Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (11): 1237-1244.DOI: 10.15541/jim20250134

• RESEARCH ARTICLE • Previous Articles Next Articles

GE Zesheng1( ), LIU Miao1, TANG Zhe1, ZHOU Yan2(

), LIU Miao1, TANG Zhe1, ZHOU Yan2( ), WAN Shun3, ZONG Peng’an1(

), WAN Shun3, ZONG Peng’an1( )

)

Received:2025-03-30

Revised:2025-05-26

Published:2025-11-20

Online:2025-06-03

Contact:

ZONG Peng’an, professor. E-mail: pazong@njtech.edu.cn;About author:GE Zesheng (1998-), male, Master candidate. E-mail: zsge37@njtech.edu.cn

Supported by:CLC Number:

GE Zesheng, LIU Miao, TANG Zhe, ZHOU Yan, WAN Shun, ZONG Peng’an. Flexible Cu0.005Bi0.5Sb1.495Te3 Thin Films: Magnetron Sputtering Preparation and Thermoelectric Properties[J]. Journal of Inorganic Materials, 2025, 40(11): 1237-1244.

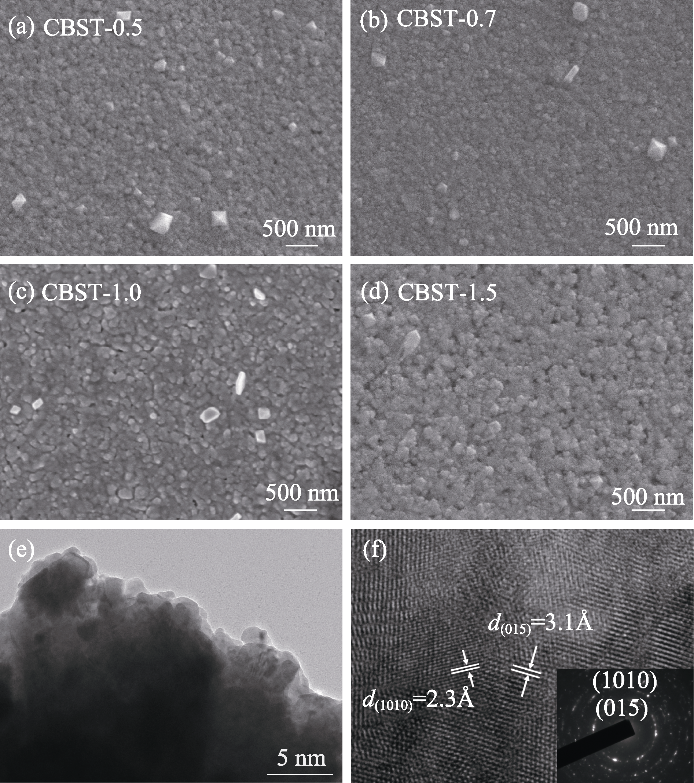

Fig. 2 Surface microstructures of CBST-x (x=0.5, 0.7, 1.0, 1.5) thin films (a-d) Surface SEM images of (a) CBST-0.5, (b) CBST-0.7, (c) CBST-1.0, and (d) CBST-1.5; (e) TEM and (f) HRTEM images with SAED pattern of CBST-0.7

