无机材料学报 ›› 2017, Vol. 32 ›› Issue (2): 113-121.DOI: 10.15541/jim20160255 CSTR: 32189.14.10.15541/jim20160255

• • 下一篇

李 想1,2, 葛武杰1,2, 王 昊1,2, 瞿美臻1

收稿日期:2016-04-13

修回日期:2016-06-06

出版日期:2017-02-20

网络出版日期:2017-01-13

作者简介:李 想(1990–), 男, 博士研究生. E-mail: bill90@126.com

基金资助:LI Xiang1,2, GE Wu-Jie1,2, WANG Hao1,2, QU Mei-Zhen1

Received:2016-04-13

Revised:2016-06-06

Published:2017-02-20

Online:2017-01-13

About author:LI Xiang. E-mail: bill90@126.com

摘要:

高镍系三元层状氧化物正极材料因其高比容量、低廉的价格以及较好的环境友好性而受到广泛关注, 但是其固有的一些缺点, 如循环过程中结构稳定性差、高温稳定性差以及储存性能差等极大地限制了其在各领域的广泛应用。本文着重总结并讨论近年来对高镍系三元层状氧化物正极材料循环过程容量衰减机理的研究进展, 并对高镍系三元层状氧化物正极材料的进一步改性作了简要的展望。

中图分类号:

李 想, 葛武杰, 王 昊, 瞿美臻. 高镍系三元层状氧化物正极材料容量衰减机理的研究进展[J]. 无机材料学报, 2017, 32(2): 113-121.

LI Xiang, GE Wu-Jie, WANG Hao, QU Mei-Zhen. Research Progress on the Capacity Fading Mechanisms of High-Nickel Ternary Layered Oxide Cathode Materials[J]. Journal of Inorganic Materials, 2017, 32(2): 113-121.

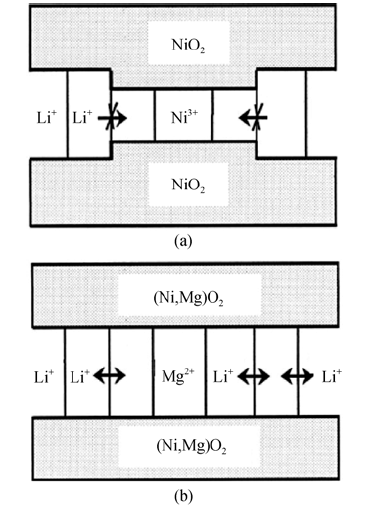

图3 Li层空间示意图 [22]

Fig. 3 Schematic representation of the inter-slab space[22](a) In the LixNi1+zO2 system, the oxidation of the Ni2+ ions during the cycling induces a local collapse of the inter-slab space which makes lithium diffusion and re-intercalation difficult; (b) The LixNi1-yMgO2 system, the electrochemically inactive Mg2+ ions do not hinder lithium diffusion since their size is very close to that of the Li+ ion

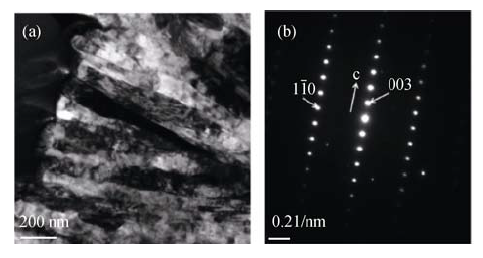

图6 (a)经过锂化的正极颗粒界面透射电镜图显示单个一次颗粒中成排的纳米结构, (b)单个纳米片的电子衍射图像显示晶胞的c轴垂直于片的基本面[43]

Fig. 6 (a) TEM image of cross-section of lithiated particle showing the aligned nanostructure inside a single particle, (b) Electron diffraction pattern on a single nanoplate showing that the c axis (in R3?m space) is perpendicular to the basal plane of the plate[43]

