无机材料学报 ›› 2023, Vol. 38 ›› Issue (1): 105-112.DOI: 10.15541/jim20220327 CSTR: 32189.14.10.15541/jim20220327

所属专题: 【结构材料】热障与环境障涂层(202506)

• 研究论文 • 上一篇

潘洋洋1,2( ), 梁波1(

), 梁波1( ), 洪督2, 祁志祥3, 牛亚然2, 郑学斌2

), 洪督2, 祁志祥3, 牛亚然2, 郑学斌2

收稿日期:2022-06-11

修回日期:2022-07-26

出版日期:2023-01-20

网络出版日期:2022-08-04

通讯作者:

梁 波, 教授. E-mail: liangbo@ysu.edu.cn作者简介:潘洋洋(1991-), 男, 博士研究生. E-mail: panyangyang4155@163.com

基金资助:

PAN Yangyang1,2( ), LIANG Bo1(

), LIANG Bo1( ), HONG Du2, QI Zhixiang3, NIU Yaran2, ZHENG Xuebin2

), HONG Du2, QI Zhixiang3, NIU Yaran2, ZHENG Xuebin2

Received:2022-06-11

Revised:2022-07-26

Published:2023-01-20

Online:2022-08-04

Contact:

LIANG Bo, professor. E-mail: liangbo@ysu.edu.cnAbout author:PAN Yangyang (1991-), male, PhD candidate. E-mail: panyangyang4155@163.com

Supported by:摘要:

TiAl合金具有低密度、高比强度的优异性能, 是一种潜在的航空发动机用结构材料。TiAl合金的服役温度范围为700~900 ℃, 在其表面制备高温热防护涂层可以进一步提高服役温度。本研究采用等离子喷涂技术在TiAl合金表面制备了新型TiAlCrY/YSZ涂层, 并与传统的NiCrAlY/YSZ热障涂层进行高温长时间服役性能对比研究。结果发现, TiAlCrY/YSZ涂层在1100 ℃空气环境中服役300 h保持完好, 表现出良好的高温性能, 而NiCrAlY/YSZ涂层在1100 ℃的服役寿命不足100 h。显微分析结果表明, TiAlCrY黏结层表面会形成一层连续且致密的TGO, 其主要成分为Al2O3, 与YSZ涂层的界面兼容性良好。并且TGO在1100 ℃空气环境中服役300 h后, 厚度仍<8 μm。以上研究表明, 与传统NiCrAlY/YSZ热障涂层相比, TiAlCrY/YSZ更适合作为TiAl合金表面的高温热防护涂层。

中图分类号:

潘洋洋, 梁波, 洪督, 祁志祥, 牛亚然, 郑学斌. TiAl合金表面TiAlCrY/YSZ涂层高温长时间服役性能[J]. 无机材料学报, 2023, 38(1): 105-112.

PAN Yangyang, LIANG Bo, HONG Du, QI Zhixiang, NIU Yaran, ZHENG Xuebin. High Temperature Long-term Service Performance of TiAlCrY/YSZ Coating on TiAl Alloy[J]. Journal of Inorganic Materials, 2023, 38(1): 105-112.

| Al | Cr | Y | Ti | Ni | Zr | O | Source | |

|---|---|---|---|---|---|---|---|---|

| TiAlCrY | 55.0 | 20.0 | 0.4 | 24.6 | — | — | — | Nanjing University of Science and Technology |

| NiCrAlY | 14.5 | 20.5 | 1.0 | — | 64.0 | — | — | Institute of Metal Research, Chinese Academy of Sciences |

| YSZ | — | — | 3.7 | — | — | 30.3 | 66.0 | Sulzer Metco |

表1 YSZ、TiAlCrY和NiCrAlY粉体成分(%, 原子分数)

Table 1 Compositions of YSZ, TiAlCrY and NiCrAlY powders (%, in atom)

| Al | Cr | Y | Ti | Ni | Zr | O | Source | |

|---|---|---|---|---|---|---|---|---|

| TiAlCrY | 55.0 | 20.0 | 0.4 | 24.6 | — | — | — | Nanjing University of Science and Technology |

| NiCrAlY | 14.5 | 20.5 | 1.0 | — | 64.0 | — | — | Institute of Metal Research, Chinese Academy of Sciences |

| YSZ | — | — | 3.7 | — | — | 30.3 | 66.0 | Sulzer Metco |

| Coating | Ar/slpm | H2/slpm | Spray distance/mm | Feed rate/(r·min-1) | Power/kW | Vacuum pressure/Pa |

