无机材料学报 ›› 2022, Vol. 37 ›› Issue (8): 853-864.DOI: 10.15541/jim20220019 CSTR: 32189.14.10.15541/jim20220019

收稿日期:2022-01-13

修回日期:2022-04-12

出版日期:2022-08-20

网络出版日期:2022-04-26

通讯作者:

曾宇平, 研究员. E-mail: yuping-zeng@mail.sic.ac.cn作者简介:张 叶(1994-),男,博士研究生. E-mail: zhangyezn@student.sic.ac.cn

基金资助:Received:2022-01-13

Revised:2022-04-12

Published:2022-08-20

Online:2022-04-26

Contact:

ZENG Yuping, professor. E-mail: yuping-zeng@mail.sic.ac.cnAbout author:ZHANG Ye (1994-), male, PhD candidate. E-mail: zhangyezn@student.sic.ac.cn

Supported by:摘要:

多孔氮化硅陶瓷兼具有高气孔率和陶瓷的优异性能, 在吸声减震、过滤等领域具有非常广泛的应用。然而, 目前常规的制备方法如气压/常压烧结、反应烧结-重烧结以及碳热还原烧结存在烧结时间长、能耗高、设备要求高等不足, 导致多孔Si3N4陶瓷的制备成本居高不下。因此, 探索新的快速、低成本的制备方法具有重要意义。近年来, 采用自蔓延高温合成法直接制备多孔氮化硅陶瓷展现出巨大潜力, 其可以利用Si粉氮化的剧烈放热同时完成多孔氮化硅陶瓷的烧结。本文综述了自蔓延反应的引发以及所制备多孔氮化硅陶瓷的微观形貌、力学性能和可靠性。通过组分设计和工艺优化, 可以制备得到氮化完全、晶粒发育良好、力学性能与可靠性优异的多孔氮化硅陶瓷。此外还综述了自蔓延合成多孔Si3N4陶瓷晶界相性质与高温力学性能之间的关系, 最后展望了自蔓延高温合成多孔Si3N4陶瓷的发展方向。

中图分类号:

张叶, 曾宇平. 自蔓延高温合成氮化硅多孔陶瓷的研究进展[J]. 无机材料学报, 2022, 37(8): 853-864.

ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis[J]. Journal of Inorganic Materials, 2022, 37(8): 853-864.

图1 溶胶-凝胶结合自蔓延合成多孔Si3N4陶瓷光学的照片(a)及放大微观结构图(b~d)[32]

Fig. 1 Optical picture (a) and amplified microstructures (b-d) of the porous Si3N4 ceramics prepared by gel-casting and SHS[32]

| Si/g | Si3N4/g | Y2O3/g | Combustion temperature/℃ | Reaction time/s | Open porosity/% | Shrinkage/% | Ref. |

|---|---|---|---|---|---|---|---|

| 30-45 | 70-55 | 2 | 1870-2050 | 30-13 | 40.5-45.8 | / | [ |

| 30-70 | 70-30 | 5 | 1820-1982 | / | 50.0-60.0 | 2.8-3.4 | [ |

表1 样品配方、自蔓延反应参数及样品性能汇总

Table 1 Composition of raw materials, parameters of SHS process and properties of the fabricated samples

| Si/g | Si3N4/g | Y2O3/g | Combustion temperature/℃ | Reaction time/s | Open porosity/% | Shrinkage/% | Ref. |

|---|---|---|---|---|---|---|---|

| 30-45 | 70-55 | 2 | 1870-2050 | 30-13 | 40.5-45.8 | / | [ |

| 30-70 | 70-30 | 5 | 1820-1982 | / | 50.0-60.0 | 2.8-3.4 | [ |

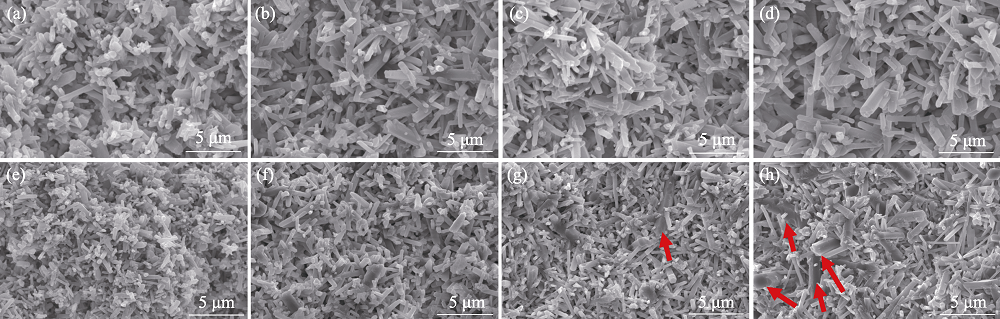

图3 不同工艺参数制备多孔Si3N4陶瓷的微观形貌(p为N2气压力, d50为Si粉粒度)[46]