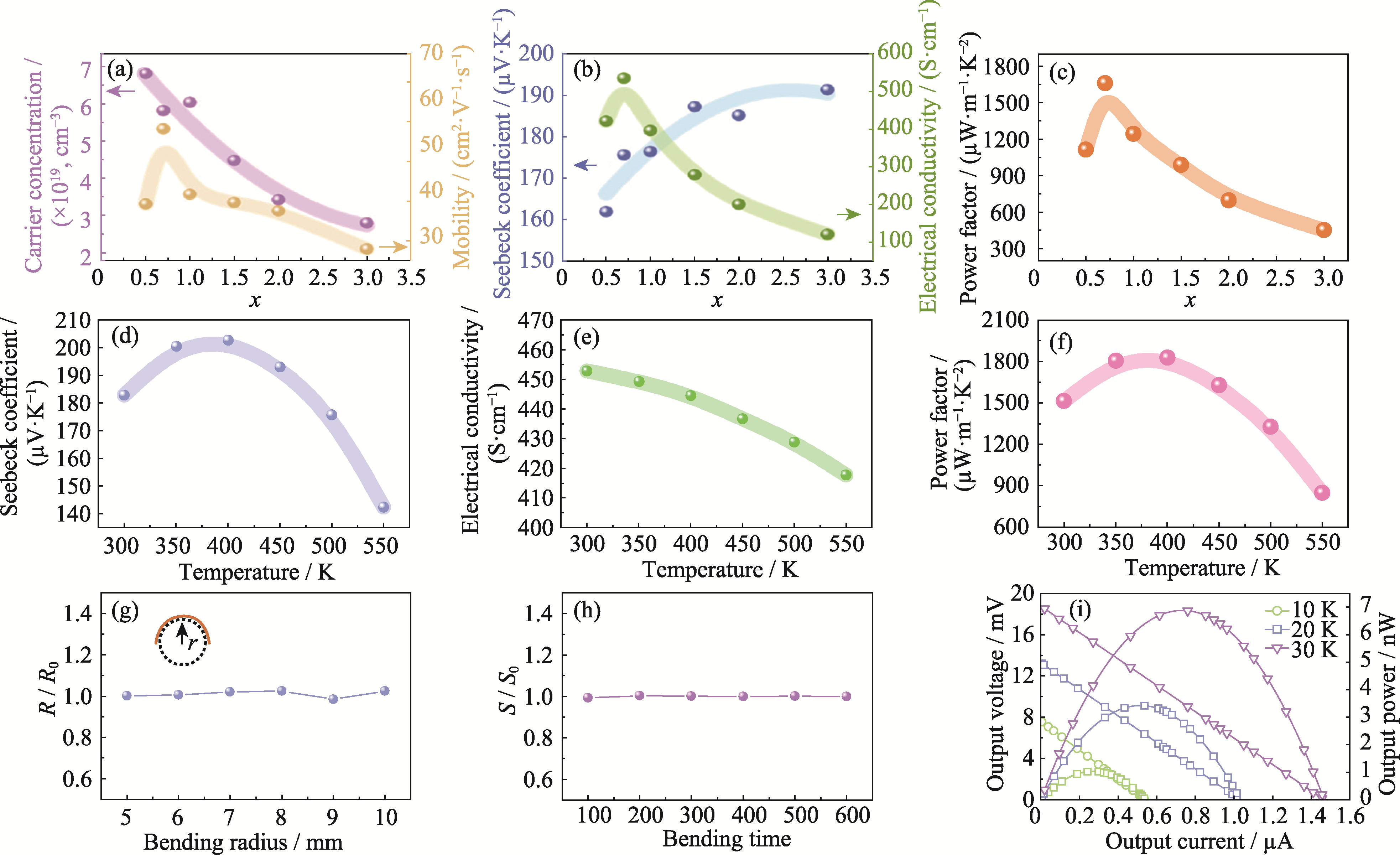

Fig. 5 Thermoelectric properties, flexibility and integrated device output properties of CBST thin films (a-c) Variation of (a) n and μ, (b) S and σ, (c) PF of CBST-x (x=0.5, 0.7, 1.0, 1.5) thin films; (d) S, (e) σ, and (f) PF of CBST-0.7 thin film (300-550 K); (g, h) Flexibility characterization of CBST-0.7 thin film: (g) Resistivity change under different bending radii (5-10 mm),(h) Seebeck coefficient changes with bending cycles (100-600 cycles); (i) Relationship between Voc, Poc and current of TEG composed of 4 single p-type thermoelectric legs with optimal performance at different temperatures (10-30 K)

