Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (10): 1167-1174.DOI: 10.15541/jim20240207

Special Issue: 【材料计算】材料模拟计算(202506); 【信息功能】功能晶体(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

HAO Yongxin1,2( ), QIN Juan3, SUN Jun4(

), QIN Juan3, SUN Jun4( ), YANG Jinfeng4, LI Qinglian1,2, HUANG Guijun1,2, XU Jingjun1

), YANG Jinfeng4, LI Qinglian1,2, HUANG Guijun1,2, XU Jingjun1

Received:2024-04-23

Revised:2024-05-20

Published:2024-10-20

Online:2024-10-09

Contact:

SUN Jun, professor. E-mail: sunjun@nankai.edu.cnAbout author:HAO Yongxin (1997-), female, PhD candidate. E-mail: bigcrystal@mail.nankai.edu.cn

Supported by:CLC Number:

HAO Yongxin, QIN Juan, SUN Jun, YANG Jinfeng, LI Qinglian, HUANG Guijun, XU Jingjun. Impact of Crucible Bottom Shape on the Growth of Congruent Lithium Niobate Crystals by Czochralski Method[J]. Journal of Inorganic Materials, 2024, 39(10): 1167-1174.

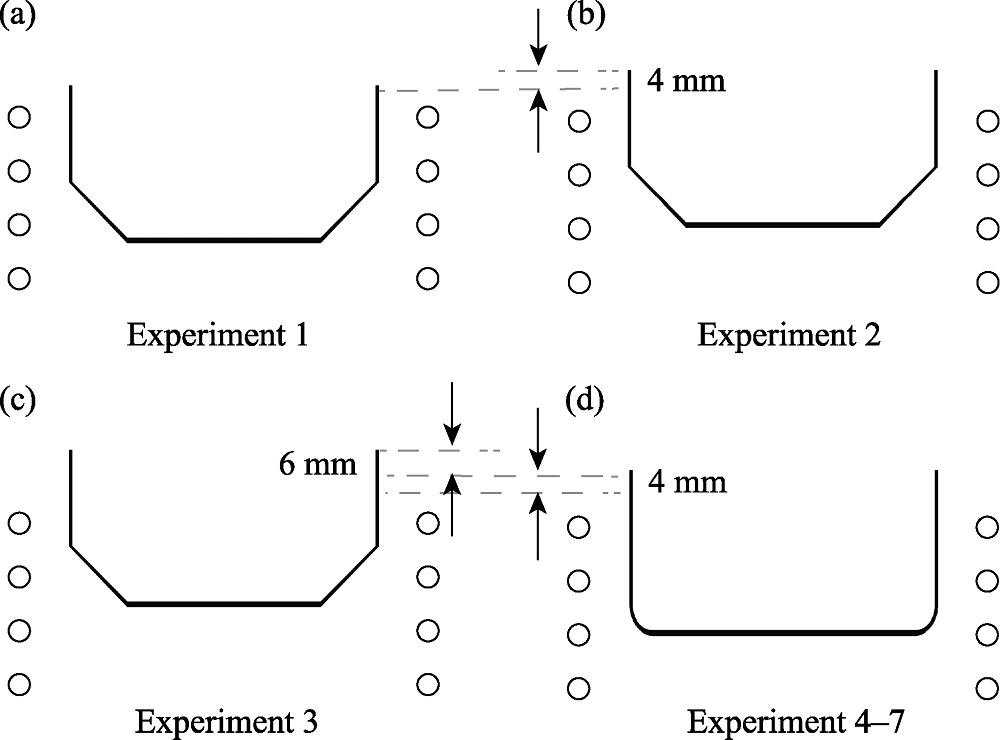

Fig. 2 Schematic diagram of the crucible bottom shape and position of the crucible relative to the induction coil for 7 times crystal growth (a) Experiment 1; (b) Experiment 2; (c) Experiment 3; (d) Experiment 4-7

