Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (9): 957-963.DOI: 10.15541/jim20240515

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Wenjin( ), LOU Chengguang, ZHANG Shuai, SU Xinghua(

), LOU Chengguang, ZHANG Shuai, SU Xinghua( )

)

Received:2024-12-12

Revised:2025-03-21

Published:2025-09-20

Online:2025-03-25

Contact:

SU Xinghua, professor. E-mail: suxinghua@chd.edu.cnAbout author:LI Wenjin (2000-), female, Master candidate. E-mail: 1691993742@qq.com

Supported by:CLC Number:

LI Wenjin, LOU Chengguang, ZHANG Shuai, SU Xinghua. Flash Joining of Metal Cu with 5YSZ Ceramics[J]. Journal of Inorganic Materials, 2025, 40(9): 957-963.

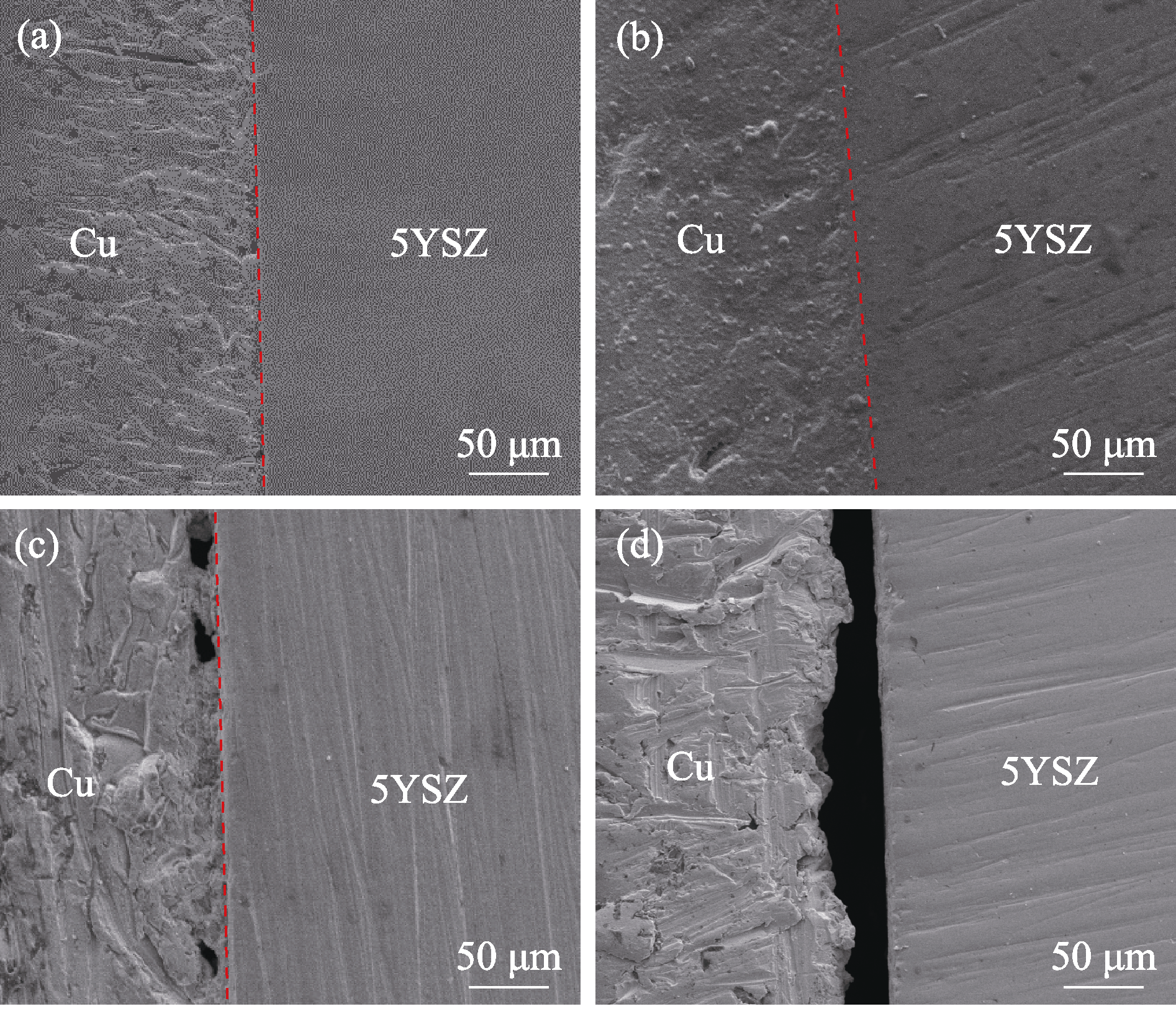

Fig. 6 SEM images of the joints with different flash joining times (a) 2 min; (b) 3 min; (c) 5 min; (d) 7 min. Preparation condition: 80 V/cm, 10 A/cm2, 753 ℃

