Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (9): 983-990.DOI: 10.15541/jim20210659

• RESEARCH ARTICLE • Previous Articles Next Articles

SHENG Lili1,2( ), CHANG Jiang1,2(

), CHANG Jiang1,2( )

)

Received:2021-10-25

Revised:2022-12-24

Published:2022-09-20

Online:2022-01-24

Contact:

CHANG Jiang, professor. E-mail: jchang@mail.sic.ac.cnAbout author:SHENG Lili (1992-), female, PhD candidate. E-mail: lilissic@163.com

Supported by:CLC Number:

SHENG Lili, CHANG Jiang. Photo/Magnetic Thermal Fe2SiO4/Fe3O4 Biphasic Bioceramic and Its Composite Electrospun Membrane: Preparation and Antibacterial[J]. Journal of Inorganic Materials, 2022, 37(9): 983-990.

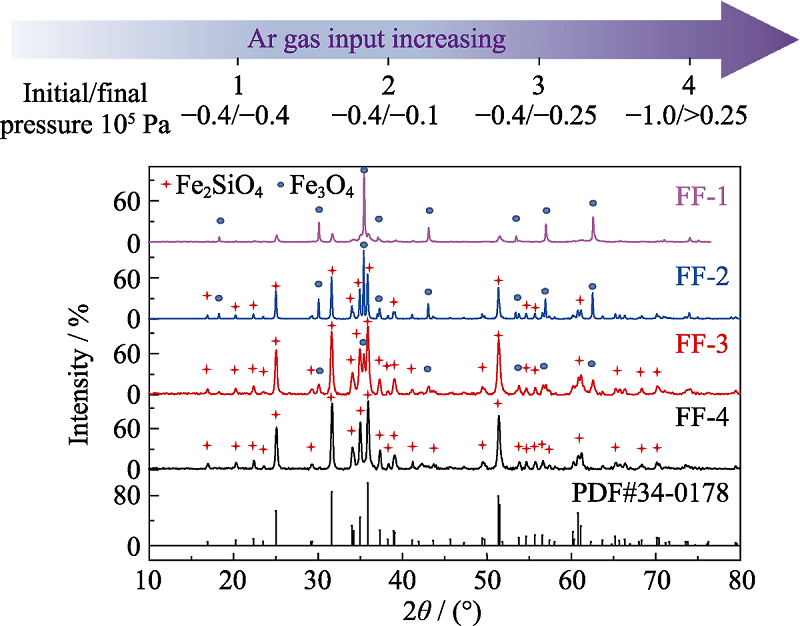

Fig. 2 XRD patterns of FF products calcined at 800 ℃ in different atmospheres FF-1: the product obtained by calcining without argon gas; FF-2-FF-4: the product obtained by calcining with argon gas at 10, 25 and >25 kPa in the furnace, respectively.

| Powder | Fe ion/(μg·mL-1) | Silicate ion/(μg·mL-1) |

|---|---|---|

| FF-1 | 43.96 | 70.12 |

| FF-2 | 28.37 | 40.23 |

| FF-3 | 13.62 | 27.16 |

| FF-4 | 5.76 | 12.68 |

Table 1 Ion release of powders prepared under different conditions after 24 h being submersed in cell culture medium ECM

| Powder | Fe ion/(μg·mL-1) | Silicate ion/(μg·mL-1) |

|---|---|---|

| FF-1 | 43.96 | 70.12 |

| FF-2 | 28.37 | 40.23 |

| FF-3 | 13.62 | 27.16 |

| FF-4 | 5.76 | 12.68 |

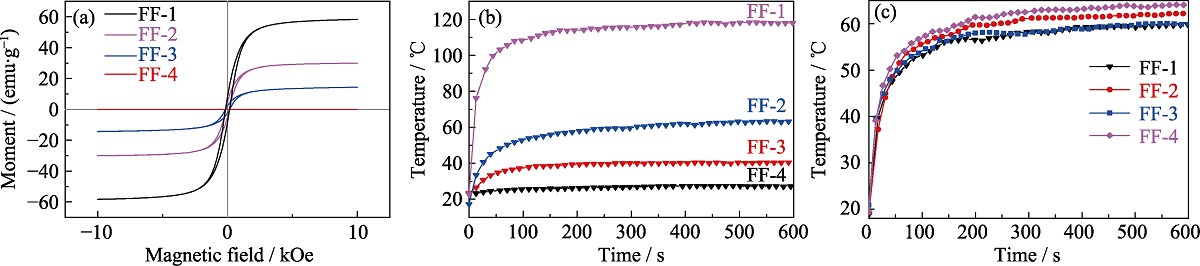

Fig. 3 Magnetothermal and photothermal properties of powder products after being calcined under different conditions (a) Magnetic analysis results; (b) Results of thermal performance of different powders under alternating magnetic field intensity of 506 kHz at 837 A·m-1; (c) Photothermal performance of different powders under 808 nm near-infrared light irradiation at a density of 0.36 W·cm-2. FF-1: the product obtained by calcining without argon gas; FF-2-FF-4: the product obtained by calcining with argon gas at 10, 25 and >25 kPa in the furnace, respectively. 1 emu=103 A·m-1, 1 Oe=1000/4π A/m Colorful figures are available on website