| Description | Value |

|---|---|

| Crucible inner radius /mm | 160 |

| Crucible wall thickness /mm | 1.5 |

| Height and width of the slipped bottom corner /mm | 30 |

| Radius of the curved bottom corner /mm | 15 |

| Crystal density /(kg·m-3) | 4640 |

| Melt density /(kg·m-3) | 3530-3670 |

| Crystal thermal conductivity /(W·m-1·K-1) | 3.539 |

| Melt thermal conductivity /(W·m-1·K-1) | 4.5 |

| Melt point /℃ | 1252 |

| Thermal expansion coefficient /K-1 | 1.7×10-4 |

| Crystal diameter /mm | 105 |

| Emissivity | 0.3 |

| Pulling rate /(mm·h-1) | 1.5 |

| Rotate rate /(r·min-1) | 7 |

Table 1 Operating parameters used for numerical simulation

| Description | Value |

|---|---|

| Crucible inner radius /mm | 160 |

| Crucible wall thickness /mm | 1.5 |

| Height and width of the slipped bottom corner /mm | 30 |

| Radius of the curved bottom corner /mm | 15 |

| Crystal density /(kg·m-3) | 4640 |

| Melt density /(kg·m-3) | 3530-3670 |

| Crystal thermal conductivity /(W·m-1·K-1) | 3.539 |

| Melt thermal conductivity /(W·m-1·K-1) | 4.5 |

| Melt point /℃ | 1252 |

| Thermal expansion coefficient /K-1 | 1.7×10-4 |

| Crystal diameter /mm | 105 |

| Emissivity | 0.3 |

| Pulling rate /(mm·h-1) | 1.5 |

| Rotate rate /(r·min-1) | 7 |

| L/mm | Gmelt by using C-S /(℃·cm-1) | Gmelt by using C-C/(℃·cm-1) | Percentage of promotion/% |

|---|---|---|---|

| 5 | 8.05 | 9.48 | 17.8 |

| 20 | 5.75 | 7.28 | 26.6 |

| 35 | 3.78 | 5.63 | 48.9 |

| 50 | 1.39 | 3.80 | 173.3 |

Table 2 Axial temperature gradient at the melt centre near the crystal-melt interface (Gmelt)

| L/mm | Gmelt by using C-S /(℃·cm-1) | Gmelt by using C-C/(℃·cm-1) | Percentage of promotion/% |

|---|---|---|---|

| 5 | 8.05 | 9.48 | 17.8 |

| 20 | 5.75 | 7.28 | 26.6 |

| 35 | 3.78 | 5.63 | 48.9 |

| 50 | 1.39 | 3.80 | 173.3 |

| L/mm | Gcrystal by using C-S/(℃·cm-1) | Gcrystal by using C-C/(℃·cm-1) | Percentage of promotion/% |

|---|---|---|---|

| 5 | 14.35 | 16.92 | 17.9 |

| 20 | 10.36 | 12.87 | 24.2 |

| 35 | 7.06 | 10.07 | 42.6 |

| 50 | 3.06 | 7.15 | 133.7 |

Table 3 Axial temperature gradient at the crystal centre near the crystal-melt interface (Gcrystal)

| L/mm | Gcrystal by using C-S/(℃·cm-1) | Gcrystal by using C-C/(℃·cm-1) | Percentage of promotion/% |