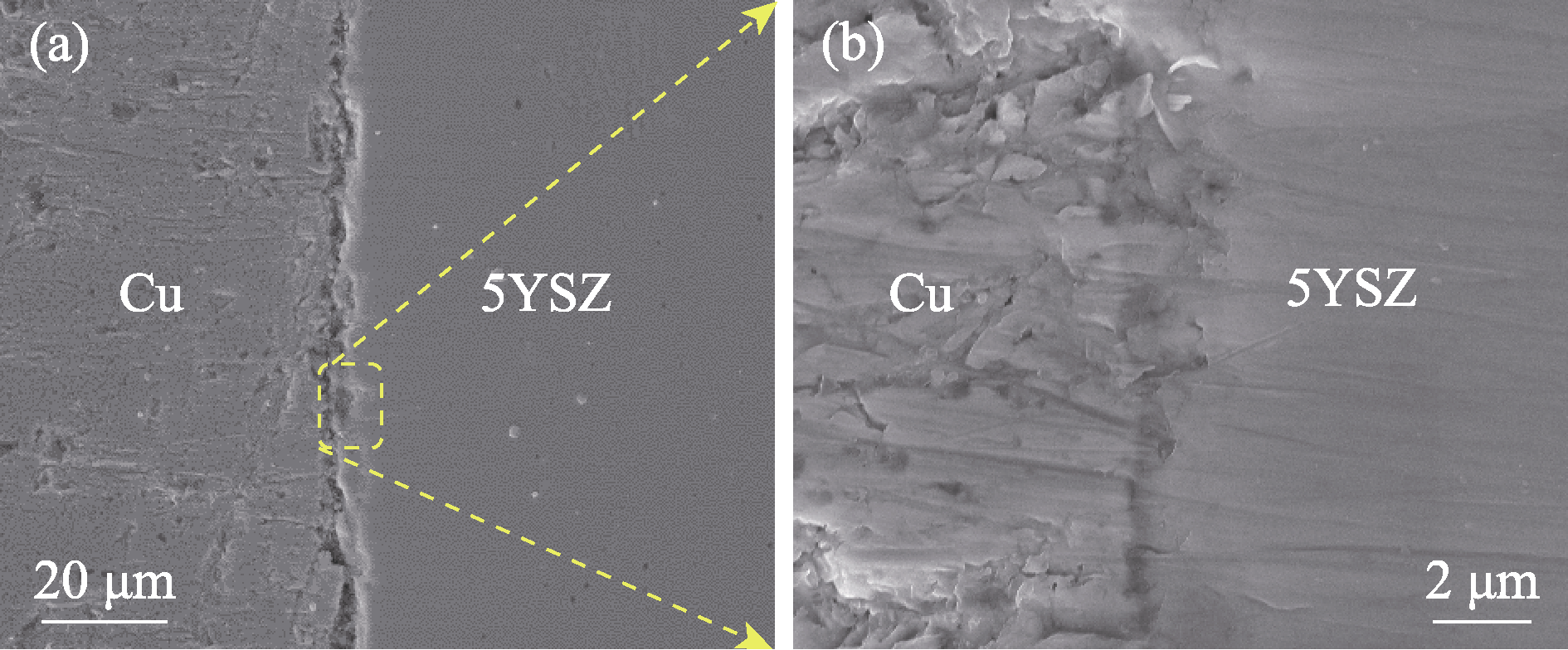

Fig. 9 SEM images of the joint flash-jointed at a current density of 12 A/cm2, a flash joining temperature of 753 ℃, and a flash joining time of 3 min (b) Local area magnification of Fig. (a)