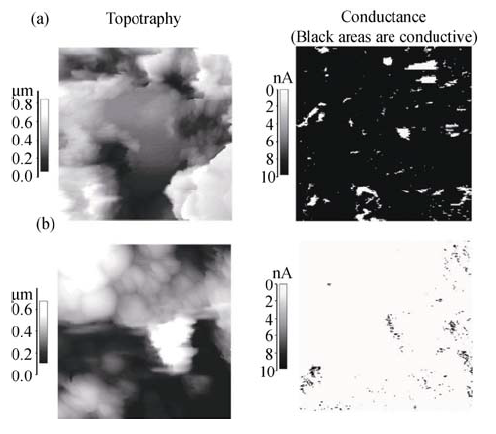

图7 5 μm×5 μm区域内LiNi0.8Co0.15Al0.05O2表面导电性(右边)和形貌(左边)的电流响应原子力显微镜图(接触电压1.0 V) [45]

Fig. 7 CSAFM images of surface conductance (right-hand panel) and topography (left-hand panel) of a 5×5 μm region of the composite LiNi0.8Co0.15Al0.05O2 cathode surface at 1.0 V tip-sample voltage difference[45](a) Virgin cell; (b) Cathode from the cell which lost 34% of power

| [1] | LIU W, OH P, LIU X E, Nickel-Rich layered lithium transition-metal oxide for high-energy lithium-ion batteries.Angewandte Chemie International Edition, 2015, 54: 4440-4457. |

| [2] | YUAN RONG-ZHONG, QU MEI-ZHEN, YU ZUO-LONG.Thermal stability of nickel-based lithium transition metal oxides as the cathode materials for lithium-ion batteries. Journal of Inorganic Materials, 2003, 18(5): 973-979. |

| [3] | LI X L, KANG F Y, SHEN W C,et al. Improvement of structural stability and electrochemical activity of a cathode material LiNi0.7Co0.3O2 by chlorine doping. Electrochimica Acta, 2007, 53(4): 1761-1765. |

| [4] | WOO S W, MYUNG S T, BANG H, et al. Improvement of electrochemical and thermal properties of LiNi0.8Co0.1Mn0.1O2 positive electrode materials by multiple metal (Al, Mg) substitution. Electrochimica Acta, 2009, 54(15): 3851-3856. |

| [5] | MUTO S, TATSUMI K, KOJIMA Y,et al. Effect of Mg-doping on the degradation of LiNiO2-based cathode materials by combined spectroscopic methods. Journal of Power Sources, 2012, 205: 449-455. |

| [6] | LIU W M, HU G R, DU K,et al. Surface coating of LiNi0.8Co0.15Al0.05O2 with LiCoO2 by a molten salt method. Surface and Coating Technology, 2013, 216: 267-272. |

| [7] | XIONG X H, WANG Z X, YAN G C, et al. Role of V2O5 coating on LiNiO2-based materials for lithium ion battery. Journal of Power Sources, 2014, 245: 183-193. |

| [8] | HUANG B, LI X H, WANG Z X,et al. Enhanced electrochemical performance in LiNi0.8Co0.15Al0.05O2 cathode material: Resulting from Mn-surface-modification using a facile oxidizing-coating method. Materials Letters, 2014, 115: 49-52. |

| [9] | XIA SHU-BIAO, ZHANG YING-JIE, DONG PENG, et al. CeO2 surface modification to improve cycle and storage performance on lithium ion battery cathode material LiNi0.8Co0.15Al0.05O2. Chin. Journal of Inorganic Chemistry, 2014, 30(3): 529-535. |

| [10] | JU S H, KANG I S, LEE Y S,et al. Improvement of the cycling performance of LiNi0.6Co0.2Mn0.2O2 cathode active materials by a dual-conductive polymer coating. ACS Applied Materials and Interfaces, 2014, 6(4): 2546-2552. |