Fig 3 Microstructures of the porous Si3N4 ceramics fabricated by different (p) pressures of N2 gas (p) and average particle sizes of Si powder (d50)[46] (a) p=3 MPa, d50=2.7 μm; (b) p=5 MPa, d50=2.7 μm; (c) p=7 MPa, d50=2.7μm; (d) p=9 MPa, d50=2.7 μm; (e) p=5 MPa, d50=1.3 μm; (f) p=5 MPa, d50=2.7 μm; (g) p=5 MPa, d50=4.5 μm; (h) p=5 MPa, d50=8.7 μm

图6 不同种类稀释剂和成型压力制备样品弯曲强度的韦伯分布拟合[59]

Fig. 6 Weibull plots of flexural strength for samples prepared with different types of Si3N4 diluent and shaping pressures[59] (Sample ST uses Si3N4 diluent with coarse particle size and high β phase while sample SA uses Si3N4 diluent with fine particle size and high α phase, -X represents the shaping pressure)

| SA-50 | SA-100 | SA-150 | SA-200 | ST-50 | ST-100 | ST-150 | ST-200 | Ref.[ | |

|---|---|---|---|---|---|---|---|---|---|

| R2 | 0.99 | 0.96 | 0.99 | 0.97 | 0.96 | 0.90 | 0.96 | 0.99 | - |

| m | 11.4 | 9.3 | 8.8 | 5.7 | 11.4 | 16.0 | 17.2 | 11.0 | 10.6-20.9 |

表2 使用两种不同Si3N4稀释剂和不同成型压力制备样品的相关系数和Weibull模量[59]

Table 2 Correlation coefficient and Weibull modulus of samples obtained with two different Si3N4 powders and varied shaping pressures[59]

| SA-50 | SA-100 | SA-150 | SA-200 | ST-50 | ST-100 | ST-150 | ST-200 | Ref.[ | |

|---|---|---|---|---|---|---|---|---|---|

| R2 | 0.99 | 0.96 | 0.99 | 0.97 | 0.96 | 0.90 | 0.96 | 0.99 | - |

| m | 11.4 | 9.3 | 8.8 | 5.7 | 11.4 | 16.0 | 17.2 | 11.0 | 10.6-20.9 |

图7 不同烧结方法制备Si3N4陶瓷的弯曲强度与孔隙率之间的关系

Fig. 7 Relationship between flexural strength and porosity of ceramics prepared by different methods SSN represents sintering Si3N4 by pressureless or gas pressure sintering[10,65⇓⇓⇓⇓⇓⇓⇓⇓-74]; SRBSN represents sintering reaction-bonded Si3N4 [75⇓⇓⇓⇓⇓⇓⇓-83]; CRS represents Si3N4 fabricated by carbothermal reduction sintering[16,84⇓-86]; SHS represents Si3N4 fabricated by self-propagating high temperature synthesis[46⇓-48,56,59-60]

