Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (9): 1037-1044.DOI: 10.15541/jim20240497

• RESEARCH LETTER • Previous Articles

LI Tingsong1,2( ), WANG Wenli1,3, LIU Qiang3, WANG Yanbin1,2, ZHOU Zhenzhen1,2, HU Chen1,2, LI Jiang1,2(

), WANG Wenli1,3, LIU Qiang3, WANG Yanbin1,2, ZHOU Zhenzhen1,2, HU Chen1,2, LI Jiang1,2( )

)

Received:2024-11-28

Revised:2024-12-25

Published:2025-09-20

Online:2025-01-24

Contact:

LI Jiang, professor. E-mail:lijiang@mail.sic.ac.cn

About author:LI Tingsong (1998-), male, Master candidate. E-mail: litingsong@mail.sic.ac.cn

Supported by:CLC Number:

LI Tingsong, WANG Wenli, LIU Qiang, WANG Yanbin, ZHOU Zhenzhen, HU Chen, LI Jiang. Influence of Cr3+ Doping Concentration on the Persistent Performance of YAGG:Ce3+,Cr3+ Luminescent Ceramics[J]. Journal of Inorganic Materials, 2025, 40(9): 1037-1044.

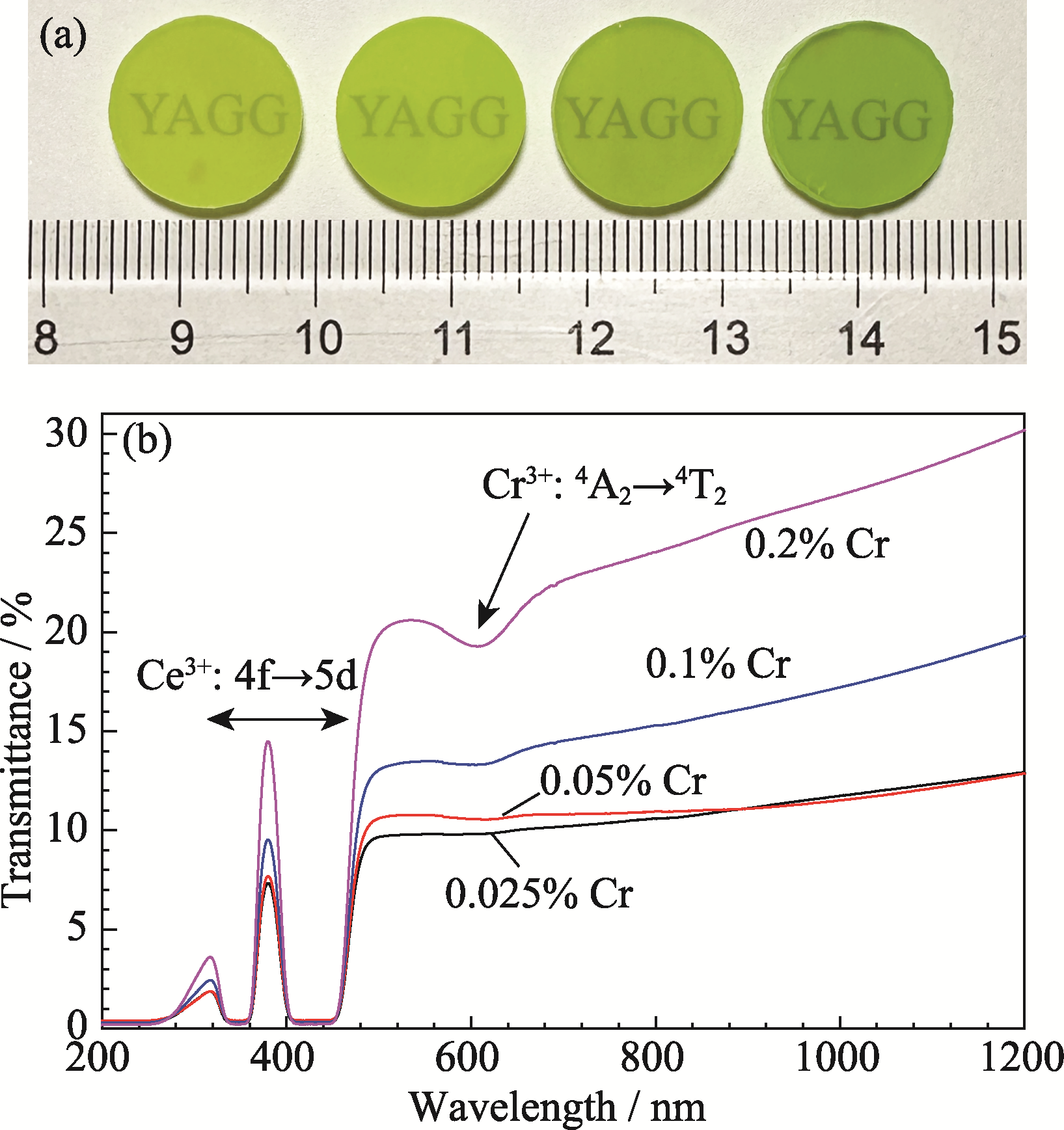

Fig. 4 Photographs and in-line transmittance of pre-sintered combined with HIP post-treated YAGG:Ce3+,Cr3+ PersL ceramics with different concentrations of Cr3+ (2.1 mm in thickness) (a) Photographs of ceramics (from left to right containing 0.025%, 0.05%, 0.1%, and 0.2% Cr, respectively); (b) In-line transmittance of ceramics

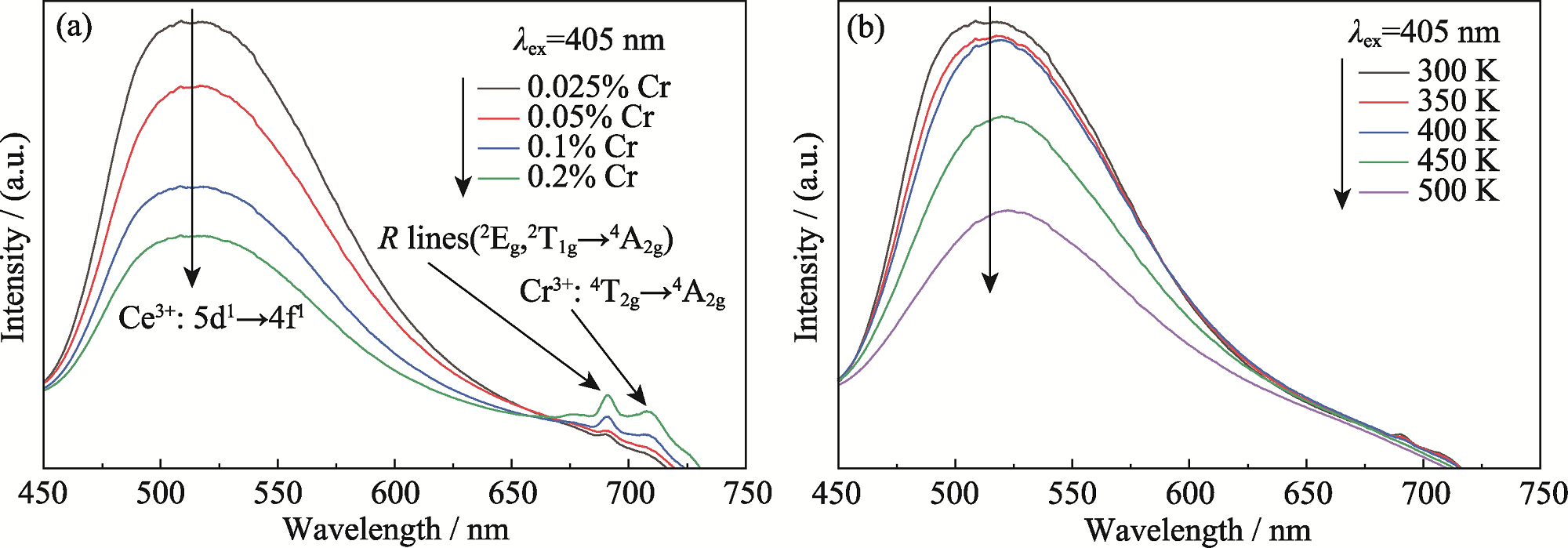

Fig. 5 PL spectra of pre-sintered combined with HIP post-treated YAGG:Ce3+,Cr3+ PersL ceramics (a) PL spectra of ceramics with different Cr3+ doping concentrations at room temperature; (b) Temperature-dependent PL spectra of ceramics with Cr3+ concentration of 0.025%

