无机材料学报 ›› 2023, Vol. 38 ›› Issue (8): 971-977.DOI: 10.15541/jim20230039 CSTR: 32189.14.10.15541/jim20230039

所属专题: 【生物材料】骨骼与齿类组织修复(202506)

收稿日期:2023-01-20

修回日期:2023-02-27

出版日期:2023-08-20

网络出版日期:2023-03-17

通讯作者:

叶松, 副教授. E-mail: yesong@tongji.edu.cn;作者简介:倪晓诗(1997-), 女, 硕士研究生. E-mail: 2030638@tongji.edu.cn

NI Xiaoshi( ), LIN Ziyang, QIN Muyan, YE Song(

), LIN Ziyang, QIN Muyan, YE Song( ), WANG Deping(

), WANG Deping( )

)

Received:2023-01-20

Revised:2023-02-27

Published:2023-08-20

Online:2023-03-17

Contact:

YE Song, associate professor. E-mail: yesong@tongji.edu.cn;About author:NI Xiaoshi (1997-), female, Master candidate. E-mail: 2030638@tongji.edu.cn

Supported by:摘要:

聚甲基丙烯酸甲酯(PMMA)骨水泥因具有良好的力学性能、适宜的凝固时间和低毒性等优点而在骨科手术中作为可注射型人工骨修复材料受到广泛的应用。然而,其生物惰性可能导致假体长期植入后产生无菌性松动。本研究采用模板法制备了介孔硼硅酸盐生物玻璃微球(MBGS), 并用硅烷偶联剂γ-甲基丙烯酰氧基丙基三甲氧基硅烷(γ-MPS)对其进行改性, 制备了MBGSSI。再将硅烷化介孔硼硅酸盐生物玻璃微球(MBGSSI)与聚甲基丙烯酸甲酯(PMMA)骨水泥复合, 制备了一种具有良好生物活性和力学性能的复合骨水泥。实验结果表明, 由于γ-MPS与MBGS的结合主要发生在介孔微球的近表面, MBGSSI比MBGS具有更大的比表面积和更小的孔容积。与MBGS/PMMA复合骨水泥相比, γ-MPS可以改善复合材料中无机相和有机相之间的结合, 因此MBGSSI/PMMA复合骨水泥的力学性能得到了改善, 符合ISO 5833:2002对丙烯酸类骨水泥的力学性能要求。此外, 在SBF溶液中浸泡42 d后, MBGS/PMMA和MBGSSI/PMMA复合骨水泥的表面均生成了羟基磷灰石(HA), 证明复合骨水泥具有良好的生物活性。因此, MBGSSI/PMMA复合骨水泥是一种潜在的骨修复材料。

中图分类号:

倪晓诗, 林子扬, 秦沐严, 叶松, 王德平. 硅烷化介孔硼硅酸盐生物玻璃微球对PMMA骨水泥生物活性和力学性能的影响[J]. 无机材料学报, 2023, 38(8): 971-977.

NI Xiaoshi, LIN Ziyang, QIN Muyan, YE Song, WANG Deping. Bioactivity and Mechanical Property of PMMA Bone Cement: Effect of Silanized Mesoporous Borosilicate Bioglass Microspheres[J]. Journal of Inorganic Materials, 2023, 38(8): 971-977.