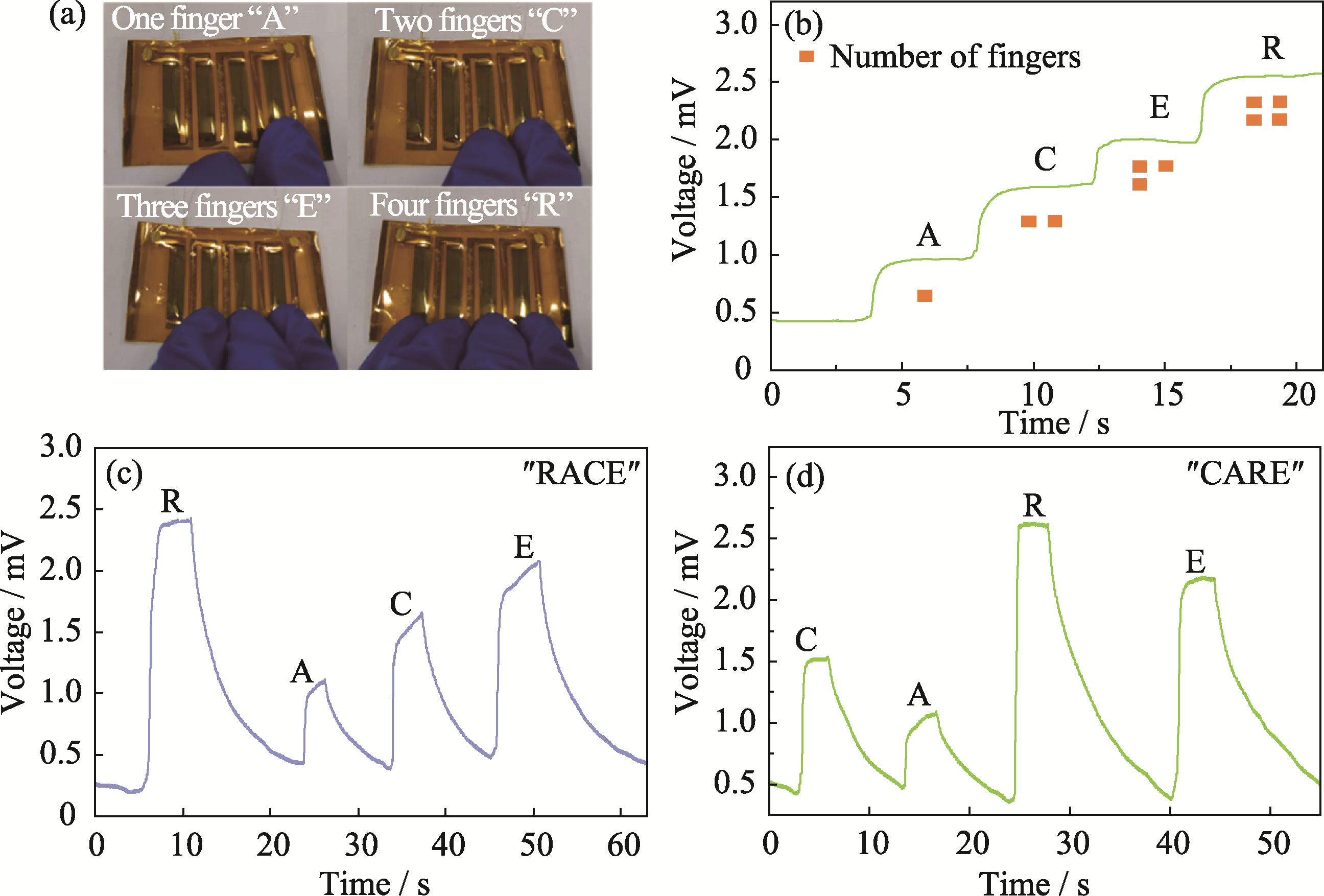

Fig. 6 Single p-type TEG and touch sensing language output design (a) Touching single-p-type TEG with different numbers of finger; (b) Voc generated by the TEG upon touching by one to four fingers; (c, d) TEG converts the resulting voltage signal into words (c) “RACE” and (d) “CARE”

| Sample | Cu/% | Bi/% | Sb/% | Te/% | (Bi+Sb)/Te | Formula |

|---|---|---|---|---|---|---|

| CBST-0.5 | 0.14 | 10.53 | 31.25 | 58.08 | 41.78/58.08 | Cu0.0066Bi0.50Sb1.48Te2.76 |

| CBST-0.7 | 0.12 | 10.52 | 29.90 | 59.46 | 40.43/59.46 | Cu0.0057Bi0.50Sb1.42Te2.83 |

| CBST-1.0 | 0.11 | 9.73 | 29.87 | 60.29 | 39.60/60.29 | Cu0.0056Bi0.50Sb1.53Te3.09 |

| CBST-1.5 | 0.09 | 10.05 | 28.52 | 61.34 | 38.57/61.34 | Cu0.0045Bi0.50Sb1.42Te3.05 |

Table S1 EDS detected atomic percentages of CBST films prepared at different working pressures (0.5-1.5 Pa)

| Sample | Cu/% | Bi/% | Sb/% | Te/% | (Bi+Sb)/Te | Formula |

|---|---|---|---|---|---|---|

| CBST-0.5 | 0.14 | 10.53 | 31.25 | 58.08 | 41.78/58.08 | Cu0.0066Bi0.50Sb1.48Te2.76 |

| CBST-0.7 | 0.12 | 10.52 | 29.90 | 59.46 | 40.43/59.46 | Cu0.0057Bi0.50Sb1.42Te2.83 |

| CBST-1.0 | 0.11 | 9.73 | 29.87 | 60.29 | 39.60/60.29 | Cu0.0056Bi0.50Sb1.53Te3.09 |

| CBST-1.5 | 0.09 | 10.05 | 28.52 | 61.34 | 38.57/61.34 | Cu0.0045Bi0.50Sb1.42Te3.05 |

| Sample | 2θ/(°) | FWHM, β/rad | Grain size, D/nm | Dislocation density, δ/ (×1015, m−2) | Strain, ε/ (×10−3, line−2·m−4) |