| [11] | LEE S H, YOON C S, KHALIL A,et al. Improvement of long-term cycling performance of Li(Ni0.8Co0.15Al0.05)O2 by AlF3 coating . Journal of Power Sources, 2013, 234: 201-207. |

| [12] | YANG H Z, LIU P X, CHEN Q L,et al. Fabrication and characteristics of high-capacity LiNi0.8Co0.15Al0.05O2 with monodisperse yolk-shell spherical precursors by a facile method . RSC Advances, 2014, 4: 35522-35527. |

| [13] | WU N T, WU H, YUAN W,et al. Facile synthesis of one-dimensional LiNi0.8Co0.15Al0.05O2 microrods as advanced cathode materials for lithium ion batteries. Journal of Materials Chemistry A, 2015, 3: 13648-13652. |

| [14] | YE NAI-QING, LIU CHANG-JIU, SHEN SHANG-YUE.Drawbacks and improve ways of LINiO2 as a cathode material for lithium ion batteries.Journal of Inorganic Materials, 2004, 19(6): 1217-1224. |

| [15] | LIN F, DENNIS N, LI Y Y,et al. Metal segregation in hierarchically structured cathode materials for high-energy lithium batteries. Nature Energy, 2016, 1: 15004. |

| [16] | MAKIMURA Y, ZHENG S J, IKUHARA Y C,et al. Microstructural observation of LiNi0.8Co0.15Al0.05O2 after charge and discharge by scanning transmission electron microscopy. Journal of The Electrochemical Society, 2012, 159(7): A1070-A1073. |

| [17] | CHO Y H, OH P, CHO J.A new type of protective surface layer for high-capacity Ni-based cathode materials: nanoscaled surface pillaring layer.Nano Letters, 2013, 13: 1145-1152. |

| [18] | KIM H J, KIM M G, JEONG H Y,et al. A new coating method for alleviating surface degradation of LiNi0.6Co0.2Mn0.2O2 cathode material: nanoscale surface treatment of primary particles. Nano Letters, 2015, 15: 2111-2119. |

| [19] | KONDO H, TAKEUCHI Y, SASAKI T,et al. Effects of Mg-substitution in Li(Ni,Co,Al)O2 positive electrode materials on the crystal structure and battery performance. Journal of Power Sources. 2007, 174(2): 1131-1136. |

| [20] | SATHIYAMOORTHI R, SHAKKTHIVEL P, RAMALAKSHMI S,et al. Influence of Mg doping on the performance of LiNiO2 matrix ceramic nanoparticles in high-voltage lithium-ion cells. Journal of Power Sources. 2007, 171(2): 922-927. |

| [21] | HUANG B, LI X, WANG Z,et al. Synthesis of Mg-doped LiNi0.8Co0.15Al0.05O2 oxide and its electrochemical behavior in high-voltage lithium-ion batteries. Ceramics International, 2014, 40: 13223-13230. |

| [22] | POUILLERIE C, CROGUENNEC L, BIENSAN P,et al. Synthesis and characterization of new LiNi1-yMgyO2 positive electrode materials for lithium-ion batteries. Journal of The Electrochemical Society, 2000, 147: 2061-2067. |

| [23] | WU F, TIAN J, SU Y F,et al. Effect of Ni2+ content on lithium/nickel disorder for Ni-rich cathode materials. ACS Appl. Mater. Interfaces, 2015, 7: 7702-7708. |

| [24] | CHEN Z Z, YUAN X J, WEN M S,et al. Preparation of LiNi0.80Co0.15Al0.05O2 cathode material via Li-rich method. Energy Storage Science and Technology, 2014, 3(6): 620-623. |

| [25] | BI Y J, YANG W C, DU R,et al. Correlation of oxygen non-stoichiometry to the instabilities and electrochemical performance of LiNi0.8Co0.1Mn0.1O2 utilized in lithium ion battery. Journal of Power Sources, 2015, 283: 211-218. |