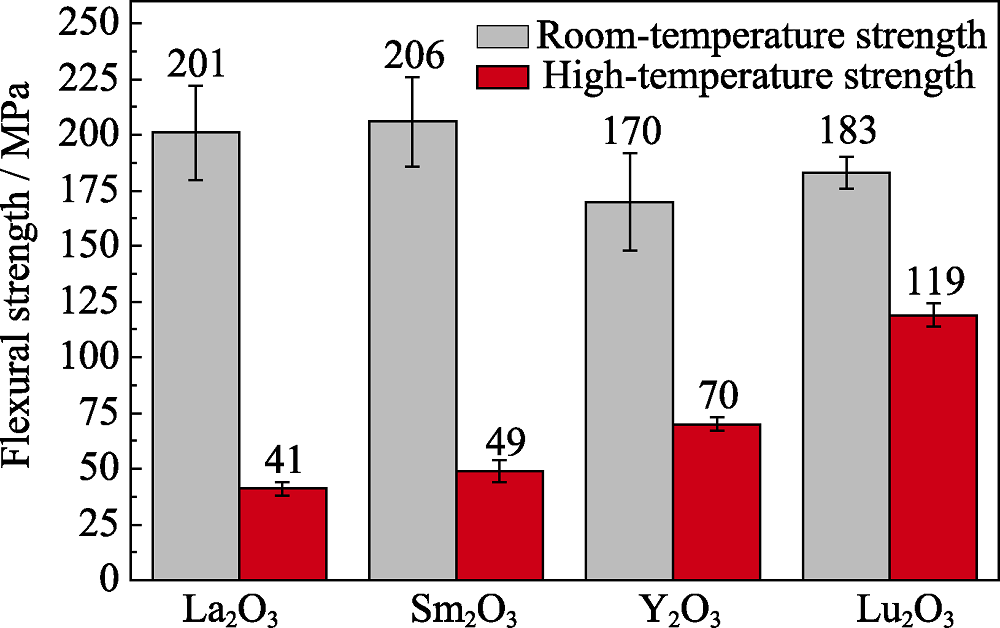

图8 不同烧结助剂制备的多孔Si3N4陶瓷的室温和高温弯曲强度[56]

Fig. 8 Room-temperature and high-temperature flexural strength of the fabricated porous Si3N4 ceramics with different sintering additives[56]

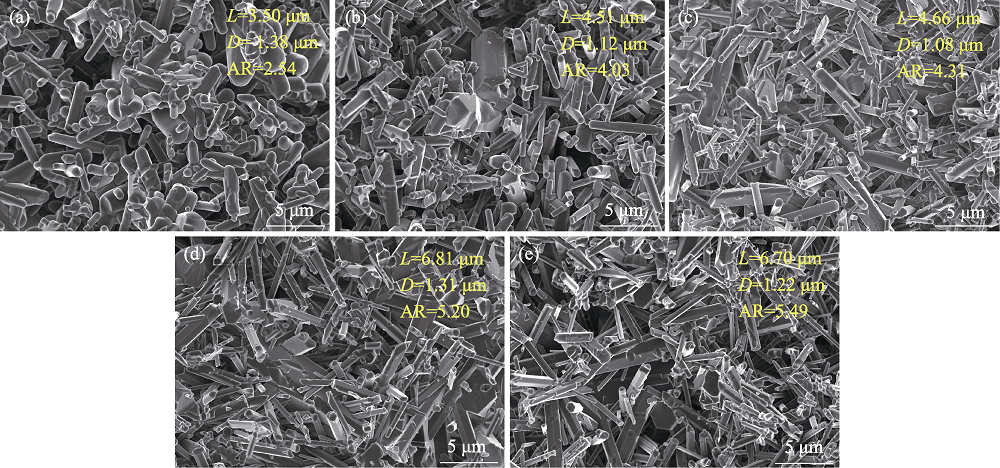

图10 采用不同质量分数Y2O3作为烧结助剂自蔓延合成Si3N4陶瓷的显微结构和平均晶粒尺寸[62]

Fig. 10 Microstructures and average grain sizes of the SHS-fabricated Si3N4 ceramics prepared with different Y2O3 mass content as sintering additive[62] (a) 0; (b) 0.4%; (c) 0.8%; (d) 1.2%; (e) 1.6%. L, D, AR represents average grain length, average grain diameter, and average aspect ratio respectively

图11 多孔Si3N4陶瓷室温和高温弯曲强度与烧结助剂添加量的关系[62]

Fig. 11 Room-temperature and high-temperature flexural strength of the fabricated porous Si3N4 ceramics as function of sintering additives addition[62]

| [1] |

WANG W D, YAO D X, CHEN H B, et al. ZrSi2-MgO as novel additives for high thermal conductivity of β-Si3N4 ceramics. J. Am. Ceram. Soc., 2020, 103(3): 2090-2100.

DOI URL |

| [2] |

WANG W, YAO D, LIANG H, et al. Effect of in-situ formed Y2O3 by metal hydride reduction reaction on thermal conductivity of β-Si3N4 ceramics. J. Eur. Ceram. Soc., 2020, 40(15): 5316-5323.

DOI URL |

| [3] |

WANG W, YAO D, LIANG H, et al. Effect of the binary nonoxide additives on the densification behavior and thermal conductivity of Si3N4 ceramics. J. Am. Ceram. Soc., 2020, 103(10): 5891-5899.