|---|---|---|---|---|---|

| CBST-0.5 | 28.26 | 0.00435 | 32.511 | 0.946 | 1.054 |

| CBST-0.7 | 28.18 | 0.00317 | 44.602 | 0.503 | 0.768 |

| CBST-1.0 | 28.14 | 0.00332 | 42.556 | 0.552 | 0.805 |

| CBST-1.5 | 27.98 | 0.00467 | 30.261 | 1.092 | 1.132 |

Table S2 XRD analysis results of CBST thin films prepared at different working pressures

| Sample | 2θ/(°) | FWHM, β/rad | Grain size, D/nm | Dislocation density, δ/ (×1015, m−2) | Strain, ε/ (×10−3, line−2·m−4) |

|---|---|---|---|---|---|

| CBST-0.5 | 28.26 | 0.00435 | 32.511 | 0.946 | 1.054 |

| CBST-0.7 | 28.18 | 0.00317 | 44.602 | 0.503 | 0.768 |

| CBST-1.0 | 28.14 | 0.00332 | 42.556 | 0.552 | 0.805 |

| CBST-1.5 | 27.98 | 0.00467 | 30.261 | 1.092 | 1.132 |

| Material | Crystal orientation | PF/(μW·m−1·K−2) |

|---|---|---|

| Bi2Te3[ | (00l) | 3000 |

| Bi0.4Sb1.6Te3[ | (00l) | 2000 |

| Bi2Te3[ | (00l) | 1610 |

| Sb2Te3[ | (015) | 1210 |

| Sb2Te3[ | (015) | 1220 |

| W-Bi0.5Sb1.5Te3[ | (015) | 1375 |

| Cu0.005Bi0.5Sb1.495Te3 (This Work) | (015) | 1660 |

Table S3 Comparison of room-temperature PF of the CBST film prepared in this work and literature

| Material | Crystal orientation | PF/(μW·m−1·K−2) |

|---|---|---|

| Bi2Te3[ | (00l) | 3000 |

| Bi0.4Sb1.6Te3[ | (00l) | 2000 |

| Bi2Te3[ | (00l) | 1610 |

| Sb2Te3[ | (015) | 1210 |

| Sb2Te3[ | (015) | 1220 |

| W-Bi0.5Sb1.5Te3[ | (015) | 1375 |

| Cu0.005Bi0.5Sb1.495Te3 (This Work) | (015) | 1660 |

| Material | Device type | N (leg numbers) | ΔT/K | Voc/mV | Pmax/nW | Average Voc/ mV | Pmax density/(μW·cm−2) |

|---|---|---|---|---|---|---|---|

| Bi2Te3/CFF (carbon fiber fabric)[ | Single p-type | 5 | 32 | 6.0 | 90.6 | 1.2 | 0.72 |

| Bi2Te3/Ni Foam[ | Single n-type | 5 | 30 | 3.7 | 22.7 | 0.8 | 0.71 |

| Bi2Te3-Sb2Te3[ | π-type | 26 | 24 | 48.9 | 693.5 | 1.9 | − |

| Bi2Te3-Sb2Te3[ | π-type | 200 | 40 | 430.0 | 32.0 | 2.2 | 94.81 |

| Bi0.5Sb1.5Te3-Bi2Te2.7Se0.3[ | π-type | 13 | 68 | 70.0 | 11000.0 | 5.4 | 140.00 |

| This work | Single p-type | 4 | 30 | 18.5 | 6.9 | 4.6 | 44.80 |

Table S4 Comparison of the output performance of the thermoelectric device in this work and literature

| Material | Device type | N (leg numbers) | ΔT/K | Voc/mV | Pmax/nW | Average Voc/ mV | Pmax density/(μW·cm−2) |

|---|---|---|---|---|---|---|---|

| Bi2Te3/CFF (carbon fiber fabric)[ | Single p-type | 5 | 32 | 6.0 | 90.6 | 1.2 | 0.72 |

| Bi2Te3/Ni Foam[ | Single n-type | 5 | 30 | 3.7 | 22.7 | 0.8 | 0.71 |

| Bi2Te3-Sb2Te3[ | π-type | 26 | 24 | 48.9 | 693.5 | 1.9 | − |

| Bi2Te3-Sb2Te3[ | π-type | 200 | 40 | 430.0 | 32.0 | 2.2 | 94.81 |

| Bi0.5Sb1.5Te3-Bi2Te2.7Se0.3[ | π-type | 13 | 68 | 70.0 | 11000.0 | 5.4 | 140.00 |

