无机材料学报 ›› 2018, Vol. 33 ›› Issue (9): 923-930.DOI: 10.15541/jim20170546 CSTR: 32189.14.10.15541/jim20170546

• • 下一篇

王海龙1, 王扬1, 王向伟2, 张宏志1

收稿日期:2017-11-16

修回日期:2018-01-07

出版日期:2018-09-20

网络出版日期:2018-08-14

作者简介:王海龙(1985-), 男, 博士研究生. E-mail: 13B908071@hit.edu.cn

基金资助:WANG Hai-Long1, WANG Yang1, WANG Xiang-Wei2, ZHANG Hong-Zhi1

Received:2017-11-16

Revised:2018-01-07

Published:2018-09-20

Online:2018-08-14

About author:WANG Hai-Long. E-mail: 13B908071@hit.edu.cn

Supported by:摘要:

热裂法自1967年提出至今已取得丰硕成果。为使国内外学者清晰掌握其研究体系和发展趋势, 有必要对热裂法近60年的研究成果进行规律性总结。本文首先明确提出热裂法的发展路线分两个方向: 非预制轨迹热裂切割和预制轨迹热裂切割。在非预制轨迹热裂切割研究领域, 切割速度、裂纹轨迹偏移量和切割面质量是最主要的优化目标参数; 在预制轨迹热裂切割研究领域, 切割速度和切割面质量是最受关注的优化目标参数。针对上述目标参数的优化, 均可通过采用新的热源形式、冷却形式和优化工艺流程得以实现, 指出热裂法切割玻璃和陶瓷关键技术研究方向在于创新发展新的热源技术、冷却技术和进一步优化工艺流程。

中图分类号:

王海龙, 王扬, 王向伟, 张宏志. 热裂法切割玻璃等硬脆材料关键技术研究进展[J]. 无机材料学报, 2018, 33(9): 923-930.

WANG Hai-Long, WANG Yang, WANG Xiang-Wei, ZHANG Hong-Zhi. Research Progress of Thermal Controlled Cracking of Hard-Brittle Plate[J]. Journal of Inorganic Materials, 2018, 33(9): 923-930.

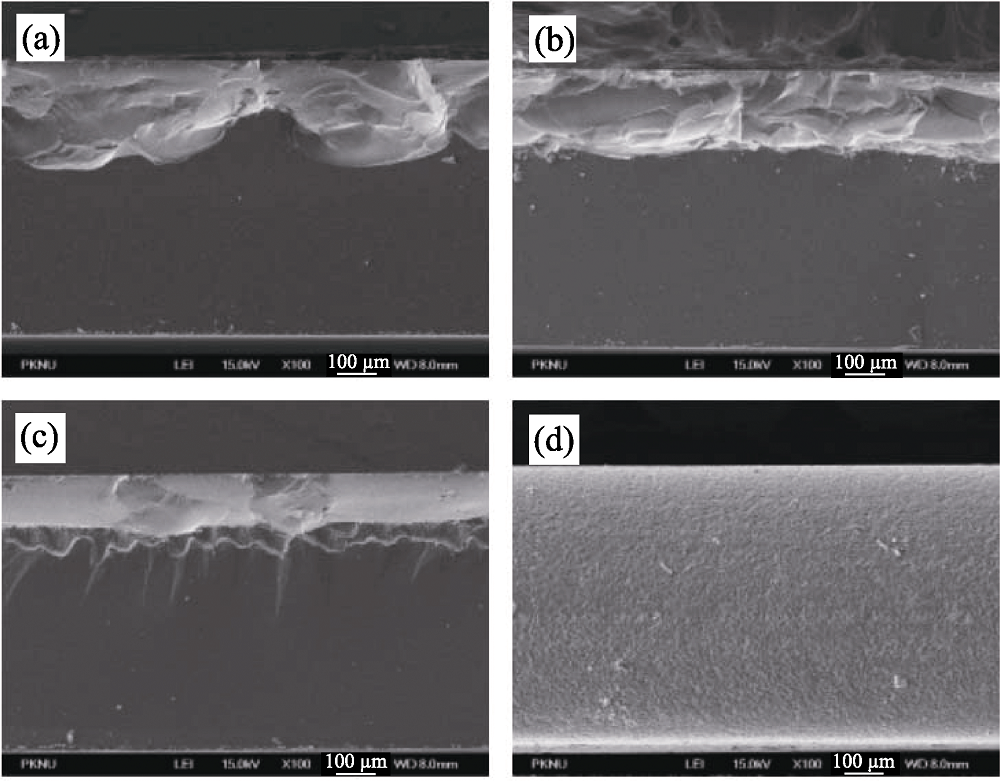

图14 飞秒划切CO2激光热裂切割玻璃截面照片[48]

