无机材料学报 ›› 2022, Vol. 37 ›› Issue (9): 925-932.DOI: 10.15541/jim20210720 CSTR: 32189.14.10.15541/jim20210720

• 研究论文 • 下一篇

安文然( ), 黄晶琪, 卢祥荣, 蒋佳宁, 邓龙辉, 曹学强(

), 黄晶琪, 卢祥荣, 蒋佳宁, 邓龙辉, 曹学强( )

)

收稿日期:2021-11-22

修回日期:2022-01-19

出版日期:2022-09-20

网络出版日期:2022-02-14

通讯作者:

曹学强, 教授. E-mail: xcao@whut.edu.cn作者简介:安文然(1996-), 女, 硕士研究生. E-mail: anwenran1019@126.com

基金资助:

AN Wenran( ), HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang(

), HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang( )

)

Received:2021-11-22

Revised:2022-01-19

Published:2022-09-20

Online:2022-02-14

Contact:

CAO Xueqiang, professor. E-mail: xcao@whut.edu.cnAbout author:AN Wenran (1996-), female, Master candidate. E-mail: anwenran1019@126.com

Supported by:摘要:

大气等离子喷涂制备的LaMgAl11O19 (LMA)热障涂层无定型相含量较高, 会严重影响涂层服役寿命。通过900~1600 ℃不同温度热处理12 h, 研究晶粒尺寸和孔隙率等微观结构和无定形相含量对LMA涂层力学、热物理以及抗热震性能的影响。结果表明: 喷涂态LMA涂层具有900和1163 ℃两个结晶温度点。900 ℃热处理后, LMA涂层中含有较多的无定形相以及最高的孔隙率((18.88±2.15)%), 1000 ℃测试时,具有最低的热扩散系数(0.53 mm2/s); 由于重结晶和烧结作用使得无定型相含量和孔隙率降低, 1100~1400 ℃之间热处理的涂层具有较高的硬度(1100℃时达到最高值(12.08±0.58) GPa); 1300 ℃热处理的涂层中含有大量微米级片状晶, 具有较高的应变容限以及平均热循环寿命(588次); 热处理温度达到1500 ℃时, 由于片状晶平行堆叠, 晶粒厚度迅速增加, 孔隙率增加、力学性能显著降低。热震过程中由于热应力的反复作用, 涂层内出现晶粒破碎和裂纹扩展等现象, 导致涂层最终失效。

中图分类号:

安文然, 黄晶琪, 卢祥荣, 蒋佳宁, 邓龙辉, 曹学强. 热处理温度对LaMgAl11O19涂层热/力学性能的影响[J]. 无机材料学报, 2022, 37(9): 925-932.

AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating[J]. Journal of Inorganic Materials, 2022, 37(9): 925-932.

| Coating | Spray distance/mm | Power/kW | Current/A | Plasma gas Ar/H2/slpm* | Gun velocity/(mm∙s-1) | Feeding rate/(g∙min-1) |

|---|---|---|---|---|---|---|

| LMA | 100 | 42 | 620 | 35/12 | 800 | 35 |

表1 APS喷涂参数

Table 1 Parameters of air plasma spraying

| Coating | Spray distance/mm | Power/kW | Current/A | Plasma gas Ar/H2/slpm* | Gun velocity/(mm∙s-1) | Feeding rate/(g∙min-1) |