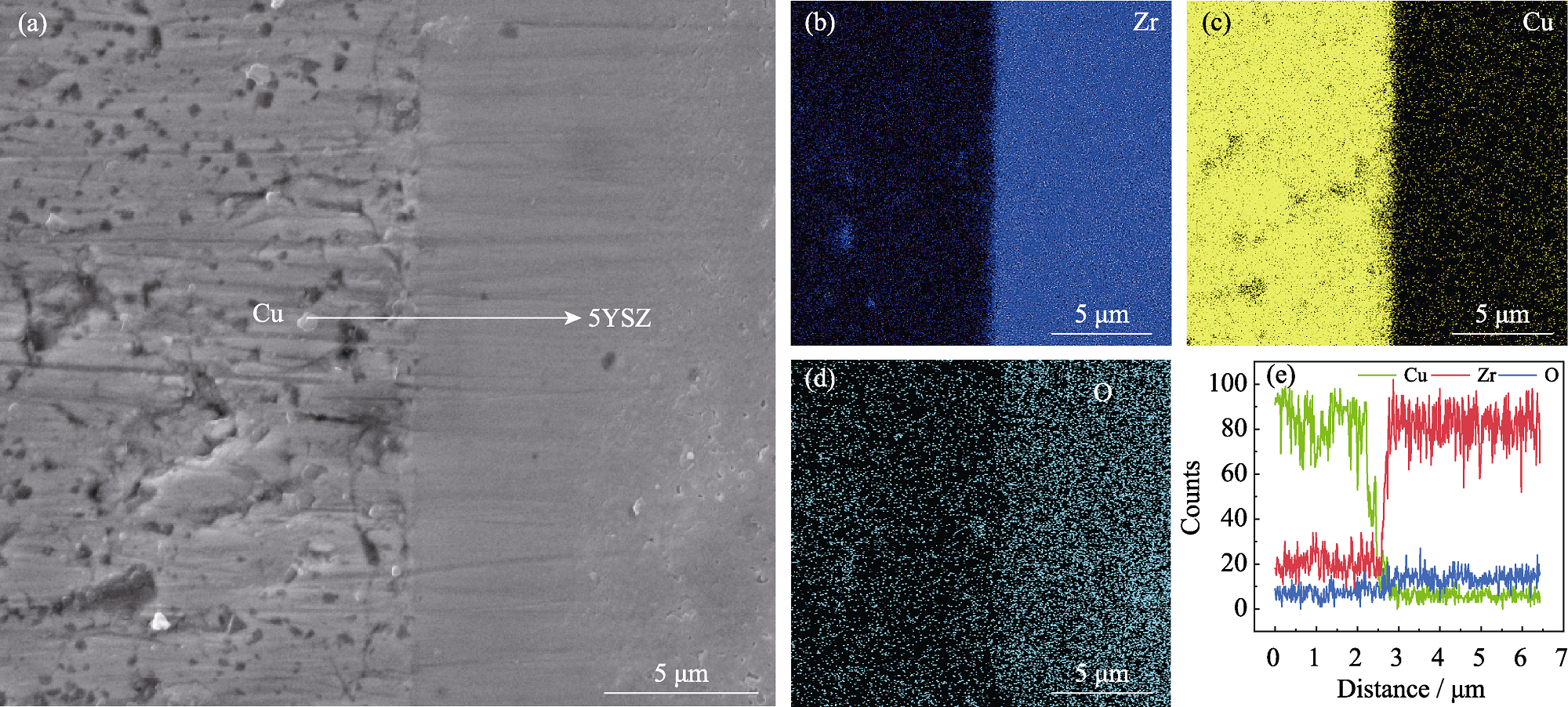

Fig. 10 (a) SEM image and (b-e) element distributions of the joint flash-jointed at a current density of 10 A/cm2, a flash joining temperature of 753 ℃, and a flash joining time of 3 min Colorful figures are available on website

| [1] | HUANG J, DU K F, WANG P L, et al. Electrochemical preparation and homogenization of face-centered FeCoNiCu medium entropy alloy electrodes enabling oxygen evolution reactions. Electrochimica Acta, 2021, 378: 138142. |

| [2] | CAO Y, XU G C, SHEN P. Flash joining of 3YSZ and 430 SS using Ag-CuO filler. Ceramics International, 2022, 48(3): 4005. |

| [3] | LIU Y H, HU J D, ZHANG Y P, et al. Joining of zirconia and Ti-6Al-4V using a Ti-based amorphous filler. Journal of Materials Science & Technology, 2011, 27(7): 653. |

| [4] | HANSON W B, IRONSIDE K I, FERNIE J A. Active metal brazing of zirconia. Acta Materialia, 2000, 48(18/19): 4673. |