|---|---|---|---|

| 5 | 14.35 | 16.92 | 17.9 |

| 20 | 10.36 | 12.87 | 24.2 |

| 35 | 7.06 | 10.07 | 42.6 |

| 50 | 3.06 | 7.15 | 133.7 |

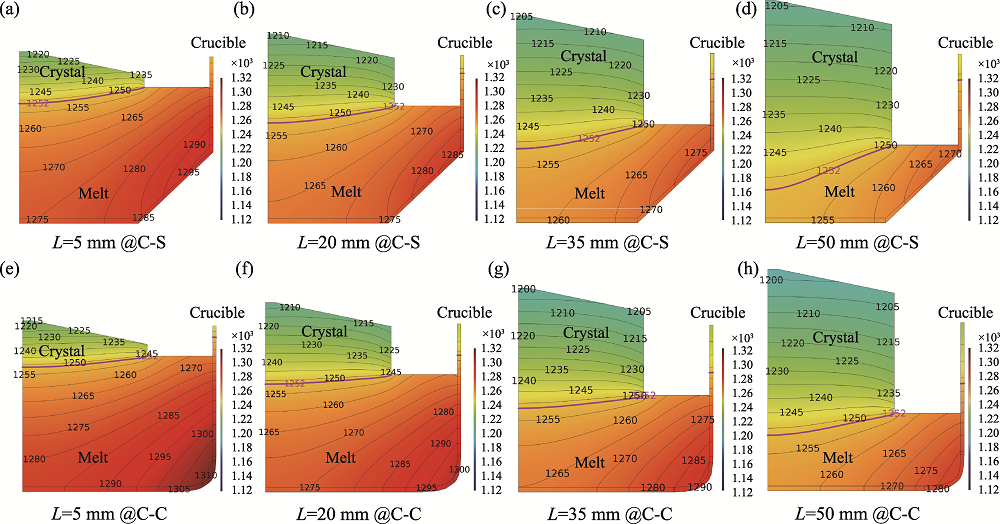

Fig. 5 Schematic temperature distributions of crystal, melt and crucible at different stages of body growth (a) L=5 mm @C-S; (b) L=20 mm @C-S; (c) L=35 mm @C-S; (d) L=50 mm @C-S; (e) L=5 mm @C-C; (f) L=20 mm @C-C; (g) L=35 mm @C-C; (h) L=50 mm @C-C