|---|---|---|---|---|---|---|

| LMA | 100 | 42 | 620 | 35/12 | 800 | 35 |

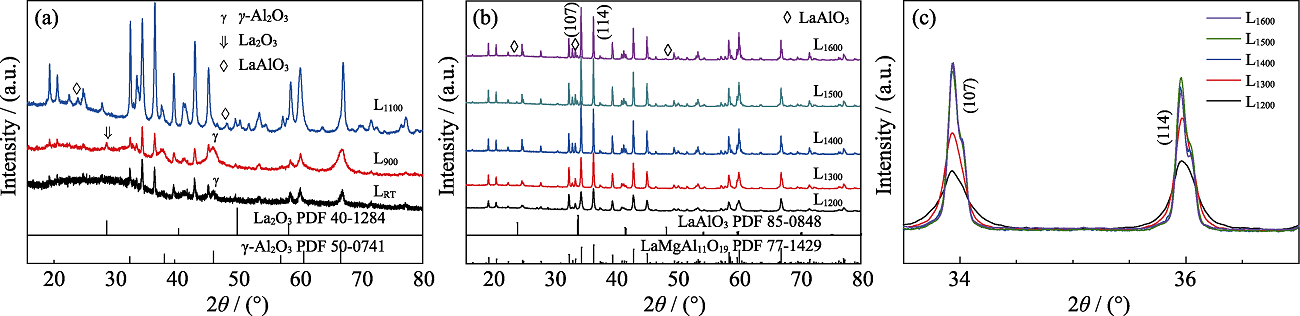

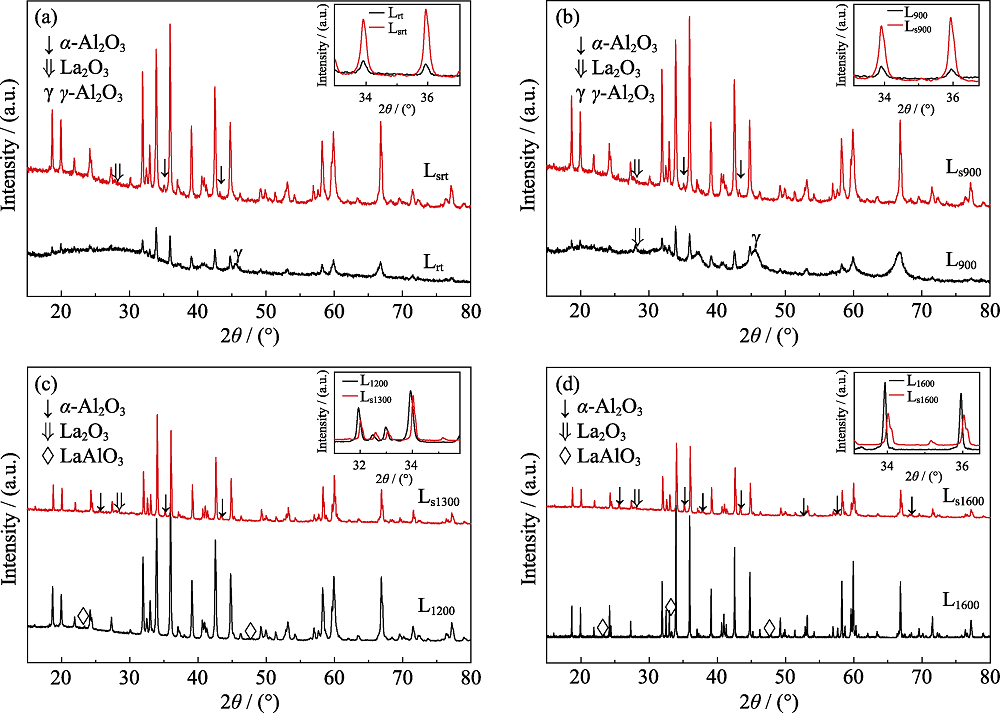

图3 不同温度热处理后LMA涂层的XRD图谱

Fig. 3 XRD patterns of LMA coatings after heat-treatement at different temperatures (a) Lrt, L900, L1100; (b) L1200, L1300, L1400, L1500, and L1600; (c) Local magnification XRD patterns at 2θ between 33.5°-37° of (b)