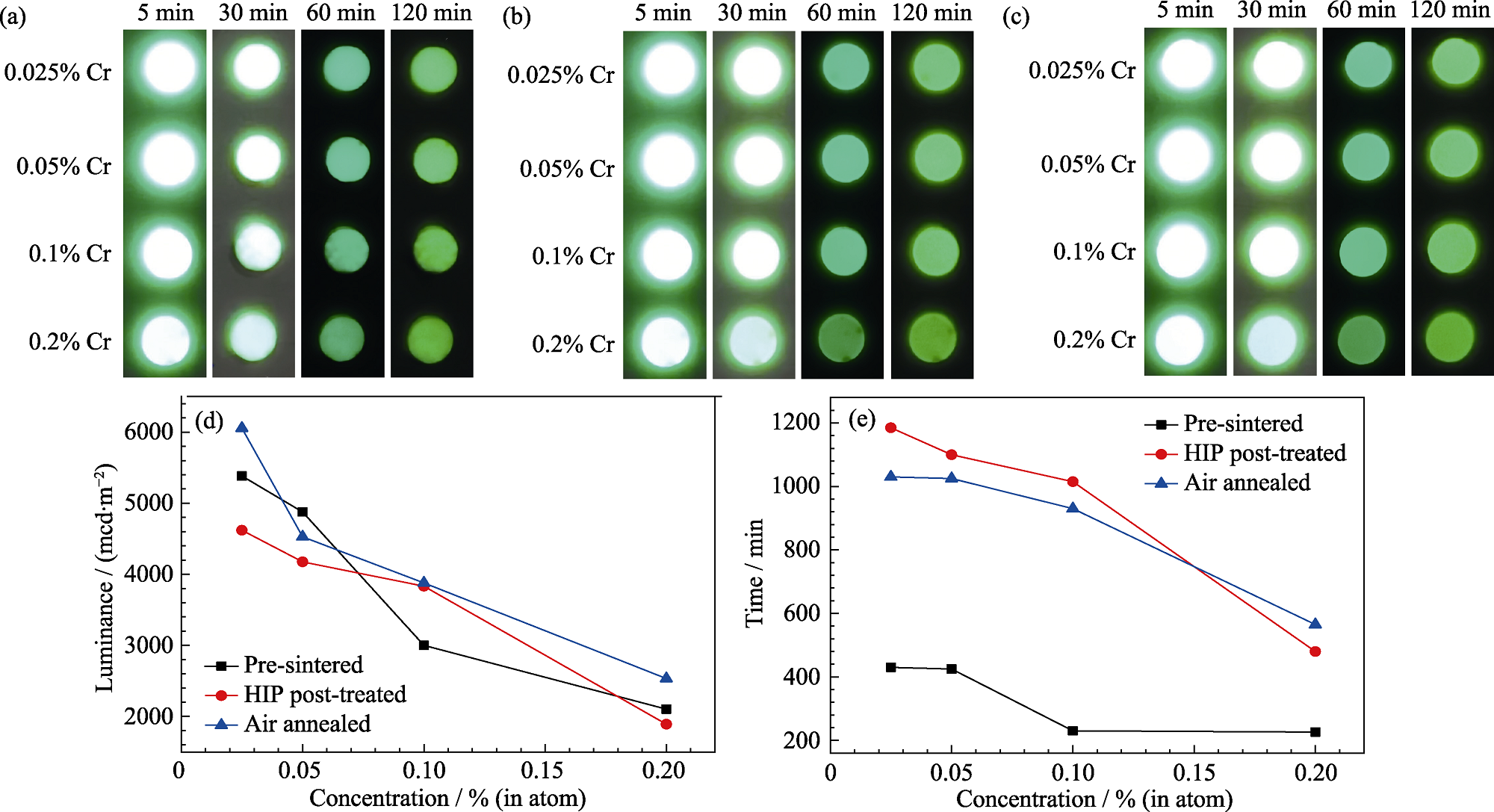

Fig. 6 Luminous photographs, initial luminescence intensity and duration of pre-sintered, HIP post-treated and air annealed YAGG:Ce3+,Cr3+ PersL ceramics with different concentrations of Cr3+ (excitation: 365 nm, 24 W, 5 min) (a) Luminous photographs of pre-sintered ceramics; (b) Luminous photographs of HIP post-treated ceramics; (c) Luminous photographs of air annealed ceramics; (d) Initial luminescence intensity of ceramics; (e) Duration of ceramics

