无机材料学报 ›› 2024, Vol. 39 ›› Issue (7): 761-768.DOI: 10.15541/jim20230518 CSTR: 32189.14.10.15541/jim20230518

所属专题: 【结构材料】超高温结构陶瓷(202506); 【结构材料】高导热陶瓷(202506)

收稿日期:2023-11-06

修回日期:2024-02-28

出版日期:2024-07-20

网络出版日期:2024-03-08

通讯作者:

周益春, 教授. E-mail: yichunzhou@xidian.edu.cn;作者简介:吴玉豪(2000-), 男, 硕士研究生. E-mail: hsarfr@163.com

基金资助:

WU Yuhao( ), PENG Renci, CHENG Chunyu, YANG Li(

), PENG Renci, CHENG Chunyu, YANG Li( ), ZHOU Yichun(

), ZHOU Yichun( )

)

Received:2023-11-06

Revised:2024-02-28

Published:2024-07-20

Online:2024-03-08

Contact:

ZHOU Yichun, professor. E-mail: yichunzhou@xidian.edu.cn;About author:WU Yuhao (2000-), male, Master candidate. E-mail: hsarfr@163.com

Supported by:摘要:

HfxTa1-xC具有高熔化温度、高硬度、高强度, 以及导电、导热性好等优异性能, 是2000 ℃以上热防护领域极有潜力的候选材料, 但其力学性质与熔化温度随组分变化规律尚不清晰。本研究基于特殊准随机结构(SQS)方法和第一性原理计算, 从共价键强度、价电子浓度(VEC)的微观角度系统地探讨了HfxTa1-xC系固溶体力学性质随组分的变化机理。力学性质计算结果表明: 5种组分(HfC、Hf0.75Ta0.25C、Hf0.5Ta0.5C、Hf0.25Ta0.75C与TaC)中, Hf0.25Ta0.75C固溶体具有最高的弹性模量和剪切模量, 这主要归因于: (1)该组分具有最高的共价键强度; (2)来自C的p轨道和来自Hf或Ta的d轨道之间的特殊键合在VEC=8.75(Hf0.25Ta0.75C)附近被完全填充, 它们强烈抑制形状变化。研究还使用基于从头算分子动力学(AIMD)的分子动力学Z方法计算了HfxTa1-xC系固溶体的熔化曲线。结果显示HfxTa1-xC系固溶体熔化温度反常增加的现象的确存在, 且在Hf0.5Ta0.5C处熔化温度最高(4270 K), 这主要归因于构型熵与共价键强度的协同作用。本研究结果为高熔化温度及高力学性能HfxTa1-xC系固溶体组分的实验选择及其耐高温涂层应用等提供了理论指导, 也为其他过渡金属碳化物研究提供了参考。

中图分类号:

吴玉豪, 彭仁赐, 程春玉, 杨丽, 周益春. HfxTa1-xC体系力学性能及熔化曲线的第一性原理研究[J]. 无机材料学报, 2024, 39(7): 761-768.

WU Yuhao, PENG Renci, CHENG Chunyu, YANG Li, ZHOU Yichun. First-principles Study on Mechanical Properties and Melting Curve of HfxTa1-xC System[J]. Journal of Inorganic Materials, 2024, 39(7): 761-768.

