无机材料学报 ›› 2021, Vol. 36 ›› Issue (10): 1067-1073.DOI: 10.15541/jim20210034 CSTR: 32189.14.10.15541/jim20210034

收稿日期:2021-01-18

修回日期:2021-03-08

出版日期:2021-10-20

网络出版日期:2021-04-05

通讯作者:

王 皓, 教授. E-mail: shswangh@whut.edu.cn

作者简介:冯明星(1996-), 男, 硕士研究生. E-mail: 15200227687@163.com

基金资助:

FENG Mingxing( ), WANG Bin, XU Pengyu, TU Bingtian, WANG Hao(

), WANG Bin, XU Pengyu, TU Bingtian, WANG Hao( )

)

Received:2021-01-18

Revised:2021-03-08

Published:2021-10-20

Online:2021-04-05

Contact:

WANG Hao, professor. E-mail: shswangh@whut.edu.cn

About author:FENG Mingxing(1996-), male, Master candidate. E-mail: 15200227687@163.com

Supported by:摘要:

尖晶石型陶瓷具有优异的热机械性能, 在高温结构材料领域具有良好的应用前景。本研究将键价模型与高温机械性能理论表征模型相结合, 建立了从变温晶体结构出发预测尖晶石型陶瓷高温热机械性能的方法, 阐明了晶体结构与高温热机械性能之间的关系。采用该方法预测了MgAl2O4透明陶瓷的高温断裂强度和断裂韧性, 其预测结果与实验值吻合。研究表明, MgAl2O4中阳离子反位率、化学键硬度和体模量随温度的变化在800 ℃上下存在显著差异, 然而由于配位多面体的耦合作用, 阳离子反位的温度效应不会显著影响MgAl2O4透明陶瓷的高温热机械性能。

中图分类号:

冯明星, 王斌, 徐鹏宇, 涂兵田, 王皓. 基于键价模型的MgAl2O4透明陶瓷热机械性能预测[J]. 无机材料学报, 2021, 36(10): 1067-1073.

FENG Mingxing, WANG Bin, XU Pengyu, TU Bingtian, WANG Hao. Predicting Thermomechanical Properties of MgAl2O4 Transparent Ceramic Based on Bond Valence Models[J]. Journal of Inorganic Materials, 2021, 36(10): 1067-1073.

