无机材料学报 ›› 2022, Vol. 37 ›› Issue (12): 1295-1301.DOI: 10.15541/jim20220238 CSTR: 32189.14.10.15541/jim20220238

郝鸿渐1( ), 李海燕1,2, 万德田1,2,3(

), 李海燕1,2, 万德田1,2,3( ), 包亦望1,2,3(

), 包亦望1,2,3( ), 李月明3

), 李月明3

收稿日期:2022-04-22

修回日期:2022-07-14

出版日期:2022-12-20

网络出版日期:2022-08-04

通讯作者:

万德田, 教授. E-mail: dtwan@ctc.ac.cn;作者简介:郝鸿渐(1996-), 男, 硕士研究生. E-mail: haohongjian1996@qq.com

基金资助:

HAO Hongjian1( ), LI Haiyan1,2, WAN Detian1,2,3(

), LI Haiyan1,2, WAN Detian1,2,3( ), BAO Yiwang1,2,3(

), BAO Yiwang1,2,3( ), LI Yueming3

), LI Yueming3

Received:2022-04-22

Revised:2022-07-14

Published:2022-12-20

Online:2022-08-04

Contact:

WAN Detian, professor. E-mail: dtwan@ctc.ac.cn;About author:HAO Hongjian (1996-), male, Master candidate. E-mail: haohongjian1996@qq.com

Supported by:摘要:

在陶瓷表面引入含压应力的涂层是一种有效的增强技术。本研究将氧化铝和石英粉混合浆料涂覆在预烧后的氧化铝坯体上, 无压共烧原位合成了热膨胀系数较低的莫来石-氧化铝涂层。利用降温过程中涂层内形成的残余压应力实现了氧化铝陶瓷的预应力强化。结果表明:随着涂层中石英掺量增加, 预应力氧化铝的强度出现先增大后减小的趋势; 当涂层中掺入石英的质量分数为15%时, 预应力增强效果最好, 涂层与基体界面结合紧密, 预应力氧化铝陶瓷的弯曲强度达到(549.44±27.2) MPa, 比普通氧化铝的强度提高了37.19%; 当涂层中掺入石英的质量分数增大到15%以上, 由于烧结收缩不匹配反而引起强度下降; 这种预应力增强效果会随着温度升高逐渐减弱, 当测试温度达到并超过1000 ℃时, 预应力氧化铝和普通氧化铝会具有大致相等的抗弯强度。由于表层压应力的存在, 预应力氧化铝还展现出更好的抗热震性能和损伤耐受性。

中图分类号:

郝鸿渐, 李海燕, 万德田, 包亦望, 李月明. 莫来石/氧化铝预应力涂层增强氧化铝的弯曲强度和抗热震性能[J]. 无机材料学报, 2022, 37(12): 1295-1301.

HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating[J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301.

