无机材料学报 ›› 2020, Vol. 35 ›› Issue (6): 669-674.DOI: 10.15541/jim20200078 CSTR: 32189.14.10.15541/jim20200078

所属专题: 结构陶瓷论文精选(二)

收稿日期:2020-02-18

修回日期:2020-03-01

出版日期:2020-06-20

网络出版日期:2020-03-05

作者简介:冀晓鹃(1981-), 女, 博士研究生. E-mail: ji_xj@bgrimm.com;基金资助:

JI Xiaojuan1,2,YU Yueguang2( ),LU Xiaoliang2

),LU Xiaoliang2

Received:2020-02-18

Revised:2020-03-01

Published:2020-06-20

Online:2020-03-05

Supported by:摘要:

降低热障涂层面层中的低熔点杂质含量, 可提高涂层的高温稳定性和延长服役寿命。SiO2、Al2O3和Fe2O3是氧化钇稳定氧化锆(Yttria-Stabilized Zirconia, YSZ)热障涂层中几种常见的低熔点氧化物杂质, 均会对涂层的性能产生一定的影响。本研究采用大气等离子喷涂法, 制备SiO2、Al2O3和Fe2O3的含量从小于0.01wt%增加至1.00wt%的YSZ热障涂层。采用扫描电镜(SEM)和透射电镜(TEM)研究了上述涂层的微观结构; 采用激光热导仪测试了涂层的热扩散系数和抗热震次数。研究结果表明, 低熔点氧化物杂质对YSZ涂层的导热性、热处理状态的孔隙率具有明显影响, 且更容易引起涂层的热震失效。当杂质氧化物含量在小于0.2wt%范围内变化时, 涂层的性能变化更为显著。

中图分类号:

冀晓鹃,于月光,卢晓亮. 杂质对氧化锆热障涂层性能的影响[J]. 无机材料学报, 2020, 35(6): 669-674.

JI Xiaojuan,YU Yueguang,LU Xiaoliang. Effects of Impurities on Properties of YSZ Thermal Barrier Coatings[J]. Journal of Inorganic Materials, 2020, 35(6): 669-674.

| ZrO2 | HfO2 | TiO2 | SiO2 | MgO | Fe2O3 |

|---|---|---|---|---|---|

| 90.28 | 1.55 | <0.01 | <0.01 | <0.01 | <0.01 |

| Y2O3 | Al2O3 | CaO | Na2O | K2O | |

| 7.92 | 0.011 | <0.01 | <0.01 | <0.01 |

表1 YSZ原料的化学成分(wt%)

Table 1 Chemical composition of YSZ raw materials (wt%)

| ZrO2 | HfO2 | TiO2 | SiO2 | MgO | Fe2O3 |

|---|---|---|---|---|---|

| 90.28 | 1.55 | <0.01 | <0.01 | <0.01 | <0.01 |

| Y2O3 | Al2O3 | CaO | Na2O | K2O | |

| 7.92 | 0.011 | <0.01 | <0.01 | <0.01 |

| No. | SiO2 | No. | Al2O3 | No. | Fe2O3 | |||

|---|---|---|---|---|---|---|---|---|

| D | M | D | M | D | M | |||

| HP | <0.01 | <0.01 | — | <0.01 | <0.01 | — | <0.01 | 0.0049 |

| S1 | 0.02 | 0.013 | A1 | 0.02 | 0.014 | F1 | 0.02 | 0.0140 |

| S2 | 0.06 | 0.038 | A2 | 0.06 | 0.030 | F2 | 0.06 | 0.0390 |

| S3 | 0.10 | 0.064 | A3 | 0.10 | 0.051 | F3 | 0.10 | 0.0800 |

| S4 | 0.16 | 0.110 | A4 | 0.15 | 0.079 | F4 | 0.16 | 0.1100 |

| S5 | 0.20 | 0.150 | A5 | 0.20 | 0.120 | F5 | 0.20 | 0.1400 |

| S6 | 0.36 | 0.260 | A6 | 0.35 | 0.230 | F6 | 0.36 | 0.3000 |

| S7 | 0.50 | 0.320 | A7 | 0.50 | 0.300 | F7 | 0.50 | 0.3400 |

| S8 | 0.66 | 0.430 | A8 | 0.65 | 0.380 | F8 | 0.66 | 0.4600 |

| S9 | 0.80 | 0.550 | A9 | 0.80 | 0.450 | F9 | 0.80 | 0.5700 |

| S10 | 1.00 | 0.620 | A10 | 1.00 | 0.640 | F10 | 1.00 | 0.5900 |

表2 YSZ喷涂粉末的设计成分(D)及涂层的实测成分(M)(wt%)