Fig. 5 SEM and TEM images of FF-2 powders (a, b) SEM images at low (a) and high (b) magnification; (c) TEM high-resolution image of the powder with inset showing electron diffraction pattern of the powder

Fig. 6 Morphologies of composite electrospun membranes with different FF-2 powder compositing amounts (a) Optical photos; (b) SEM images. 0, 10, 20, 30, and 40 in the figures represent composite membranes with powder contents of 0, 10%, 20%, 30%, and 40%, respectively

| Powder content/% | Fe ion/(μg·mL-1) | Silicate ion/(μg·mL-1) |

|---|---|---|

| 0 | 0 | 0 |

| 10 | 0.05 | 0.27 |

| 20 | 0.13 | 1.45 |

| 30 | 0.32 | 2.76 |

| 40 | 0.61 | 5.98 |

Table 2 Ion release properties of composite electrospun films with different powder contents in cell culture medium ECM

| Powder content/% | Fe ion/(μg·mL-1) | Silicate ion/(μg·mL-1) |

|---|---|---|

| 0 | 0 | 0 |

| 10 | 0.05 | 0.27 |

| 20 | 0.13 | 1.45 |

| 30 | 0.32 | 2.76 |

| 40 | 0.61 | 5.98 |

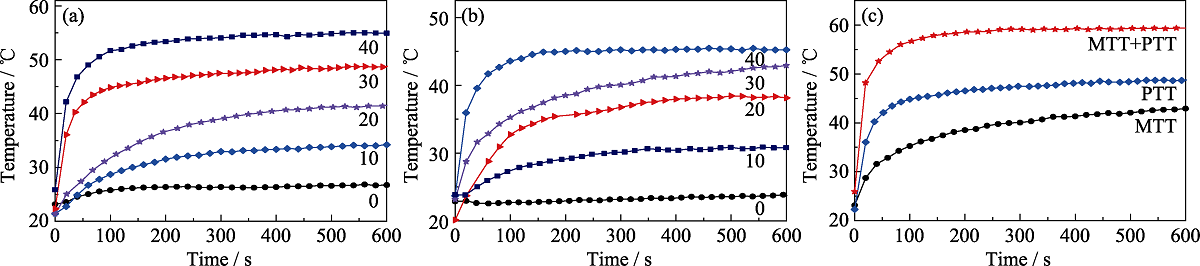

Fig. 7 Photothermal and magnetothermal properties of composite membranes with different powder contents (a) Under NIR light (0.36 W·cm-2) irradiation at a wavelength of 808 nm; (b) In an alternating magnetic field (506 kHz, 837A·m-1); (c) Composite film with 30% powder content under laser, alternating magnetic field and laser in combination with alternating magnetic field, respectively. 0, 10, 20, 30, and 40 in the figures represent composite membranes with powder contents of 0, 10%, 20%, 30%, and 40%, respectively. MTT: magnetothermal; PTT: photothermal; MTT+PTT: combined photothermal and magnetothermal

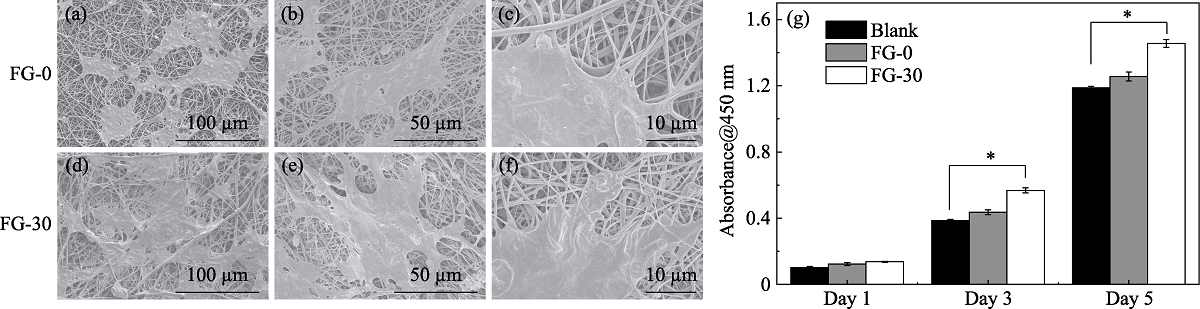

Fig. 8 Cytocompatibility of FG-30 composite electrospun membranes (a-f) SEM images of cell adhesion on FG-0 membrane (a-c) and FG-30 composite membrane (d-f) after 24 h of HUVEC culture, respectively; (g) Effect of composite membrane on HUVECs proliferation. Blank, FG-0, and FG-30 in the figures indicate blank control group, FG-0 electrospun membrane group, and FG-30 composite electrospun membrane group, respectively. * indicates p<0.05 which means significant difference between groups