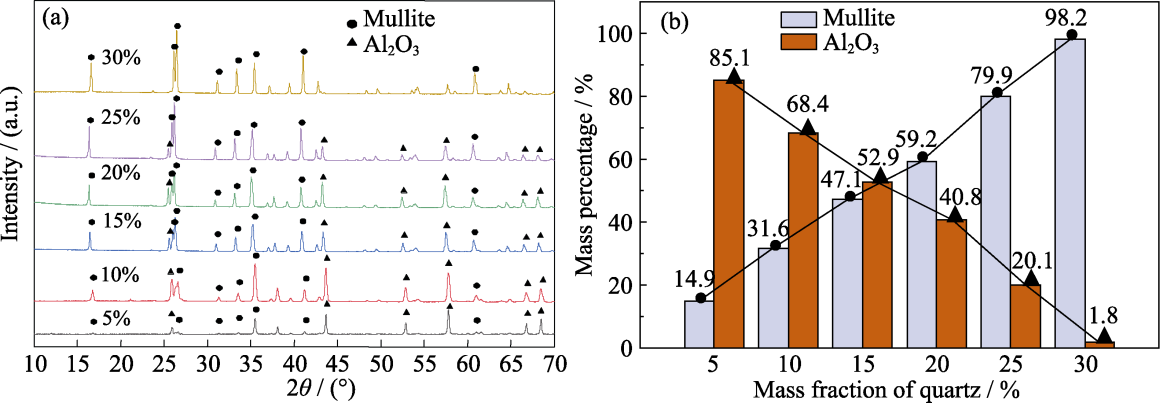

图2 不同石英含量制备的莫来石-氧化铝涂层材料物相分析

Fig. 2 Phase analyses of mullite-alumina coating materials fabricated with different mass fractions of quartz (a) XRD patterns after sintered at 1550 ℃; (b) Quantitative analysis by Rietveld method

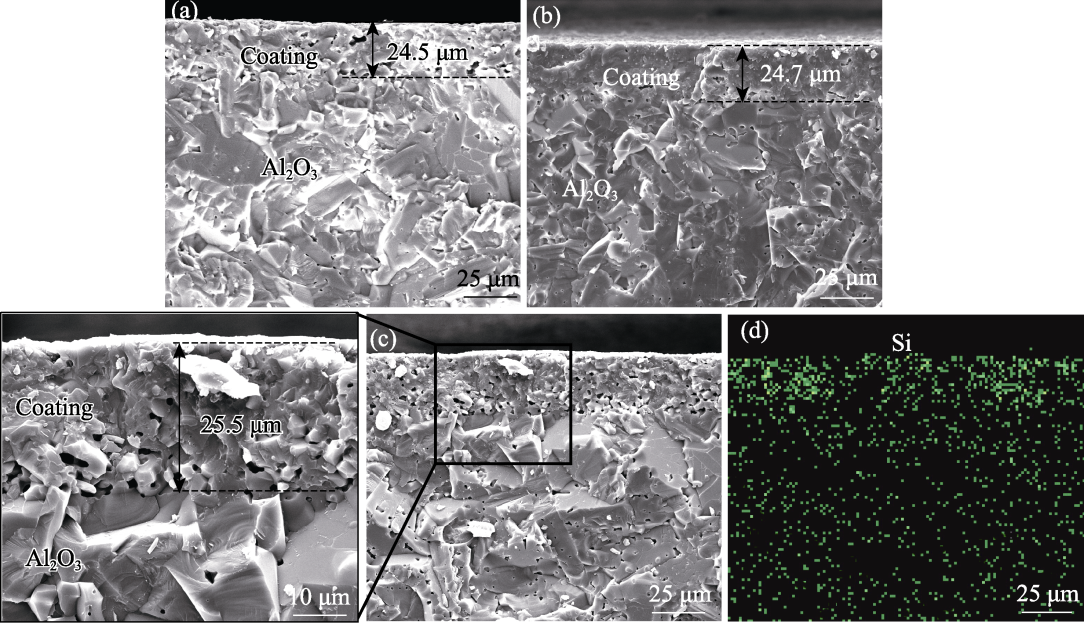

图5 预应力氧化铝((a) C10-A, (b) C25-A, (c) C15-A)断面扫描电镜照片, (d) C15-A的EDS分析

Fig. 5 Fracture section SEM images of pre-stressed alumina ((a) C10-A, (b) C25-A, (c) C15-A), (d) EDS analysis of C15-A

| Sample | Ec/GPa | Es/GPa | αc/(×10-6, K-1) | αs/(×10-6, K-1) | hc/μm | hs/μm | ΔT | σc/MPa | σs/MPa |