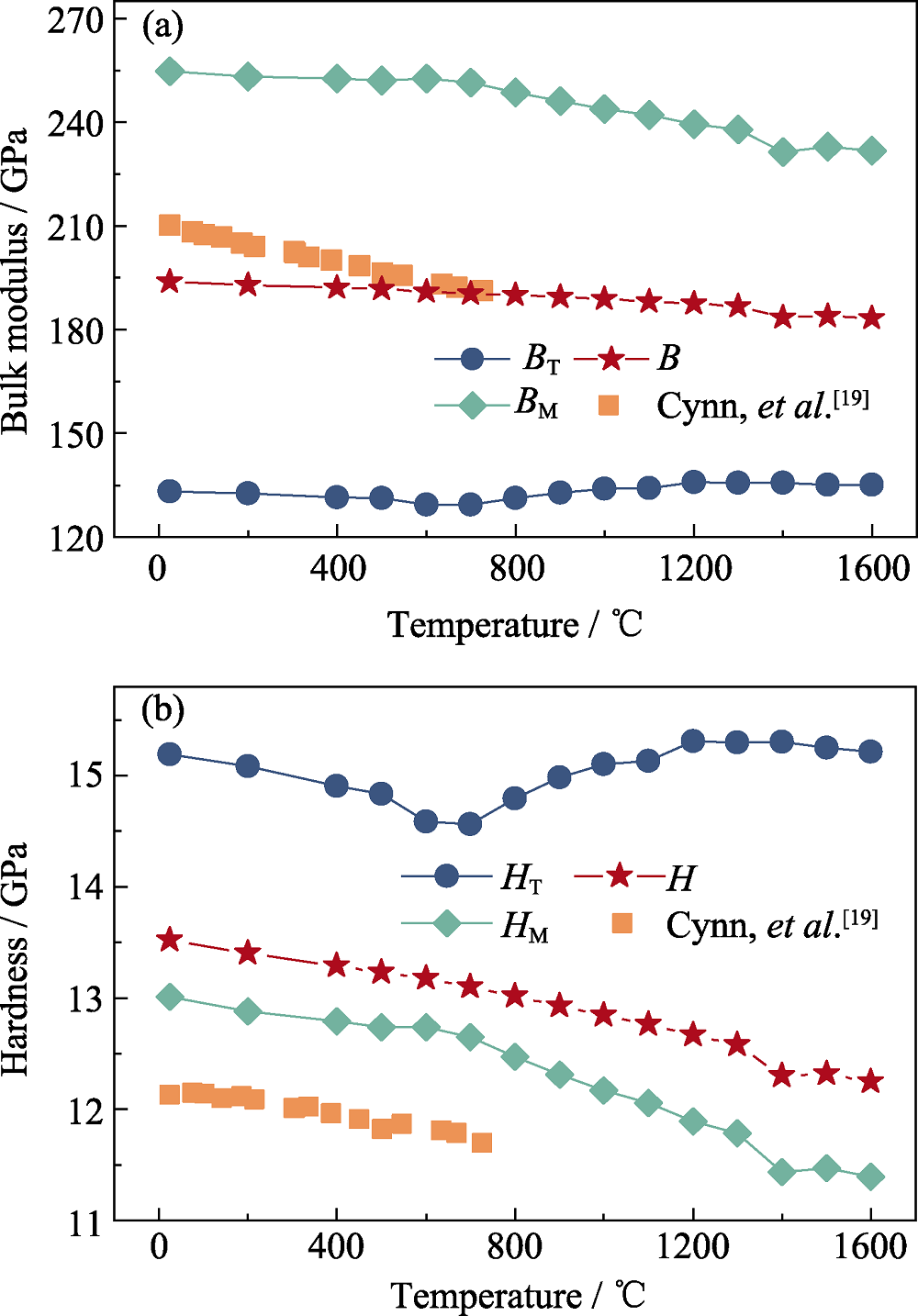

图1 不同温度下MgAl2O4的(a)体模量和(b)硬度(实验值来源于文献[19])

Fig. 1 (a) Bulk modulus and (b) hardness of MgAl2O4 under various temperatures (experimental data obtained from the literature[19])BT and BM denote the bulk modulus of bonds in tetrahedra and octahedra, respectively; B is the bulk modulus of MgAl2O4 crystal; HT and HM represent the hardness of bonds in tetrahedra and octahedra, respectively; H is the hardness of MgAl2O4 crystal