Table 2 Design composition (D) of YSZ powders and measured composition (M) of YSZ coatings (wt%)

| No. | SiO2 | No. | Al2O3 | No. | Fe2O3 | |||

|---|---|---|---|---|---|---|---|---|

| D | M | D | M | D | M | |||

| HP | <0.01 | <0.01 | — | <0.01 | <0.01 | — | <0.01 | 0.0049 |

| S1 | 0.02 | 0.013 | A1 | 0.02 | 0.014 | F1 | 0.02 | 0.0140 |

| S2 | 0.06 | 0.038 | A2 | 0.06 | 0.030 | F2 | 0.06 | 0.0390 |

| S3 | 0.10 | 0.064 | A3 | 0.10 | 0.051 | F3 | 0.10 | 0.0800 |

| S4 | 0.16 | 0.110 | A4 | 0.15 | 0.079 | F4 | 0.16 | 0.1100 |

| S5 | 0.20 | 0.150 | A5 | 0.20 | 0.120 | F5 | 0.20 | 0.1400 |

| S6 | 0.36 | 0.260 | A6 | 0.35 | 0.230 | F6 | 0.36 | 0.3000 |

| S7 | 0.50 | 0.320 | A7 | 0.50 | 0.300 | F7 | 0.50 | 0.3400 |

| S8 | 0.66 | 0.430 | A8 | 0.65 | 0.380 | F8 | 0.66 | 0.4600 |

| S9 | 0.80 | 0.550 | A9 | 0.80 | 0.450 | F9 | 0.80 | 0.5700 |

| S10 | 1.00 | 0.620 | A10 | 1.00 | 0.640 | F10 | 1.00 | 0.5900 |

| Coal oil /(L·h-1) | O2 /(L·min-1) | Ar (Carrier gas) /(L·min-1) | Powder feeding rate/(g·min-1) | Distance/ mm |

|---|---|---|---|---|

| 26 | 900 | 8 | 75 | 380 |

表3 HVOF喷涂工艺参数

Table 3 Parameters of HVOF process

| Coal oil /(L·h-1) | O2 /(L·min-1) | Ar (Carrier gas) /(L·min-1) | Powder feeding rate/(g·min-1) | Distance/ mm |

|---|---|---|---|---|

| 26 | 900 | 8 | 75 | 380 |

| Current/A | Voltage/V | Power/kW | Distance/mm |

|---|---|---|---|

| 620 | 76 | 47 | 100 |

| Ar/(L·min-1) | H2/(L·min-1) | Ar(Carrier gas)/ (L·min-1) | Powder feeding rate/(g·min-1) |

| 38 | 13 | 4.5 | 30 |

表4 APS喷涂工艺参数

Table 4 Parameters of APS process

| Current/A | Voltage/V | Power/kW | Distance/mm |

|---|---|---|---|

| 620 | 76 | 47 | 100 |

| Ar/(L·min-1) | H2/(L·min-1) | Ar(Carrier gas)/ (L·min-1) | Powder feeding rate/(g·min-1) |