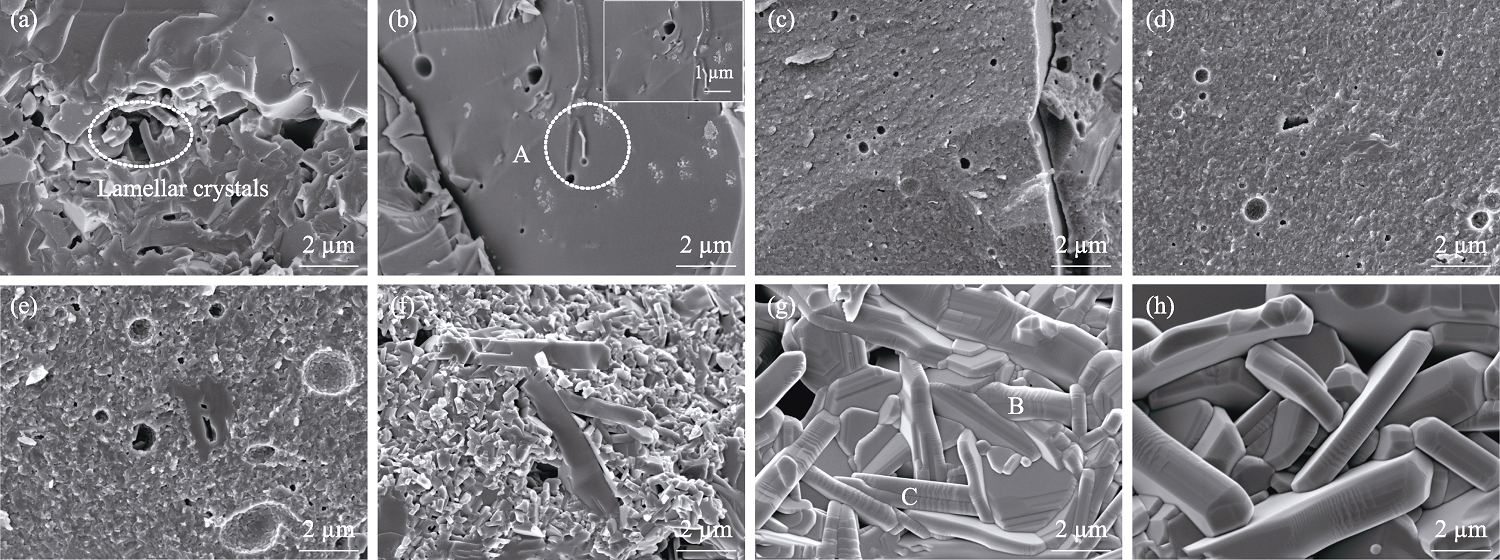

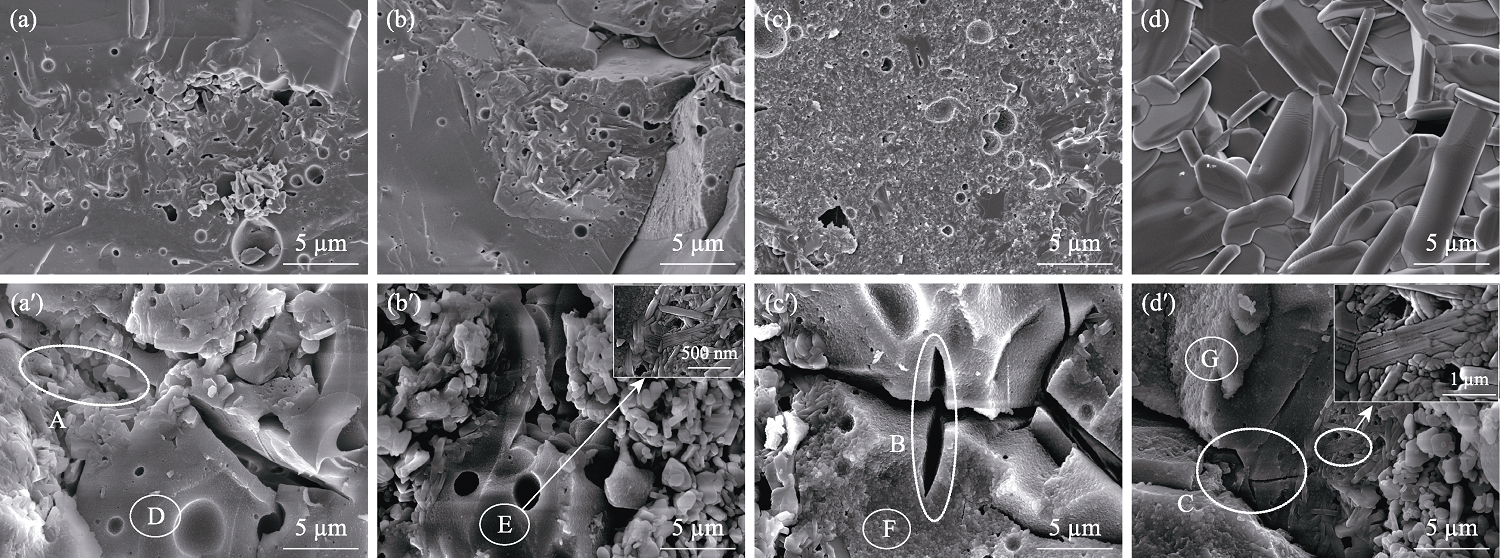

图4 不同温度热处理后LMA涂层的断面SEM照片

Fig. 4 Fractured cross-section morphologies of LMA coatings after heat-treatement at different temperatures (a) Lrt; (b) L900; (c) L1100; (d) L1200; (e) L1300; (f) L1400; (g) L1500; (h) L1600