|---|---|---|---|---|---|---|

| TiAlCrY/ NiCrAlY | 30-40 | 5-15 | 200-300 | 15-30 | 30-40 | 1-3 |

| YSZ | 30-40 | 5-15 | 90-130 | 15-30 | 38-48 | — |

表2 YSZ、TiAlCrY和NiCrAlY涂层喷涂参数

Table 2 Spray parameters of YSZ, TiAlCrY and NiCrAlY coatings

| Coating | Ar/slpm | H2/slpm | Spray distance/mm | Feed rate/(r·min-1) | Power/kW | Vacuum pressure/Pa |

|---|---|---|---|---|---|---|

| TiAlCrY/ NiCrAlY | 30-40 | 5-15 | 200-300 | 15-30 | 30-40 | 1-3 |

| YSZ | 30-40 | 5-15 | 90-130 | 15-30 | 38-48 | — |

图3 TiAlCrY/YSZ涂层热处理后的截面形貌(a, b)和EDS结果(c, d)

Fig. 3 Cross-sectional morphologies (a, b) and EDS analyses (c, d) of TiAlCrY/YSZ coating after heat-treatment

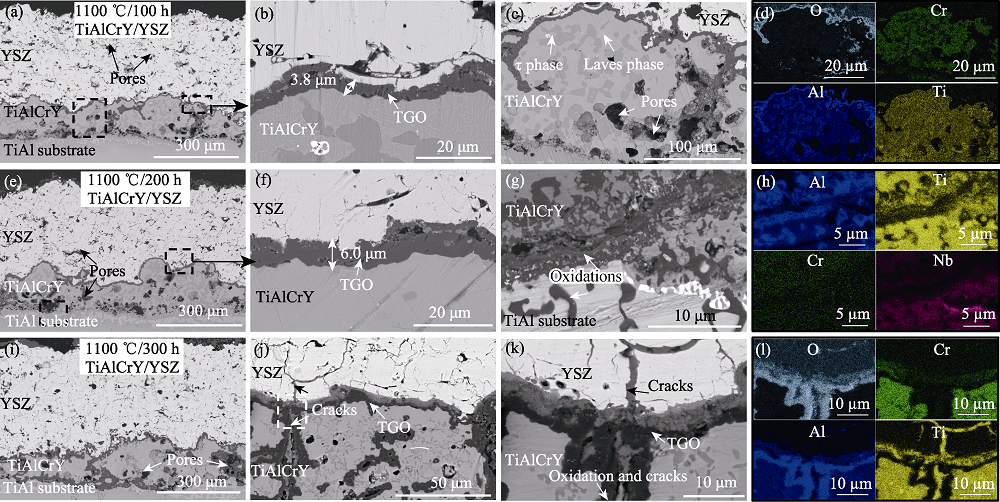

图4 TiAlCrY/YSZ涂层经1100 ℃处理100 h (a~d)、200 h (e~h)和300 h (i~l)的截面形貌和EDS分析结果

Fig. 4 Cross-sectional morphologies and EDS results of TiAlCrY/YSZ coating after heat-treatment at 1100 ℃ for 100 h (a-d), 200 h (e-h) and 300 h (i-l)

图5 TiAlCrY涂层经1100 ℃处理100 h的截面形貌(a, c, d)和EDS结果(b)

Fig. 5 Cross-sectional morphologies (a, c, d) and EDS analyse (b) of TiAlCrY coating after heat-treatment at 1100 ℃ for 100 h

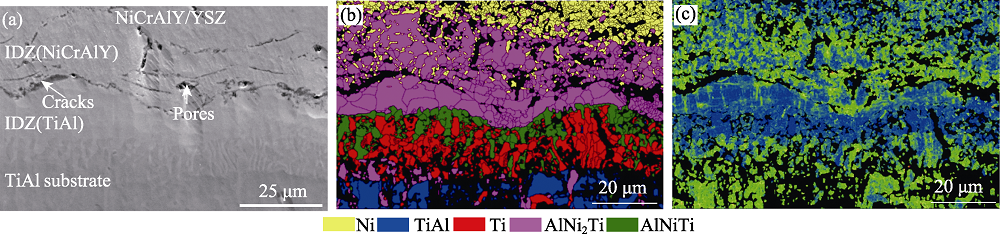

图6 iCrAlY/YSZ涂层经1100 ℃处理100 h后的截面形貌(a)和EBSD结果(b, c)

Fig. 6 Cross-sectional morphologies (a) and EBSD results (b, c) of NiCrAlY/YSZ coating after 100 h thermal-treatment at 1100 ℃. Colorful images are available on the website