DOI URL |

| [4] |

WANG W, YAO D, LIANG H, et al. Novel silicothermic reduction method to obtain Si3N4 ceramics with enhanced thermal conductivity and fracture toughness. J. Eur. Ceram. Soc., 2021, 41(2): 1735-1738.

DOI URL |

| [5] |

BECHER P F, PAINTER G S, SHIBATA N, et al. Effects of rare- earth (RE) intergranular adsorption on the phase transformation, microstructure evolution, and mechanical properties in silicon nitride with RE2O3 + MgO additives: RE=La, Gd, and Lu. J. Am. Ceram. Soc., 2008, 91(7): 2328-2336.

DOI URL |

| [6] |

TATARKO P, KAŠIAROVA M, DUSZA J, et al. Influence of rare- earth oxide additives on the oxidation resistance of Si3N4-SiC nanocomposites. J. Eur. Ceram. Soc., 2013, 33(12): 2259-2268.

DOI URL |

| [7] |

ROUXEL T, SANGLEBOEUF J C, HUGER M, et al. Temperature dependence of Young's modulus in Si3N4-based ceramics: roles of sintering additives and of SiC-particle content. Acta Mater., 2002, 50(7): 1669-1682.

DOI URL |

| [8] |

LI X Q, YAO D X, ZUO K H, et al. Fabrication, microstructural characterization and gas permeability behavior of porous silicon nitride ceramics with controllable pore structures. J. Eur. Ceram. Soc., 2019, 39(9): 2855-2861.

DOI URL |

| [9] |

LI X Q, YAO D X, ZUO K H, et al. Microstructure and gas permeation performance of porous silicon nitride ceramics with unidirectionally aligned channels. J. Am. Ceram. Soc., 2020, 103(11): 6565-6574.

DOI URL |

| [10] |

XIA Y F, ZENG Y P, JIANG D L. Mechanical and dielectric properties of porous Si3N4 ceramics using PMMA as pore former. Ceram. Int., 2011, 37(8): 3775-3779.

DOI URL |

| [11] |

PRADEILLES N, RECORD M C, GRANIER D, et al. Synthesis of β-SiAlON: a combined method using Sol-Gel and SHS processes. Ceram. Int., 2008, 34(5): 1189-1194.

DOI URL |

| [12] |

JENNINGS H M, RICHMAN M H. Structure, formation mechanisms and kinetics of reaction-bonded silicon-nitride. J. Mater. Sci., 1976, 11(11): 2087-2098.

DOI URL |

| [13] |

ZIEGLER G, HEINRICH J, WOTTING G. Relationships between processing, microstructure and properties of dense and reaction- bonded silicon-nitride. J. Mater. Sci., 1987, 22(9): 3041-3086.

DOI URL |

| [14] | MATSUNAGA C, ZHOU Y, KUSANO D, et al. Nitridation behavior of silicon powder compacts of various thicknesses with Y2O3 and MgO as sintering additives. Int. J. Appl. Ceram, 2017, 14(6): 1157-1163. |

| [15] |

SHAN S Y, YANG J F, GAO J Q, et al. Porous silicon nitride ceramics prepared by reduction-nitridation of silica. J. Am. Ceram. Soc., 2005, 88 (9): 2594-2596.

DOI URL |

| [16] |

YANG J F, SHAN S Y, JANSSEN R, et al. Synthesis of fibrous β-Si3N4 structured porous ceramics using carbothermal nitridation of silica. Acta Mater., 2005, 53(10): 2981-2990.

DOI URL |

| [17] |

ZHI Q, WANG B, ZHAO S, et al. Synthesis and mechanical properties of highly porous ultrafine-grain Si3N4 ceramics via carbothermal reduction-nitridation combined with liquid phase sintering. Ceram. Int., 2019, 45(17): 21359-21364.

DOI URL |

| [18] |

MUNIR Z A, HOLT J B, The combustion synthesis of refractory nitrides. J. Mater. Sci., 1987, 22(2): 710-714.

DOI URL |

| [19] | ZAKI Z, MOSTAFA N, AHMED Y, et al. Processing of high- density magnesia spinel electro-conducting ceramic composite and its oxidation at 1400 ℃. Int. J. Appl. Ceram, 2016, 13(4): 662-669. |

| [20] |

ADACHI S, WADA T, MIHARA T, et al. High-pressure self- combustion sintering of alumina titanium carbide ceramic composite. J. Am. Ceram. Soc., 1990, 73(5): 1451-1452.