|---|---|---|---|---|---|---|---|---|---|

| C5-A | 91.36 | 380.11 | 6.69 | 7.58 | 50 | 1450 | 1000 ℃ | -119.66 | 4.80 |

| C10-A | 80.18 | 380.11 | 6.06 | 7.58 | 50 | 1450 | 1000 ℃ | -151.94 | 6.09 |

| C15-A | 73.33 | 380.11 | 5.33 | 7.58 | 50 | 1450 | 1000 ℃ | -181.86 | 7.29 |

| C20-A | 67.71 | 380.11 | 5.04 | 7.58 | 50 | 1450 | 1000 ℃ | -189.74 | 7.60 |

| C25-A | 62.14 | 380.11 | 4.72 | 7.58 | 50 | 1450 | 1000 ℃ | -196.17 | 7.86 |

| C30-A | 58.31 | 380.11 | 4.41 | 7.58 | 50 | 1450 | 1000 ℃ | -197.69 | 7.91 |

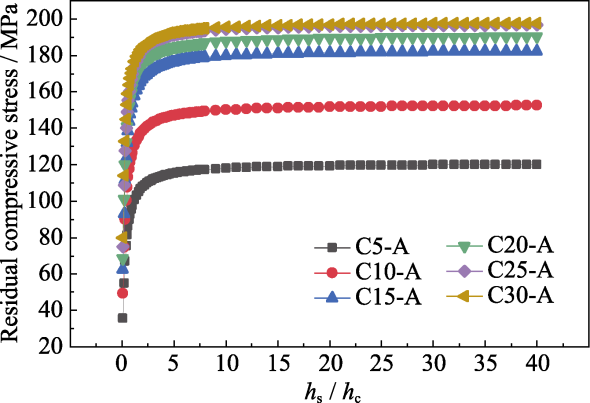

表1 不同石英含量制备预应力氧化铝的涂层和基体残余应力的计算结果

Table 1 Calculation of residual stresses of coatings and substrates in pre-stressed Al2O3 fabricated with different mass fractions of quartz

| Sample | Ec/GPa | Es/GPa | αc/(×10-6, K-1) | αs/(×10-6, K-1) | hc/μm | hs/μm | ΔT | σc/MPa | σs/MPa |

|---|---|---|---|---|---|---|---|---|---|

| C5-A | 91.36 | 380.11 | 6.69 | 7.58 | 50 | 1450 | 1000 ℃ | -119.66 | 4.80 |

| C10-A | 80.18 | 380.11 | 6.06 | 7.58 | 50 | 1450 | 1000 ℃ | -151.94 | 6.09 |

| C15-A | 73.33 | 380.11 | 5.33 | 7.58 | 50 | 1450 | 1000 ℃ | -181.86 | 7.29 |

| C20-A | 67.71 | 380.11 | 5.04 | 7.58 | 50 | 1450 | 1000 ℃ | -189.74 | 7.60 |

| C25-A | 62.14 | 380.11 | 4.72 | 7.58 | 50 | 1450 | 1000 ℃ | -196.17 | 7.86 |

| C30-A | 58.31 | 380.11 | 4.41 | 7.58 | 50 | 1450 | 1000 ℃ | -197.69 | 7.91 |

图8 不同预应力氧化铝涂层中残余压应力和基体与涂层厚度比之间的理论关系

Fig. 8 Theoretical relationship between residual compressive stress and substrate-to-coating thickness ratio in different pre- stressed aluminas

| [1] |

NIELSEN J H, THIELE K, SCHNEIDER J, et al. Compressive zone depth of thermally tempered glass. Construction and Building Materials, 2021, 310: 125238.

DOI URL |

| [2] |

GREEN D J. Crack arrest and multiple cracking in glass through the use of designed residual stress profiles. Science, 1999, 283(5406): 1295-1297.

PMID |

| [3] |

BERMEJO R, TORRES Y, SÁNCHEZ-HERENCIA A J, et al. Residual stresses, strength and toughness of laminates with different layer thickness ratios. Acta Materialia, 2006, 54(18): 4745-4757.

DOI URL |

| [4] |

BERMEJO R, PASCUAL J, LUBE T, et al. Optimal strength and toughness of Al2O3-ZrO2 laminates designed with external or internal compressive layers. Journal of the European Ceramic Society, 2008, 28(8): 1575-1583.