Fig. 14 Cross-sectional views of femtosecond laser scribing followed by CO2 laser heating and rapid cooling[48] (a) After one laser pass; (b) After five laser passes; (c) After six laser passes; (d) Initial crack propagation

| [1] | ZHANG CHONG, YUAN SONG-MEI, AMIN MUHAMMAD,et al. Development of a cutting force prediction model based on brittle fracture for C/SiC in rotary ultrasonic facing milling. International Journal of Advanced Manufacturing Technology, 2016, 85(1-4): 573-583. |

| [2] | SENER KARABULUT, HENIFI CINICI, HALIL KARAKOC.Experimental investigation and optimization of cutting force and tool wear in milling Al7075 and open-cell SiC foam composite.Arabian Journal for Science & Engineering, 2016, 41(5): 1797-1812. |

| [3] | ZHAO GUO-LONG, HUANG CHUANZHEN, HE NING,et al. Fabrication and cutting performance of reactively hot-pressed TiB2-TiC-SiC ternary cutting tool in hard turning of AISI H13 steel. International Journal of Advanced Manufacturing Technology, 2017, 91: 943-954. |

| [4] | YUAN SONG-MEI, FAN HUITAO, AMIN MUHANMMAD,et al. A cutting force prediction dynamic model for side milling of ceramic matrix composites C/SiC based on rotary ultrasonic machining. International Journal of Advanced Manufacturing Technology, 2016, 86(1-4): 37-48. |

| [5] | SHARMA VIKAS, VINOD KUMAR.Investigating the quality characteristics of Al5052/SiC metal matrix composites machined by CO2 laser curve cutting.Proceedings of the Institution of Mechanical Engineers Part L: Journal of Materials Design & Applications, 2015, 232(1): 3-19. |

| [6] | SHIN DONGSIG, YONGKWON CHO, HYONKEE SOHN.Towards optimized efficiency of ablation in copper using a 515 nm picosecond laser process.Journal of Laser Micro, 2015, 10(3): 241-244. |

| [7] | YASUHISA SANO, KOHEI AIDA, TAKEHIRO KATO, ,et al. Cutting of SiC wafer by atmospheric-pressure plasma etching with wire electrode. Materials Science Forum, 2012, 717-720: 865-868. |

| [8] | SAVRUN E, TAYA M.Surface characterization of SiC whisker/2124 aluminium and Al2O3, composites machined by abrasive water jet.Journal of Materials Science, 1988, 23(4): 1453-1458. |

| [9] | SON HYEON-TAEK, KIM DAE-GUEN, PARK SOON-SUB,et al. Spark plasma sintering and ultra-precision machining characteristics of SiC. Korean Journal of Materials Research, 2010, 20(11): 559-569. |

| [10] | PRASHANTHA S, VEERESHA R B, SHASHIDHARA S M,et al. A study on machining characteristics of Al6061-SiC metal matrix composite through wire-cut electro discharge machining. Materials Today Proceedings, 2017, 4(10): 10779-10785. |

| [11] | ZHOU WEIGUO, GONG KEYU, WAN JIE,et al. Molecular dynamics simulation study on ablation of silicon by water-jet-guided laser. Proceedings of the Institution of Mechanical Engineers Part E Journal of Process Mechanical Engineering, 2017, 231(6): 1217-1225. |

| [12] | DANIEL LAROUCHE, JOSEPH LANGLAIS, WU WEI-LI,et al. A constitutive model for the tensile deformation of a binary aluminum alloy at high fractions of solid. Metallurgical & Materials Transactions B, 2006, 37(3): 431-443. |

| [13] | SUYITNO, KOOL W H, KATGERMAN L. Integrated approach for prediction of hot tearing.Metallurgical & Materials Transactions A, 2009, 40(10): 2388-2400. |

| [14] | RACHID MHAMDIA, SERIER B, AIBEDAH A,et al. Numerical analysis of the influences of thermal stresses on the efficiency of bonded composite repair of cracked metallic panels. Journal of Composite Materials, 2017, 51(26): 3701-3709. |

| [15] | BILČÍK J, SONNENSCHEIN R, GAŽOVIČOVÁ N. Causes of early-age thermal cracking of concrete foundation slabs and their reinforcement to control the cracking.Slovak Journal of Civil Engineering, 2017, 25(3): 8-14. |