| 38 | 13 | 4.5 | 30 |

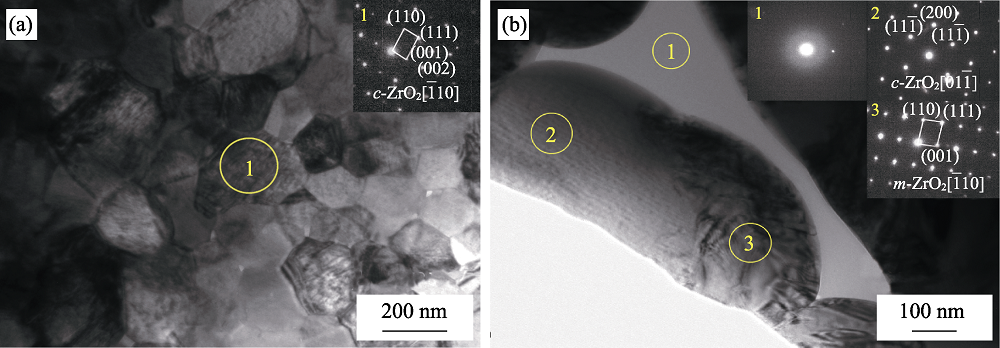

图6 含1wt% SiO2YSZ涂层的(a)喷涂态及(b)经1400 ℃热处理10 h后的TEM照片及衍射斑点

Fig. 6 TEM microstructures and diffraction spots of YSZ coatings doped with 1wt% SiO2 (a) As-sprayed; (b) After heat- treatment at 1400 ℃ for 10 h

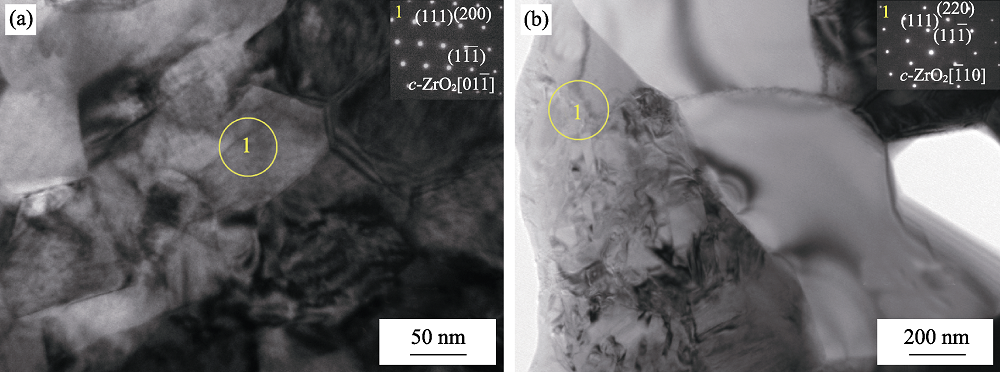

图7 含1wt% Al2O3的YSZ涂层的(a)喷涂态及(b)经1400 ℃热处理10 h后的TEM照片及衍射斑点

Fig. 7 TEM microstructure and diffraction spots of YSZ coatings doped with 1wt% Al2O3 (a) As-sprayed; (b) After heat- treatment at 1400 ℃ for 10 h

| [1] |

DAROLIA R . Thermal barrier coatings technology: critical review, progress update, remaining challenges and prospects. International Materials Reviews, 2013,58(6):315-348.

DOI URL |

| [2] | CURRY N, MARKOCSAN N, LI X H , et al. Next generation thermal barrier coatings for the gas turbine industry. Journal of Thermal Spray Technology, 2011,20(1/2):108-115. |

| [3] | STӦVER D, PRACHT G, LEHMANN H , et al. New material concepts for the next generation of plasma-sprayed thermal barrier coatings. Journal of Thermal Spray Technology, 2004,13(1):76-83. |

| [4] | XUE Z L, GUO H B, GONG S K , et al. Novel ceramic materials for thermal barrier coatings. Journal of Aeronautical Materials, 2018,38(2):10-20. |

| [5] | CURRY N, JANIKOWSKI W, PALA Z , et al. Impact of impurity content on the sintering resistance and phase stability of dysprosia- and yttria-stabilized zirconia thermal barrier coatings. Journal of Thermal Spray Technology, 2014,23(1/2):160-169. |

| [6] | LYU G, CHOI B G, LU Z , et al. Effect of thermal cycling frequency on the durability of Yb-Gd-Y-based thermal barrier coatings. Surface & Coatings Technology, 2019,364:187-195. |

| [7] | GORAL M, KOTOWSKI S, NOWOTNIK A , et al. PS-PVD deposition of thermal barrier coatings. Surface & Coatings Technology, 2013,237:51-55. |

| [8] | ŁATKA L . Thermal barrier coatings manufactured by suspension plasma spraying- a review. Advances in Materials Science, 2018,18(3):95-117. |