| [26] | LI X, XIE Z W, LIU W J,et al. Effects of fluorine doping on structure, surface chemistry, and electrochemical performance of LiNi0.8Co0.15Al0.05O2. Electrochimica Acta, 2015, 174: 1122-1130. |

| [27] | ZHUANG G R V, CHEN G Y, SHIM J,et al. Li2CO3 in LiNi0.8Co0.15Al0.05O2 cathodes and its effects on capacity and power. Journal of Power Sources, 2004, 134(2): 293-297. |

| [28] | LIU W M, HU G R, DU K,et al. Enhanced storage property of LiNi0.8Co0.15Al0.05O2 coated with LiCoO2. Journal of Power Sources, 2013, 230: 201-206. |

| [29] | ZHU L, LIU Y, WU W Y,et al. Surface fluorinated LiNi0.8Co0.15Al0.05O2 as a positive electrode material for lithium ion batteries. Journal of Materials Chemistry A, 2015, 3: 15156-15162. |

| [30] | XIONG X H, WANG Z X, YUE P,et al. Washing effects on electrochemical performance and storage characteristics of LiNi0.8Co0.1Mn0.1O2 as cathode material for lithium-ion batteries. Journal of Power Sources, 2013, 222: 318-325. |

| [31] | ZHENG X B, LI X H, WANG Z X,et al. Investigation and improvement on the electrochemical performance and storage characteristics of LiNiO2-based materials for lithium ion battery. Electrochimica Acta, 2016, 191: 832. |

| [32] | BI Y J, WANG T, LIU M,et al. Stability of Li2CO3 in cathode of lithium ion battery and its influence on electrochemical performance. RSC Advances, 2016, 6: 19233-19237. |

| [33] | DOKKO K, NISHIZAWA M, HORIKOSHI S,et al. In situ observation of LiNiO2 single-particle fracture during Li-ion extraction and insertion. Electrochemical and Solid-State Letters, 2000, 3(3): 125-127. |

| [34] | ROBERT R, BÜNZLI C,BERG E J,et al.Activation mechanism of LiNi0.8Co0.15Al0.05O2: surface and bulk operando electrochemical, differential electrochemical mass spectrometry, and X ray diffraction analyses. Chemistry of Materials, 2015, 27: 526-536. |

| [35] | ITOU Y, UKYO Y.Performance of LiNiCoO2 materials for advanced lithium-ion batteries.Journal of Power Sources, 2005, 146(1/2): 39-44. |

| [36] | ZHENG S J, HUANG R, MAKIMURA Y,et al. Microstructural changes in LiNi0.8Co0.15Al0.05O2 positive electrode material during the first cycle .Journal of The Electrochemical Society, 2011, 158(4): A357-A362. |

| [37] | WATANABE S, KINOSHIRA M, HASOKAWA T,et al. Capacity fade of LiAlyNi1-x-yCoxO2 cathode for lithium-ion batteries during accelerated calendar and cycle life tests (surface analysis of LiAlyNi1-x-yCoxO2 cathode after cycle tests in restricted depth of discharge ranges). Journal of Power Sources, 2014, 258: 210-217. |

| [38] | MAKIMURA Y, ZHENG S J, IKUHARA Y,et al. Microstructural observation of LiNi0.8Co0.15Al0.05O2 after charge and discharge by scanning transmission electron microscopy. Journal of The Electrochemical Society, 2012, 159(7): A1070-A1073. |

| [39] | NOH H J, YOUN S, YOON C S,et al. Comparison of the structural and electrochemical properties of layered Li[NixCoyMnz]O2(x=1/3, 0.5, 0.6, 0.7, 0.8 and 0.85) cathode material for lithium-ion batteries. Journal of Power Sources, 2013, 233: 121-130. |

| [40] | OHZUKU T, UEDA A, NAGAYAMA M.Electrochemistry and structural chemistry of LiNiO2 (R-3m) for 4 V secondary lithium cells.Journal of The Electrochemical Society, 1993, 140: 1862-1870. |