DOI URL |

| [5] |

LAKSHMINARAYANAN R, SHETTY D, CUTLER R A. Toughening of layered ceramic composites with residual surface compression. Journal of the American Ceramic Society, 1996, 79(1): 79-87.

DOI URL |

| [6] |

BAO Y W, KUANG F H, SUN Y, et al. A simple way to make pre-stressed ceramics with high strength. Journal of Materiomics, 2019, 5(4): 657-662.

DOI |

| [7] |

LI H Y, HAO H J, TIAN Y, et al. Effects of residual stresses on strength and crack resistance in ZrO2 ceramics with alumina coating. Journal of Inorganic Materials, 2022, 37(4): 467-472.

DOI URL |

| [8] |

BAO Y W, SUN Y, KUANG F H, et al. Development and prospects of high strength pre-stressed ceramics. Journal of Inorganic Materials, 2020, 35(4): 399-408.

DOI |

| [9] |

LI N, ZHANG X Y, QU Y N, et al. A simple and efficient way to prepare porous mullite matrix ceramics via directly sintering SiO2- Al2O3 microspheres. Journal of the European Ceramic Society, 2016, 36(11): 2807-2812.

DOI URL |

| [10] |

LI H, LIU Y S, LIU Y S, et al. Silica strengthened alumina ceramic cores prepared by 3D printing. Journal of the European Ceramic Society, 2021, 41(4): 2938-2947.

DOI URL |

| [11] |

LIN Y M, LI C W, WANG C A. Effects of mullite content on the properties and microstructure of porous anorthite/mullite composite ceramics. Journal of Inorganic Materials, 2011, 26(10): 1095-1100.

DOI |

| [12] |

JIANG Y, CHANG L F, RU H Q, et al. Microstructure and oxidation behaviors of dense mullite-silicon carbide-silicon coating for graphite fabricated by dipping-pyrolysis and reactive infiltration. Surface and Coatings Technology, 2018, 350: 410-418.

DOI URL |

| [13] | 包亦望. 先进陶瓷力学性能评价方法与技术. 北京: 中国建材工业出版社, 2017: 3. |

| [14] |

ZHOU X, LIU D, BU H L, et al. XRD-based quantitative analysis of clay minerals using reference intensity ratios, mineral intensity factors, Rietveld, and full pattern summation methods: a critical review. Solid Earth Sciences, 2018, 3(1): 16-29.

DOI URL |

| [15] |

BAO Y W, SU S B, HUANG J L. An uneven strain model for analysis of residual stress and interface stress in laminate composites. Journal of Composite Materials, 2002, 36(14): 1769-1778.

DOI URL |

| [16] | CAI P Z, GREEN D J, MESSING G L. Constrained densification of alumina/zirconia hybrid laminates, II: viscoelastic stress computation. Journal of the American Ceramic Society, 1997, 80(8): 1948-1949. |

| [17] |

JIANG R, SUN X, LIU H T, et al. Microstructure and mechanical properties improvement of the Nextel™ 610 fiber reinforced alumina composite. Journal of the European Ceramic Society, 2021, 41(10): 5394-5399.

DOI URL |

| [18] |

PABST W, GREGOROVÁ E, ČERNÝ M. Isothermal and adiabatic Young's modulus of alumina and zirconia ceramics at elevated temperatures. Journal of the European Ceramic Society, 2013, 33(15): 3085-3093.

DOI URL |

| [19] |

WANG W, SHI Z, WANG Z, et al. Phase transformation and properties of high-quality mullite ceramics synthesized using desert drift sands as raw materials. Materials Letters, 2018, 221: 271-274.

DOI URL |

| [20] |

WEI C G, LIU Z, BAO Y W, et al. Evaluating thermal expansion coefficient and density of ceramic coatings by relative method. Materials Letters, 2015, 161: 542-544.

DOI URL |

| [21] |

BAO Y W, ZHOU Y C, BU X X, et al. Evaluating elastic modulus and strength of hard coatings by relative method. Materials Science and Engineering: A, 2007, 458(1): 268-274.