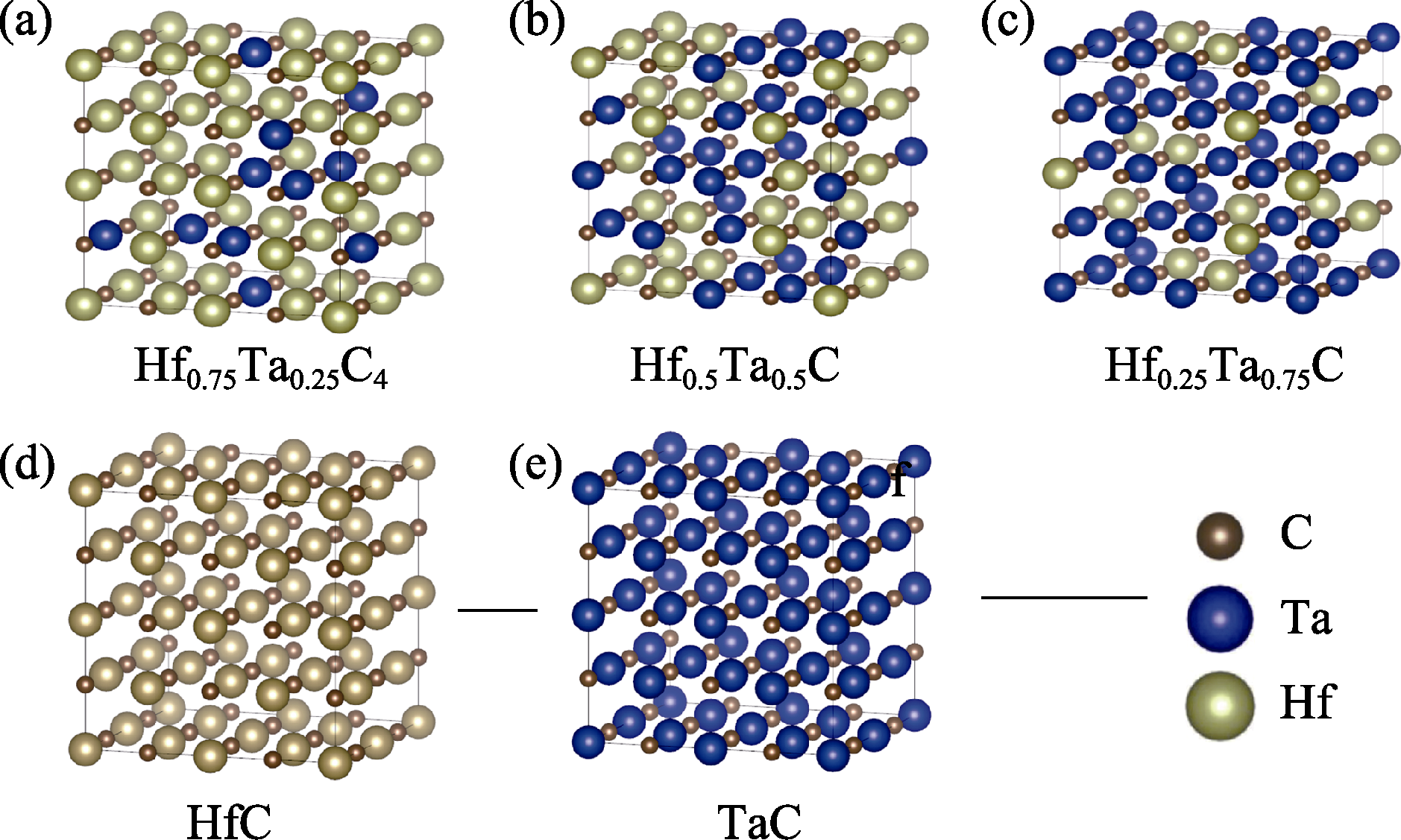

图1 (a) Hf0.75Ta0.25C, (b) Hf0.5Ta0.5C, (c) Hf0.25Ta0.75C, (d) HfC和(e) TaC结构弛豫后得到的稳定结构

Fig. 1 Stable crystal structures after structural relaxation of (a) Hf0.75Ta0.25C, (b) Hf0.5Ta0.5C, (c) Hf0.25Ta0.75C, (d) HfC, and (e) TaC

| Compound | Lattice constant/Å | Ecoh/(eV·atom-1) | Emix/(eV·atom-1) |

|---|---|---|---|

| HfC | a=b=c=9.293 | -10.525 | |

| Hf0.75Ta0.25C | a=9.197, b=9.197, c=9.198 | -10.696 | -0.21 |

| Hf0.5Ta0.5C | a=9.112, b=9.108, c=9.109 | -10.842 | -0.22 |

| Hf0.25Ta0.75C | a=9.034, b=9.034, c=9.023 | -10.977 | -0.15 |

| TaC | a=b=c=8.957 | -11.102 |

表S1 HfC、Hf0.75Ta0.25C、Hf0.5Ta0.5C、Hf0.25Ta0.75C、TaC的晶格常数、内聚能(Ecoh)和混合能(Emix)