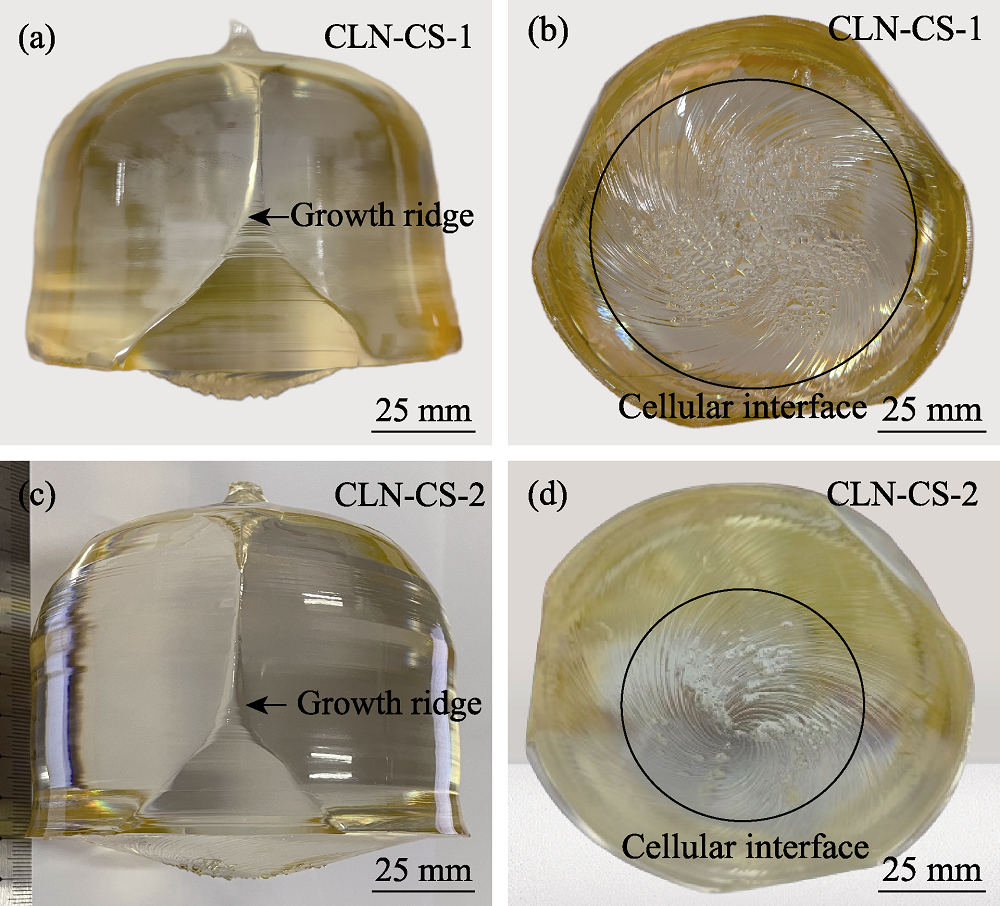

Fig. 7 Pictures of crystals grown before and after promoting the position of the crucible relative to the induction coil using crucible with slipped bottom corner (experiments 1, 2) (a) Side of crystal CLN-CS-1; (b) Bottom interface of crystal CLN-CS-1; (c) Side of crystal CLN-CS-2; (d) Bottom interface of crystal CLN-CS-2