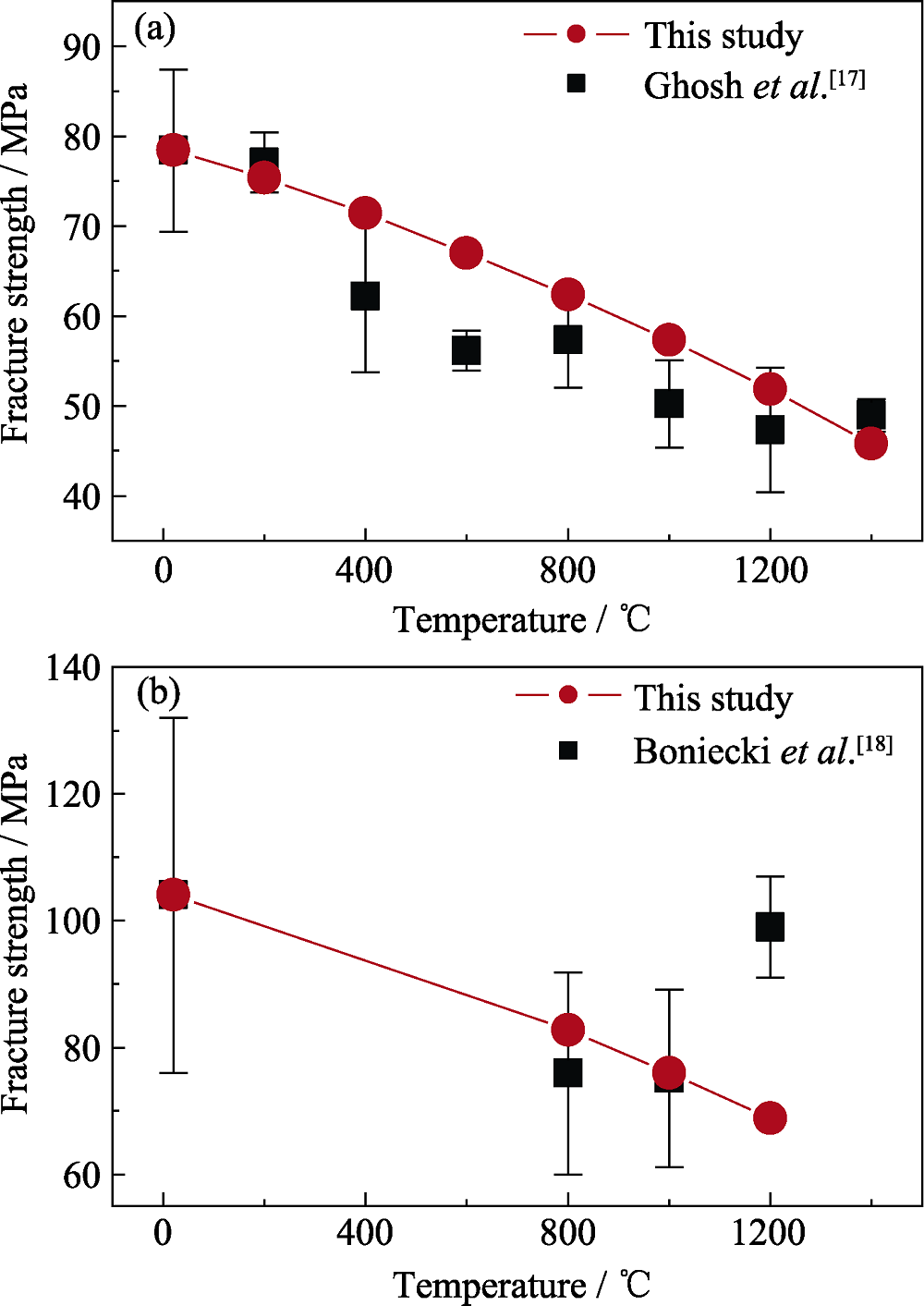

图4 MgAl2O4温度相关性断裂强度的预测值与(a) Ghosh等[17], (b) Boniecki等[18]的实验值的对比

Fig. 4 Comparison of prediction with experimental data (a) of Ghosh, et al[17], (b) Boniecki, et al[18] of the temperature dependent fracture strengths of MgAl2O4

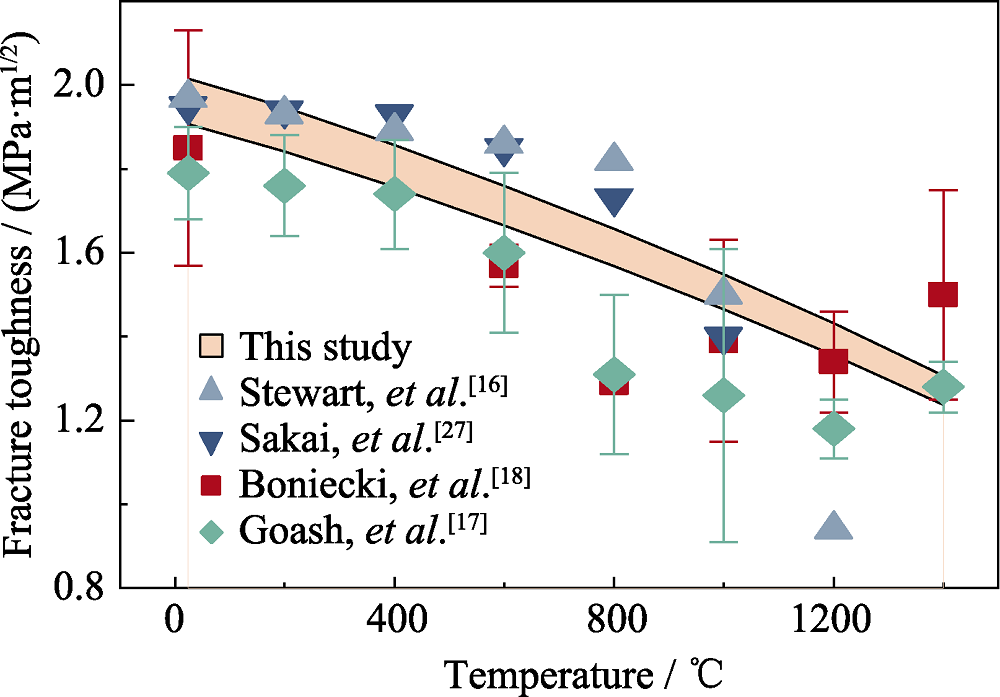

图5 MgAl2O4温度相关性断裂韧性的预测值与实验值[16-18,27]的对比

Fig. 5 Comparison of prediction with experimental data of temperature dependent fracture toughnesses of MgAl2O4[16-18,27]