DOI URL |

| [21] |

BHAUMIK S K, DIVAKAR C, SINGH A K, et al. Synthesis and sintering of TiB2 and TiB2-TiC composite under high pressure. Mater. Sci. Eng., A, 2000, 279(1/2): 275-281.

DOI URL |

| [22] |

BHAUMIK S K, DIVAKAR C, DEVI S U, et al. Synthesis and sintering of SiC under high pressure and high temperature. J. Mater. Res., 1999, 14(3): 906-911.

DOI URL |

| [23] | 梁宝岩, 张艳丽, 张旺玺, 等. Ti/Al/TiN体系自蔓延高温合成钛铝氮复合材料. 粉末冶金材料科学与工程, 2014, 105(4): 417-420. |

| [24] | CINCOTTI A, LICHERI R, LOCCI A M, et al. A review on combustion synthesis of novel materials: recent experimental and modeling results. J. Chem. Technol. Biotechnol., 2003, 78(2/3): 122-127. |

| [25] |

TIAN Z B, ZHANG J, SUN S Y, et al. Combustion synthesis of α-Si3N4 with the addition of NH4Cl. Ceram. Int., 2018, 44(16): 20591-20594.

DOI URL |

| [26] |

GE Y Y, SUN S Y, WANG Q, et al. Effect of Fe-contained species on the preparation of α-Si3N4 fibers in combustion synthesis. J. Am. Ceram. Soc., 2016, 99(4): 1464-1471.

DOI URL |

| [27] |

WU X M, LIU G H, LI J Q, et al. Combustion synthesis of ZrN and AlN using Si3N4 and BN as solid nitrogen sources. Ceram. Int., 2018, 44(10): 11914-11917.

DOI URL |

| [28] |

HIRANAKA A, YI X, SAITO G, et al. Effects of Al particle size and nitrogen pressure on AlN combustion synthesis. Ceram. Int., 2017, 43(13): 9872-9876.

DOI URL |

| [29] |

SHAHIEN M, RADWAN M, KIRIHARA S, et al. Combustion synthesis of single-phase β-SiAlONs (z=2-4). J. Eur. Ceram. Soc., 2010, 30(9): 1925-1930.

DOI URL |

| [30] |

WANG Q, GE Y Y, CHEN Y, et al. SHS of Eu2+-doped β-SiAlON phosphors: impacts of N2 pressure and Si particle size. Ceram. Int., 2017, 43(5): 4456-4461.

DOI URL |

| [31] |

XU J K, HU Z L, HAN Y, et al. Combustion synthesis of MgSiN2 powders and Si3N4-MgSiN2 composite powders: effects of processing parameters. J. Am. Ceram. Soc., 2020, 103(1): 122-135.

DOI URL |

| [32] |

CUI W, ZHU Y, GE Y Y, et al. Effects of nitrogen pressure and diluent content on the morphology of gel-cast-foam-assisted combustion synthesis of elongated β-Si3N4 particles. Ceram. Int., 2014, 40(8): 12553-12560.

DOI URL |

| [33] |

CANO I G, BOROVINSKAYA I P, RODRIGUEZ M A, et al. Effect of dilution and porosity on self-propagating high-temperature synthesis of silicon nitride. J. Am. Ceram. Soc., 2002, 85(9): 2209-2211.

DOI URL |

| [34] |

YANG J H, HAN L S, CHEN Y X, et al. Effects of pelletization of reactants and diluents on the combustion synthesis of Si3N4 powder. J. Alloys Compd., 2012, 511(1): 81-84.

DOI URL |

| [35] |

WON H I, WON C W, NERSISYAN H H, et al. Salt-assisted combustion synthesis of silicon nitride with high α-phase content. J. Alloys Compd., 2010, 496(1/2): 656-659.

DOI URL |

| [36] |

CHEN Y X, LI J T, DU J S. Cost effective combustion synthesis of silicon nitride. Mater. Res. Bull., 2008, 43(6): 1598-1606.

DOI URL |

| [37] |

CANO I G, BAELO S P, RODRIGUEZ M A, et al. Self-propagating high temperature-synthesis of Si3N4: role of ammonium salt addition. J. Eur. Ceram. Soc., 2001, 21(3): 291-295.

