模型的不同拉伸强度对应的临界孔隙率

Fig. 7 (a) Position shift (strain) of the composite model during tensile fracture; (b) Critical porosities corresponding to different tensile strengths of composite materials with different pore defect radii

图8 (a)不同孔隙缺陷半径下的拉伸强度与孔隙率的关系拟合曲线; (b)指数因子n与孔隙缺陷半径r的关系拟合直线

Fig. 8 (a) Relationship between tensile strength and porosity under different pore defect radii; (b) Relationship between exponential factor n and pore defect radius r

| [1] | RITCHIE R O. The conflicts between strength and toughness. Nature Materials, 2011, 10(11): 817. |

| [2] | DONALD I, MCMILLAN P. Ceramic-matrix composites. Journal of Materials Science, 1976, 11: 949. |

| [3] | NASLAIN R R. Fiber-reinforced ceramic matrix composites: state of the art, challenge and perspective. Kompozyty (Composites), 2005, 5(1): 3. |

| [4] | PETERS A B, ZHANG D, CHEN S, et al. Materials design for hypersonics. Nature Communications, 2024, 15: 3328. |

| [5] | ALAM M A, YA H, SAPUAN S, et al. Recent advancements in advanced composites for aerospace applications:a review//MAZLAN N, SAPUAN S M, ILYAS R A. Advanced composites in aerospace engineering applications. Switzerland: Springer Nature, 2022: 319-339. |

| [6] | KAYA H. The application of ceramic-matrix composites to the automotive ceramic gas turbine. Composites Science and Technology, 1999, 59(6): 861. |

| [7] | PRAMANIK S, MANNA A, TRIPATHY A, et al. Current advancements in ceramic matrix composites//KAR K K. Composite materials:processing, applications, characterizations. Berlin: Springer, 2017: 457-496. |

| [8] | ATAOLLAHI O A, PRAMANIK S, SHIRAZI S F, et al. A comparison in mechanical properties of cermets of calcium silicate with Ti-55Ni and Ti-6Al-4V alloys for hard tissues replacement. The Scientific World Journal, 2014, 2014: 616804. |

| [9] | MAHMOUDINEZHAD S, SADI M, GHIASIRAD H, et al. A comprehensive review on the current technologies and recent developments in high-temperature heat exchangers. Renewable and Sustainable Energy Reviews, 2023, 183: 113467. |

| [10] | RASHID A B, HAQUE M, ISLAM S M M, et al. Breaking boundaries with ceramic matrix composites: a comprehensive overview of materials, manufacturing techniques, transformative applications, recent advancements, and future prospects. Advances in Materials Science and Engineering, 2024, 2024: 2112358. |

| [11] | SHRIVASTAVA S, RAJAK D K, JOSHI T, et al. Ceramic matrix composites: classifications, manufacturing, properties, and applications. Ceramics, 2024, 7(2): 652. |

| [12] | 张俊敏, 蔡飞燕, 靳喜海, 等. 连续纤维增强陶瓷基复合材料研究与应用进展. 陶瓷学报, 2023, 44(2): 195. |

| [13] | RAMACHANDRAN K, BEAR J C, JAYASEELAN D D. Oxide-based ceramic matrix composites for high-temperature environments: a review. Advanced Engineering Materials, 2025, 27(7): 2402000. |

| [14] | WANG Y, LIU H T, CHENG H F, et al. Research progress on oxide/oxide ceramic matrix composites. Journal of Inorganic Materials, 2014, 29(7): 673. |

| [15] | DHANASEKAR S, GANESAN A T, RANI T L, et al. A comprehensive study of ceramic matrix composites for space applications. Advances in Materials Science and Engineering, 2022, 2022: 1. |

| [16] | 蔡德龙, 陈斐, 何凤梅, 等. 高温透波陶瓷材料研究进展. 现代技术陶瓷, 2019, 40(Z1): 4. |

| [17] | PARK S J, SEO M K. Interface science and composites. Oxford: Elsevier, 2011: 555-619. |

| [18] | WALOCK M J, HENG V, NIETO A, et al. High temperature durability of oxide-oxide ceramic matrix composites exposed to engine relevant conditions. Proceedings of the 12th Pacific Rim Conference on Ceramic and Glass Technology, Hoboken, 2018: 329-342. |

| [19] | ASHOK B, KANNAN C, MASON B, et al. Towards safer and smarter design for lithium-ion-battery-powered electric vehicles: a comprehensive review on control strategy architecture of battery management system. Energies, 2022, 15(12): 4227. |