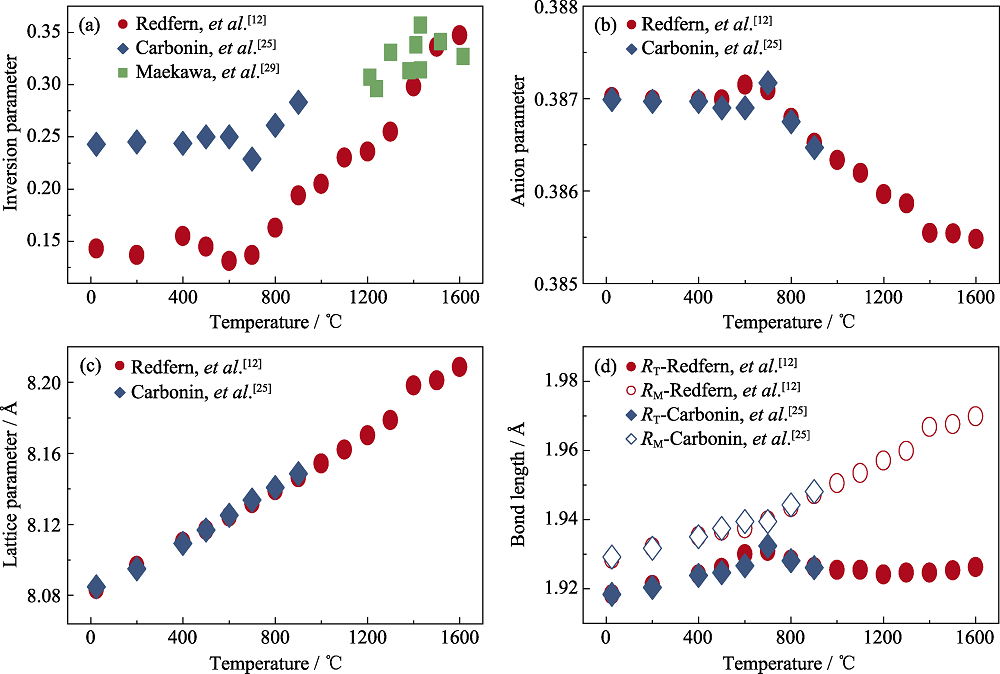

图6 不同温度下MgAl2O4的(a)反位率, (b)阴离子参数, (c)晶格常数和(d)平均键长[12,25,29]

Fig. 6 Temperature dependence of (a) inversion parameter, (b) anion parameter, (c) lattice constant, and (d) averaged bond length for MgAl2O4[12,25,29] RT and RM denote the bond length in tetrahedra and octahedra, respectively (1 Å=0.1 nm)