图7 YSZ 涂层、TiAl 、TiAlCrY 和NiCrAlY 合金在100~ 1100 ℃范围的热膨胀系数

Fig. 7 Thermal expansion coefficients (CTE) of YSZ coating, TiAl, TiAlCrY, and NiCrAlY alloys in the range of 100-1100 ℃

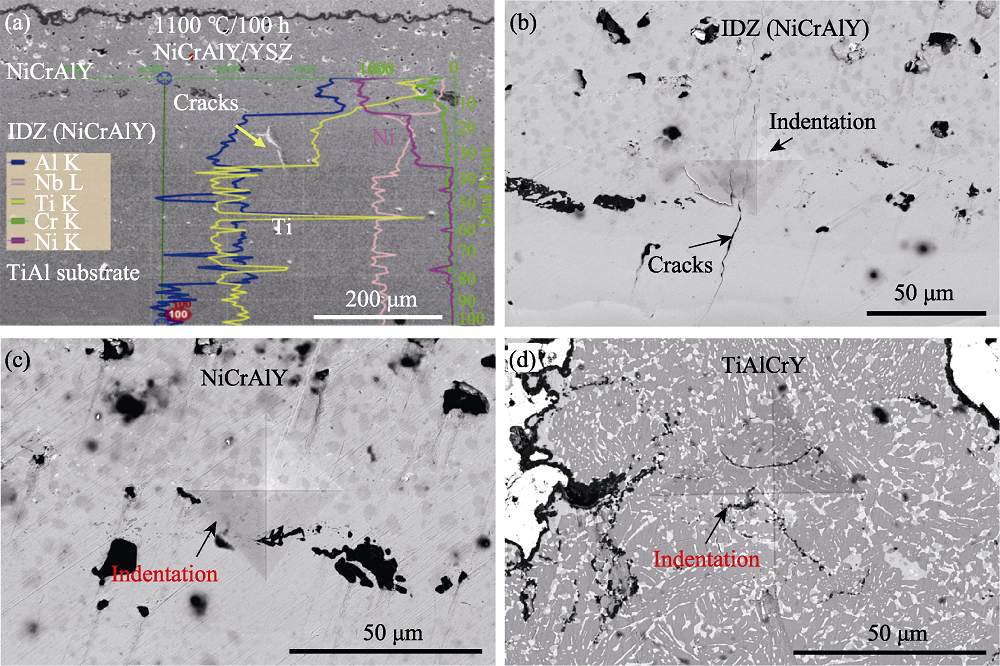

图8 IDZ的EDS结果(a)和IDZ (b)、NiCrAlY(c)、TiAlCrY(d)涂层在4.9 N载荷力下的典型压痕形貌

Fig. 8 EDS results (a) of IDZ and indentation morphologies of IDZ(b), NiCrAlY (c), and TiAlCrY (d) coatings under 4.9 N load

| [1] |

DIMIDUK D M. Gamma titanium aluminide alloys—an assessment within the competition of aerospace structural materials. Materials Science and Engineering: A, 1999, 263(2): 281.

DOI URL |

| [2] |

CLEMENS HELMUT, MAYER SVEA. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Advanced Engineering Materials, 2013, 15(4): 191.

DOI URL |

| [3] |

CLEMENS HELMUT, KESTLER HEINRICH. Processing and applications of intermetallic γ-TiAl-based alloys. Advanced Engineering Materials, 2000, 2(9): 551.

DOI URL |

| [4] | 彭小敏, 夏长清, 王志辉. TiAl 基合金高温氧化及防护的研究进展. 中国有色金属学报, 2010, 20(6): 1116. |

| [5] |

CLARKE DAVID R, OECHSNER M, PADTURE N P, et al. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bulletin, 2012, 37(10): 891.

DOI URL |

| [6] |

GLEESON B. Thermal barrier coatings for aeroengine applications. Journal of Propulsion and Power, 2006, 22(2): 375.

DOI URL |

| [7] |

LEYENS C, VAN LIERE J W, PETERS M, et al. Magnetron- sputtered Ti-Cr-Al coatings for oxidation protection of titanium alloys. Surface & Coatings Technology, 1998, 108-109(10): 30.

DOI URL |

| [8] |

FOX-RABINOVICH G S, WILKINSON D S, VELDHUIS S C, et al. Oxidation resistant Ti-Al-Cr alloy for protective coating applications. Intermetallic, 2006, 14(2): 189.