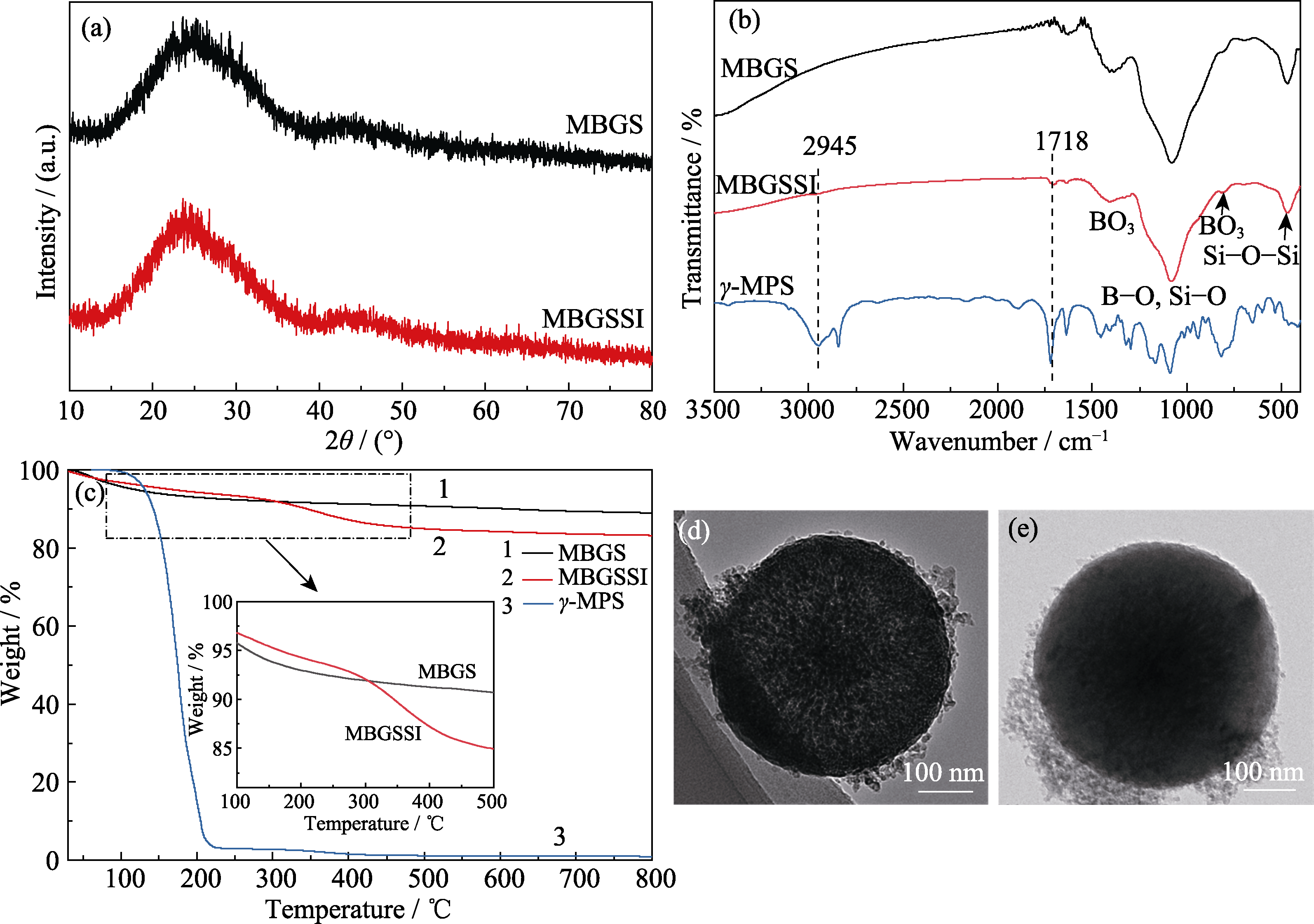

Fig. 1 Microstructures and constituents of MBGS and MBGSSI (a) XRD patterns of MBGS and MBGSSI; (b, c) FT-IR spectra (b) and TG curves (c) of MBGS, MBGSSI and γ-MPS; (d, e) TEM images of MBGS (d) and MBGSSI (e)

Fig. 2 (a) N2 adsorption-desorption isotherms and (b) corresponding pore size distributions of MBGS, and (c) schematic diagram of the surface silanization

| Sample | Specific surface area/(m2•g-1) | Average pore diameter/nm | Total pore volume/(mL•g-1) |

|---|---|---|---|

| MBGS | 84.047 | 33.9676 | 0.7137 |

| MBGSSI | 227.856 | 10.22 | 0.5822 |

Table 1 Specific surface area, average pore diameter and total pore volume of MBGS and MBGSSI

| Sample | Specific surface area/(m2•g-1) | Average pore diameter/nm | Total pore volume/(mL•g-1) |

|---|---|---|---|

| MBGS | 84.047 | 33.9676 | 0.7137 |

| MBGSSI | 227.856 | 10.22 | 0.5822 |

| Sample | C1s/% | O1s/% | Si2p/% | B1s/% | Ca2p/% |

|---|---|---|---|---|---|

| MBGS | 5.02 | 72.38 | 5.27 | 2.71 | 14.62 |

| MBGSSI 0 nm | 7.91 | 70.26 | 5.68 | 2.27 | 13.88 |

| MBGSSI 100 nm | 5.32 | 68.88 | 6.81 | 2.25 | 16.74 |

Table 2 Atomic concentrations of MBGS, MBGSSI and MBGSSI (etching depth at 100 nm)

| Sample | C1s/% | O1s/% | Si2p/% | B1s/% | Ca2p/% |

|---|---|---|---|---|---|

| MBGS | 5.02 | 72.38 | 5.27 | 2.71 | 14.62 |

| MBGSSI 0 nm | 7.91 | 70.26 | 5.68 | 2.27 | 13.88 |

| MBGSSI 100 nm | 5.32 | 68.88 | 6.81 | 2.25 | 16.74 |

| Sample | Dough time/s | Setting time/min | Peak temperature/℃ | Compressive strength/MPa | Compressive modulus/MPa | Flexural strength/MPa | Flexural modulus/MPa |