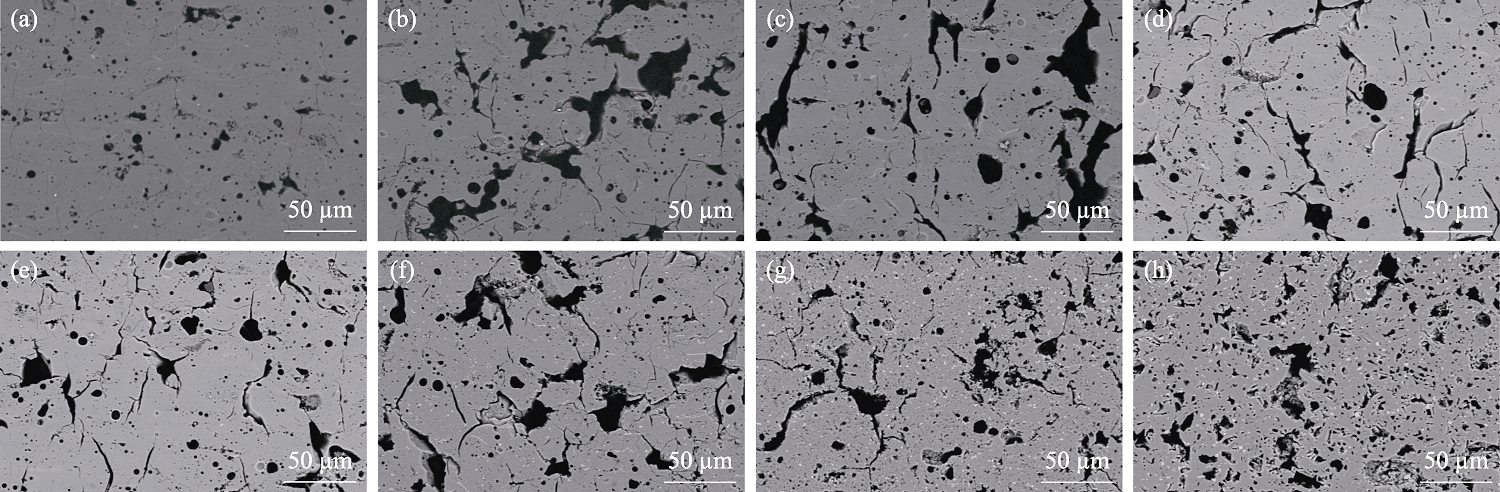

图6 不同温度热处理后LMA涂层截面的SEM照片

Fig. 6 Cross-sectional morphologies of LMA coatings after heat-treatement at different temperatures (a) Lrt; (b) L900; (c) L1100; (d) L1200; (e) L1300; (f) L1400; (g) L1500; (h) L1600