DOI URL |

| [9] | ZHOU C G, YANG Y, GONG S K, et al. Effect of Ti-Al-Cr coatings on the high temperature oxidation behavior of TiAl alloys. Materials Science & Engineering A, 2001, 307(1/2): 182. |

| [10] | BRAUN R, BRAUE W, FROHLICH M, et al. Thermally grown oxide scales on gamma-TiAl coated with thermal protection systems. High Temperature Technology, 2009, 26(3): 305. |

| [11] |

BRAUN R, FRÖHLICH M, BRAUE W, et al. Oxidation behaviour of gamma titanium aluminides with EB-PVD thermal barrier coatings exposed to air at 900 ℃. Surface & Coatings Technology, 2007, 202(4-7): 676.

DOI URL |

| [12] | 唐兆麟, 王福会, 吴维. TiAlCr涂层对TiAl金属间化合物抗高温氧化性能的影响. 中国腐蚀与防护学报, 1998, 18(1): 35. |

| [13] |

PAN Y Y, LIANG B, NIU Y R, et al. Thermal shock behaviors of plasma sprayed TiAlCrY/YSZ system on TiAl alloys. Ceramics International, 2022, 48(5): 6199.

DOI URL |

| [14] |

PAN Y Y, LIANG B, HONG D, et al. Effect of TiAlCrNb buffer layer on thermal cycling behavior of TiAlCrY/YSZ coatings on γ-TiAl alloys. Surface & Coatings Technology, 2021, 431(15): 128000.

DOI URL |

| [15] |

RACHELEH A P, REZA S R, REZA M, et al. Improving the thermal shock resistance of plasma sprayed CYSZ thermal barrier coatings by laser surface modification. Opt. Laser. Eng., 2012, 50(5): 780.

DOI URL |

| [16] | 许世鸣, 张小锋, 刘敏, 等. APS制备7YSZ热障涂层镀铝改性的抗氧化性. 材料导报, 2019, 33(1): 283. |

| [17] |

JAMALI H, MOZAFARINIA R, RAZAVI R S, et al. Comparison of thermal shock resistances of plasma-sprayed nanostructured and conventional yttria stabilized zirconia thermal barrier coatings, Ceramics International, 2012, 38(8): 6705.

DOI URL |

| [18] |

ZHANG X F, ZHOU K S, ZHANG J F, et al. Structure evolution of 7YSZ thermal barrier coating during thermal shock testing. Journal of Inorganic Materials, 2015, 30(12): 1261.

DOI URL |

| [19] |

BRADY M P, SMIALEK J L, HUMPHREY D L, et al. The role of Cr in promoting protective alumina scale formation by γ-based Ti-Al-Cr alloys—II. Oxidation behavior in air. Acta Materialia, 1997, 45(6): 2371.

DOI URL |

| [20] |

LIU C T, ZHU J H, BRADY M P, et al. Physical metallurgy and mechanical properties of transition-metal Laves phase alloys. Intermetallic, 2000, 8(9/10/11):1119.

DOI URL |

| [21] | TAKEYAMA M, LIU C T. Microstructure and mechanical properties of Laves-phase alloys based on Cr2Nb. Materials Science & Engineering A, 1991, 132(91): 61. |

| [22] |

WEISS M, LU M, P VAN DER HEIDE, et al. Radiation enhanced diffusion of Ti in Al2O3. Journal of Chemical Physics, 2000, 113(12): 5058.

DOI URL |

| [23] |

KLIAUGA A M, Ferrante M. Interface compounds formed during the diffusion bonding of Al2O3 to Ti. Journal of Materials Science, 2000, 35(17): 4243.

DOI URL |

| [24] |

HILLE T S, TURTELTAUB S, SUIKER A S J, et al. Oxide growth and damage evolution in thermal barrier coatings. Engineering Fracture Mechanics, 2011, 78(10): 2139.

DOI URL |

| [25] |

CUI Y J, GUO M Q, WANG C L, et al. Evolution of the residual stress in porous ceramic abradable coatings under thermal exposure. Surface and Coatings Technology, 2020, 394(25): 125915.

DOI URL |

| [26] |

ABBA A A, ABUL F M A, SOHAIL A. Evolution of internal cracks and residual stress during deposition of TBC. Ceramics International, 2020, 46(17): 26731.

DOI URL |

| [27] |

LI D, PENG B Z, QU W, et al. Finite-element simulation of residual stress in zirconia thermal barrier coating. Advanced Materials Research, 2011, 311-313: 210.

DOI URL |

| [28] |

HILLE T S, TURTELTAUB S, SUIKER A S J. Oxide growth and damage evolution in thermal barrier coatings. Engineering Fracture Mechanics, 2011, 78(10): 2139.