Fig. 9 Combined photo/magneto-thermal inhibition of S.aureus by FG-30 composite membrane (a) Optical photographs of colony coated plates; (b) Statistical results of inhibition rate. Blank, FG-0, FG-30, FG-30 (MTT), FG-30 (PTT), and FG-30 (MTT+PTT) denote blank control, FG-0 membrane, FG-30 membrane, FG-30 membrane with magnetothermal, FG-30 membrane with photothermal, FG-30 membrane with combined photothermal and magnetothermal, respectively. * indicates p<0.05 which means significant difference between groups

| [1] |

BELKAID Y, TAMOUTOUNOUR S. The influence of skin microorganisms on cutaneous immunity. Nature Reviews Immunology, 2016, 16(6): 353-366.

DOI URL |

| [2] |

FALANGA V. Wound healing and its impairment in the diabetic foot. Lancet, 2005, 366(9498): 1736-1743.

DOI URL |

| [3] |

ROBSON M. Wound infection - a failure of wound healing caused by an imbalance of bacteria. Surgical Clinics of North America, 1997, 77(3): 637-650.

DOI URL |

| [4] |

LI P L, HAN F X, CAO W W, et al. Carbon quantum dots derived from lysine and arginine simultaneously scavenge bacteria and promote tissue repair. Applied Materials Today, 2020, 19(1): 100601.

DOI URL |

| [5] |

XIE X, WU J R, CAI X J, et al. Photothermal/pH response B-CuS-DOX nanodrugs for chemo-photothermal synergistic therapy of tumor. Journal of Inorganic Materials, 2020, 36(1): 81-87.

DOI URL |

| [6] |

ZENG Y L, CHEN J J, TIAN Z F, et al. Preparation of mesoporous organosilica-based nanosystem for in vitro synergistic chemo-and photothermal therapy. Journal of Inorganic Materials, 2020, 35(12): 1365-1372.

DOI URL |

| [7] |

ZHAO L Y, LIU Y M, XING R R, et al. Supramolecular photothermal effects: a promising mechanism for efficient thermal conversion. Angewandte Chemie International Edition, 2020, 59(10): 3793-3801.

DOI URL |

| [8] |

WU G Z, WU Z Y, LIU L, et al. NIR light responsive MoS2 nanomaterials for rapid sterilization: optimum photothermal effect via sulfur vacancy modulation. Chemical Engineering Journal, 2022, 427(1): 132007.

DOI URL |

| [9] |

CHEN R, ROMERO G, CHRISTIANSEN M G, et al. Wireless magnetothermal deep brain stimulation. Science, 2015, 347(6229): 1477-1480.

DOI URL |

| [10] |

LI W, WEI W Y, WU X P, et al. The antibacterial and antibiofilm activities of mesoporous hollow Fe3O4 nanoparticles in an alternating magnetic field. Biomaterials Science, 2020, 8(16): 4492-4507.

DOI URL |

| [11] |

ZHUANG H, LIN R C, LIU Y Q, et al. 3D-printed bioceramic scaffolds with osteogenic activity for simultaneous photo-magnetothermal therapy of bone tumor. ACS Biomaterials Science and Engineering, 2019, 5(12): 6725-6734.

DOI URL |

| [12] |

FU D P, LIU J L, REN Q L, et al. Magnetic iron sulfide nanoparticles as thrombolytic agents for magnetocaloric therapy and photothermal therapy of thrombosis. Frontiers in Materials, 2019, 6(1): 316.

DOI URL |

| [13] |

LIU J C, GUO X, ZHAO Z, et al. Fe3S4 nanoparticles for arterial inflammation therapy: integration of magnetic hyperthermia and photothermal treatment. Applied Materials Today, 2020, 18(1): 100457.

DOI URL |

| [14] |

LI H Y, CHANG J. Stimulation of proangiogenesis by calcium silicate bioactive ceramic. Acta Biomaterialia, 2013, 9(2): 5379-5389.

DOI URL |

| [15] |

ZHAI W Y, LU H X, CHEN L, et al. Silicate bioceramics induce angiogenesis during bone regeneration. Acta Biomaterialia, 2012, 8(1): 341-349.

DOI URL |

| [16] |

YU Q Q, CHANG J, WU C. Silicate bioceramics: from soft tissue regeneration to tumor therapy. Journal of Material Chemistry B, 2019, 7(36): 5449-5460.