DOI URL |

| [38] |

CHEN D Y, ZHANG B L, ZHUANG H R, et al. Synthesis of β-Si3N4 whiskers by SHS. Mater. Res. Bull., 2002, 37(8): 1481-1485.

DOI URL |

| [39] |

PENG G H, JIANG G J, ZHUANG H R, et al. Fabrication of β-Si3N4 whiskers by combustion synthesis with MgSiN2 as additives. Mater. Res. Bull., 2005, 40(12): 2139-2143.

DOI URL |

| [40] |

GERMAN R, SURI P, PARK S, Review: liquid phase sintering. J. Mater. Sci., 2009, 44(1): 1-39.

DOI URL |

| [41] |

KRSTIC Z, KRSTIC V D. Silicon nitride: the engineering material of the future. J. Mater. Sci., 2011, 47(2): 535-552.

DOI URL |

| [42] |

ZIEGLER A, IDROBO J C, CINIBULK M K, et al. Interface structure and atomic bonding characteristics in silicon nitride ceramics. Science, 2004, 306(5702): 1768-1770.

DOI URL |

| [43] |

SHIBATA N, PENNYCOOK S J, GOSNELL T R, et al. Observation of rare-earth segregation in silicon nitride ceramics at subnanometre dimensions. Nature, 2004, 428(6984): 730-733.

DOI URL |

| [44] |

CHEN D, ZHANG B, ZHUANG H, et al. Combustion synthesis of network silicon nitride porous ceramics. Ceram. Int., 2003, 29(4): 363-364.

DOI URL |

| [45] | LI W K, CHEN D Y, ZHANG B L, et al. Effect of rare-earth oxide additives on the morphology of combustion synthesized rod-like β-Si3N4crystals. Mater. Lett., 2004, 58(17/18): 2322-2325. |

| [46] |

ZHANG Y, YAO D, ZUO K, et al. Effects of N2 pressure and Si particle size on mechanical properties of porous Si3N4 ceramics prepared via SHS. J. Eur. Ceram. Soc., 2020, 40(13): 4454-4461.

DOI URL |

| [47] |

ZHANG Y, YAO D, ZUO K, et al. Fabrication and mechanical properties of porous Si3N4 ceramics prepared via SHS. Ceram. Int., 2019, 45(12): 14867-14872.

DOI URL |

| [48] |

WANG L, HE G, YANG Z, et al. Combustion synthesis of high flexural strength, low linear shrinkage and machinable porous β-Si3N4 ceramics. J. Eur. Ceram. Soc., 2020, 41(4): 2395-2399.

DOI URL |

| [49] |

CAO Y G, EG C C, ZHOU Z J, et al. Combustion synthesis of α-Si3N4 whiskers. J. Mater. Res., 1999, 14(3): 876-880.

DOI URL |

| [50] |

WAKIHARA T, YABUKI H, TATAMI J, et al. In situ measurement of shrinkage during postreaction sintering of reaction-bonded silicon nitride. J. Am. Ceram. Soc., 2008, 91(10): 3413-3415.

DOI URL |

| [51] |

WANG C, QIAO R Q, CHEN L J. Fabrication and erosion resistance of dense α-Si3N4/SiAlON coating on porous Si3N4 ceramic. RSC Adv., 2016, 6(68): 63801-63808.

DOI URL |

| [52] |

LEE J S, MUN J H, HAN B D, et al. Effect of raw-Si particle size on the properties of sintered reaction-bonded silicon nitride. Ceram. Int., 2004, 30(6): 965-976.

DOI URL |

| [53] |

KRAMER M, HOFFMANN M J, PETZOW G. Grain-growth studies of silicon-nitride dispersed in an oxynitride glass. J. Am. Ceram. Soc., 1993, 76(11): 2778-2784.

DOI URL |

| [54] |

CHEN S L, WANG L, HE G, et al. Microstructure and properties of porous Si3N4 ceramics by gelcasting-self-propagating high- temperature synthesis (SHS). J. Adv. Ceram., 2021, 11: 172-183.

DOI URL |

| [55] | ZHANG Y, YAO D, ZUO K, et al. A novel route for the fabrication of porous Si3N4 ceramics with unidirectionally aligned channels. Mater. Lett., 2020, 276: 128246. |

| [56] |

ZHANG Y, YAO D, ZUO K, et al. Effects of different types of sintering additives and post-heat treatment (PHT) on the mechanical properties of SHS-fabricated Si3N4 ceramics. Ceram. Int., 2021, 47(16): 22461-22467.

