无机材料学报 ›› 2020, Vol. 35 ›› Issue (12): 1385-1390.DOI: 10.15541/jim20200031 CSTR: 32189.14.10.15541/jim20200031

所属专题: 结构陶瓷论文精选(2020)

陈博文1,2,3( ),王敬晓1,2,姜佑霖1,2,3,周海军1,2,廖春景1,2,张翔宇1,2,阚艳梅1,2,倪德伟1,2(

),王敬晓1,2,姜佑霖1,2,3,周海军1,2,廖春景1,2,张翔宇1,2,阚艳梅1,2,倪德伟1,2( ), 董绍明1,3

), 董绍明1,3

收稿日期:2020-01-13

出版日期:2020-12-20

网络出版日期:2020-06-09

作者简介:陈博文(1994–), 男, 博士研究生. E-mail: chenbowen@student.sic.ac.cn

CHEN Bowen1,2,3( ),WANG Jingxiao1,2,JIANG Youlin1,2,3,ZHOU Haijun1,2,LIAO Chunjing1,2,ZHANG Xiangyu1,2,KAN Yanmei1,2,NI Dewei1,2(

),WANG Jingxiao1,2,JIANG Youlin1,2,3,ZHOU Haijun1,2,LIAO Chunjing1,2,ZHANG Xiangyu1,2,KAN Yanmei1,2,NI Dewei1,2( ), DONG Shaoming1,3

), DONG Shaoming1,3

Received:2020-01-13

Published:2020-12-20

Online:2020-06-09

About author:CHEN Bowen(1994–), male, PhD candidate. E-mail: chenbowen@student.sic.ac.cn

Supported by:摘要:

本研究提出了一种利用离心纺丝技术制备稳定碳化锆(ZrC)纤维的有效方法。此方法使用醋酸锆和蔗糖作为锆源和碳源, 聚乙烯吡咯烷酮(PVP)作为纺丝助剂, 经过1600 ℃的裂解与碳热还原热处理后, 所纺原丝转化成由均匀纳米ZrC晶体组成的ZrC纤维。研究结果表明, 纤维中残留的少量碳可助力ZrC纤维在2000 ℃的超高温环境下仍保持较好的结构稳定性。

中图分类号:

陈博文, 王敬晓, 姜佑霖, 周海军, 廖春景, 张翔宇, 阚艳梅, 倪德伟, 董绍明. 基于离心纺丝技术制备稳定的碳化锆纤维[J]. 无机材料学报, 2020, 35(12): 1385-1390.

CHEN Bowen, WANG Jingxiao, JIANG Youlin, ZHOU Haijun, LIAO Chunjing, ZHANG Xiangyu, KAN Yanmei, NI Dewei, DONG Shaoming. Stable Zirconium Carbide Fibers Fabricated by Centrifugal Spinning Technique[J]. Journal of Inorganic Materials, 2020, 35(12): 1385-1390.

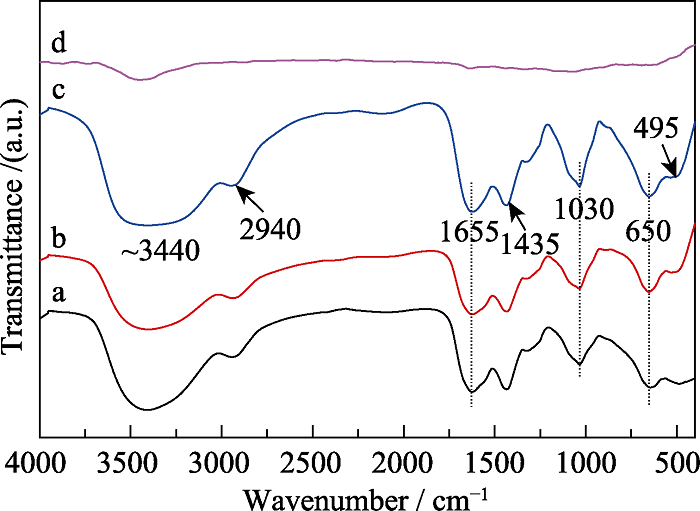

Fig. 2 FT-IR spectra of ZrC precursors with different ZrO(CH3COO)2 : C12H22O11 ratios: (a) 4 : 1; (b) 4 : 1.2; (c) 4 : 1.5; and (d) ZrC precursor (with ZrO(CH3COO)2 : C12H22O11= 4 : 1.5) after pyrolysis at 600 ℃