| [41] | YANG X Q, SUN X, MCBREEN J.Structural changes and thermal stability: In situ X-ray diffraction studies of a new cathode material LiMg0.125Ti0.125Ni0.75O2.Electrochemical Communications, 2000, 2: 733-737. |

| [42] | SUN Y K, CHEN Z H, NOH H J, et al. Nanostructured high-energy cathode materials for advanced lithium batteries. Nature Materials, 2012, 11: 942-947. |

| [43] | LEE E J, CHEN Z H, NOH H J,et al. Development of microstrain in aged lithium transition metal oxides. Nano Letters, 2014, 14: 4873-4880. |

| [44] | YANG J, XIA Y Y.Suppressing the phase transition of the layered Ni-rich oxide cathode during high-voltage cycling by introducing low-content Li2MnO3.ACS Applied Materials and Interfaces, 2016, 8(2): 1297-1308. |

| [45] | KOSTECKI R, MCLARNON F.Local-probe studies of degradation of composite LiNi0.8Co0.15Al0.05O2 cathodes in high-power Lithium-ion cells.Electrochemical and Solid-State Letters, 2004, 7(10): A380-A383. |

| [46] | KOSTECKI R, MCLARNON F.Degradation of LiNi0.8Co0.2O2 cathode surfaces in high-power lithium-ion batteries.Electrochemical and Solid-State Letters, 2002, 5(7): A164-A166. |

| [47] | KOSTECKI R, LEI J L, MCLARNON F,et al. Diagnostic evaluation of detrimental phenomena in high-power lithium-ion batteries. Journal of The Electrochemical Society, 2006, 153(4): A669-A672. |

| [48] | LEI J L, MCLARNON F, KOSTECKI R,et al. In situ Raman microscopy of individual LiNi0.8Co0.15Al0.05O2 particles in a Li-ion battery composite cathode. Journal of Physical Chemistry B, 2005, 109(2): 952-957. |

| [49] | SASAKI T, NONAKA T, OKA H,et al. Capacity-fading mechanisms of LiNiO2-based lithium-ion batteries I. Analysis by electrochemical and spectroscopic examination. Journal of The Electrochemical Society, 2009, 156(4): A289-A293. |

| [50] | MUTO S, SASANO Y, TATSUMI K,et al. Capacity-fading mechanisms of LiNiO2-based lithium-ion batteries II. Diagnostic analysis by electron microscopy and spectroscopy. Journal of The Electrochemical Society, 2009, 156(5): A371-A377. |

| [51] | KOJIMA Y, MUTO S, TATSUMI K,et al. Degradation analysis of a Ni-based layered positive-electrode active material cycled at elevated temperatures studied by scanning transmission electron microscopy and electron energy-loss spectroscopy. Journal of Power Sources, 2011, 196: 7721-7727. |

| [52] | BAK S M, NAM K W, CHANG W Y,et al. Correlating structural changes and gas evolution during the thermal decomposition of charged LixNi0.8Co0.15Al0.05O2 cathode materials. Chemistry of Materials, 2013, 25: 337-351. |

| [53] | WU L J, NAM K W, WANG X J,et al. Structural origin of overcharge-induced thermal instability of Ni-containing layered-cathodes for high-energy-density lithium batteries. Chemistry of Materials, 2011, 23: 3953-3960. |

| [54] | SHIM J, KOSTECKI R, RICHARDSON T,et al. Electrochemical analysis for cycle performance and capacity fading of a lithium-ion battery cycled at elevated temperature. Journal of Power Sources, 2002, 112: 222-230. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [13] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [14] | 朱志杰, 申明远, 吴涛, 李文翠. Cu和Mg协同取代抑制钠离子电池正极材料P2-Na2/3Ni1/3Mn2/3O2的P2-O2相变[J]. 无机材料学报, 2025, 40(2): 184-195. |

| [15] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||