| [9] | JONNALAGADDA K P, ERIKSSON R, LI X H , et al. Thermal barrier coatings: life model development and validation. Surface & Coatings Technology, 2019,362:293-301. |

| [10] | PARK H M, JUN S H, LYU G , et al. Thermal durability of thermal barrier coatings in furnace cyclic thermal fatigue test: effects of purity and monoclinic phase in feedstock powder. Journal of the Korean Ceramic Society, 2018,55(6):608-617. |

| [11] | KARLSSON A M . Modeling failures of thermal barrier coatings. Key Engineering Materials, 2007,333:155-166. |

| [12] | HUA J J, ZHANG L P, LIU Z W , et al. Progress of research on the failure mechanism of thermal barrier coatings. Journal of Inorganic Materials, 2012,27(7):681-686. |

| [13] | MATSUI K . Sintering kinetics at constant rates of heating: mechanism of silica-enhanced sintering of fine zirconia powder. Journal of the American Ceramic Society, 2008,91(8):2534-2539. |

| [14] | TSIPAS S A, GOLOSNOY I O, DAMANI R , et al. The effect of a high thermal gradient on sintering and stiffening in the top coat of a thermal barrier coating system. Journal of Thermal Spray Technology, 2004,13(3):370-376. |

| [15] | CHOI S R, ZHU D M, MILLER R A . Effect of sintering on mechanical properties of plasma-sprayed zirconia-based thermal barrier coatings. Journal of the American Ceramic Society, 2005,88(10):2859-2867. |

| [16] | VAβEN R, CZECH N, MALLÉNER W , et al. Influence of impurity content and porosity of plasma-sprayed yttria-stabilized zirconia layers on the sintering behaviour. Surface and Coatings Technology, 2001,141:135-140. |

| [17] | PAUL S, CIPITRIA A, GOLOSNOY I O , et al. Effects of impurity content on the sintering characteristics of plasma-sprayed zirconia. Journal of Thermal Spray Technology, 2007,16(5/6):798-803. |

| [18] |

XIE L, DORFMAN M R, CIPITRIA A , et al. Properties and performance of high-purity thermal barrier coatings. Journal of Thermal Spray Technology, 2007,16(5/6):804-808.

DOI URL |

| [19] | HELMINIAK M A, YANAR N M, PETTIT F S , et al. The behavior of high-purity, low-density air plasma sprayed thermal barrier coatings. Surface & Coatings Technology, 2009,204:793-796. |

| [20] | MARKOCSAN N, NYLÉN P, WIGREN J, et al. Low thermal conductivity coatings for gas turbine applications. Journal of Thermal Spray Technology, 2007,16(4):498-505. |

| [21] | ZHU D M, MILLER R A . Development of advanced low conductivity thermal barrier coatings. International Journal of Applied Ceramic Technology, 2004,1(1):86-94. |

| [22] | WANG L, WANG Y, SUN X G , et al. Influence of pores on the thermal insulation behavior of thermal barrier coatings prepared by atmospheric plasma spray. Materials and Design, 2011,32:36-47. |

| [23] | ZHU D M, MILLER R A . Thermal conductivity and elastic modulus evolution of thermal barrier coatings under high heat flux conditions. Journal of Thermal Spray Technology, 2000,9(2):175-180. |

| [24] | ZHU D M, MILLER R A, NAGARAJ B A , et al. Thermal conductivity of EB-PVD thermal barrier coatings evaluated by a steady- state laser heat flux technique. Surface and Coatings Technology, 2001,138:1-8. |

| [25] | LI Y J, YU Y G, JI X J , et al. Effects of Al2O3 content on properties of YSZ thermal barrier coatings. Thermal Spray Technology, 2018,10(1):61-67. |

| [26] | GREMILLARD L, EPICIER T, CHEVALIER J , et al. Microstructural stucy of silica-doped zirconia ceramics. Acta Materialia, 2000,48:4647-4652. |

| [27] | HODGSON S N B, CAWLEY J, CLUBLEY M . The role of SiO2 impurities in the microstructure and properties of Y-TZP. Journal of Materials Processing Technology, 1999,86:139-145. |

| [28] | MATSUI K, YOSHIDA H, IKUHARA Y . Phase-transformation and grain-growth kinetics in yttria-stabilized tetragonal zirconia polycrystal doped with a small amount of alumina. Journal of the European Ceramic Society, 2010,30:1679-1690. |

| [29] | SAKKA Y, ISHII T, SUZUKI T S , et al. Fabrication of high-strain rate superplastic yttria-doped zirconia polycrystals by adding manganese and aluminum oxides. Journal of the European Ceramic Society, 2004,24:449-453. |

| [30] |

WU S X, BROOK R J . Kinetics of densification in stabilized zirconia. Solid State Ionics, 1984,14:123-130.