| [5] | CAI Q S, LIU W S, MA Y Z, et al. Diffusion brazing of tungsten and steel using Ti-Ni liquid phase forming interlayer. Fusion Engineering and Design, 2015, 91: 67. |

| [6] | POLANCO R, MIRANZO P, OSENDI M I. Fabrication and microstructure of a ZrO2-Ni functionally graded bonding interlayer using the airbrush spraying method. Acta Materialia, 2006, 54(8): 2215. |

| [7] | POLANCO R, MIRANZO P, OSENDI M I. ZrO2-Ni functionally graded joining interlayers: microstructure and properties. Advanced Engineering Materials, 2007, 9(11): 1005. |

| [8] | COLOGNA M, RASHKOVA B, RAJ R. Flash sintering of nanograin zirconia in <5 s at 850 ℃. Journal of the American Ceramic Society, 2010, 93(11): 3556. |

| [9] | STEIL M C, MARINHA D, AMAN Y, et al. From conventional AC flash-sintering of YSZ to hyper-flash and double flash. Journal of the European Ceramic Society, 2013, 33(11): 2093. |

| [10] | DOWNS J A, SGLAVO V M. Electric field assisted sintering of cubic zirconia at 390 ℃. Journal of the American Ceramic Society, 2013, 96(5): 1342. |

| [11] | XIA J B, REN K, WANG Y G. One-second flash joining of zirconia ceramic by an electric field at low temperatures. Scripta Materialia, 2019, 165: 34. |

| [12] | MUNDRA R, GUPTA P, EQBAL A, et al. Flash joining of metal-ceramic multi-layered sandwich structure. Journal of the European Ceramic Society, 2024, 44(1): 353. |

| [13] | XIA J B, REN K, WANG Y G, et al. Reversible flash-bonding of zirconia and nickel alloys. Scripta Materialia, 2018, 153: 31. |

| [14] | YANG B, SHEN P, YU L T, et al. Electrochemically-driven direct joining of Ni and ZrO2. Scripta Materialia, 2017, 141: 41. |

| [15] | XIA J B, REN K, LIU W, et al. Ultrafast joining of zirconia ceramics using electric field at low temperatures. Journal of the European Ceramic Society, 2019, 39(10): 3173. |

| [16] | ZHOU L, LI C, SI X Q, et al. Flash joining of SiC at ultra-low temperature. Journal of the European Ceramic Society, 2023, 43(6): 2713. |

| [17] | XIA J B, REN K, WANG Y G. Flash joining of alumina ceramics under a small current density. Journal of the European Ceramic Society, 2021, 41(4): 2782. |

| [18] | XIA J B, REN K, WANG Y G. Rapid joining of heterogeneous ceramics with a composite interlayer under the action of an electric field. Journal of the European Ceramic Society, 2021, 41(14): 7164. |

| [19] | LIU G W, QIAO G J, WANG H J, et al. Pressureless brazing of zirconia to stainless steel with Ag-Cu filler metal and TiH2 powder. Journal of the European Ceramic Society, 2008, 28(14): 2701. |

| [20] | GAMBARO S, VALENZA F, PASSERONE A, et al. Brazing transparent YAG to Ti6Al4V: reactivity and characterization. Journal of the European Ceramic Society, 2016, 36(16): 4185. |

| [21] | XIA J B, REN W. Flash joining of BaTiO3 ceramic to NiCrFe medium-entropy alloy by using an electric field. Ceramics International, 2023, 49(24): 40924. |

| [22] | WANG L, YU H, HAO Z D, et al. Investigating the effect of solid loading on microstructure, mechanical properties, and translucency of highly translucent zirconia ceramics prepared via stereolithography- based additive manufacturing. Journal of the Mechanical Behavior of Biomedical Materials, 2023, 144: 105952. |

| [23] | LIU C, ZHENG J J, LIU X F, et al. Facile laser-based process of superwetting zirconia ceramic with adjustable adhesion for self-cleaning and lossless droplet transfer. Applied Surface Science, 2023, 638: 158069. |

| [24] | GHAEMI M H, REICHERT S, KRUPA A, et al. Zirconia ceramics with additions of alumina for advanced tribological and biomedical applications. Ceramics International, 2017, 43(13): 9746. |

| [25] | LIU D G, FAN J Y, ZHAO K, et al. Preparation of super-strong ZrO2 ceramics using dynamic hot forging. Journal of the European Ceramic Society, 2023, 43(2): 733. |