Table S1 Lattice constants, cohesive enthalpy ( E c o h), and mixing enthalpy ( E m i x ) of HfC, Hf0.75Ta0.25C, Hf0.5Ta0.5C, Hf0.25Ta0.75C and TaC

| Compound | Lattice constant/Å | Ecoh/(eV·atom-1) | Emix/(eV·atom-1) |

|---|---|---|---|

| HfC | a=b=c=9.293 | -10.525 | |

| Hf0.75Ta0.25C | a=9.197, b=9.197, c=9.198 | -10.696 | -0.21 |

| Hf0.5Ta0.5C | a=9.112, b=9.108, c=9.109 | -10.842 | -0.22 |

| Hf0.25Ta0.75C | a=9.034, b=9.034, c=9.023 | -10.977 | -0.15 |

| TaC | a=b=c=8.957 | -11.102 |

| Compound | C11/GPa | C44/GPa | C12/GPa | |||

|---|---|---|---|---|---|---|

| This work | Ren et al.[ | This work | Ren et al.[ | This work | Ren et al.[ | |

| HfC | 516.2 | 540 | 175.5 | 171 | 102.9 | 112 |

| Hf0.75Ta0.25C | 554.1 | 601 | 185.9 | 187 | 114.8 | 117 |

| Hf0.5Ta0.5C | 627.2 | 654 | 182.5 | 182 | 108.9 | 120 |

| Hf0.25Ta0.75C | 687.8 | 706 | 182.6 | 183 | 120.1 | 124 |

| TaC | 679.2 | 674 | 170.9 | 167 | 137.5 | 172 |

表1 HfC、Hf0.75Ta0.25C、Hf0.5Ta0.5C、Hf0.25Ta0.75C、TaC的弹性常数

Table 1 Elastic constants of HfC, Hf0.75Ta0.25C, Hf0.5Ta0.5C, Hf0.25Ta0.75C, and TaC

| Compound | C11/GPa | C44/GPa | C12/GPa | |||

|---|---|---|---|---|---|---|

| This work | Ren et al.[ | This work | Ren et al.[ | This work | Ren et al.[ | |

| HfC | 516.2 | 540 | 175.5 | 171 | 102.9 | 112 |

| Hf0.75Ta0.25C | 554.1 | 601 | 185.9 | 187 | 114.8 | 117 |

| Hf0.5Ta0.5C | 627.2 | 654 | 182.5 | 182 | 108.9 | 120 |

| Hf0.25Ta0.75C | 687.8 | 706 | 182.6 | 183 | 120.1 | 124 |

| TaC | 679.2 | 674 | 170.9 | 167 | 137.5 | 172 |

图2 HfC、Hf0.75Ta0.25C、Hf0.5Ta0.5C、Hf0.25Ta0.75C和TaC的力学性质变化规律

Fig. 2 Mechanical properties of Hf, Hf0.75Ta0.25C, Hf0.5Ta0.5C, Hf0.25Ta0.75C, and TaC (a) Bulk modulus; (b) Shear modulus; (c) Pugh' ratio; (d) Young's modulus; (e) Hardness

图3 (a) HfxTa1-xC系固溶体的总态密度, 以及(b) TaC, (c) HfC, (d) Hf0.75Ta0.25C, (e) Hf0.5Ta0.5C和(f) Hf0.25Ta0.75C的分态密度

Fig. 3 (a) Total density of states (TDOS) for ternary HfxTa1-xC solid solution, and partial density of states (DOS) for (b) TaC, (c) HfC, (d) Hf0.75Ta0.25C, (e) Hf0.5Ta0.5C, and (f) Hf0.25Ta0.75C Colorful figures are available on website