| [16] | CHU DONG-YANG, LI XIANG, LIU ZHANLI.Study the dynamic crack path in brittle material under thermal shock loading by phase field modeling.International Journal of Fracture, 2017, 330: 1-16. |

| [17] | GRAHAM C E, LUMLEY R M, OBERHOLZER D J.Laser Substrate Parting: US, US3629545. 1971. |

| [18] | KARLSSON M N A, DEPPERT K, WACASER B A,et al. Size-controlled nanoparticles by thermal cracking of iron pentacarbonyl. Applied Physics A, 2005, 80(7): 1579-1583. |

| [19] | FRIEDL D I.Method for Laser Thermal Separation of Ceramic or Other Brittle Flat Materials: EP, EP1990168. 2012.06.27. |

| [20] | UEDA T, YAMADA K, OISO K,et al. Thermal stress cleaving of brittle materials by laser beam. CIRP Annals - Manufacturing Technology, 2002, 51(1): 149-152. |

| [21] | TSAI CHWAN-HUEI, HUANG BO-WEN.Diamond scribing and laser breaking for LCD glass substrates.Journal of Materials Processing Technology, 2008, 198(1/2/3): 350-358. |

| [22] | SHEPELOV G V, SHIGANOV I N.Cutting sheet glass with the beam of a solid-state laser.Welding International, 2000, 14(12): 988-991. |

| [23] | KONDRATENKO VLADIMIR S.Method of Splitting Non-metallic Materials: US, US 5609284 A. 1997. |

| [24] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Thermal stress analysis on laser scribing of glass. Journal of Laser Applications, 2008, 20(4): 193-200. |

| [25] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Three-dimensional thermal stress analysis on laser scribing of glass. Precision Engineering, 2008, 32(4): 301-308. |

| [26] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Partial growth of crack in laser scribing of glass. Journal of Laser Applications, 2009, 21(2): 917-923. |

| [27] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Influence of thermal expansion coefficient in laser scribing of glass. Precision Engineering, 2010, 34(1): 70-75. |

| [28] | YAMAMOTO KOJI, HASAKA NOBORU, MORITA HIDEKI,et al. Influence of glass substrate thickness in laser scribing of glass. Precision Engineering, 2010, 34(1): 55-61. |

| [29] | YAHATA KEISUKE, YAMAMOTO KOJI, ETSUJI OHMURA.Crack propagation analysis in laser scribing of glass (machine elements, design and manufacturing).Journal of Laser Micro, 2010, 5(2): 109-114. |

| [30] | ABRAMOV ANATOLI A, Black MATTHEW L, GLAESEMANN G SCOTT.Laser separation of chemically strengthened glass.Physics Procedia, 2010, 5: 285-290. |

| [31] | ABRAMOV ANATOLI A, SUN YA-WEI, XU WEI, et al. Laser Scoring of Glass Sheets at High Speeds and With Low Residual Stress: US, US8011207. 2011. |

| [32] | NORIO KARUBE, HIROSHI MIURA.Full-body Laser Scribing Method of Fragile Material: US, US20070062921. 2007. |

| [33] | KOJIRO KARUBE, NORIO KARUBE.Laser-induced cleavage of LCD glass as full-body cutting.Proceedings of SPIE, 2008, 6880: 1-10. |

| [34] | SALMAN NISAR, SHEIKH M A, LI LIN,et al. Effect of thermal stresses on chip-free diode laser cutting of glass. Optics & Laser Technology, 2009, 41(3): 318-327. |

| [35] | SALMAN NISAR, KHAN SOHAIB Z, ALI MUHAMMAD,et al. Comparison of cut path deviation between CO2, and diode lasers in float-glass cutting. Journal of Russian Laser Research, 2014, 35(2): 182-192. |

| [36] | SALMAN NISAR, SHEIKH M A, LI LIN,et al. The effect of laser beam geometry on cut path deviation in diode laser chip-free cutting of glass. Journal of Manufacturing Science & Engineering, 2010, 132(1): 165-174. |

| [37] | SALMAN NISAR, LI LIN, ALI MUHAMMAD,et al. The effect of continuous and pulsed beam modes on cut path deviation in diode laser cutting of glass. International Journal of Advanced Manufacturing Technology, 2010, 49(1-4): 167-175. |

| [38] | MIYASHITA YUKIO, MASASHI MOGI, HIROTAKA HASEGAWA,et al. Study on a controlling method for crack nucleation and propagation behavior in laser cutting of glass. Journal of Solid Mechanics and Materials Engineering, 2008, 2(12): 1555-1566. |