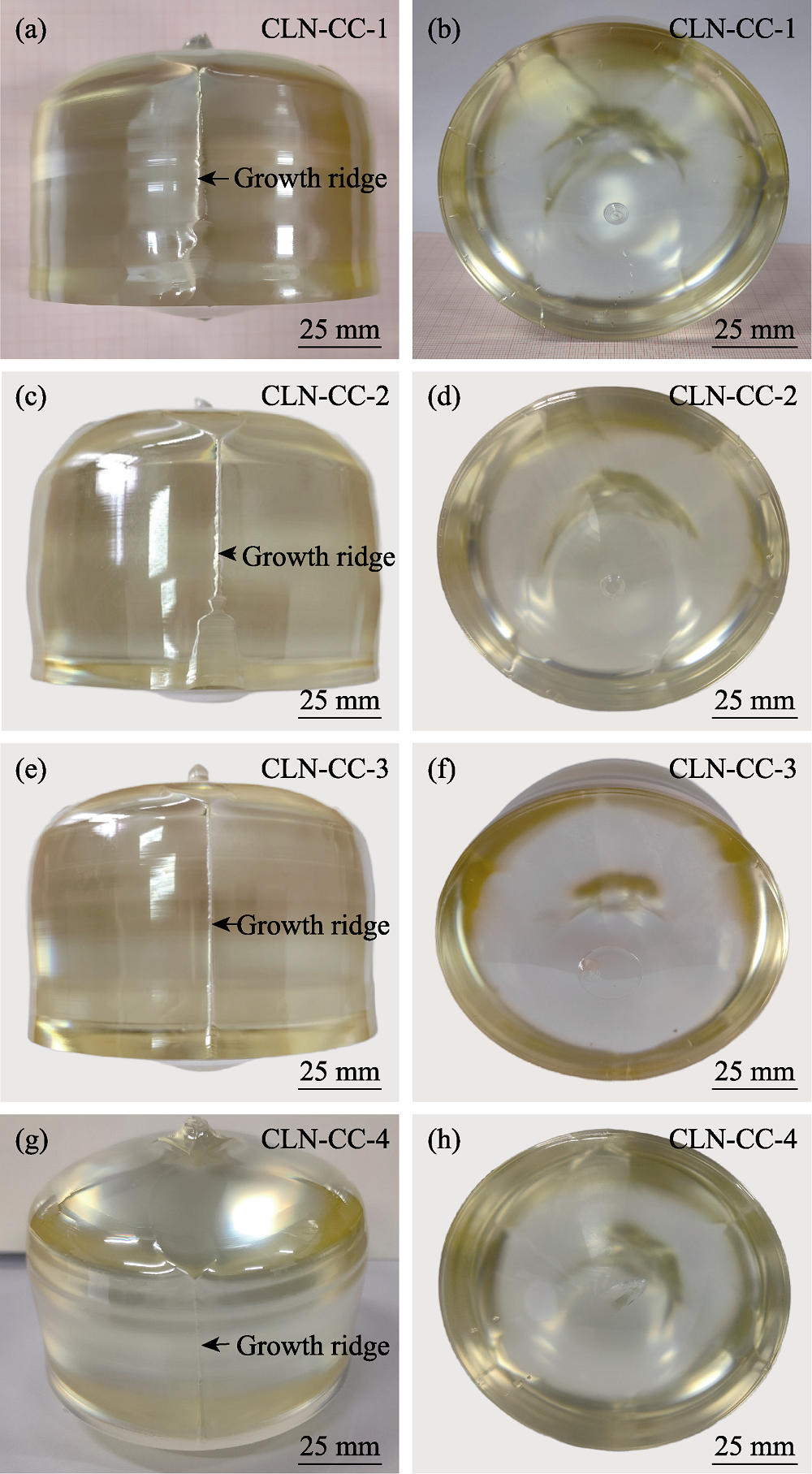

Fig. 8 Pictures of crystals grown by using crucible with curved bottom corner (experiments 4-7) (a) Side of crystal CLN-CC-1; (b) Bottom interface of crystal CLN-CC-1; (c) Side of crystal CLN-CC-2; (d) Bottom interface of crystal CLN-CC-2; (e) Side of crystal CLN-CC-3; (f) Bottom interface of crystal CLN-CC-3; (g) Side of crystal CLN-CC-4; (h) Bottom interface of crystal CLN-CC-4

| [1] | BOES A, CHANG L, LANGROCK C, et al. Lithium niobate photonics: unlocking the electromagnetic spectrum. Science, 2023, 379(6627): eabj4396. |

| [2] | KONG Y F, BO F, WANG W W, et al. Recent progress in lithium niobate: optical damage, defect simulation, and on-chip devices. Advanced Materials, 2020, 32(3): 1806452. |

| [3] | SÁNCHEZ-DENA O, FIERRO-RUIZ C D, VILLALOBOS- MENDOZA S D, et al. Lithium niobate single crystals and powders reviewed—Part I. Crystals, 2020, 10(11): 973. |

| [4] | LIU H D, WANG W W, ZHANG Z Z, et al. Defect structure of lithium niobate crystals. Journal of Synthetic Crystals, 2024, 53(3): 355. |

| [5] | BURROWS L. Now entering, lithium niobate valley. (2017-12-21) [2024-04-13]. https://seas.harvard.edu/news/2017/12/now-entering-lithium-niobate-valley. |

| [6] | XIE Z D, BO F, LIN J T, et al. Recent development in integrated lithium niobate photonics. Advances in Physics: X, 2024, 9(1): 2322739. |

| [7] | TIAN X H, SHANG M H, ZHU S N, et al. Lithium niobate based photonic quantum devices and integration technology: opportunities and challenges. Physics, 2023, 52(8): 534. |

| [8] | YANG R G, CHEN G. Thermal conductivity modeling of periodic two-dimensional nanocomposites. Physical Review B, 2004, 69(19): 195316. |

| [9] | SAADATIRAD M, TAVAKOLI M H, KHODAMORADI H, et al. Effect of the pulling, crystal and crucible rotation rate on the thermal stress and the melt-crystal interface in the Czochralski growth of germanium crystals. CrystEngComm, 2021, 23(39): 6967. |

| [10] | LU C W, CHEN J C. Numerical simulation of thermal and mass transport during Czochralski crystal growth of sapphire. Crystal Research and Technology, 2010, 45(4): 371. |

| [11] | YAO S, WANG J, LIU H, et al. Growth, optical and thermal properties of near-stoichiometric LiNbO3 single crystal. Journal of Alloys and Compounds, 2008, 455(1/2): 501. |

| [12] | TAO D J, ZHU G X, YAN R S, et al. Czochralski growth of gadolinium gallium garnet (GGG) crystals. Chinese Journal of Quantum Electronics, 2003, 20(5): 550. |