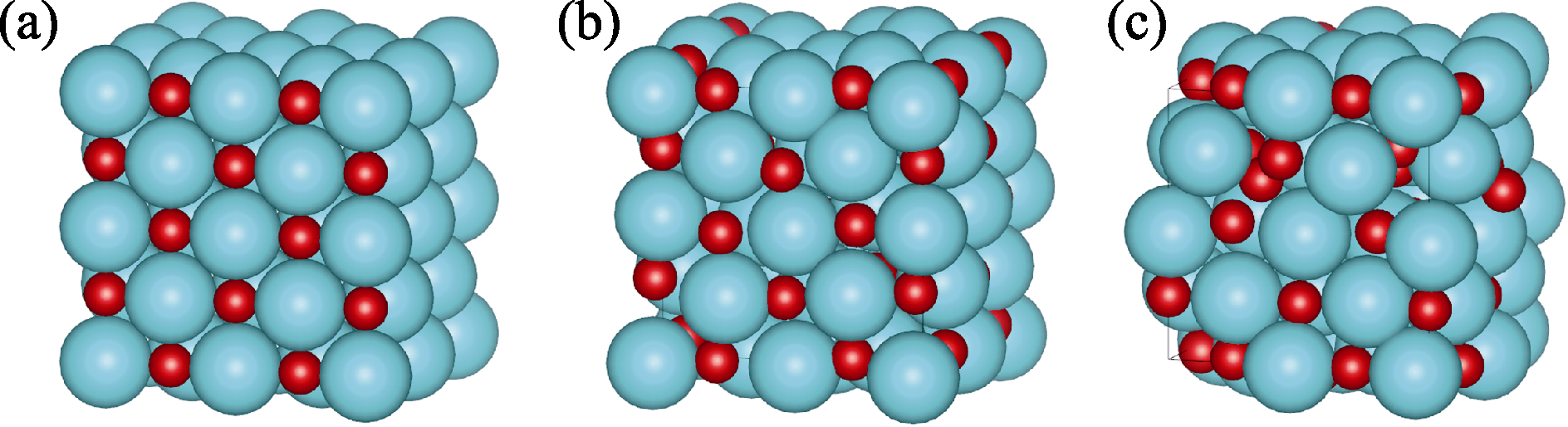

图S1 HfC的熔化过程示意图

Fig. S1 Schematic diagrams of the melting process of HfC (a) Original stable crystal structure (0 ps); (b) Melting begins (0.1 ps); (c) Complete melting (2.5 ps)