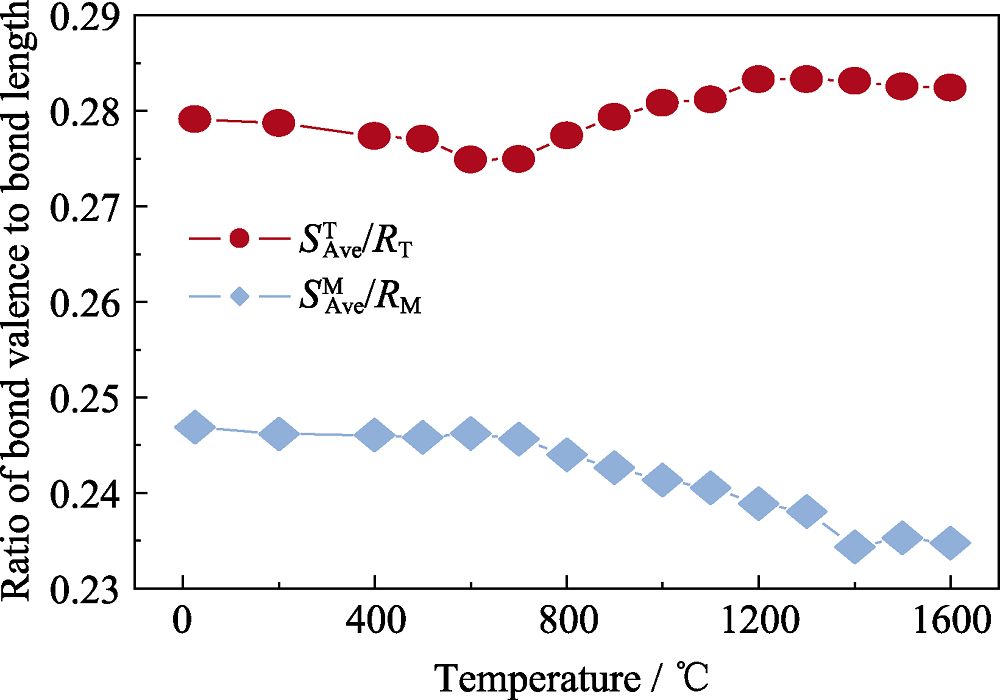

图7 不同温度下MgAl2O4的键价与键长之比

Fig. 7 Ratio of bond valence to bond length of MgAl2O4 under various temperatures $S _{Ave}^{T}/ R_{T}$ and $ S _{Ave}^{M}/ R_{M}$ represent the ratio of bond valence to bond length in tetrahedra and octahedra, respectively

| Sij/(v.u.) | $\frac{\mathrm{d} R}{\mathrm{~d} T} /\left(\times 10^{-7}, \mathrm{~nm} /{ }^{\circ} \mathrm{C}\right)$ | R0 | |

|---|---|---|---|

| [Mg-O]T | 0.54 | 13 | 1.693 |

| [Al-O]T | 0.49 | 16 | 1.651 |

| [Mg-O]M | 0.53 | 14 | 1.693 |

| [Al-O]M | 0.47 | 17 | 1.651 |

表1 MgAl2O4化学键性质参数

Table 1 Chemical bond properties of MgAl2O4

| Sij/(v.u.) | $\frac{\mathrm{d} R}{\mathrm{~d} T} /\left(\times 10^{-7}, \mathrm{~nm} /{ }^{\circ} \mathrm{C}\right)$ | R0 | |

|---|---|---|---|

| [Mg-O]T | 0.54 | 13 | 1.693 |

| [Al-O]T | 0.49 | 16 | 1.651 |

| [Mg-O]M | 0.53 | 14 | 1.693 |

| [Al-O]M | 0.47 | 17 | 1.651 |

| [1] |

LI WEIGUO, YANG FAN, FANG DAINING. The temperature- dependent fracture strength model for ultra-high temperature ceramics. Acta Mechanica Sinica, 2010, 26(2):235-239.

DOI URL |

| [2] |

CHENG TIANBAO, LI WEIGUO. The temperature-dependent ideal tensile strength of ZrB2, HfB2, and TiB2. Journal of the American Ceramic Society, 2015, 98(1):190-196.

DOI URL |

| [3] |

WANG RUZHUAN, LI WEIGUO, LI DINGYU, et al. A new temperature dependent fracture strength model for the ZrB2-SiC composites. Journal of the European Ceramic Society, 2015, 35(10):2957-2962.

DOI URL |

| [4] |

DENG YONG, LI WEIGUO, SHAO JIXING, et al. A novel theoretical model to predict the temperature-dependent fracture strength of ceramic materials. Journal of the European Ceramic Society, 2017, 37(15):5071-5077.

DOI URL |

| [5] |

WANG HAOMIN, HUANG ZHANGYI, QI JIANQI, et al. A new methodology to obtain the fracture toughness of YAG transparent ceramics. Journal of Advanced Ceramics, 2019, 8(3):418-426.

DOI URL |

| [6] |

ZERR A, RIEDEL R, SEKINE T, et al. Recent advances in new hard high-pressure nitrides. Advanced Materials, 2006, 18(22):2933-2948.

DOI URL |

| [7] |

GOLDSTEIN A, KRELL A. Transparent ceramics at 50: progress made and further prospects. Journal of the American Ceramic Society, 2016, 99(10):3173-3197.

DOI URL |

| [8] |

BROWN I D. Recent developments in the methods and applications of the bond valence model. Chemical Reviews, 2009, 109(12):6858-6919.