| [13] | TAVAKOLI M H, WILKE H, CRNOGORAC N. Influence of the crucible bottom shape on the heat transport and fluid flow during the seeding process of oxide Czochralski crystal growth. Crystal Research and Technology, 2007, 42(12): 1252. |

| [14] | MOKHTARI F, BOUABDALLAH A, ZIZI M, et al. Combined effects of crucible geometry and Marangoni convection on silicon Czochralski crystal growth. Crystal Research and Technology, 2009, 44(8): 787. |

| [15] | TAVAKOLI M H, MOHAMMADI-MANESH E, OJAGHI A. Influence of crucible geometry and position on the induction heating process in crystal growth systems. Journal of Crystal Growth, 2009, 311(17): 4281. |

| [16] | SAEEDI H, ASADIAN M, ENAYATI S, et al. The effect of crucible bottom deformation on the quality of Nd: GGG crystals grown by Czochralski method. Crystal Research and Technology, 2011, 46(12): 1229. |

| [17] | KHODAMORADI H, TAVAKOLI M H, MOHAMMADI K. Influence of crucible and coil geometry on the induction heating process in Czochralski crystal growth system. Journal of Crystal Growth, 2015, 421: 66. |

| [18] | NGUYEN T H U, CHEN J C, CHEN C C. Effects of different crucible shapes on heat and oxygen transport during continuous Czochralski silicon crystal growth. Journal of Crystal Growth, 2024, 626: 127474. |

| [19] | QIN J, SUN J, HAO Y X, et al. Effect of exposed crucible wall on the Czochralski growth of an LN crystal. CrystEngComm, 2023, 25(3): 450. |

| [20] | 闵乃本. 晶体生长的物理基础. 南京: 南京大学出版社, 2019: 21-23 |

| [21] | TSUKADA T, KAKINOKI K, HOZAWA M, et al. Numerical and experimental studies on crack formation in LiNbO3 single crystal. Journal of Crystal Growth, 1997, 180(3/4): 543. |

| [22] | ZHONG W Z, LUO H S, HUA S K. Growth units and crystal morphology of lithium niobate (LN) crystal. Journal of Synthetic Crystals, 1994, 23(4): 255. |

| [23] | HUA S K, JAN Y, ZHONG W Z. Crystallisation habits of lithium niobate crystals. Journal of Synthetic Crystals, 1983, 12(1): 7. |

| [24] | MIN N B. Cellular interface and cellular structure due to constitutional supercooling in Czochralski growth LiNbO3 single crystals. Acta Physics Sinica, 1979, 28(1): 33. |

| [25] | MIN N B, ZHOU F Q. Experimental investigation of stability of planar crystal-melt interface and evolution of cellular interface during Czochralski growth of LiNbO3 single crystals doped with yttrium. Acta Physica Sinica, 1986, 35(12): 1603. |

| [1] | LI Xianke, ZHANG Chaoyi, HUANG Lin, SUN Peng, LIU Bo, XU Jun, TANG Huili. High-quality Indium-doped Gallium Oxide Single Crystal Growth by Floating Zone Method [J]. Journal of Inorganic Materials, 2024, 39(12): 1384-1390. |

| [2] | CAI Hao, WANG Qihang, ZOU Zhaoyong. Crystallization Pathway of Monohydrocalcite via Amorphous Calcium Carbonate Regulated by Magnesium Ion [J]. Journal of Inorganic Materials, 2024, 39(11): 1275-1282. |

| [3] | QIN Juan, LIANG Dandan, SUN Jun, YANG Jinfeng, HAO Yongxin, LI Qinglian, ZHANG Ling, XU Jingjun. Flat Shoulder Congruent Lithium Niobate Crystals Grown by the Czochralski Method [J]. Journal of Inorganic Materials, 2023, 38(8): 978-986. |