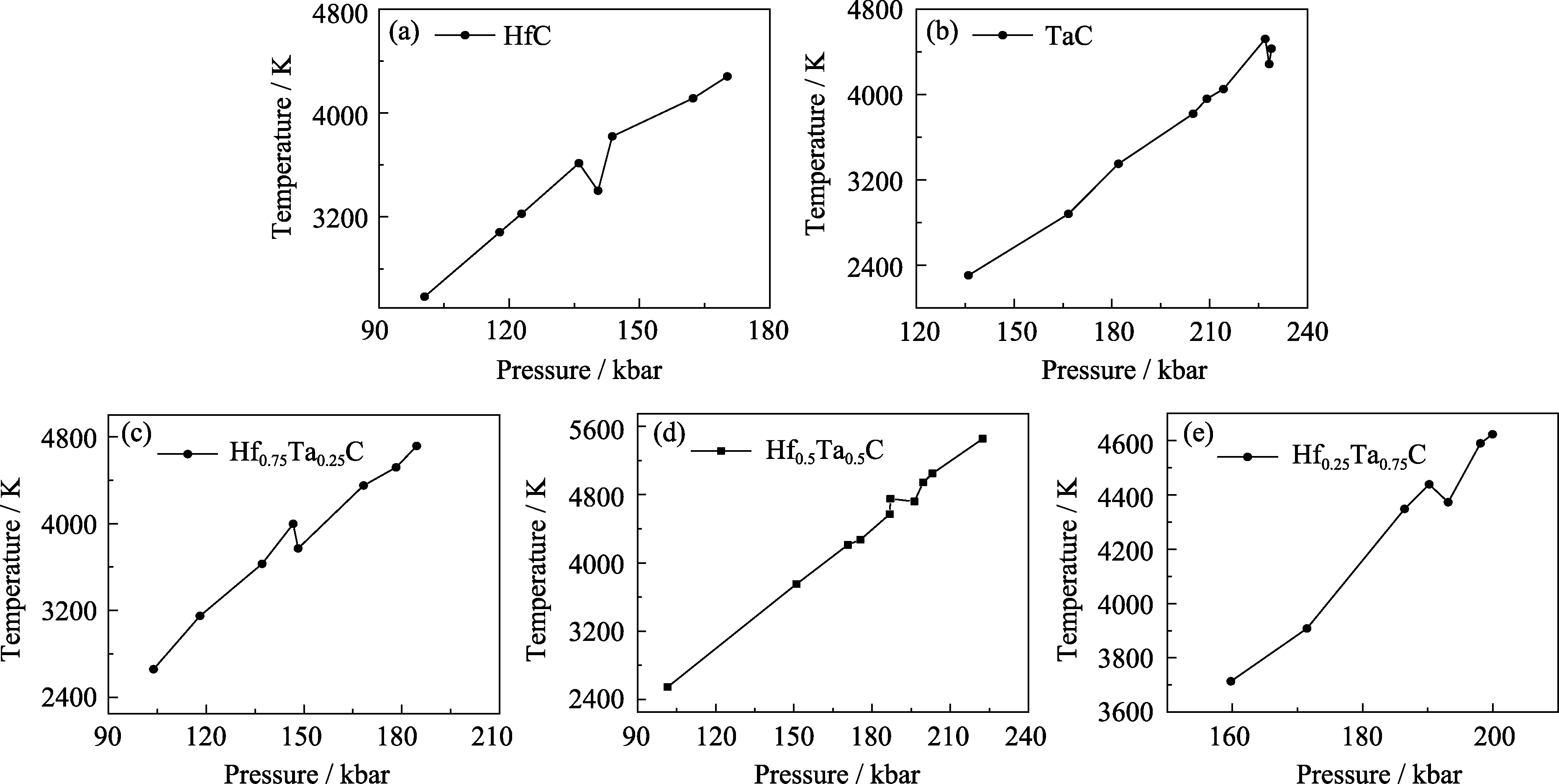

图S3 熔化过程的压力-温度等容曲线

Fig. S3 Pressure-temperature isovolumetric curves during melting process The highest melting point material searched by Bayesian global optimization with deep potential molecular dynamics (a) TaC; (b) HfC; (c) Hf0.75Ta0.25C; (d) Hf0.5Ta0.5C; (e) Hf0.25Ta0.75C

| Compound | Pressure/GPa | Melting temperature/K |

|---|---|---|

| HfC | 14.05 | 3402.1 |

| Hf0.75Ta0.25C | 14.82 | 3771.8 |

| Hf0.5Ta0.5C | 19.62 | 4720.2 |

| Hf0.25Ta0.75C | 19.31 | 4373.0 |

| TaC | 22.83 | 4285.3 |

表S2 HfC、Hf0.75Ta0.25C、Hf0.5Ta0.5C、Hf0.25Ta0.75C和TaC的熔化温度及对应的压力

Table S2 Melting temperatures and corresponding pressures of HfC, Hf0.75Ta0.25C, Hf0.5Ta0.5C, Hf0.25Ta0.75C, and TaC

| Compound | Pressure/GPa | Melting temperature/K |

|---|---|---|

| HfC | 14.05 | 3402.1 |

| Hf0.75Ta0.25C | 14.82 | 3771.8 |

| Hf0.5Ta0.5C | 19.62 | 4720.2 |

| Hf0.25Ta0.75C | 19.31 | 4373.0 |

| TaC | 22.83 | 4285.3 |

| [1] | NI D, CHENG Y, ZHANG J, et al. Advances in ultra-high temperature ceramics, composites, and coatings. Journal of Advanced Ceramics, 2022, 11: 1. |