DOI URL |

| [9] |

LIU XIAO, WANG HAO, LAVINA B, et al. Chemical composition, crystal structure, and their relationships with the intrinsic properties of spinel-type crystals based on bond valences. Inorganic Chemistry, 2014, 53(12):5986-5992.

DOI URL |

| [10] | LIU XIAO, WANG HAO, WANG WEIMIN, et al. Simple method for the hardness estimation of inorganic crystals by the bond valence model. Inorganic Chemistry, 2016, 55(21):11089-11095. |

| [11] |

BROWN I D, DABKOWSKI A, MCCLEARY A. Thermal expansion of chemical bonds. Acta Crystallographica Section B: Structural Science, 1997, 53(5):750-761.

DOI URL |

| [12] |

REDFERN S A, HARRISON R J, O’NEILL H S C, et al. Thermodynamics and kinetics of cation ordering in MgAl2O4 spinel up to 1600 ℃ from in situ neutron diffraction. American Mineralogist, 1999, 84(3):299-310.

DOI URL |

| [13] | MICHAEL B. Handbook of Optics: Volume IV-Optical Properties of Materials, Nonlinear Optics, Quantum Optics, 3rd. New York: McGraw-Hill Education, 2010: 118-120. |

| [14] |

SHORNIKOV S. Thermodynamic properties of spinel MgAl2O4: a mass spectrometric study. Russian Journal of Physical Chemistry, 2017, 91(1):287-294.

DOI URL |

| [15] |

MECHOLSKY J J, FREIMAM S W, RICE R W. Fracture surface analysis of ceramics. Journal of Materials Science, 1976, 11(7):1310-1319.

DOI URL |

| [16] |

STEWART R L, BRADT R C. Fracture of polycrystalline MgAl2O4. Journal of the American Ceramic Society, 1980, 63(11):619-623.

DOI URL |

| [17] |

GHOSH A, WHITE K W, JENKINS M G, et al. Fracture-resistance of a transparent magnesium aluminate spinel. Journal of the American Ceramic Society, 1991, 74(7):1624-1630.

DOI URL |

| [18] | BONIECKI M, LIBRANT Z, SADOWSKI T, et al. The Thermal Shock Resistance and Mechanical Properties at Elevated Temperature of Transparent Ceramics. in: ÖCHSNER A, DA SILVA L F M, ALTENBACH H. Materials with Complex Behaviour II: Properties, Non-Classical Materials and New Technologies. Berlin, Heidelberg: Springer, 2012: 307-321. |

| [19] |

CYNN H, ANDERSON O L, NICOL M. Effects of cation disordering in a natural MgAl2O4 spinel observed by rectangular parallelepiped ultrasonic resonance and Raman measurements. Pure and Applied Geophysics, 1993, 141(2):415-444.

DOI URL |

| [20] |

WHITE K W, KELKAR G P. Fracture mechanisms of a coarse- grained, transparent MgAl2O4 at elevated temperatures. Journal of the American Ceramic Society, 1992, 75(12):3440-3444.

DOI URL |

| [21] |

BRADT R C. Fracture of single crystal MgAl2O4. Journal of Materials Science, 1980, 15(1):67-72.

DOI URL |

| [22] | RICHET P, FIQUET G. High-temperature heat capacity and premelting of minerals in the system MgO-CaO-Al2O3-SiO2. Journal of Geophysical Research Solid Earth, 1991, 96(1):445-456. |

| [23] |

LANDA Y A, NAUMOVA I A. Determining the enthalpy and specific heat of magnesia spinels in the range 1400-2200 K. Refractories, 1979, 20(5):335-337.

DOI URL |

| [24] |

BONNICKSON K R. High temperature heat contents of aluminates of calcium and magnesium. The Journal of Physical Chemistry, 1955, 59(3):220-221.

DOI URL |

| [25] |

CARBONIN S, MARTIGNAGO F, MENEGAZZO G, et al. X-ray single-crystal study of spinels: in situ heating. Physics and Chemistry of Minerals, 2002, 29(8):503-514.

DOI URL |

| [26] |

HALLSTEDT B. Thermodynamic assessment of the system MgO-Al2O3. Journal of the American Ceramic Society, 1992, 75(6):1497-1507.

DOI URL |

| [27] |

SAKAI M, BRADT R C, KOBAYASHI A S. The toughness of polycrystalline MgAl2O4. Journal of the Ceramic Society of Japan, 1988, 96(5):525-531.