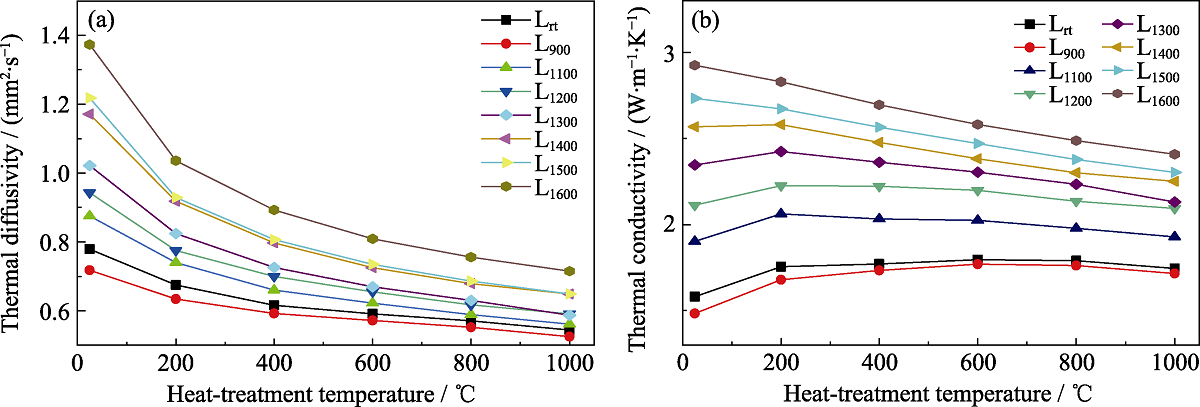

图9 不同温度热处理后涂层的热物理性能

Fig. 9 Thermophysical properties of coatings after heat-treatement at different temperatures (a) Thermal diffusivity; (b) Thermal conductivity

图10 热震失效前后涂层XRD图谱对比

Fig. 10 Comparisons of XRD patterns of coatings before and after thermal shock (a) Lrt and Lsrt; (b) L900 and Ls900; (c) L1300 and Ls1300; (d) L1600 and Ls1600

图11 涂层热震前后涂层断面的微观结构

Fig. 11 Fractured cross-sectional morphologies of coatings before and after thermal shock (a) Lrt; (a′) Lsrt; (b) L900; (b′) Ls900; (c) L1300; (c′) Ls1300; (d) L1600; (d′) Ls1600