| [2] | FAHRENHOLTZ W G, HILMAS G E. Ultra-high temperature ceramics: materials for extreme environments. Scripta Materialia, 2017, 129: 94. |

| [3] | ZHANG J, ZHANG Y, FU Y, et al. Growth mechanism and ablation behavior of CVD-HfC coating on the surface of C/C composites and CVD-SiC coating. Corrosion Science, 2021, 192: 109819. |

| [4] | REN J, FENG E, ZHANG Y, et al. Influences of deposition temperature, gas flow rate and ZrC content on the microstructure and anti-ablation performance of CVD-HfC-ZrC coating. Ceramics International, 2021, 47(1): 556. |

| [5] | ZHANG M, REN X, CHU H, et al. Oxidation inhibition behaviors of the HfB2-SiC-TaSi2 coating for carbon structural materials at 1700 ℃. Corrosion Science, 2020, 177: 108982. |

| [6] | REN X, CHU H, WU K, et al. Effect of the ZrB2 content on the oxygen blocking ability of ZrB2-SiC coating at 1973 K. Journal of the European Ceramic Society, 2021, 41(2): 1059. |

| [7] | KE Y, CHEN Y I. Mechanical properties, bonding characteristics, and thermal stability of magnetron-sputtered HfNx films. Surface and Coatings Technology, 2020, 388: 125575. |

| [8] | CEDILLOS-BARRAZA O, GRASSO S, Al N N, et al. Sintering behaviour, solid solution formation and characterisation of TaC, HfC and TaC-HfC fabricated by spark plasma sintering. Journal of the European Ceramic Society, 2016, 36(7): 1539. |

| [9] | ANDRIEVSKII R A, STREL'NIKOVA N S, POLTORATSKII N I, et al. Melting point in systems ZrC-HfC, TaC-ZrC, TaC-HfC. Soviet Powder Metallurgy and Metal Ceramics, 1967, 6: 65. |

| [10] | SMITH C J, YU X X, GUO Q, et al. Phase, hardness, and deformation slip behavior in mixed HfxTa1-xC. Acta Materialia, 2018, 145: 142. |

| [11] | ZHANG Y, LI S, LI N, et al. Experimental and theoretical study on electronic structure and mechanical property of TaxHf1-xC. Journal of Alloys and Compounds, 2021, 884: 161040. |

| [12] | KIM J, KIM M, ROH K M, et al. Bond characteristics, mechanical properties, and high-temperature thermal conductivity of (Hf1-xTax)C composites. Journal of the American Ceramic Society, 2019, 102(10): 6298. |

| [13] | ZUNGER A, WEI S H, FERREIRA L G, et al. Special quasirandom structures. Physical Review Letters, 1990, 65(3): 353. |

| [14] | PENG J, TIKHONOV E. Improving the mechanical properties of HfC-based ceramics by exploring composition space of Hf1-xTaxC and HfC1-xNx. Computational Materials Science, 2021, 195: 110464. |

| [15] | HONG Q J, VAN D W A. Prediction of the material with highest known melting point from ab initio molecular dynamics calculations. Physical Review B, 2015, 92(2): 020104. |

| [16] | AGTE C, ALTERTHUM H. Untersuchungen über systeme hochschmelzender carbide: nebst beiträgen zum problem der kohlenstoffschmelzung. Z. Tech. Physik, 1930, 11: 182. |

| [17] | RUDY E. Ternary phase equilibria in transition metal-boron- carbon-silicon systems: part V. Compendium of phase diagram data. USA: Air Force Materials Laboratory, 1969. |

| [18] | WANG Y N, WEN B, JIAO J J, et al. The highest melting point material: searched by Bayesian global optimization with deep potential molecular dynamics. Journal of Advanced Ceramics, 2023, 12(4): 803. |