| This work | Single p-type | 4 | 30 | 18.5 | 6.9 | 4.6 | 44.80 |

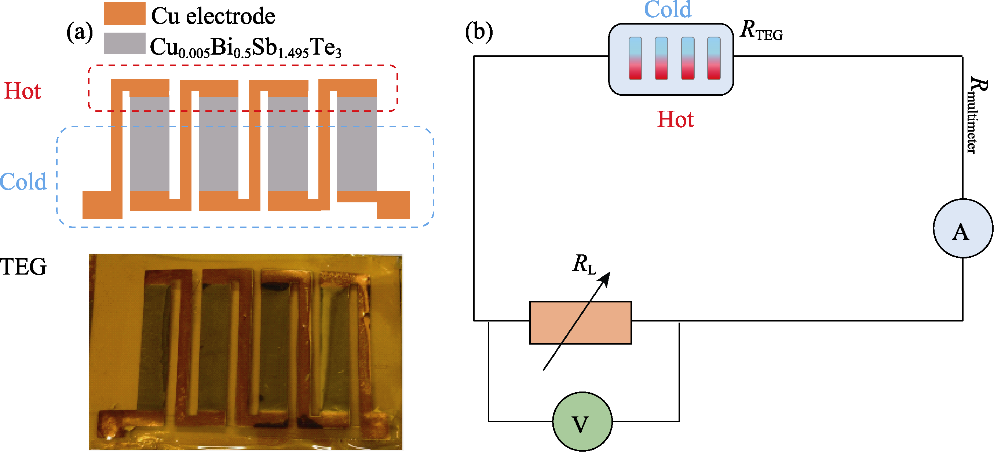

Fig. S4 TEG structure diagram, physical diagram and power generation circuit diagram (a) Schematic and photograph of the single-p-type TEG composed of four thin-film legs with optimized performance; (b) Circuit schematic of the TEG integrated with an external load resistor

| [1] | BIAN X L, YANG Z L, ZHANG T, et al. Multifunctional flexible AgNW/MXene/PDMS composite films for efficient electromagnetic interference shielding and strain sensing. ACS Applied Materials & Interfaces, 2023, 15(35): 41906. |

| [2] | FU Y T, ZHANG Q H, HU Z L, et al. Mg3(Bi,Sb)2-based thermoelectric modules for efficient and reliable waste-heat utilization up to 750 K. Energy & Environmental Science, 2022, 15: 3265. |

| [3] |

LI L, LIU W D, LIU Q F, et al. Multifunctional wearable thermoelectrics for personal thermal management. Advanced Functional Materials, 2022, 32(22): 2200548.

DOI URL |

| [4] | GAO M Y, WANG P, JIANG L L, et al. Power generation for wearable systems. Energy & Environmental Science, 2021, 14(4): 2114. |

| [5] |

LU Y, ZHOU Y, WANG W, et al. Staggered-layer-boosted flexible Bi2Te3 films with high thermoelectric performance. Nature Nanotechnology, 2023, 18(11): 1281.

DOI |

| [6] |

ZHANG Q H, HUANG X Y, BAI S Q, et al. Thermoelectric devices for power generation: recent progress and future challenges. Advanced Engineering Materials, 2016, 18(2): 194.

DOI URL |

| [7] |

HSIEH Y Y, ZHANG Y, ZHANG L, et al. High thermoelectric power-factor composites based on flexible three-dimensional graphene and polyaniline. Nanoscale, 2019, 11(14): 6552.

DOI URL |

| [8] |

TIAN R M, LIU Y Q, KOUMOTO K, et al. Body heat powers future electronic skins. Joule, 2019, 3(6): 1399.

DOI |

| [9] |

ZHU J J, SUN C, FENG W L, et al. Permeable carbon fiber based thermoelectric film with exceptional EMI shielding performance and sensor capabilities. Journal of Advanced Ceramics, 2024, 13(8): 1119.

DOI URL |

| [10] |

PEREZ-TABORDA J A, VERA L, CABALLERO-CALERO O, et al. Pulsed hybrid reactive magnetron sputtering for high zT Cu2Se thermoelectric films. Advanced Materials Technologies, 2017, 2(7): 1700012.

DOI URL |

| [11] | HAO F, QIU P F, TANG Y S, et al. High efficiency Bi2Te3-based materials and devices for thermoelectric power generation between 100 and 300 ℃. Energy & Environmental Science, 2016, 9(10): 3120. |

| [12] |

HAO F, QIU P F, SONG Q F, et al. Roles of Cu in the enhanced thermoelectric properties in Bi0.5Sb1.5Te3. Materials, 2017, 10(3): 251.