|---|---|---|---|---|---|---|---|

| PMMA | 287.5±7.8 | 11.38±0.37 | 49.15±1.45 | 70.01±1.85 | 878.67±55.84 | 67.75±1.88 | 2925.05±144.71 |

| MBGS/PMMA | 136.0±2.8 | 14.77±0.07 | 40.65±0.25 | 71.22±2.20 | 1029.66±63.54 | 44.53±2.59 | 4003.19±125.79 |

| MBGSSI/PMMA | 174.0±5.7 | 18.97±0.20 | 38.40±0.4 | 81.77±1.45 | 1091.50±75.64 | 59.42±4.34 | 3330.03±214.02 |

Table 3 Setting and mechanical properties of PMMA, MBGS/PMMA and MBGSSI/PMMA bone cements

| Sample | Dough time/s | Setting time/min | Peak temperature/℃ | Compressive strength/MPa | Compressive modulus/MPa | Flexural strength/MPa | Flexural modulus/MPa |

|---|---|---|---|---|---|---|---|

| PMMA | 287.5±7.8 | 11.38±0.37 | 49.15±1.45 | 70.01±1.85 | 878.67±55.84 | 67.75±1.88 | 2925.05±144.71 |

| MBGS/PMMA | 136.0±2.8 | 14.77±0.07 | 40.65±0.25 | 71.22±2.20 | 1029.66±63.54 | 44.53±2.59 | 4003.19±125.79 |

| MBGSSI/PMMA | 174.0±5.7 | 18.97±0.20 | 38.40±0.4 | 81.77±1.45 | 1091.50±75.64 | 59.42±4.34 | 3330.03±214.02 |

| [1] |

SHRIDHAR P, CHEN Y, KHALIL R, et al. A review of PMMA bone cement and intra-cardiac embolism. Materials, 2016, 9(10): 821.

DOI URL |

| [2] | GLADIUS L. Alternative acrylic bone cement formulations for cemented arthroplasties: present status, key issues, and future prospects. Journal of Biomedical Materials Research. Part B, Applied Biomaterials, 2008, 84(2): 301. |

| [3] |

ZHU J J, JIANG G Q, QIU Z Y, et al. Modification of poly(methyl methacrylate) bone cement for vertebroplasty. Journal of Biomaterials and Tissue Engineering, 2018, 8(5): 607.

DOI URL |

| [4] |

CHEN L, ZHAI D, HUAN Z G, et al. Silicate bioceramic/PMMA composite bone cement with distinctive physicochemical and bioactive properties. RSC Advances, 2015, 5(47): 37314.

DOI URL |

| [5] | SA Y, YANG F, WIJN J R D, et al. Physicochemical properties and mineralization assessment of porous polymethylmethacrylate cement loaded with hydroxyapatite in simulated body fluid. Materials Science & Engineering C, 2016, 61: 190. |

| [6] |

FERREIRA B J M L, BARROCA N B, LOPES P P, et al. Properties of novel PMMA-co-EHA bone cements filled with hydroxyapatite. Polymer Composites, 2014, 35(4): 759.

DOI URL |

| [7] |

SERGI R, BELLUCCI D, CANNILLO V. A comprehensive review of bioactive glass coatings: state of the art, challenges and future perspectives. Coatings, 2020, 10(8): 757.

DOI URL |

| [8] |

BAINO F, FIUME E, MIOLA M, et al. Bioactive Sol-Gel glasses: processing, properties, and applications. International Journal of Applied Ceramic Technology, 2018, 15(4): 841.

DOI URL |

| [9] |

LI Y, CHEN X, NING C, et al. Facile synthesis of mesoporous bioactive glasses with controlled shapes. Materials Letters, 2015, 161: 605.

DOI URL |

| [10] |

ZHONG J P, GREENSPAN D C. Processing and properties of Sol-Gel bioactive glasses. Journal of Biomedical Materials Research, 2000, 53(6): 694.

DOI URL |

| [11] | CUI X, HUANG C C, ZHANG M, et al. Enhanced osteointegration of poly(methylmethacrylate) bone cements by incorporating strontium-containing borate bioactive glass. Journal of the Royal Society Interface, 2017, 14(131): 20161057. |

| [12] |

BOLAINA-LORENZO E D, CERVANTES-UC J M, CAUICH- RODRIGUEZ J V, et al. Effect of barium sulfate surface treatments on the mechanical properties of acrylic bone cements. Polymer Bulletin, 2020, 78(3): 1.

DOI |

| [13] | DEBNATH S, RANADE R, WUNDER S L, et al. Interface effects on mechanical properties of particle-reinforced composites. Dental Materials: Official Publication of the Academy of Dental Materials, 2004, 20(7): 677. |

| [14] |

LUNG C Y K, MATINLINNA J P. Aspects of silane coupling agents and surface conditioning in dentistry: an overview. Dental Materials, 2012, 28(5): 467.