| HV/GPa | Lrt | L900 | L1300 | L1600 |

|---|---|---|---|---|

| Before | 6.61 | 6.56 | 11.08 | 6.76 |

| After | 10.12 | 10.89 | 12.07 | 11.01 |

表2 涂层热震失效前后硬度对比

Table 2 Vickers hardness of coatings before and after thermal shock

| HV/GPa | Lrt | L900 | L1300 | L1600 |

|---|---|---|---|---|

| Before | 6.61 | 6.56 | 11.08 | 6.76 |

| After | 10.12 | 10.89 | 12.07 | 11.01 |

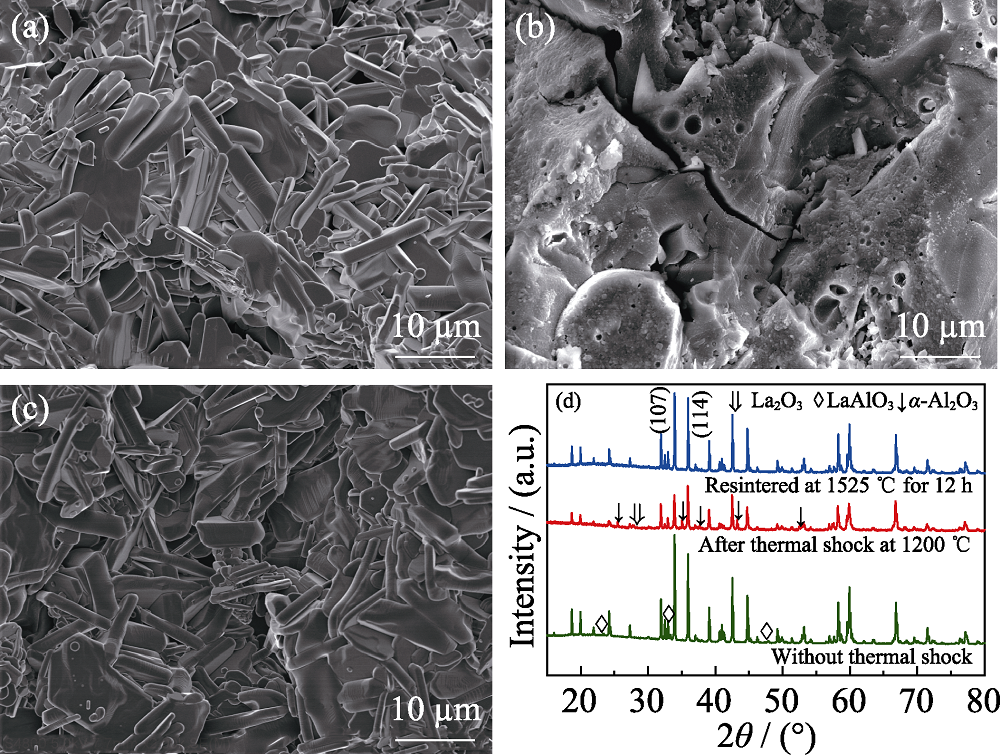

图12 L1600在不同状态下的(a~c)断面微观结构及(d) XRD图谱

Fig. 12 (a-c) Fractured cross-section morphologies and (d) XRD patterns of L1600 heat-treatement at different conditions (a) L1600; (b) Ls1600; (c) Ls1600-1525

| [1] |

CAO X Q, VASSEN R, STOEVER D. Ceramic materials for thermal barrier coatings. Journal of the European Ceramic Society, 2004, 24(1): 1-10.

DOI URL |

| [2] |

CLARKE D R, OECHSNER M, PADTURE N P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bulletin, 2012, 37(10): 891-902.

DOI URL |

| [3] | CLARKE D R, PHILLPOT S R. Thermal barrier coating materials. Materials Today, 2005, 8(6): 22-29. |

| [4] |

EVANS A G, CLARKE D R, LEVI C G. The influence of oxides on the performance of advanced gas turbines. Journal of the European Ceramic Society, 2008, 28(7): 1405-1419.

DOI URL |

| [5] | MAO W G, LUO J M, DAI C Y, et al. Effect of heat treatment on deformation and mechanical properties of 8mol% yttria-stabilized zirconia by berkovich nanoindentation. Applied Surface Science, 2015, 338: 92-98. |

| [6] |

ZHOU X, HE L M, CAO X Q, et al. La2(Zr0.7Ce0.3)2O7 thermal barrier coatings prepared by electron beam-physical vapor deposition that are resistant to high temperature attack by molten silicate. Corrosion Science, 2016, 115(16): 143-151.

DOI URL |

| [7] |

ZHOU F F, WANG Y, CUI Z Y, et al. Thermal cycling behavior of nanostructured 8YSZ, SZ/8YSZ and 8CSZ/8YSZ thermal barrier coatings fabricated by atmospheric plasma spraying. Ceramics International, 2017, 43(5): 4102-4111.

DOI URL |

| [8] |

HUANG L L, MENG H M, TANG J. Crystallization behavior of plasma-sprayed lanthanide magnesium hexaaluminate coatings. International Journal of Minerals, Metallurgy and Materials, 2014, 21(12): 1247-1253.

DOI URL |

| [9] |

LU H R, WANG C A, ZHANG C G, et al. Thermo-physical properties of rare-earth hexaaluminates LnMgAl11O19 (Ln: La, Pr, Nd, Sm, Eu and Gd) magnetoplumbite for advanced thermal barrier coatings. Journal of the European Ceramic Society, 2015, 35(4): 1297-1306.