| [19] | BELONOSHKO A B, SKORODUMOVA N V, ROSENGREN A, et al. Melting and critical superheating. Physical Review B, 2006, 73(1): 012201. |

| [20] | BELONOSHKO A B, DAVIS S, SKORODUMOVA N V, et al. Properties of the fcc Lennard-Jones crystal model at the limit of superheating. Physical Review B, 2007, 76(6): 064121. |

| [21] | GONZÁLEZ-CATALDO F, CORVACHO F, GUTIÉRREZ G. Melting curve of Si by means of the Z-method. Journal of Physics: Conference Series, 2018, 1043(1): 012038. |

| [22] | FOMIN Y D. Melting line and thermodynamic properties of a supeionic compound SrCl2 by molecular dynamics simulation. Physics and Chemistry of Liquids, 2022, 60(1): 59. |

| [23] | CUI C, XIAN J, LIU H, et al. Melting curve of magnesium up to 460 GPa from ab initio molecular dynamics simulations. Journal of Applied Physics, 2022, 131(19): 195901. |

| [24] | KRESSE G, FURTHMÜLLER J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane- wave basis set. Computational Materials Science, 1996, 6(1): 15. |

| [25] | KRESSE G, FURTHMÜLLER J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Physical review B, 1996, 54(16): 11169. |

| [26] | KRESSE G, JOUBERT D. From ultrasoft pseudopotentials to the projector augmented-wave method. Physical Review B, 1999, 59(3): 1758. |

| [27] | BLÖCHL P E. Projector augmented-wave method. Physical Review B, 1994, 50(24): 17953. |

| [28] | PERDEW J P, BURKE K, ERNZERHOF M. Generalized gradient approximation made simple. Physical Review Letters, 1996, 77(18): 3865. |

| [29] | PERDEW J P, RUZSINSZKY A, CSONKA G I, et al. Restoring the density-gradient expansion for exchange in solids and surfaces. Physical Review Letters, 2008, 100(13): 136406. |

| [30] | TIAN L Y, HU Q M, YANG R, et al. Elastic constants of random solid solutions by SQS and CPA approaches: the case of fcc Ti-Al. Journal of Physics: Condensed Matter, 2015, 27(31): 315702. |

| [31] | VOIGT W. Lehrbuch der kristallphysik. Leipzig: BG Teubner, 1928. |

| [32] | REUSS A. Calculation of the flow limits of mixed crystals on the basis of the plasticity of monocrystals. Zeitschrift fur Angewandte Mathematik und Mechanik, 1929, 9: 49. |

| [33] | HILL R. The elastic behaviour of a crystalline aggregate. Proceedings of the Physical Society. Section A, 1952, 65(5): 349. |

| [34] | PUGH S F. XCII. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1954, 45(367): 823. |

| [35] | CHEN X Q, NIU H, LI D, et al. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics, 2011, 19(9): 1275. |

| [36] | DRONSKOWSKI R, BLÖCHL P E. Crystal orbital Hamilton populations (COHP): energy-resolved visualization of chemical bonding in solids based on density-functional calculations. Journal of Physical Chemistry, 1993, 97(33): 8617. |

| [37] | JHI S H, IHM J, LOUIE S G, et al. Electronic mechanism of hardness enhancement in transition-metal carbonitrides. Nature, 1999, 399(6732): 132. |

| [38] | FINE M E, BROWN L D, MARCUS H L. Elastic constants versus melting temperature in metals. Scripta Metallurgica, 1984, 18(9): 951. |

| [39] | WANG S L, PAN Y. Insight into the structures, melting points, and mechanical properties of NbSi2 from first-principles calculations. Journal of the American Ceramic Society, 2019, 102(8): 4822. |

| [40] | LIU S Y, ZHANG S, LIU S, et al. Phase stability, mechanical properties and melting points of high-entropy quaternary metal carbides from first-principles. Journal of the European Ceramic Society, 2021, 41(13): 6267. |

| [41] | 张硕鑫, 刘士余, 严达利, 等. Ta1-xHfxC和Ta1-xZrxC固溶体的结构稳定性和力学性质的第一性原理研究. 物理学报, 2021, 70(11): 308. |