DOI URL |

| [1] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [2] | 郑斌, 康凯, 张青, 叶昉, 解静, 贾研, 孙国栋, 成来飞. 前驱体转化陶瓷法制备Ti3SiC2陶瓷及其热稳定性研究[J]. 无机材料学报, 2024, 39(6): 733-740. |

| [3] | 俞瑞仙, 王国栋, 王守志, 胡小波, 徐现刚, 张雷. 高温退火对PVT法生长的AlN晶体质量的影响[J]. 无机材料学报, 2023, 38(3): 343-349. |

| [4] | 王华进, 寇华敏, 王墉哲, 姜大朋, 张博, 钱小波, 王静雅, 朱琳玲, 曾爱军, 杨秋红, 苏良碧. 193 nm激光下不同含量Y杂质CaF2晶体辐照损伤研究[J]. 无机材料学报, 2023, 38(2): 219-224. |

| [5] | 潘洋洋, 梁波, 洪督, 祁志祥, 牛亚然, 郑学斌. TiAl合金表面TiAlCrY/YSZ涂层高温长时间服役性能[J]. 无机材料学报, 2023, 38(1): 105-112. |

| [6] | 安文然, 黄晶琪, 卢祥荣, 蒋佳宁, 邓龙辉, 曹学强. 热处理温度对LaMgAl11O19涂层热/力学性能的影响[J]. 无机材料学报, 2022, 37(9): 925-932. |

| [7] | 刘强, 王倩, 陈鹏辉, 李晓英, 章立轩, 谢腾飞, 李江. 两步烧结法制备红色Ce:8YSZ透明陶瓷及其性能研究[J]. 无机材料学报, 2022, 37(8): 911-917. |

| [8] | 蔚海浪, 曹学强, 邓龙辉, 蒋佳宁. LaMeAl11O19/YSZ热障涂层热力学性能和热循环寿命[J]. 无机材料学报, 2022, 37(12): 1259-1266. |

| [9] | 郝鸿渐, 李海燕, 万德田, 包亦望, 李月明. 莫来石/氧化铝预应力涂层增强氧化铝的弯曲强度和抗热震性能[J]. 无机材料学报, 2022, 37(12): 1295-1301. |

| [10] | 朱嘉桐, 楼志豪, 张萍, 赵佳, 孟轩宇, 许杰, 高峰. 稀土钽酸盐(RETaO4)高熵陶瓷的制备与热学性能研究[J]. 无机材料学报, 2021, 36(4): 411-417. |

| [11] | 桑玮玮, 张红松, 陈华辉, 温斌, 李新春. (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7高熵陶瓷的制备及热物理性能[J]. 无机材料学报, 2021, 36(4): 405-410. |

| [12] | 樊文琪, 宋雪梅, 黄怡玲, 常程康. CMAS对YSZ涂层腐蚀引起的结构变化及其相变分布[J]. 无机材料学报, 2021, 36(10): 1059-1066. |

| [13] | 高纪明, 杨阳, 雷霆, 王进, 刘杰, 张丽敏. 原位聚合法制备SiC@SiO2/BN/PI复合材料及其表征[J]. 无机材料学报, 2021, 36(1): 36-42. |

| [14] | 范佳锋,张小锋,周克崧,刘敏,邓畅光,邓春明,牛少鹏,邓子谦. 镀铝改性对PS-PVD 7YSZ热障涂层抗CMAS腐蚀影响机制[J]. 无机材料学报, 2019, 34(9): 938-946. |

| [15] | 马伯乐, 马文, 黄威, 白玉, 贾瑞灵, 董红英. 单相双稀土改性SrZrO3热障涂层的热物理性能[J]. 无机材料学报, 2019, 34(4): 394-400. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||