| [26] | BICALHO L A, BAPTISTA C A R P, SOUZA R C, et al. Fatigue and subcritical crack growth in ZrO2-bioglass ceramics. Ceramics International, 2013, 39(3): 2405. |

| [27] | YANG H Y, MA Z C, LEI C H, et al. High strength and high conductivity Cu alloys: a review. Science China Technological Sciences, 2020, 63(12): 2505. |

| [28] | LI X W, ZHANG D T, QIU C, et al. Microstructure and mechanical properties of dissimilar pure copper/1350 aluminum alloy butt joints by friction stir welding. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1298. |

| [29] | MUHAMMAD N A, WU C S. Ultrasonic vibration assisted friction stir welding of aluminium alloy and pure copper. Journal of Manufacturing Processes, 2019, 39: 114. |

| [30] | YOSHIDA H, HAYASAKA H, SOGA K, et al. Doping effect on the flash sintering of Y2O3: promotion of densification and optical translucency. Journal of the European Ceramic Society, 2020, 40(15): 6053. |

| [31] | YANG J X, FU M Y, TIAN Q, et al. Preparation of Gd2Zr2O7 nanoceramics by flash sintering and two-step flash sintering. Ceramics International, 2023, 49(11): 16594. |

| [32] |

JIA Y J, SU X H, WU Y J, et al. Flash sintering of 3YSZ/Al2O3-platelet composites. Journal of the American Ceramic Society, 2020, 103(4): 2351.

DOI |

| [33] | JHA S K, TERAUDS K, LEBRUN J M, et al. Beyond flash sintering in 3 mol% yttria stabilized zirconia. Journal of the Ceramic Society of Japan, 2016, 124(4): 283. |

| [34] | BIESUZ M, PINTER L, SAUNDERS T, et al. Investigation of electrochemical, optical and thermal effects during flash sintering of 8YSZ. Materials, 2018, 11(7): 1214. |

| [35] | DASHTBOZORG B, SHI F Z, TAGLIAFERRO A, et al. Plasma defect-engineering of bulk oxygen-deficient zirconia. Acta Materialia, 2024, 262: 119457. |

| [36] | SU X H, LI W J, CHEN D, et al. Rapid fabrication of oxygen-deficient zirconia by flash sintering treatment. Journal of Advanced Ceramics, 2024, 13(11): 1881. |

| [37] | ZHANG J J, GAO Y F, JIA X R, et al. Oxygen vacancy-rich mesoporous ZrO2 with remarkably enhanced visible-light photocatalytic performance. Solar Energy Materials and Solar Cells, 2018, 182: 113. |

| [38] | LV H F, ZHOU Y J, ZHANG X M, et al. Infiltration of Ce0.8Gd0.2O1.9 nanoparticles on Sr2Fe1.5Mo0.5O6-δ cathode for CO2 electroreduction in solid oxide electrolysis cell. Journal of Energy Chemistry, 2019, 35: 71. |

| [39] | LIU P, HENSEN E J M. Highly efficient and robust Au/MgCuCr2O4 catalyst for gas-phase oxidation of ethanol to acetaldehyde. Journal of the American Chemical Society, 2013, 135(38): 14032. |

| [40] | GAO B H, TAN B M, LIU Y L, et al. A study of FTIR and XPS analysis of alkaline-based cleaning agent for removing Cu-BTA residue on Cu wafer. Surface and Interface Analysis, 2019, 51(5): 566. |

| [41] | FINŠGAR M, KOVAČ J, MILOŠEV I. Surface analysis of 1-hydroxybenzotriazole and benzotriazole adsorbed on Cu by X-ray photoelectron spectroscopy. Journal of the Electrochemical Society, 2010, 157(2): C52. |

| [42] |

XIA J B, REN K, WANG Y G. Reversible joining of zirconia to titanium alloy. Ceramics International, 2019, 45(2): 2509.