DOI URL |

| [13] | TANWAR A, KAUR R, PADMANATHAN N, et al. Electrodeposited CuSbTe thin films with enhanced thermoelectric performance. Sustainable Energy & Fuels, 2023, 7(17): 4160. |

| [14] |

JOO S J, KIM B S, MIN B K, et al. Deposition of n-type Bi2Te3 thin films on polyimide by using RF magnetron co-sputtering method. Journal of Nanoscience and Nanotechnology, 2015, 15(10): 8299.

DOI URL |

| [15] |

TAKASHIRI M, TAKANO K, HAMADA J. Use of H2-Ar gas mixtures in radio-frequency magnetron sputtering to produce high-performance nanocrystalline bismuth telluride thin films. Thin Solid Films, 2018, 664: 100.

DOI URL |

| [16] |

DONG G Y, FENG J H, QIU G J, et al. Oriented Bi2Te3-based films enabled high performance planar thermoelectric cooling device for hot spot elimination. Nature Communications, 2024, 15: 9695.

DOI |

| [17] |

ZHU W, DENG Y, WANG Y, et al. Preferential growth transformation of Bi0.5Sb1.5Te3 films induced by facile post-annealing process: enhanced thermoelectric performance with layered structure. Thin Solid Films, 2014, 556: 270.

DOI URL |

| [18] | ROKNABADI M R, MOLLAEE M, GARAZHIAN S. Fabrication and thermoelectric properties of nano Sb2Te3, Bi2Te3 thin films using PVD of synthesized nano powder. Journal of Materials Science: Materials in Electronics, 2025, 36(3): 218. |

| [19] | LIU Z R, ZHANG Y L, XUE F N, et al. High-performance W-doped Bi0.5Sb1.5Te3 flexible thermoelectric films and generators. ACS Applied Materials & Interfaces, 2024, 16(20): 26025. |

| [20] | SHANG H J, LI T G, LUO D, et al. High-performance Ag-modified Bi0.5Sb1.5Te3 films for the flexible thermoelectric generator. ACS Applied Materials & Interfaces, 2020, 12(6): 7358. |

| [21] |

MU X, ZHOU H Y, HE D Q, et al. Enhanced electrical properties of stoichiometric Bi0.5Sb1.5Te3 film with high-crystallinity via layer-by-layer in situ growth. Nano Energy, 2017, 33: 55.

DOI URL |

| [22] |

SATHYAMOORTHY R, DHEEPA J. Structural characterization of thermally evaporated Bi2Te3 thin films. Journal of Physics and Chemistry of Solids, 2007, 68(1): 111.

DOI URL |

| [23] |

KHUMTONG T, SUKWISUTE P, SAKULKALAVEK A, et al. Microstructure and electrical properties of antimony telluride thin films deposited by RF magnetron sputtering on flexible substrate using different sputtering pressures. Journal of Electronic Materials, 2017, 46(5): 3166.

DOI URL |

| [24] | ANDERS A. Discharge physics of high power impulse magnetron sputtering. Surface and Coatings Technology, 2011, 205: S1. |

| [25] |

MCINTYRE N S, COOK M G. X-ray photoelectron studies on some oxides and hydroxides of cobalt, nickel, and copper. Analytical Chemistry, 1975, 47(13): 2208.

DOI URL |

| [26] |

PARMIGIANI F, PACCHIONI G, ILLAS F, et al. Studies of the Cu-O bond in cupric oxide by X-ray photoelectron spectroscopy and ab initio electronic structure models. Journal of Electron Spectroscopy and Related Phenomena, 1992, 59(3): 255.

DOI URL |

| [27] |

SHI T F, CHEN M R, ZHANG C R, et al. Modifying carbon fiber fabric for flexible thermoelectric energy conversion. Applied Surface Science, 2023, 610: 155479.

DOI URL |

| [28] |

AFSIN B, ROBERTS M W. Formation of an oxy-chloride overlayer at a Bi(000l) surface. Spectroscopy Letters, 1994, 27(1): 139.

DOI URL |

| [29] |

MORGAN W E, STEC W J, VAN WAZER J R. Inner-orbital binding-energy shifts of antimony and bismuth compounds. Inorganic Chemistry, 1973, 12(4): 953.

DOI URL |

| [30] | LIU W K, YUEN W T, STRADLING R A. Preparation of InSb substrates for molecular beam epitaxy. Journal of Vacuum Science & Technology B, 1995, 13(4): 1539. |

| [31] | BENVENUTTI E V, GUSHIKEM Y, VASQUEZ A, et al. X-ray photoelectron spectroscopy and mössbauer spectroscopy study of iron(III) and antimony(V) oxides grafted onto a silica gel surface. Journal of the Chemical Society, Chemical Communications, 1991(19): 1325. |

| [32] |

WANG J Q, FENG D M, WU W H, et al. An investigation of the flame retardation mechanism of polypropylene containing a chlorine flame retardant system by XPS(ESCA). Polymer Degradation and Stability, 1991, 31(2): 129.