| [1] | POELMAN D, VAN DER HEGGEN D, DU J, et al. Persistent phosphors for the future: fit for the right application. Journal of Applied Physics, 2020, 128(24): 240903. |

| [2] | XU J, TANABE S. Persistent luminescence instead of phosphorescence: history, mechanism, and perspective. Journal of Luminescence, 2019, 205: 581. |

| [3] | LI Y, GECEVICIUSA M, QIU J R. Long persistent phosphors- from fundamentals to applications. Chemical Society Reviews, 2016, 45(8): 2090. |

| [4] | MATSUZAWA T, AOKI Y, TAKEUCHI N, et al. A new long phosphorescent phosphor with high brightness, SrAl2O4:Eu2+,Dy3+. Journal of the Electrochemical Society, 2019, 143(8): 2670. |

| [5] | CHERNOV V, SALAS-CASTILLO P, DÍAZ-TORRES L A, et al. Thermoluminescence and infrared stimulated luminescence in long persistent monoclinic SrAl2O4:Eu2+,Dy3+ and SrAl2O4:Eu2+,Nd3+ phosphors. Optical Materials, 2019, 92: 46. |

| [6] | SMET P F, BOTTERMAN J, VAN DEN EECKHOUT K, et al. Persistent luminescence in nitride and oxynitride phosphors: a review. Optical Materials, 2014, 36(11): 1913. |

| [7] | XUE H L, YANG M P, SUN J J, et al. Study on the flux for SrAl2O4:Eu2+, Dy3+ phosphor preparation used in fluorescent fiber. Ceramics International, 2024, 50(1): 1137. |

| [8] | HÖLSÄ J. Persistent luminescence beats the afterglow: 400 years of persistent luminescence. Journal of the Electrochemical Society, 2009, 18(4): 42. |

| [9] | ZENG Q Q, WU Y Z, CHENG H Y, et al. Calcium doped self- activated zinc germanate long afterglow materials: multicolor afterglow and application in dynamic anti-counterfeiting. Journal of Inorganic Materials, 2023, 38(8): 901. |

| [10] | CAI Y Y, LIU S B, ZHAO L, et al. Delayed stress memory by CaAl2O4:Eu2+ mechanoluminescent phosphor with defect engineering regulation. Journal of Advanced Ceramics, 2022, 11(8): 1319. |

| [11] | ZHOU S H, LOU B B, MA C G, et al. First-principles study on persistent luminescence mechanism of LiYGeO4:Eu3+. Journal of Rare Earths, 2023, 41(10): 1519. |

| [12] | LI Q L, LI N X, LI Y C, et al. Research progress of radio- photoluminescence materials and their applications. Journal of Inorganic Materials, 2023, 38(7): 731. |

| [13] | ZHAO J T, LEI L, YE R G, et al. Sunlight activated ultra-stable long persistent luminescence glass ceramic for outdoor information display. Journal of Advanced Ceramics, 2022, 11(6): 974. |

| [14] | VAN DEN EECKHOUT K, POELMAN D, SMET P F. Persistent luminescence in non-Eu2+-doped compounds: a review. Materials, 2013, 6(7): 2789. |

| [15] | ZHENG H R, LIU L, LI Y A, et al. X-ray excited Mn2+-doped persistent luminescence materials with biological window emission for in vivo bioimaging. Journal of Rare Earths, 2024, 42(1): 28. |

| [16] | YIN X G, ZHONG H Y, LIU L, et al. X-ray-activated Bi3+/Pr3+ co-doped LiYGeO4 phosphor with UV and NIR dual-emissive persistent luminescence. Journal of Rare Earths, 2024, 42(5): 955. |