DOI URL |

| [15] |

CHANG Y C, LIN Z Y, XIE X, et al. An injectable composite bone cement based on mesoporous borosilicate bioactive glass spheres Journal of Inorganic Materials, 2020, 35(12): 1398.

DOI URL |

| [16] |

MATINLINNA J P, LUNG C Y K, TSOI J K H. Silane adhesion mechanism in dental applications and surface treatments: a review. Dental Materials, 2018, 34(1): 13.

DOI URL |

| [17] |

ALONSO L M, GARCIA-MENOCAL J A, AYMERICH M T, et al. Calcium phosphate glasses: silanation process and effect on the bioactivity behavior of glass-PMMA composites. Journal of Biomedical Materials Research. Part B, Applied Biomaterials, 2014, 102(2): 205.

DOI URL |

| [18] | SALON M C B, BAYLE P A, ABDELMOULEH M, et al. Kinetics of hydrolysis and self condensation reactions of silanes by NMR spectroscopy. Colloids and Surfaces a-Physicochemical and Engineering Aspects, 2008, 312(2): 83. |

| [19] | ISO member body. International Standard. Implants for Surgery-Acrylic Resin Cements. ISO5833: 2002. Switzerland: ISO organization-(IX-ISO), 2002. |

| [20] |

LIU X, RAHAMAN M N, DAY D E. Conversion of melt-derived microfibrous borate (13-93B3) and silicate (45S5) bioactive glass in a simulated body fluid. Journal of Materials Science. Materials in Medicine, 2013, 24(3): 583.

DOI URL |

| [21] |

ALI A A, RAMMAH Y S, EL-MALLAWANY R, et al. FTIR and UV spectra of pentaternary borate glasses. Measurement, 2017, 105: 72.

DOI URL |

| [22] |

ZAGRAJCZUK B, DZIADEK M, OLEJNICZAK Z, et al. Structural and chemical investigation of the gel-derived bioactive materials from the SiO2-CaO and SiO2-CaO-P2O5 systems. Ceramics International, 2017, 43(15): 12742.

DOI URL |

| [23] |

DOU B J, HU Q, LI J J, et al. Adsorption performance of VOCs in ordered mesoporous silicas with different pore structures and surface chemistry. Journal of Hazardous Materials, 2011, 186(2/3): 1615.

DOI URL |

| [24] |

CHEN Z D, MA Y X, GOU L A, et al. Construction of caffeic acid modified porous starch as the dual-functional microcapsule for encapsulation and antioxidant property. International Journal of Biological Macromolecules, 2022, 228: 358.

DOI URL |

| [25] |

CHRISTIAN H, V B D, BRIAN Y, et al. Polymer nanocomposites having a high filler content: synthesis, structures, properties, and applications. Nanoscale, 2019, 11(11): 4653.

DOI URL |

| [26] |

ALDABIB J M, ISHAK Z A M. Effect of hydroxyapatite filler concentration on mechanical properties of poly (methyl methacrylate) denture base. SN Applied Sciences, 2020, 2: 732.

DOI |

| [27] | KINLOCH A J. Adhesion and adhesives: science and technology: London: Chapman and Hall, 1987: 171-187. |

| [1] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [2] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [3] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [4] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [5] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [6] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [7] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [8] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [9] | 孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670. |

| [10] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [11] | 刘国昂, 王海龙, 方成, 黄飞龙, 杨欢. B4C含量对(Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C陶瓷力学性能及抗氧化性能的影响[J]. 无机材料学报, 2024, 39(6): 697-706. |

| [12] | 粟毅, 史扬帆, 贾成兰, 迟蓬涛, 高扬, 马青松, 陈思安. 浆料浸渍辅助PIP工艺制备C/HfC-SiC复合材料的微观结构及性能研究[J]. 无机材料学报, 2024, 39(6): 726-732. |

| [13] | 李雷, 程群峰. 高性能MXenes纳米复合材料研究进展[J]. 无机材料学报, 2024, 39(2): 153-161. |

| [14] | 刘艳艳, 谢曦, 刘增乾, 张哲峰. MAX相陶瓷增强金属基复合材料: 制备、性能与仿生设计[J]. 无机材料学报, 2024, 39(2): 145-152. |

| [15] | 王博, 蔡德龙, 朱启帅, 李达鑫, 杨治华, 段小明, 李雅楠, 王轩, 贾德昌, 周玉. SrAl2Si2O8增强BN陶瓷的力学性能及抗热震性能[J]. 无机材料学报, 2024, 39(10): 1182-1188. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||