DOI URL |

| [33] |

TKALICH A K, DEMIN V N, ZLOMANOV V P. Oxidation states of In in Pb1-xInxTe. Journal of Solid State Chemistry, 1995, 116(1): 33.

DOI URL |

| [34] |

ZHOU Y, ZHOU S, YING P H, et al. Unusual deformation and fracture in gallium telluride multilayers. The Journal of Physical Chemistry Letters, 2022, 13(17): 3831.

DOI URL |

| [35] |

KONNO H, YAMAMOTO Y. Ylide-metal complexes. XIV. An X-ray photoelectron spectroscopic study on tellurium complexes of methylenetriphenylphosphorane. Bulletin of the Chemical Society of Japan, 1988, 61(8): 2990.

DOI URL |

| [36] |

CHOWDARI B V R, KUMARI P P. Thermal, electrical and XPS studies of Ag2O·TeO2·P2O5 glasses. Journal of Non-Crystalline Solids, 1996, 197(1): 31.

DOI URL |

| [37] |

STARÝ Z, HORÁK J, STORDEUR M, et al. Antisite defects in Sb2-xBixTe3 mixed crystals. Journal of Physics and Chemistry of Solids, 1988, 49(1): 29.

DOI URL |

| [38] |

KAVEI G, KARAMI M A. Formation of anti-site defects and bismuth overstoichiometry in p-type Sb2-xBixTe3thermoelectric crystals. The European Physical Journal Applied Physics, 42(2): 67.

DOI URL |

| [39] |

SUN Y, ZHANG E, JOHNSEN S, et al. Growth of FeSb2 thin films by magnetron sputtering. Thin Solid Films, 2011, 519(16): 5397.

DOI URL |

| [40] |

FAN P, LI R Y, CHEN Y X, et al. High thermoelectric performance achieved in Bi0.4Sb1.6Te3 films with high (00l) orientation via magnetron sputtering. Journal of the European Ceramic Society, 2020, 40(12): 4016.

DOI URL |

| [41] |

SNYDER G J, TOBERER E S. Complex thermoelectric materials. Nature Materials, 2008, 7: 105.

DOI PMID |

| [42] |

NORIMASA O, CHIBA T, HASE M, et al. Improvement of thermoelectric properties of flexible Bi2Te3 thin films in bent states during sputtering deposition and post-thermal annealing. Journal of Alloys and Compounds, 2022, 898: 162889.

DOI URL |

| [43] |

KIANWIMOL S, SAKDANUPHAB R, CHANLEK N, et al. Effect of annealing temperature on thermoelectric properties of bismuth telluride thick film deposited by DC magnetron sputtering. Surface and Coatings Technology, 2020, 393: 125808.

DOI URL |

| [44] |

JUNLABHUT P, NUTHONGKUM P, SAKDANUPHAB R, et al. Influence of sputtering power density on the thermoelectric and mechanical properties of flexible thermoelectric antimony telluride films deposited by DC magnetron sputtering. Journal of Electronic Materials, 2020, 49(5): 2747.

DOI |

| [45] |

LU Z Q, LIU K K, LI Q, et al. Donor-like effect and thermoelectric performance in p-type Bi0.5Sb1.5Te3 alloy. Journal of Inorganic Materials, 2023, 38(11): 1331.

DOI URL |

| [46] |

SHI T F, CHEN M R, LIU Z G, et al. A Bi2Te3-filled nickel foam film with exceptional flexibility and thermoelectric performance. Nanomaterials, 2022, 12(10): 1693.

DOI URL |

| [47] |

KONG D Y, ZHU W, GUO Z P, et al. High-performance flexible Bi2Te3 films based wearable thermoelectric generator for energy harvesting. Energy, 2019, 175: 292.

DOI URL |

| [48] |

FRANCIOSO L, DE PASCALI C, FARELLA I, et al. Flexible thermoelectric generator for ambient assisted living wearable biometric sensors. Journal of Power Sources, 2011, 196(6): 3239.

DOI URL |

| [49] |

MALLICK M M, FRANKE L, RÖSCH A G, et al. High figure- of-merit telluride-based flexible thermoelectric films through interfacial modification via millisecond photonic-curing for fully printed thermoelectric generators. Advanced Science, 2022, 9(31): 2202411.