| [17] | DONG S M, WANG J Y, NI D W. Structural ceramics-the cornerstone of human civilization. Journal of Inorganic Materials, 2024, 39(6): 569. |

| [18] | ZHUANG Y X, KATAYAMA Y, UEDA J, et al. A brief review on red to near-infrared persistent luminescence in transition-metal- activated phosphors. Optical Materials, 2014, 36(11): 1907. |

| [19] | KADENGE V, KIPROTICH S, KAWIRA M, et al. Effect of Dy3+ concentrationson the structural and optical properties of SrAl2O4:Eu2+,Dy3+ NPs. Trends in Sciences, 2024, 21: 1. |

| [20] | YANG L, GAI S L, DING H, et al. Recent progress in inorganic afterglow materials: mechanisms, persistent luminescent properties, modulating methods, and bioimaging applications. Advanced Optical Materials, 2023, 11(11): 2202382. |

| [21] | LIANG L L, CHEN J Y, SHAO K, et al. Controlling persistent luminescence in nanocrystalline phosphors. Nature Materials, 2023, 22: 289. |

| [22] | ZHUANG Y X, UEDA J, TANABE S. Photochromism and white long-lasting persistent luminescence in Bi3+-doped ZnGa2O4 ceramics. Optical Materials Express, 2012, 2(10): 1378. |

| [23] | ZHUANG Y X, UEDA J, TANABE S. Enhancement of red persistent luminescence in Cr3+-doped ZnGa2O4 phosphors by Bi2O3 codoping. Applied Physics Express, 2013, 6(5): 052602. |

| [24] | DAI Z F, MAO X Y, LIU Q, et al. Effect of dopant concentration on the optical characteristics of Cr3+:ZnGa2O4 transparent ceramics exhibiting persistent luminescence. Optical Materials, 2022, 125: 112127. |

| [25] | DAI Z F, BOIKO V, GRZESZKIEWICZ K, et al. Effect of annealing treatment on the persistent luminescence of Y3Al2Ga3O12:Ce3+, Cr3+,Pr3+ ceramics. Optical Materials, 2020, 105: 109888. |

| [26] | LIU Q, WANG W L, DAI Z F, et al. Fabrication and long persistent luminescence of Ce3+-Cr3+ co-doped yttrium aluminum gallium garnet transparent ceramics. Journal of Rare Earths, 2022, 40(11): 1699. |

| [27] | YANG Y M, LI Z Y, ZHANG J Y, et al. X-ray-activated long persistent phosphors featuring strong UVC afterglow emissions. Light: Science & Applications, 2018, 7: 88. |

| [28] | LI T S, LIU Q, ZHU D Y, et al. Fabrication and characterizations of Eu2+-Dy3+ co-doped SrAl2O4 ceramics with persistent luminescence. Journal of the American Ceramic Society, 2023, 106(10): 5877. |

| [29] | UEDA J, DORENBOS P, BOS A J J, et al. Control of electron transfer between Ce3+ and Cr3+ in the Y3Al5-xGaxO12 host via conduction band engineering. Journal of Materials Chemistry C, 2015, 3(22): 5642. |

| [30] | XU J, MURATA D, UEDA J, et al. Toward rechargeable persistent luminescence for the first and third biological windows via persistent energy transfer and electron trap redistribution. Inorganic chemistry, 2018, 57(9): 5194. |

| [31] | DAI Z F, BOIKO V, GRZESZKIEWICZ K, et al. Effect of annealing temperature on persistent luminescence of Y3Al2Ga3O12:Cr3+ co-doped with Ce3+ and Pr3+. Optical Materials, 2021, 111: 110522. |

| [32] | DAI Z, BOIKO V, MARKOWSKA M, et al. Optical studies of Y3(Al,Ga)5O12:Ce3+,Cr3+,Nd3+ nano-phosphors obtained by the Pechini method. Journal of Rare Earths, 2019, 37(11): 1132. |

| [33] | XIA Z G, MEIJERINK A. Ce3+-doped garnet phosphors: composition modification, luminescence properties and applications. Chemical Society Reviews, 2017, 46(1): 275. |