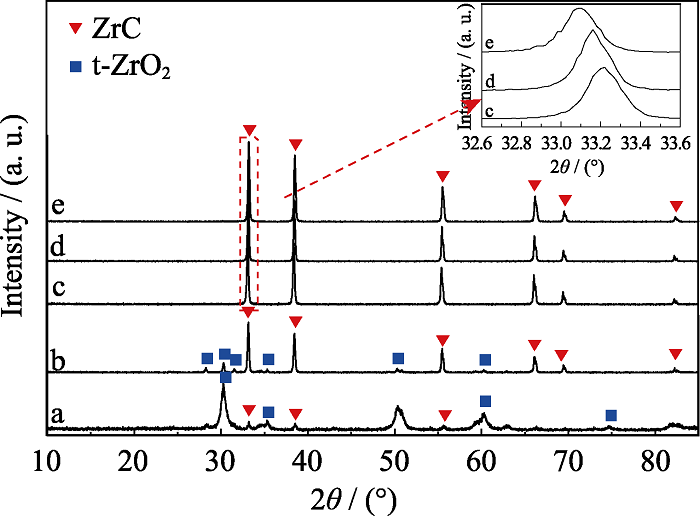

Fig. 4 XRD patterns of ZrC fibers prepared from ZrC precursors with different ZrO(CH3COO)2:C12H22O11 ratios after heat- treatment at temperature range from 1400 to 1600 ℃ for 2 h (a) 4 : 1.5 @1400 ℃; (b) 4 : 1.5 @1500 ℃; (c) 4 : 1.5 @1600 ℃; (d) 4 : 1.2 @1600 ℃; (e) 4 : 1 @1600 ℃

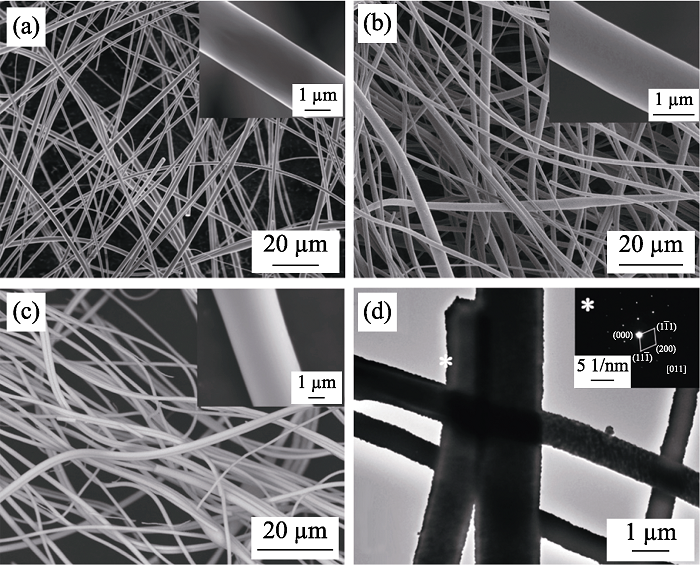

Fig. 5 SEM images of ZrC fibers prepared from ZrC precursor with ZrO(CH3COO)2 : C12H22O11=4 : 1.5((a) as-spun green fibers; (b) after heat-treatment at 600 ℃ and (c) after heat- treatment at 1600 ℃); and (d) TEM image of ZrC fibers after heat-treatment at 1600 ℃ The insets in (a,b,c) are the corresponding local enlarged images; while the inset in (d) is the selected area electron diffraction (SAED) pattern of ZrC fibers