DOI URL |

| [57] | GRIFFITH A A. The phenomena of rupture and flow in solids. Philos. Trans. Royal Soc., 1920, 221: 163-198. |

| [58] |

DING H, HU Y, LI X, et al. Microstructure, mechanical properties and sintering mechanism of pressureless-sintered porous Si3N4 ceramics with YbF3-MgF2 composite sintering aids. Ceram. Int., 2020, 46(2): 2558-2564.

DOI URL |

| [59] |

ZHANG Y, YAO D, ZUO K, et al. Self-propagating high temperature synthesis (SHS) of porous Si3N4-based ceramics with considerable dimensions and study on mechanical properties and oxidation behavior. J. Eur. Ceram. Soc., 2021, 41(8): 4452-4461.

DOI URL |

| [60] |

HU Y, ZUO K, XIA Y, et al. Microstructure and permeability of porous Si3N4 supports prepared via SHS. Ceram. Int., 2021, 47(2): 1571-1577.

DOI URL |

| [61] |

KAWAI C. Effect of grain size distribution on the strength of porous Si3N4 ceramics composed of elongated β-Si3N4 grains. J. Mater. Sci., 2001, 36(23): 5713-5717.

DOI URL |

| [62] |

ZHANG Y, YU X, GU H, et al. Microstructure evolution and high-temperature mechanical properties of porous Si3N4 ceramics prepared by SHS with a small amount of Y2O3 addition. Ceram. Int., 2021, 47(4): 5656-5662.

DOI URL |

| [63] |

YU F L, WANG H R, YANG J F, et al. Effects of organic additives on microstructure and mechanical properties of porous Si3N4 ceramics. Bull. Mater. Sci., 2010, 33(3): 285-291.

DOI URL |

| [64] |

KALEMTAS A, TOPATES G, OZCOBAN H, et al. Mechanical characterization of highly porous β-Si3N4 ceramics fabricated via partial sintering & starch addition. J. Eur. Ceram. Soc., 2013, 33(9): 1507-1515.

DOI URL |

| [65] |

KAWAI C, YAMAKAWA A. Effect of porosity and microstructure on the strength of Si3N4: designed microstructure for high strength, high thermal shock resistance, and facile machining. J. Am. Ceram. Soc., 1997, 80(10): 2705-2708.

DOI URL |

| [66] |

YANG J F, DENG Z Y, OHJI T. Fabrication and characterisation of porous silicon nitride ceramics using Yb2O3 as sintering additive. J. Eur. Ceram. Soc., 2003, 23(2): 371-378.

DOI URL |

| [67] | YIN X W, LI X M, ZHANG L T, et al. Microstructure and mechanical properties of Lu2O3-doped porous silicon nitride ceramics using phenolic resin as pore-forming agent. Int. J. Appl. Ceram, 2010, 7(3): 391-399. |

| [68] | LI X M, YIN X W, ZHANG L T, et al. Microstructure and properties of porous Si3N4 ceramics with a dense surface. Int. J. Appl. Ceram, 2011, 8(3): 627-636. |

| [69] |

YUE J S, DONG B C, WANG H J. Porous Si3N4 fabricated by phase separation method using benzoic acid as pore-forming agent. J. Am. Ceram. Soc., 2011, 94(7): 1989-1991.

DOI URL |

| [70] |

DING H H, ZHAO Z H, QI T, et al. High α-β phase transition and properties of YbF3-added porous Si3N4 ceramics obtained by low temperature pressureless sintering. Int. J. Refract. Hard. Met., 2019, 78: 131-137.

DOI URL |

| [71] |

JIANG G P, YANG J F, GAO J Q, et al. Porous silicon nitride ceramics prepared by extrusion using starch as binder. J. Am. Ceram. Soc., 2008, 91(11): 3510-3516.

DOI URL |

| [72] |

LIU X H, HUANG Z Y, GE Q M, et al. Microstructure and mechanical properties of silicon nitride ceramics prepared by pressureless sintering with MgO-Al2O3-SiO2 as sintering additive. J. Eur. Ceram. Soc., 2005, 25(14): 3353-3359.