| [34] | WEI Z Y, MENG G H, CHEN L, et al. Progress in ceramic materials and structure design toward advanced thermal barrier coatings. Journal of Advanced Ceramics, 2022, 11(7): 985. |

| [35] | UEDA J, KUROISHI K, TANABE S. Yellow persistent luminescence in Ce3+-Cr3+-codoped gadolinium aluminum gallium garnet transparent ceramics after blue-light excitation. Applied Physics Express, 2014, 7(6): 062201. |

| [36] | MÉVEL C, CARREAUD J, DELAIZIR G, et al. First ZnGa2O4 transparent ceramics. Journal of the European Ceramic Society, 2021, 41(9): 4934. |

| [37] | KARACAOGLU E, ÖZTÜRK E, UYANER M, et al. Atomic layer deposition (ALD) of nanoscale coatings on SrAl2O4-based phosphor powders to prevent aqueous degradation. Journal of the American Ceramic Society, 2020, 103(6): 3706. |

| [38] | XU J, UEDA J, TANABE S. Novel persistent phosphors of lanthanide-chromium co-doped yttrium aluminum gallium garnet: design concept with vacuum referred binding energy diagram. Journal of Materials Chemistry C, 2016, 4(20): 4380. |

| [39] | BOIKO V, DAI Z F, MARKOWSKA M, et al. Particle size-related limitations of persistent phosphors based on the doped Y3Al2Ga3O12 system. Scientific Reports, 2021, 11: 141. |

| [40] | KATAYAMA Y, VIANA B, GOURIER D, et al. Photostimulation induced persistent luminescence in Y3Al2Ga3O12:Cr3+. Optical Materials Express, 2016, 6(4): 1405. |

| [41] | BOIKO V, ZELER J, MARKOWSKA M, et al. Persistent luminescence from Y3Al2Ga3O12 doped with Ce3+ and Cr3+ after X-ray and blue light irradiation. Journal of Rare Earths, 2019, 37(11): 1200. |

| [42] | XU J, UEDA J, KUROISHI K, et al. Fabrication of Ce3+-Cr3+ co-doped yttrium aluminium gallium garnet transparent ceramic phosphors with super long persistent luminescence. Scripta Materialia, 2015, 102: 47. |

| [43] | CHEN R, LAWLESS J L, PAGONIS V. A model for explaining the concentration quenching of thermoluminescence. Radiation Measurements, 2011, 46(12): 1380. |

| [44] |

CHEN B, WANG F. Combating concentration quenching in upconversion nanoparticles. Accounts of Chemical Research, 2020, 53(2): 358.

DOI PMID |

| [45] |

WANG Z J, MEIJERINK A. Concentration quenching in upconversion nanocrystals. Journal of Physical Chemistry C, 2018, 122(45): 26298.

DOI PMID |

| [46] | PAN Z W, LU Y Y, LIU F. Sunlight-activated long-persistent luminescence in the near-infrared from Cr3+-doped zinc gallogermanates. Nature Materials, 2011, 11: 58. |

| [1] | YE Junhao, ZHOU Zhenzhen, HU Chen, WANG Yanbin, JING Yanqiu, LI Tingsong, CHENG Ziqiu, WU Junlin, IVANOV Maxim, HRENIAK Dariusz, LI Jiang. Yb:Sc2O3 Transparent Ceramics Fabricated from Co-precipitated Nano-powders: Microstructure and Optical Property [J]. Journal of Inorganic Materials, 2025, 40(2): 215-224. |

| [2] | SHI Rui, LIU Wei, LI Lin, LI Huan, ZHANG Zhijun, RAO Guanghui, ZHAO Jingtai. Preparation and Properties of BaSrGa4O8: Tb3+ Mechanoluminescent Materials [J]. Journal of Inorganic Materials, 2024, 39(10): 1107-1113. |

| [3] | LIU Qiang, WANG Qian, CHEN Penghui, LI Xiaoying, ZHANG Lixuan, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Red Ce-doped 8YSZ Transparent Ceramics by Two-step Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 911-917. |