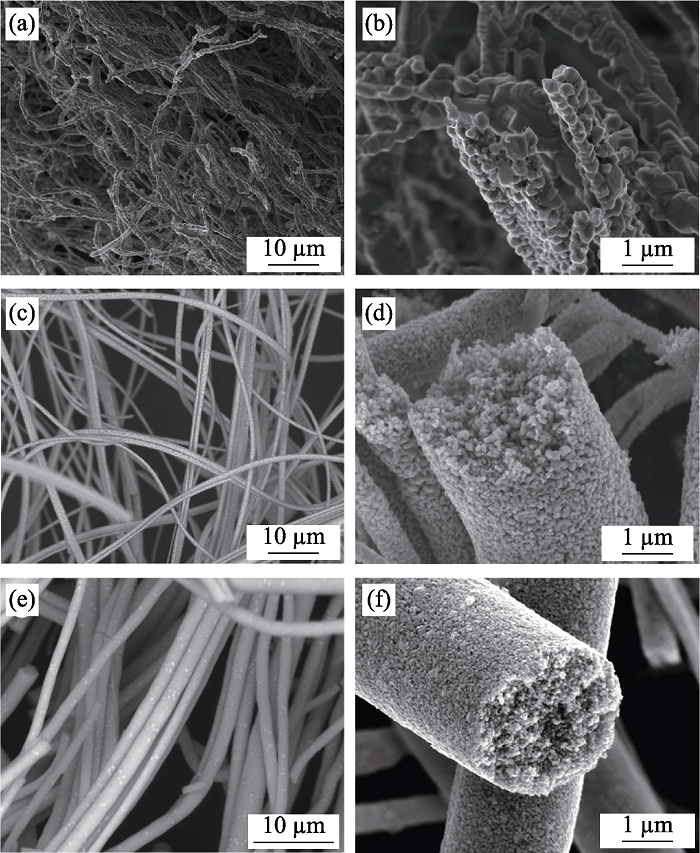

Fig. 6 SEM images of ZrC fibers prepared from ZrC precursors with different ZrO(CH3COO)2 : C12H22O11 ratios after heat-treatment at 2000 ℃ for 2 h (a, b) 4 : 1; (c, d) 4 : 1.2; (e, f) 4 : 1.5

| [1] | FAHRENHOLTZ W G, HILMAS G E, TALMY I G, et al. Refractory diborides of zirconium and hafnium. J. Am. Ceram. Soc., 2007,90(5):1347-1364. |

| [2] | ZHANG G J, NI D W, ZOU J, et al. Inherent anisotropy in transition metal diborides and microstructure/property tailoring in ultra- high temperature ceramics—a review. J. Eur. Ceram. Soc., 2018,38(2):371-389. |

| [3] | CHARBONNIER F M, MACKIE W A, HARTMAN R L, et al. Robust high current field emitter tips and arrays for vacuum microelectronics devices. J. Vac. Sci. Technol, B: Microelectron. Nanometer. Struct., 2001,19(3):1064-1072. |

| [4] | COCKERAM B V, MEASURES D P, MUELLER A J. The development and testing of emissivity enhancement coatings for themophotovoltaic (TPV) radiator applications. Thin Solid Films, 1999,355(1):17-25. |

| [5] | SHEATS J R, MACKIE W A, ANZ S, et al. Polymer electroluminescent devices with zirconium carbide cathodes. Pro. SPIE - Int. Soc. Opt. Eng., 1997,3148:219-227. |

| [6] |

LI F, KANG Z, HUANG X, et al. Fabrication of zirconium carbide nanofibers by electrospinning. Ceram. Int., 2014,40(7):10137-10141.

DOI URL |

| [7] | KUROKAWA Y, OTA H, SATO T. Preparation of carbide fibres by thermal decomposition of cellulose-metal (Ti, Zr) alkoxide gel fibres. J. Mate. Sci. Lett., 1994,13(7):516-518. |

| [8] |

CUI X M, NAM Y S, LEE J Y, et al. Fabrication of zirconium carbide (ZrC) ultra-thin fibers by electrospinning. Mater. Lett., 2008,62(12/13):1961-1964.