DOI URL |

| [22] |

CAI P Z, GREEN D J, MESSING G L. Constrained densification of alumina/zirconia hybrid laminates, I: experimental observations of processing defects. Journal of the American Ceramic Society, 1997, 80(8): 1929-1939.

DOI URL |

| [1] | 郑斌, 康凯, 张青, 叶昉, 解静, 贾研, 孙国栋, 成来飞. 前驱体转化陶瓷法制备Ti3SiC2陶瓷及其热稳定性研究[J]. 无机材料学报, 2024, 39(6): 733-740. |

| [2] | 靳赛, 刘小根, 齐爽, 赵润昌, 李志军. 激光诱导损伤对熔石英玻璃弯曲强度弱化影响及安全设计[J]. 无机材料学报, 2023, 38(6): 671-677. |

| [3] | 李海燕, 旷峰华, 吴昊龙, 刘小根, 包亦望, 万德田. 残余拉应力的温度依赖性及其对裂纹扩展行为的影响[J]. 无机材料学报, 2023, 38(11): 1265-1270. |

| [4] | 李海燕, 郝鸿渐, 田远, 汪长安, 包亦望, 万德田. 残余应力对涂覆Al2O3涂层的ZrO2陶瓷的强度和裂纹扩展阻力的影响[J]. 无机材料学报, 2022, 37(4): 467-472. |

| [5] | 冀晓鹃,于月光,卢晓亮. 杂质对氧化锆热障涂层性能的影响[J]. 无机材料学报, 2020, 35(6): 669-674. |

| [6] | 袁 康, 廖其龙, 王 辅, 代云雅, 黄金山. 烧结助剂(Y3+、La3+和Mg2+)对半透明氧化铝陶瓷的透光率的影[J]. 无机材料学报, 2017, 32(9): 1004-1008. |

| [7] | 刘 钊, 包亦望, 万德田, 胡春林, 马德隆, 田 远. 两种方法评价管材力学性能的研究[J]. 无机材料学报, 2016, 31(2): 213-219. |

| [8] | 雷卓研, 王 志, 范恒冰, 马文斌, 陈 健, 王 旭. 氧化硼-磷酸浸渍对中间相炭微球复合材料抗氧化及力学性能的影响[J]. 无机材料学报, 2015, 30(7): 769-773. |

| [9] | 田 卓, 段小明, 杨治华, 贾德昌, 周 玉. AlN添加量对BN基复合陶瓷热学性能与抗热震性的影响[J]. 无机材料学报, 2014, 29(5): 503-508. |

| [10] | 张高校, 温兆银, 吴相伟, 张敬超. 钠电池用梯度封接材料制备与性能[J]. 无机材料学报, 2013, 28(10): 1132-1136. |

| [11] | 陈圣博, 刘旭光, 张宝泉. 多孔α-Al2O3基陶瓷片状载体的制备与性能[J]. 无机材料学报, 2013, 28(06): 599-604. |

| [12] | 姚 旺, 张宇民, 韩杰才, 周玉锋. 反应烧结碳化硅的磨削特征[J]. 无机材料学报, 2012, 27(7): 764-768. |

| [13] | 罗朝华, 江东亮, 张景贤, 林庆玲, 陈忠明, 黄政仁. Na2O-B2O3-SiO2玻璃焊料连接碳化硅陶瓷接口抗热震性能[J]. 无机材料学报, 2012, 27(3): 234-238. |

| [14] | 吕志翚, 江东亮, 张景贤, 林庆玲, 黄政仁. 水基流延成型制备 ZrB2 和 ZrB2-20vol% SiC 复合材料的微观结构和抗热震性能[J]. 无机材料学报, 2011, 26(3): 244-248. |

| [15] | 和永岗,李克智,魏建锋,郭领军,张磊磊. 2D C/C复合材料微观结构与力学性能的研究[J]. 无机材料学报, 2010, 15(2): 173-176. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||