| [1] | 靳宇翔, 宋二红, 朱永福. 3d过渡金属单原子掺杂石墨烯缺陷电催化还原CO2的第一性原理研究[J]. 无机材料学报, 2024, 39(7): 845-852. |

| [2] | 张睿, 张侃, 袁梦雅, 谷鑫磊, 郑伟涛. 氮空位调控晶格畸变度强化(NbMoTaW)Nx薄膜的力学性质和耐磨损性[J]. 无机材料学报, 2024, 39(6): 715-725. |

| [3] | 王伟华, 张磊宁, 丁峰, 代兵, 韩杰才, 朱嘉琦, 贾怡, 杨宇. 铱衬底上金刚石外延形核与生长: 第一性原理计算[J]. 无机材料学报, 2024, 39(4): 416-422. |

| [4] | 张宇晨, 陆知遥, 赫晓东, 宋广平, 朱春城, 郑永挺, 柏跃磊. 硫族MAX相硼化物的物相稳定性和性能预测[J]. 无机材料学报, 2024, 39(2): 225-232. |

| [5] | 周靖渝, 李兴宇, 赵晓琳, 王有伟, 宋二红, 刘建军. Ti和Cu掺杂β-NaMnO2正极材料:钠离子电池的倍率和循环性能[J]. 无机材料学报, 2024, 39(12): 1404-1412. |

| [6] | 陈梦杰, 王倩倩, 吴成铁, 黄健. 基于DFT的描述符预测生物陶瓷的降解性[J]. 无机材料学报, 2024, 39(10): 1175-1181. |

| [7] | 周云凯, 刁亚琪, 王明磊, 张宴会, 王利民. 聚苯胺改性Ti3C2(OH)2抗氧化性的第一性原理计算研究[J]. 无机材料学报, 2024, 39(10): 1151-1158. |

| [8] | 吴晓维, 张涵, 曾彪, 明辰, 孙宜阳. 杂化泛函HSE和PBE0计算CsPbI3缺陷性质的比较研究[J]. 无机材料学报, 2023, 38(9): 1110-1116. |

| [9] | 张守超, 陈洪雨, 刘洪飞, 杨羽, 李欣, 刘德峰. 6H-SiC中子辐照肿胀高温回复及光学特性研究[J]. 无机材料学报, 2023, 38(6): 678-686. |

| [10] | 杨颖康, 邵怡晴, 李柏良, 吕志伟, 王路路, 王亮君, 曹逊, 吴宇宁, 黄荣, 杨长. Cl掺杂对CuI薄膜发光性能增强研究[J]. 无机材料学报, 2023, 38(6): 687-692. |

| [11] | 文志勤, 黄彬荣, 卢涛仪, 邹正光. 压力对PbTiO3结构和热物性质影响的第一性原理研究[J]. 无机材料学报, 2022, 37(7): 787-794. |

| [12] | 孙铭, 邵溥真, 孙凯, 黄建华, 张强, 修子扬, 肖海英, 武高辉. RGO/Al复合材料界面性质第一性原理研究[J]. 无机材料学报, 2022, 37(6): 651-659. |

| [13] | 肖美霞, 李苗苗, 宋二红, 宋海洋, 李钊, 毕佳颖. 表面端基卤化Ti3C2 MXene应用于锂离子电池高容量电极材料的研究[J]. 无机材料学报, 2022, 37(6): 660-668. |

| [14] | 袁罡, 马新国, 贺华, 邓水全, 段汪洋, 程正旺, 邹维. 平面应变对二维单层MoSi2N4能带结构和光电性质的影响[J]. 无机材料学报, 2022, 37(5): 527-533. |

| [15] | 冯清影, 刘东, 张莹, 冯浩, 李强. 太阳能驱动的两步热化学循环二氧化碳裂解反应活性材料的热力学与第一性原理评价[J]. 无机材料学报, 2022, 37(2): 223-229. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||