DOI URL |

| [28] |

BAUDIN C, MARTINEZ R, PENA P. High-temperature mechanical behavior of stoichiometric magnesium spinel. Journal of the American Ceramic Society, 1995, 78(7):1857-1862.

DOI URL |

| [29] |

MAEKAWA H, KATO S, KAWAMURA K, et al. Cation mixing in natural MgAl2O4 spinel: a high-temperature27Al NMR study. American Mineralogist, 1997, 82(11):1125-1132.

DOI URL |

| [30] |

REN LU, WANG HAO, TU BINGTIAN, et al. Theoretical study on composition- and pressure-dependent mechanical properties of AlON solid solution. Journal of the American Ceramic Society, 2020, 103(8):4390-4401.

DOI URL |

| [1] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [2] | 吕朝阳, 徐勇, 杨久延, 涂广升, 涂兵田, 王皓. MgF2助剂对MgAl1.9Ga0.1O4透明陶瓷的制备与光学性能的影响[J]. 无机材料学报, 2024, 39(5): 531-538. |

| [3] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| [4] | 汪德文, 王俊平, 袁厚呈, 刘章, 周进, 邓佳杰, 王鑫, 吴贲华, 章健, 王士维. 真空反应烧结制备米级尺寸钇铝石榴石(YAG)透明陶瓷[J]. 无机材料学报, 2023, 38(12): 1483-1484. |

| [5] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [6] | 母利成, 杨金萍, 王俊平, 赵瑾, 刘梦玮, 汪德文, 章健. 环氧树脂改性自发凝固成型制备YAG透明陶瓷[J]. 无机材料学报, 2022, 37(9): 941-946. |

| [7] | 刘强, 王倩, 陈鹏辉, 李晓英, 章立轩, 谢腾飞, 李江. 两步烧结法制备红色Ce:8YSZ透明陶瓷及其性能研究[J]. 无机材料学报, 2022, 37(8): 911-917. |

| [8] | 肖舒琳, 戴中华, 李定妍, 张凡博, 杨利红, 任晓兵. 氧化镧掺杂铌酸钾钠陶瓷的电、光性能研究[J]. 无机材料学报, 2022, 37(5): 520-526. |

| [9] | 荆延秋, 刘强, 苏莎, 李晓英, 刘子玉, 王静雅, 李江. 1.5 μm被动调Q可饱和吸收体用Co:MgAl 2O4透明陶瓷的制备[J]. 无机材料学报, 2021, 36(8): 877-882. |

| [10] | 曾建军, 张魁宝, 陈代梦, 郭海燕, 邓婷, 刘奎. 真空烧结制备(La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7高熵透明陶瓷[J]. 无机材料学报, 2021, 36(4): 418-424. |

| [11] | 刘子玉, TOCI Guido, PIRRI Angela, PATRIZI Barbara, 冯亚刚, 陈肖朴, 胡殿君, 田丰, 吴乐翔, VANNINIMatteo, 李江. 固体激光用Nd:Lu2O3透明陶瓷的制备和光学性能研究[J]. 无机材料学报, 2021, 36(2): 210-216. |

| [12] | 黄新友, 刘玉敏, 刘洋, 李晓英, 冯亚刚, 陈肖朴, 陈鹏辉, 刘欣, 谢腾飞, 李江. 醇水共沉淀法制备Yb:YAG透明陶瓷及其性能研究[J]. 无机材料学报, 2021, 36(2): 217-224. |

| [13] | 张金诚, 王皓, 徐鹏宇, 涂兵田, 王为民, 傅正义. ZnO·2.56Al2O3透明陶瓷凝胶注模成型与烧结制备[J]. 无机材料学报, 2019, 34(10): 1072-1076. |

| [14] | 郭胜强, 王皓, 涂兵田, 王斌, 徐鹏宇, 王为民, 傅正义. 细晶MgO·1.44Al2O3透明陶瓷的制备及其性能研究[J]. 无机材料学报, 2019, 34(10): 1067-1071. |

| [15] | 张舟, 王皓, 涂兵田, 徐鹏宇, 王为民, 傅正义. Mg0.27Al2.58O3.73N0.27透明陶瓷机械性能评价[J]. 无机材料学报, 2018, 33(9): 1006-1010. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||