DOI |

| [43] | JANEK J, KORTE C. Electrochemical blackening of yttria-stabilized zirconia-morphological instability of the moving reaction front. Solid State Ionics, 1999, 116(3/4): 181. |

| [44] | XIA J B, DING T, REN W, et al. Ceramics/metals joining under the influence of electric field: a review. Journal of the European Ceramic Society, 2023, 43(12): 5061. |

| [45] | ZHANG K Y, LI T Y, ZHAO Z Y, et al. Flash joining of Y2O3 transparent ceramic to titanium alloy. Journal of the European Ceramic Society, 2024, 44(1): 408. |

| [46] | XIA J B, REN W, ZHANG Y X, et al. Fast joining of 8YSZ to NiCrFe medium-entropy alloy by using an electric field. Journal of the European Ceramic Society, 2023, 43(10): 4431. |

| [1] | ZHOU Yangyang, ZHANG Yanyan, YU Ziyi, FU Zhengqian, XU Fangfang, LIANG Ruihong, ZHOU Zhiyong. Enhancement of Piezoelectric Properties in CaBi4Ti4O15-based Ceramics through Bi3+ Self-doping Strategy [J]. Journal of Inorganic Materials, 2025, 40(6): 719-728. |

| [2] | YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid [J]. Journal of Inorganic Materials, 2025, 40(6): 711-718. |

| [3] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [4] | FAN Xiaoxuan, ZHENG Yonggui, XU Lirong, YAO Zimin, CAO Shuo, WANG Kexin, WANG Jiwei. Organic Pollutant Fenton Degradation Driven by Self-activated Afterglow from Oxygen-vacancy-rich LiYScGeO4: Bi3+ Long Afterglow Phosphor [J]. Journal of Inorganic Materials, 2025, 40(5): 481-488. |

| [5] | PENG Ping, TAN Litao. Structure and Piezoelectric Properties of CuO-doped (Ba,Ca)(Ti,Sn)O3 Ceramics [J]. Journal of Inorganic Materials, 2024, 39(10): 1100-1106. |

| [6] | LUO Shuwen, MA Mingsheng, LIU Feng, LIU Zhifu. Corrosion Behavior and Mechanism of LTCC Materials in Ca-B-Si System [J]. Journal of Inorganic Materials, 2023, 38(5): 553-560. |

| [7] | DU Jianyu, GE Chen. Recent Progress in Optoelectronic Artificial Synapse Devices [J]. Journal of Inorganic Materials, 2023, 38(4): 378-386. |

| [8] | CHEN Lei, HU Hailong. Evolution of Electric Field and Breakdown Damage Morphology for Flexible PDMS Based Dielectric Composites [J]. Journal of Inorganic Materials, 2023, 38(2): 155-162. |

| [9] | LIU Yan, ZHANG Keying, LI Tianyu, ZHOU Bo, LIU Xuejian, HUANG Zhengren. Electric-field Assisted Joining Technology for the Ceramics Materials: Current Status and Development Trend [J]. Journal of Inorganic Materials, 2023, 38(2): 113-124. |

| [10] | MA Xinquan, LI Xibao, CHEN Zhi, FENG Zhijun, HUANG Juntong. BiOBr/ZnMoO4 Step-scheme Heterojunction: Construction and Photocatalytic Degradation Properties [J]. Journal of Inorganic Materials, 2023, 38(1): 62-70. |

| [11] | WEI Tingting, XU Huarui, ZHU Guisheng, LONG Shenfeng, ZHANG Xiuyun, ZHAO Yunyun, JIANG Xupeng, SONG Jinjie, GUO Ningjie, GONG Yipeng. Preparation and Properties of BaTiO3 Ceramics by Low Temperature Cold Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 903-910. |

| [12] | LIU Jinling, LIU Dianguang, REN Ke, WANG Yiguang. Research Progress on the Flash Sintering Mechanism of Oxide Ceramics and Its Application [J]. Journal of Inorganic Materials, 2022, 37(5): 473-480. |

| [13] | WU Xishi, ZHU Yunzhou, HUANG Qing, HUANG Zhengren. Effect of Pore Structure of Organic Resin-based Porous Carbon on Joining Properties of Cf/SiC Composites [J]. Journal of Inorganic Materials, 2022, 37(12): 1275-1280. |

| [14] | ZHU Zimin, ZHANG Minhui, ZHANG Xuanyu, YAO Aihua, LIN Jian, WANG Deping. In Vitro Mineralization Property of Borosilicate Bioactive Glass under DC Electric Field [J]. Journal of Inorganic Materials, 2021, 36(9): 1006-1012. |

| [15] | LI Pengpeng, WANG Bing, WANG Yingde. Ultrafast CO Sensor Based on Flame-annealed Porous CeO2 Nanosheets for Environmental Application [J]. Journal of Inorganic Materials, 2021, 36(11): 1223-1230. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||