DOI URL |

| [1] | YANG Guang, ZHANG Nan, CHEN Shujin, WANG Yi, XIE An, YAN Yujie. WO3 Films Based on Porous ITO Electrodes: Preparation and Electrochromic Property [J]. Journal of Inorganic Materials, 2025, 40(7): 781-789. |

| [2] | DONG Chenyu, ZHENG Weijie, MA Yifan, ZHENG Chunyan, WEN Zheng. Characterizations by Piezoresponse Force Microscopy on Relaxor Properties of Pb(Mg,Nb)O3-PbTiO3 Ultra-thin Films [J]. Journal of Inorganic Materials, 2025, 40(6): 675-682. |

| [3] | BAO Ke, LI Xijun. Chemical Vapor Deposition of Vanadium Dioxide for Thermochromic Smart Window Applications [J]. Journal of Inorganic Materials, 2024, 39(3): 233-258. |

| [4] | LIU Song, ZHANG Faqiang, LUO Jin, LIU Zhifu. 0.9BaTiO3-0.1Bi(Mg1/2Ti1/2)O3 Ferroelectric Thin Films: Preparation and Energy Storage [J]. Journal of Inorganic Materials, 2024, 39(3): 291-298. |

| [5] | XU Xiangming, Husam N ALSHAREEF. Perspective of MXetronics [J]. Journal of Inorganic Materials, 2024, 39(2): 171-178. |

| [6] | ZHANG Botao, SUN Tingting, WANG Lianjun, JIANG Wan. Inkjet Printing Preparation of AgCuTe Thermoelectric Thin Films [J]. Journal of Inorganic Materials, 2024, 39(12): 1325-1330. |

| [7] | HU Ying, LI Ziqing, FANG Xiaosheng. Solution-prepared AgBi2I7 Thin Films and Their Photodetecting Properties [J]. Journal of Inorganic Materials, 2023, 38(9): 1055-1061. |

| [8] | CHEN Mingyue, YAN Zhichao, CHEN Jing, LI Minjuan, LIU Zhiyong, CAI Chuanbing. YBa2Cu3O7-δ Thin Film: Preparation by BaCl2/BaF2-MOD Method and Superconducting Property [J]. Journal of Inorganic Materials, 2023, 38(2): 199-204. |

| [9] | XIA Qiuying, SUN Shuo, ZAN Feng, XU Jing, XIA Hui. Amorphous LiSiON Thin Film Electrolyte for All-solid-state Thin Film Lithium Battery [J]. Journal of Inorganic Materials, 2022, 37(2): 230-236. |

| [10] | WANG Ying, ZHANG Wenlong, XING Yanfeng, CAO suqun, DAI Xinyi, LI Jingze. Performance of Amorphous Lithium Phosphate Coated Lithium Titanate Electrodes in Extended Working Range of 0.01-3.00 V [J]. Journal of Inorganic Materials, 2021, 36(9): 999-1005. |

| [11] | ZHAO Changjiang,MA Chao,LIU Juncheng,LIU Zhigang,CHEN Yan. Sputtering Power on the Microstructure and Properties of MgF2 Thin Films Prepared with Magnetron Sputtering [J]. Journal of Inorganic Materials, 2020, 35(9): 1064-1070. |

| [12] | WANG Bin, ZHENG Jin-Hui, WANG Xiao-Hong, ZHAO Bo, XU Liang, LIU Zong-Rui. Preparation and Chemically Responsive Luminescent Switching of the Flexible Self-supporting TbW10-Agarose Green Emission Thin Films [J]. Journal of Inorganic Materials, 2019, 34(8): 844-850. |

| [13] | Xin XU, Shu-Rong WANG, Xun MA, Shuai YANG, Yao-Bin LI, Hong-Bin YANG. Comparative Study of Cu2ZnSnS4 Thin Films Prepared by Chalcogenide and Single Targets [J]. Journal of Inorganic Materials, 2019, 34(5): 529-534. |

| [14] | SONG Jian-Min, DAI Xiu-Hong, LIANG Jie-Tong, ZHAO Lei, ZHOU Yang, GE Da-Yong, MENG Xu-Dong, LIU Bao-Ting. Resistive Switching Effect and Dielectric Property of Epitaxial BiFeO3 Thin Films by Off-axis Magnetron Sputtering [J]. Journal of Inorganic Materials, 2018, 33(9): 1017-1021. |

| [15] | XIAO Na, PANG Yang, SONG Yun, WU Xiao-Jing, FU Zheng-Wen, ZHOU Yong-Ning. Electrochemical Behavior of Sb-Si Nanocomposite Thin Films as Anode Materials for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2018, 33(5): 494-500. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||