| [39] | CAI NA, YANG LI-JUN, WANG YANG, ,et al. Experimental research of YAG laser cutting soda-lime glass sheets with controlled fracture. Key Engineering Materials, 2010, 431-432: 507-510. |

| [40] | SILVIO GEORGI.Separating and structuring of brittle material by the use of laser radiation. Proceedings of SPIE, 2003, 5063: 426-431. |

| [41] | SHALUPAEV S V, SHERSHNEV E B, NIKITYUK YU V,et al. Two-beam laser thermal cleavage of brittle nonmetallic materials. Journal of Optics Technology, 2006, 73(5): 356-359. |

| [42] | CHOI WON-SEOK, KIM JONG-HYEONG, KIM JOOHAN.Thermal cleavage on glass by a laser-induced plume.Optics & Lasers in Engineering, 2014, 53(2): 60-68. |

| [43] | WANG HAI-LONG, ZHANG HONG-ZHI, WANG-YANG.Splitting of glass and SiC ceramic sheets using controlled fracture technique with elliptic microwave spot.Ceramics International, 2017, 43(2): 1669-1676. |

| [44] | HANG KYOUNG-SHIK, HONG SOON-KUG,OH SEOK-CHANG,et al. A study of cutting glass by laser. Proceedings of SPIE, 2002, 4426: 367-370. |

| [45] | HUANG KUO-CHENG, WU WEN-HONG, TSENG SHIH-FENG,et al. The mixed processing models development of thermal fracture and laser ablation on glass substrate. International Conference on Advances in Materials and Processing Technologies, 2010, 1: 1612-1617. |

| [46] | HUANG KUO-CHENG, HSIAO WEN-TSE, HWANG CHI-HUNG,et al. The laser ablation model development of glass substrate cutting assisted with the thermal fracture and ultrasonic mechanisms. Optics & Lasers in Engineering, 2015, 67: 31-35. |

| [47] | SU CHAO-TON, HSIAO YU-HSIANG, CHANG CHIA-CHIN.Parameter optimization design for touch panel laser cutting process.IEEE Transactions on Automation Science and Engineering, 2012, 9(2): 320-329. |

| [48] | KIM KWANG-RYUL, KIM JAE-HOON, FARSON DAVE F,et al. Hybrid laser cutting for flat panel display glass. Japanese Journal of Applied Physics, 2008, 47(8): 6978-6981. |

| [49] | TSAI CHWAN-HUEI, CHANG WEI-HAN.Pulsed laser breaking technique for glass substrates.Proceedings of SPIE, 2009, 7204: 1-9. |

| [50] | WANG XU-HUANG, YAO JIAN-HUA, ZHOU GUO-BIN,et al. Research of the technology of laser cutting LCD glass substrates based on thermal cracking method. Laser Technology, 2011, 35(4): 472-476. |

| [51] | WANG XU-HUANG, YAO JIAN-HUA, ZHOU GUO-BIN,et al. Numerical simulation and experiment of laser cuttingLiquid crystal display glass substrates . Chinese Journal of Lasers, 2011, 38(6): 1-5. |

| [1] | 余艺平, 肖鹏, 赵长浩, 徐梦迪, 姚立冬, 李伟, 王松. 耐高温层状Ta/Ta0.5Hf0.5C金属陶瓷的高频等离子体风洞烧蚀行为研究[J]. 无机材料学报, 2025, 40(7): 790-798. |

| [2] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [3] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [4] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [5] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [6] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [7] | 唐莹, 李洁, 相怀成, 方维双, 林慧兴, 杨俊峰, 方亮. Rattling效应: 一种影响微波介质陶瓷谐振频率温度系数的新机制[J]. 无机材料学报, 2025, 40(6): 656-666. |

| [8] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [9] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [10] | 周阳阳, 张艳艳, 于子怡, 傅正钱, 许钫钫, 梁瑞虹, 周志勇. 通过Bi3+自掺杂增强CaBi4Ti4O15基陶瓷压电性能[J]. 无机材料学报, 2025, 40(6): 719-728. |

| [11] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [12] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [13] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [14] | 尹长志, 成名飞, 雷微程, 蔡弋炀, 宋小强, 付明, 吕文中, 雷文. Ga3+掺杂对SrAl2Si2O8陶瓷晶体结构及微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 704-710. |

| [15] | 吴鲁康, 傅正钱, 于子怡, 杨俊, 周斌, 陈学锋, 许钫钫. 电子能量损失谱在BaTiO3基多层陶瓷电容器中的应用研究[J]. 无机材料学报, 2025, 40(6): 683-689. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||