| [4] | JING Yanqiu, LIU Qiang, SU Sha, LI Xiaoying, LIU Ziyu, WANG Jingya, LI Jiang. Fabrication of Highly Transparent Co:MgAl2O4 Ceramic Saturable Absorber for Passive Q-switching in 1.5 μm [J]. Journal of Inorganic Materials, 2021, 36(8): 877-882. |

| [5] | ZHANG Cong, LI Yurou, SHAO Kang, LIN Jing, WANG Kai, PAN Zaifa. Luminescence Property of the Multicolor Persistent Luminescence Materials for Dynamic Anti-counterfeiting Applications [J]. Journal of Inorganic Materials, 2021, 36(12): 1256-1262. |

| [6] | ZHU Danyang, QIAN Kang, CHEN Xiaopu, HU Zewang, LIU Xin, LI Xiaoying, PAN Yubai, MIHÓKOVÁ Eva, NIKL Martin, LI Jiang. Fine-grained Ce,Y:SrHfO3 Scintillation Ceramics Fabricated by Hot Isostatic Pressing [J]. Journal of Inorganic Materials, 2021, 36(10): 1118-1124. |

| [7] | WANG Kai, YAN Li-Ping, SHAO Kang, ZHANG Cong, PAN Zai-Fa. Near-infrared Afterglow Enhancement and Trap Distribution Analysis of Silicon-chromium Co-doped Persistent Luminescence Materials Zn1+xGa2-2xSixO4:Cr3+ [J]. Journal of Inorganic Materials, 2019, 34(9): 983-990. |

| [8] | ZHANG Jin-Cheng, WANG Hao, XU Peng-Yu, TU Bing-Tian, WANG Wei-Min, FU Zheng-Yi. Preparation of ZnO·2.56Al2O3 Transparent Ceramics by Aqueous Gelcasting and Hot Isostatic Pressing [J]. Journal of Inorganic Materials, 2019, 34(10): 1072-1076. |

| [9] | ABDUKAYUM Abdukader, TUERDI Ailijiang, ABDURAHMAN Renagul, TURSUN Mamutjan, NURMAT Nurbiya. Synthesis and Luminescence Properties of Dy,Cr Co-doped ZnGa2O4 Persistent Luminescence Nanoparticles [J]. Journal of Inorganic Materials, 2016, 31(12): 1363-1369. |

| [10] | YUAN Ze, WANG Hao, TU Bing-Tian, LIU Xin, XU Chun-Lai, WANG Wei-Ming, FU Zheng-Yi. Preparation of MgO·1.5Al2O3 Transparent Ceramic by Pressureless Sintering and Hot Isostatic Pressing [J]. Journal of Inorganic Materials, 2015, 30(8): 843-847. |

| [11] | SHEN Dong-Dong, JI Zhen-Guo. Mechanoluminescence of Persistent Luminescent SrAl2O4: (Eu2+, Dy3+) Material Prepared by Electron Beam Reduction [J]. Journal of Inorganic Materials, 2015, 30(1): 93-96. |

| [12] | TANG Hui-Yi,ZHU De-Gui,LIU Bo,SUN Hong-Liang. High Temperature Oxidation Mechanism of Ti3SiC2-64vol%SiC Ceramics [J]. Journal of Inorganic Materials, 2009, 24(4): 821-826. |

| [13] | ZOU Jian-Peng,RUAN Jian-Ming,HUANG Bai-Yun,ZHOU Zhong-Cheng,LIU Yu-Long. Preparation and Microstructure of HA-316L Stainless Steel Fibre Asymmetrical Functionally Graded Biomaterial [J]. Journal of Inorganic Materials, 2005, 20(5): 1181-1188. |

| [14] | LI Shao-Bo,LI Guo-An,LOU Yan-Liang,LUO Hui-Qian. Computer Simulation of Hot Isostatic Pressing Densification and its Application in TZP Ceramics [J]. Journal of Inorganic Materials, 2000, 15(2): 324-330. |

| [15] | DONG Shao-Ming,JIANG Dong-Liang,TAN Shou-Hong,GUO Jing-Kun. Strengthening and Toughening of Hot Isostatically Pressed SiC Based Composites [J]. Journal of Inorganic Materials, 1999, 14(1): 61-65. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||