DOI URL |

| [9] | NAM Y S, CUI X M, JEONG L, et al. Fabrication and characterization of zirconium carbide (ZrC) nanofibers with thermal storage property. Thin Solid Films, 2009,517(24):6531-6538. |

| [10] | FIRBAS P, SEEBER A, CHENG Y B. Creation of titanium and zirconium carbide fibers with the forcespinning technique. Int. J. App. Ceram. Technol., 2016,13(4):619-628. |

| [11] | SHE J, ZHAN Y, PANG M, et al. In situ synthesized (ZrB2+ZrC) hybrid short fibers reinforced Zr matrix composites for nuclear applications. Int. J. Refract. Met. Hard Mater., 2011,29(3):401-404. |

| [12] | LIU H Y, HOU X Q, WANG X Q, et al. Fabrication of high-strength continuous zirconia fibers and their formation mechanism study. J. Am. Ceram. Soc., 2004,87(12):2237-2241. |

| [13] | TAO X, QIU W, LI H, et al. Synthesis of nanosized zirconium carbide from preceramic polymers by the facile one-pot reaction. Polym. Adv. Technol., 2010,21(4):300-304. |

| [14] | DONG Z, ZHANG X, HUANG Q, et al. Synthesis and pyrolysis behavior of a soluble polymer precursor for ultra-fine zirconium carbide powders. Ceram. Int., 2015,41(6):7359-7365. |

| [15] | LI F, LIANG M, MA X F, et al. Preparation and characterization of stoichiometric zirconium carbide foams by direct foaming of zirconia sols. J. Porous Mater., 2015,22(2):493-500. |

| [16] | WANG J X, NI D W, DONG S M, et al. Synthesis of nanocrystallized zirconium carbide based on an aqueous solution-derived precursor. RSC Adv., 2017,37(7):22722-22727. |

| [1] | 王晓波, 朱于良, 薛稳超, 史汝川, 骆柏锋, 罗骋韬. PT含量变化对PMN-PT单晶的大功率性能影响[J]. 无机材料学报, 2025, 40(7): 840-846. |

| [2] | 汤新丽, 丁自友, 陈俊锐, 赵刚, 韩颖超. 基于稀土铕离子荧光标记的磷酸钙纳米材料体内分布与代谢研究[J]. 无机材料学报, 2025, 40(7): 754-764. |

| [3] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [4] | 杨光, 张楠, 陈舒锦, 王义, 谢安, 严育杰. 基于多孔ITO电极的WO3薄膜的制备及其电致变色性能[J]. 无机材料学报, 2025, 40(7): 781-789. |

| [5] | 孙晶, 李翔, 毛小建, 章健, 王士维. 月桂酸改性剂对氮化铝粉体抗水解性能的影响[J]. 无机材料学报, 2025, 40(7): 826-832. |

| [6] | 柴润宇, 张镇, 王孟龙, 夏长荣. 直接组装法制备氧化铈基金属支撑固体氧化物燃料电池[J]. 无机材料学报, 2025, 40(7): 765-771. |

| [7] | 王鲁杰, 张玉新, 李彤阳, 于源, 任鹏伟, 王建章, 汤华国, 姚秀敏, 黄毅华, 刘学建, 乔竹辉. 深海服役环境下碳化硅陶瓷材料的腐蚀及磨损行为[J]. 无机材料学报, 2025, 40(7): 799-807. |

| [8] | 李文元, 徐佳楠, 邓瀚澳, 常爱民, 张博. 钒取代对LaTaO4陶瓷微观结构和微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 697-703. |

| [9] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [10] | 董晨雨, 郑维杰, 马一帆, 郑春艳, 温峥. 压电力显微镜表征Pb(Mg,Nb)O3-PbTiO3超薄膜弛豫特性[J]. 无机材料学报, 2025, 40(6): 675-682. |

| [11] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [12] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [13] | 安然, 林锶, 郭世刚, 张冲, 祝顺, 韩颖超. 铁掺杂纳米羟基磷灰石的制备及紫外吸收性能研究[J]. 无机材料学报, 2025, 40(5): 457-465. |

| [14] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [15] | 熊思宇, 莫尘, 朱肖伟, 朱国斌, 陈德钦, 刘来君, 施晓东, 李纯纯. 超低介电常数LiBxAl1-xSi2O6微波介质陶瓷的低温烧结[J]. 无机材料学报, 2025, 40(5): 536-544. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||