| [4] | LIN Siqi, LI Airan, FU Chenguang, LI Rongbing, JIN Min. Crystal Growth and Thermoelectric Properties of Zintl Phase Mg3X2 (X=Sb, Bi) Based Materials: a Review [J]. Journal of Inorganic Materials, 2023, 38(3): 270-279. |

| [5] | YANG Jiaxue, LI Wen, WANG Yan, ZHU Zhaojie, YOU Zhenyu, LI Jianfu, TU Chaoyang. Spectroscopic and Yellow Laser Features of Dy3+: Y3Al5O12 Single Crystals [J]. Journal of Inorganic Materials, 2023, 38(3): 350-356. |

| [6] | WU Zhen, LI Huifang, ZHANG Zhonghan, ZHANG Zhen, LI Yang, LAN Jianghe, SU Liangbi, WU Anhua. Growth and Characterization of CeF3 Crystals for Magneto-optical Application [J]. Journal of Inorganic Materials, 2023, 38(3): 296-302. |

| [7] | SUN Han, LI Wenjun, JIA Zixuan, ZHANG Yan, YIN Liying, JIE Wanqi, XU Yadong. Effect of ACRT Technology on the Large Size ZnTe Crystals Grown by Solution Method and Corresponding Terahertz Properties [J]. Journal of Inorganic Materials, 2023, 38(3): 310-315. |

| [8] | QI Xuejun, ZHANG Jian, CHEN Lei, WANG Shaohan, LI Xiang, DU Yong, CHEN Junfeng. Macroscopic Defects of Large Bi12GeO20 Crystals Grown Using Vertical Bridgman Method [J]. Journal of Inorganic Materials, 2023, 38(3): 280-287. |

| [9] | QI Zhanguo, LIU Lei, WANG Shouzhi, WANG Guogong, YU Jiaoxian, WANG Zhongxin, DUAN Xiulan, XU Xiangang, ZHANG Lei. Progress in GaN Single Crystals: HVPE Growth and Doping [J]. Journal of Inorganic Materials, 2023, 38(3): 243-255. |

| [10] | ZHANG Chaoyi, TANG Huili, LI Xianke, WANG Qingguo, LUO Ping, WU Feng, ZHANG Chenbo, XUE Yanyan, XU Jun, HAN Jianfeng, LU Zhanwen. Research Progress of ScAlMgO4 Crystal: a Novel GaN and ZnO Substrate [J]. Journal of Inorganic Materials, 2023, 38(3): 228-242. |

| [11] | CHEN Kunfeng, HU Qianyu, LIU Feng, XUE Dongfeng. Multi-scale Crystallization Materials: Advances in in-situ Characterization Techniques and Computational Simulations [J]. Journal of Inorganic Materials, 2023, 38(3): 256-269. |

| [12] | WANG Haidong, WANG Yan, ZHU Zhaojie, LI Jianfu, LAKSHMINARAYANA Gandham, TU Chaoyang. Crystal Growth and Structural, Optical, and Visible Fluorescence Traits of Dy3+-doped SrGdGa3O7 Crystal [J]. Journal of Inorganic Materials, 2023, 38(12): 1475-1482. |

| [13] | MING Yue, HU Yue, MEI Anyi, RONG Yaoguang, HAN Hongwei. Application of Lead Acetate Additive for Printable Perovskite Solar Cell [J]. Journal of Inorganic Materials, 2022, 37(2): 197-203. |

| [14] | MENG Meng, QI Qiang, DING Dongzhou, HE Chongjun, ZHAO Shuwen, WAN Bo, CHEN Lu, SHI Junjie, REN Guohao. Twisted Growth, Component Segregation and Characteristics of Gd3(Al,Ga)5O12:Ce Scintillation Crystal [J]. Journal of Inorganic Materials, 2021, 36(2): 188-196. |

| [15] | XU Jiayue, LI Zhichao, PAN Yunfang, ZHOU Ding, WEN Feng, MA Wenjun. Research Progress of Hyperstoichiometric UO2 Crystals [J]. Journal of Inorganic Materials, 2020, 35(11): 1183-1192. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||