DOI URL |

| [10] |

KINGERY W D, MCQUARRIE M C. Thermal conductivity: i, concepts of measurement and factors affecting thermal conductivity of ceramic materials. Journal of the American Ceramic Society, 1954, 37(2): 67-72.

DOI URL |

| [11] | LIU H Z, OUYANG J H, LIU Z G, et al. Microstructure, thermal shock resistance and thermal emissivity of plasma sprayed LaMAl11O19 (M=Mg, Fe) coatings for metallic thermal protection systems. Applied Surface Science, 2013, 217: 52-59. |

| [12] |

CAO X Q, ZHANG Y F, ZHANG J F, et al. Failure of the plasma-sprayed coating of lanthanum hexaluminate. Journal of the European Ceramic Society, 2008, 28(10): 1979-1986.

DOI URL |

| [13] |

SUN J B, WANG J S, ZHOU X, et al. Thermal cycling behavior of the plasma-sprayed coating of lanthanum hexaaluminate. Journal of the European Ceramic Society, 2018, 38(4): 1919-1929.

DOI URL |

| [14] |

ZENG J Y, SUN J B, LIANG P P, et al. Heat-treated lanthanum magnesium hexaaluminate coatings exposed to molten calcium- magnesium-alumino-silicate. Ceramics International, 2019, 45(9): 11723-11733.

DOI URL |

| [15] | SUN J B, WANG J S, DONG S J, et al. Effect of heat treatment on microstructure and property of plasma-sprayed lanthanum hexaaluminate coating. Journal of Alloys and Compounds, 2018, 739: 856-865. |

| [16] |

CHAO C Y, REN Z H, ZHU Y H, et al. Self-templated synthesis of single-crystal and single-domain ferroelectric nanoplates. Angewandte Chemie International Edition, 2012, 51(37): 9283-9287.

DOI URL |

| [17] |

SUN J B, WANG J S, ZHOU X, et al. Microstructure and thermal cycling behavior of plasma-sprayed LaMgAl11O19 coatings. Ceramics International, 2018, 44(5): 5572-5580.

DOI URL |

| [18] |

DOMINGUEZ C, CHEVALIER J, TORRECILLAS R, et al. Microstructure development in calcium hexaluminate. Journal of the European Ceramic Society, 2001, 21(3): 381-387.

DOI URL |

| [19] | SUN X M, DU L Z, LAN H, et al. Study on thermal shock behavior of YSZ abradable sealing coating prepared by mixed solution precursor plasma spraying. Surface & Coatings Technology, 2020, 397: 126045. |

| [20] |

ZHOU X, SONG W J, YUAN J Y, et al. Thermophysical properties and cyclic lifetime of plasma sprayed SrAl12O19 for thermal barrier coating applications. Journal of the American Ceramic Society, 2020, 103(10): 5599-5611.

DOI URL |

| [21] |

TARASI F, MEDRAJ M, DOLATABADI A, et al. High- temperature performance of alumina-zirconia composite coatings containing amorphous phases. Advanced Functional Materials, 2011, 21(21): 4143-4151.

DOI URL |

| [22] |

CHEN X L, ZHANG Y F, ZHONG X H, et al. Thermal cycling behaviors of the plasma sprayed thermal barrier coatings of hexaluminates with magnetoplumbite structure. Journal of the European Ceramic Society, 2010, 30(7): 1649-1657.

DOI URL |

| [23] | 杨晓洁, 常雪婷, 范润华. 快速多重旋转碾压诱导Ti-6Al-4V 表面纳米晶及性能研究. 表面技术, 2021, 50(5): 177-183. |

| [24] |

ARAI Y, INOUE R, KAKISAWA H. Anisotropic crack propagation behavior for the silicon-bond coat layer in a multilayer coated system. International Journal of Applied Ceramic Technology, 2021, 18(3): 947-956.