DOI URL |

| [29] |

KARUNARATNE M S A, KYAW S, JONES A, et al. Modelling the coefficient of thermal expansion in Ni-based superalloys and bond coatings. Journal of Materials Science, 2016, 51(9): 4213.

DOI URL |

| [30] |

LASSEUR V, GOUTIER S, GARCIA V M, et al. Residual stress evolution in zirconia (Y2O38%) coatings during atmospheric plasma spraying for substrates under rotating kinematic. Journal of Thermal Spray Technology, 2020, 29(5/6): 1313.

DOI URL |

| [31] | ARAI M, WADA E, KISHIMOTO K. Residual stress analysis of ceramic thermal barrier coating based on thermal spray process. Transactions of the Japan Society of Mechanical Engineers, 2007, 72(717): 1251. |

| [1] | 梁锐辉, 钟鑫, 洪督, 黄利平, 牛亚然, 郑学斌. Yb2O3改性硅黏结层的环境障涂层体系耐高温水氧腐蚀行为研究[J]. 无机材料学报, 2025, 40(4): 425-432. |

| [2] | 马文, 申喆, 刘琪, 高元明, 白玉, 李荣星. 悬浮液等离子喷涂制备Y2O3涂层及耐等离子刻蚀性[J]. 无机材料学报, 2024, 39(8): 929-936. |

| [3] | 李捷, 罗志新, 崔阳, 张广珩, 孙鲁超, 王京阳. 大气等离子喷涂Y3Al5O12/Al2O3陶瓷涂层的CMAS腐蚀抗力[J]. 无机材料学报, 2024, 39(6): 671-680. |

| [4] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [5] | 代钊,王铭,王双,李静,陈翔,汪大林,祝迎春. 氧化锆基微量元素共掺杂羟基磷灰石增韧涂层研究[J]. 无机材料学报, 2020, 35(2): 179-186. |

| [6] | 范佳锋,张小锋,周克崧,刘敏,邓畅光,邓春明,牛少鹏,邓子谦. 镀铝改性对PS-PVD 7YSZ热障涂层抗CMAS腐蚀影响机制[J]. 无机材料学报, 2019, 34(9): 938-946. |

| [7] | 谢玲玲, 牛亚然, 王亮, 陈文亮, 郑学斌, 黄贞益. 等离子喷涂ZrC基涂层逐道逐层沉积残余应力模拟与实验验证[J]. 无机材料学报, 2019, 34(7): 768-774. |

| [8] | 周炎哲, 刘敏, 杨焜, 曾威, 宋进兵, 邓春明, 邓畅光. 大气等离子喷涂MoSi2-30Al2O3电热涂层的组织结构及性能[J]. 无机材料学报, 2019, 34(6): 646-652. |

| [9] | 陈书赢, 马国政, 何鹏飞, 刘喆, 刘明, 邢志国, 王海斗, 王海军. 基于粒子飞行特性及铺展行为的WC-10Co4Cr涂层孔隙形成机理研究[J]. 无机材料学报, 2018, 33(8): 895-902. |

| [10] | 张小锋, 周克崧, 刘敏, 邓春明, 牛少鹏, 许世鸣. 等离子喷涂-物理气相沉积Si/莫来石/Yb2SiO5环境障涂层[J]. 无机材料学报, 2018, 33(3): 325-330. |

| [11] | 孙旭轩, 陈宏飞, 杨光, 刘斌, 高彦峰. YSZ-Ti3AlC2热障涂层及其高温自愈合行为[J]. 无机材料学报, 2017, 32(12): 1269-1274. |

| [12] | 于方丽, 白 宇, 吴秀英, 王海军, 吴九汇. 等离子喷涂镍基可磨耗封严涂层抗腐蚀及耐磨性能分析[J]. 无机材料学报, 2016, 31(7): 687-693. |

| [13] | 毛金元, 刘 敏, 毛 杰, 邓春明, 曾德长, 徐 林. 等离子喷涂制备ZrB2-MoSi2复合涂层及其抗氧化性能[J]. 无机材料学报, 2015, 30(3): 282-286. |

| [14] | 张小锋, 周克崧, 宋进兵, 邓春明, 牛少鹏, 邓子谦. 等离子喷涂-物理气相沉积7YSZ热障涂层沉积机理及 其CMAS腐蚀失效机制[J]. 无机材料学报, 2015, 30(3): 287-293. |

| [15] | 陈 丹, 王 玉, 白 宇, 王运会, 赵 蕾, 付倩倩, 王海军, 韩志海. 等离子喷涂中雷诺数对熔滴扁平化行为的影响[J]. 无机材料学报, 2015, 30(1): 65-70. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||