DOI URL |

| [73] |

YANG J, YANG J F, SHAN S Y, et al. Effect of sintering additives on microstructure and mechanical properties of porous silicon nitride ceramics. J. Am. Ceram. Soc., 2006, 89(12): 3843-3845.

DOI URL |

| [74] |

FAN L, ZHOU M, WANG H J, et al. Low-temperature preparation of β-Si3N4 porous ceramics with a small amount of Li2O-Y2O3. J. Am. Ceram. Soc., 2014, 97(5): 1371-1374.

DOI URL |

| [75] |

YAO D, CHEN H, ZUO K H, et al. High temperature mechanical properties of porous Si3N4 prepared via SRBSN. Ceram. Int., 2018, 44(11): 11966-11971.

DOI URL |

| [76] |

YAO D X, XIA Y F, ZENG Y P. et al. Porous Si3N4 ceramics prepared via slip casting of Si and reaction bonded silicon nitride. Ceram. Int., 2011, 37(8): 3071-3076.

DOI URL |

| [77] |

YAO D X, XIA Y F, ZUO K H, et al. The effect of fabrication parameters on the mechanical properties of sintered reaction bonded porous Si3N4 ceramics. J. Eur. Ceram. Soc., 2014, 34(15): 3461-3467.

DOI URL |

| [78] |

YAO D X, ZENG Y P. High flexural strength porous silicon nitride prepared via nitridation of silicon powder. J. Inorg. Mater., 2011, 26(4): 422-426.

DOI URL |

| [79] |

YAO D X, ZENG Y P, ZUO K H, et al. The effects of BN addition on the mechanical properties of porous Si3N4/BN ceramics prepared via nitridation of silicon powder. J. Am. Ceram. Soc., 2011, 94(3): 666-670.

DOI URL |

| [80] | YAO D X, ZENG Y P, ZUO K H, et al. Porous Si3N4 ceramics prepared via nitridation of Si powder with Si3N4 Filler and postsintering. Int. J. Appl. Ceram., 2012, 9(2): 239-245. |

| [81] | HU H L, YAO D X, XIA Y F, et al. Porous Si3N4/SiC ceramics prepared via nitridation of Si powder with SiC addition. Int. J. Appl. Ceram. 2014, 11(5): 845-850. |

| [82] |

HU H L, ZENG Y P, ZUO K H, et al. Synthesis of porous Si3N4/SiC ceramics with rapid nitridation of silicon. J. Eur. Ceram. Soc., 2015, 35(14): 3781-3787.

DOI URL |

| [83] |

HU H L, ZENG Y P, XIA Y F, et al. Rapid fabrication of porous Si3N4/SiC ceramics via nitridation of silicon powder with ZrO2 as catalyst. Ceram. Int., 2014, 40(5): 7579-7582.

DOI URL |

| [84] |

LU Y, YANG J F, LU W Z, et al. Porous silicon nitride ceramics fabricated by carbothermal reduction-reaction bonding. Mater. Manuf. Processes, 2011, 26(6): 855-861.

DOI URL |

| [85] |

SHAN S Y, JIA Q M, JIANG L H, et al. Microstructure control and mechanical properties of porous silicon nitride ceramics. Ceram. Int., 2009, 35(8): 3371-3374.

DOI URL |

| [86] |

SHAN S Y, YANG J F, GAO J Q, et al. Fabrication of porous silicon nitride with high porosity. Key Eng. Mater., 2007, 336-338: 1105-1108.

DOI URL |

| [87] |

LU H H, HUANG J L, Effect of Y2O3 and Yb2O3 on the microstructure and mechanical properties of silicon nitride. Ceram. Int., 2001, 27(6): 621-628.

DOI URL |

| [88] |

KLEMM H, PEZZOTTI G. Fracture toughness and time-dependent strength behavior of low-doped silicon nitrides for applications at 1400 ℃. J. Am. Ceram. Soc., 1994, 77(2): 553-561.

DOI URL |

| [89] |

LANGE F F. High-temperature strength behavior of hot-pressed Si3N4: evidence for subcritical crack growth. J. Am. Ceram. Soc., 1974, 57(2): 84-87.

DOI URL |

| [90] |

RILEY F L. Silicon nitride and related materials. J. Am. Ceram. Soc., 2000, 83(2): 245-265.

DOI URL |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [8] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [9] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [10] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [11] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [12] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [13] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [14] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [15] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||