DOI URL |

| [25] |

SONG X M, SUHONEN T, SUN C, et al. Microstructures, microhardness, and crystallization behaviors of amorphous Al2O3- YSZ coatings prepared by air plasma spraying. Surface Review and Letters, 2015, 22(4): 1550047.

DOI URL |

| [1] | 李捷, 罗志新, 崔阳, 张广珩, 孙鲁超, 王京阳. 大气等离子喷涂Y3Al5O12/Al2O3陶瓷涂层的CMAS腐蚀抗力[J]. 无机材料学报, 2024, 39(6): 671-680. |

| [2] | 吴爽, 苟燕子, 王永寿, 宋曲之, 张庆雨, 王应德. 高温热处理对国产KD-SA型SiC纤维组成结构与力学性能的影响[J]. 无机材料学报, 2023, 38(5): 569-576. |

| [3] | 张硕, 付前刚, 张佩, 费杰, 李伟. C/C多孔体的高温热处理对C/C-SiC复合材料摩擦磨损行为的影响[J]. 无机材料学报, 2023, 38(5): 561-568. |

| [4] | 蔚海浪, 曹学强, 邓龙辉, 蒋佳宁. LaMeAl11O19/YSZ热障涂层热力学性能和热循环寿命[J]. 无机材料学报, 2022, 37(12): 1259-1266. |

| [5] | 朱嘉桐, 楼志豪, 张萍, 赵佳, 孟轩宇, 许杰, 高峰. 稀土钽酸盐(RETaO4)高熵陶瓷的制备与热学性能研究[J]. 无机材料学报, 2021, 36(4): 411-417. |

| [6] | 桑玮玮, 张红松, 陈华辉, 温斌, 李新春. (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7高熵陶瓷的制备及热物理性能[J]. 无机材料学报, 2021, 36(4): 405-410. |

| [7] | 朱勇, 顾军, 于涛, 何海佟, 姚睿. 铂钴合金纳米电催化剂的制备及性能研究[J]. 无机材料学报, 2021, 36(3): 299-305. |

| [8] | 魏玉全,杨勇,刘盟,郦其乐,黄政仁. 高温热处理对SiBCN/HfC复相陶瓷物相组成及微观结构的影响[J]. 无机材料学报, 2020, 35(8): 931-938. |

| [9] | 王志虎,张菊梅,白力静,张国君. AZ31镁合金微弧氧化陶瓷层表面Mg(OH)2膜层的制备及耐蚀性[J]. 无机材料学报, 2020, 35(6): 709-716. |

| [10] | 冀晓鹃,于月光,卢晓亮. 杂质对氧化锆热障涂层性能的影响[J]. 无机材料学报, 2020, 35(6): 669-674. |

| [11] | 付亚康,翁杰,刘耀文,张科宏. 钛网表面含hBMP-2的复合涂层制备及hBMP-2的释放研究[J]. 无机材料学报, 2020, 35(2): 173-178. |

| [12] | 汪丹丹, 田无边, 丁健翔, 马爱斌, 张培根, 何炜, 孙正明. 等通道转角挤压制备Ag/Ti3AlC2复合材料及其热处理研究[J]. 无机材料学报, 2020, 35(1): 46-52. |

| [13] | 马伯乐, 马文, 黄威, 白玉, 贾瑞灵, 董红英. 单相双稀土改性SrZrO3热障涂层的热物理性能[J]. 无机材料学报, 2019, 34(4): 394-400. |

| [14] | 王林, 丁坤英, 林小娉, 李泽, 郑润国, 杨连威. 8YSZ双层热障涂层缺陷演变与微裂纹水浸超声宏观检测[J]. 无机材料学报, 2019, 34(12): 1265-1271. |

| [15] | 廖春景, 董绍明, 靳喜海, 胡建宝, 张翔宇, 吴惠霞. 沉积温度及热处理对低压化学气相沉积氮化硅涂层的影响[J]. 无机材料学报, 2019, 34(11): 1231-1237. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||