| [20] | JIA Y N, CAO X, JIAO X L, et al. Preparation of alumina ceramic continuous fibers with inorganic acidic aluminum sol as precursor. Journal of Inorganic Materials, 2023, 38(11): 1257. |

| [21] | WANG X G, YANG Q Q, LIN G L, et al. High temperature tensile property of domestic 550-grade continuous alumina ceramic fiber. Journal of Inorganic Materials, 2022, 37(6): 629. |

| [22] | KRENKEL W. Ceramic matrix composites: fiber reinforced ceramics and their applications. Weinheim: John Wiley & Sons, 2008. |

| [23] | TARIQ M, HANIF F, ASHRAF A. Overview of NextelTM based structures for space applications. Journal of Space Technology, 2011, 1(1): 88. |

| [24] | 焦秀玲, 陈代荣. 氧化铝基陶瓷连续纤维研究进展. 硅酸盐学报, 2024, 52(8): 2738. |

| [25] | 刘海韬, 姜如, 孙逊, 等. 连续氧化铝纤维增韧陶瓷基复合材料. 北京: 科学出版社, 2022: 55-58. |

| [26] | YANG J Y, WEAVER J H, ZOK F W, et al. Processing of oxide composites with three-dimensional fiber architectures. Journal of the American Ceramic Society, 2009, 92(5): 1087. |

| [27] | SCOLA A, EBERLING-FUX N, TURENNE S, et al. New liquid processing of oxide/oxide 3D wowen ceramic matrix composites. Journal of the American Ceramic Society, 2018, 102(6): 3256. |

| [28] | 冻瑞岚, 彭志航, 向阳, 等. 氧化铝纤维增强氧化铝陶瓷基复合材料的组成及制备工艺的研究进展. 材料工程, 2023, 51(10): 27. |

| [29] | XIANG Y, WEN J, WANG Y, et al. Degradation of Al2O3f/SiO2 composites exposed to Na2SO4 environment and MMH/N2O4 bipropellants test. International Journal of Applied Ceramic Technology, 2020, 17(5): 2114. |

| [30] | XIAO H, WU J M, CHEN A N, et al. Alumina fiber-reinforced silica matrix composites with improved mechanical properties prepared by a novel DCC-HVCI method. Ceramics International, 2017, 43(18): 16436. |

| [31] | LIU P S, FU C, LI T F, et al. Relationship between tensile strength and porosity for high porosity metals. Science in China Series E: Technological Sciences, 1999, 42(1): 100. |

| [32] | LIU P S, WANG X S, LUO H Y. Relationship between tensile strength and porosity for foamed metals under equal speed biaxial tension. Materials Science and Technology, 2003, 19(7): 985. |

| [33] | 张兆杭, 崔少康, 谭志勇, 等. C/C-SiC缎纹编织复合材料孔隙缺陷的建模及其拉伸性能仿真. 复合材料学报, 2020, 37(8): 1969. |

| [34] | HAN D, YE F, CHENG L, et al. Matrix cracking of 2D SiC/SiC composite characterized by in situ SEM and nano-CT. Ceramics International, 2023, 49(8): 12508. |

| [35] | LI X, PAN K, ZHANG F, et al. An overview of tensile and shear failure mechanisms of silicon carbide-based ceramic matrix composites. Journal of Materials Research and Technology, 2024, 33: 2924. |

| [1] | 石金瑜, 雷一明, 王晨旭, 张洁, 王京阳. 不同化学计量碳化钛的离子辐照损伤行为研究[J]. 无机材料学报, 2026, 41(3): 322-330. |

| [2] | 张韵铂, 王兵, 李威, 宋曲之, 杜贻昂, 王应德. BNNS/聚硼氮烷杂化先驱体转化BN纤维中的纳米片尺寸效应[J]. 无机材料学报, 2026, 41(3): 359-369. |

| [3] | 袁旺, 胡建宝, 周亮, 阚艳梅, 张翔宇, 董绍明. 氩气气氛热处理对Shicolon-II SiC纤维机械性能和微观结构演变的影响[J]. 无机材料学报, 2026, 41(1): 119-128. |

| [4] | 张永恒, 陈继新. 镱铝硅酸盐玻璃和SiC改性h-BN基复合材料的制备与性能研究[J]. 无机材料学报, 2026, 41(1): 37-44. |

| [5] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [6] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [7] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [8] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [9] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [10] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [11] | 马文, 申喆, 刘琪, 高元明, 白玉, 李荣星. 悬浮液等离子喷涂制备Y2O3涂层及耐等离子刻蚀性[J]. 无机材料学报, 2024, 39(8): 929-936. |

| [12] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [13] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [14] | 孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670. |

| [15] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||