DOI URL |

| [17] |

MAO L X, XIA L G, CHANG J, et al. The synergistic effects of Sr and Si bioactive ions on osteogenesis, osteoclastogenesis and angiogenesis for osteoporotic bone regeneration. Acta Biomaterialia, 2017, 61(1): 217-232.

DOI URL |

| [18] | GAO L, ZhOU Y L, PENG J L, et al. A novel dual-adhesive and bioactive hydrogel activated by bioglass for wound healing. NPG Asia Materials, 2019, 11: 66. |

| [19] | WEINTRAUB L R, GORAL A, GRASSO J, et al. Collagen biosynthesis in iron overload. Annals of the New York Academy of Sciences, 1988, 526(1): 179-184. |

| [20] |

SHENG L, ZHANG Z, ZHANG Y, et al. A novel “hot spring”-mimetic hydrogel with excellent angiogenic properties for chronic wound healing. Biomaterials, 2020, 264(1): 120414.

DOI URL |

| [21] |

XING M, HUAN Z G, LI Q, et al. Containerless processing of Ca-Sr-Si system bioactive materials: thermophysical properties and ion release behaviors. Ceramics International, 2017, 43(6): 5156-5163.

DOI URL |

| [22] |

LI H Y, CHANG J. Bioactive silicate materials stimulate angiogenesis in fibroblast and endothelial cell co-culture system through paracrine effect. Acta Biomaterialia, 2013, 9(6): 6981-6991.

DOI URL |

| [23] |

XING M, WANG X Y, WANG E D, et al. Bone tissue engineering strategy based on the synergistic effects of silicon and strontium ions. Acta Biomaterialia, 2018, 72(1): 381-395.

DOI URL |

| [24] |

ZHANG J, SHI H S, LIU J Q, et al. Good hydration and cell-biological performances of superparamagnetic calcium phosphate cement with concentration-dependent osteogenesis and angiogenesis induced by ferric iron. Journal of Materials Chemistry B, 2015, 3(45): 8782-8795.

DOI URL |

| [25] |

WU M, DEOKAR A R, LIAO J, et al. Graphene-based photothermal agent for rapid and effective killing of bacteria. ACS Nano, 2013, 7(2): 1281-1290.

DOI URL |

| [26] |

IBELLI T, TEMPLETON S, LEVI-POLYACHENKO N. Progress on utilizing hyperthermia for mitigating bacterial infections. International Journal of Hyperthermia, 2018, 34(2): 144-156.

DOI URL |

| [1] | TANG Xinli, DING Ziyou, CHEN Junrui, ZHAO Gang, HAN Yingchao. In vivo Distribution and Metabolism of Calcium Phosphate Nanomaterials Based on Fluorescent Labeling with Rare Earth Europium Ions [J]. Journal of Inorganic Materials, 2025, 40(7): 754-764. |

| [2] | DONG Chenyu, ZHENG Weijie, MA Yifan, ZHENG Chunyan, WEN Zheng. Characterizations by Piezoresponse Force Microscopy on Relaxor Properties of Pb(Mg,Nb)O3-PbTiO3 Ultra-thin Films [J]. Journal of Inorganic Materials, 2025, 40(6): 675-682. |

| [3] | TANG Ying, LI Jie, XIANG Huaicheng, FANG Weishuang, LIN Huixing, YANG Junfeng, FANG Liang. Rattling Effect: A New Mechanism Affecting the Resonant Frequency Temperature Coefficient of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 656-666. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | ZHOU Houlin, SONG Zhiqing, TIAN Guo, GAO Xingsen. Effects of Growth Conditions on the Formation of Self-assembly Grown Topological Domain in BiFeO3 Nanoislands [J]. Journal of Inorganic Materials, 2025, 40(6): 667-674. |

| [6] | CHEN Libo, SHENG Ying, WU Ming, SONG Jiling, JIAN Jian, SONG Erhong. Na and O Co-doped Carbon Nitride for Efficient Photocatalytic Hydrogen Evolution [J]. Journal of Inorganic Materials, 2025, 40(5): 552-562. |

| [7] | SUN Yuxuan, WANG Zheng, SHI Xue, SHI Ying, DU Wentong, MAN Zhenyong, ZHENG Liaoying, LI Guorong. Defect Dipole Thermal-stability to the Electro-mechanical Properties of Fe Doped PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 545-551. |

| [8] | PAN Yuzhou, HE Fajian, XU Lulu, DAI Shixun. Broadband 3 μm Mid-infrared Emission in Dy3+/Yb3+ Co-doped Tellurite Glass under 980 nm LD Excitation [J]. Journal of Inorganic Materials, 2025, 40(5): 521-528. |

| [9] | XIONG Siyu, MO Chen, ZHU Xiaowei, ZHU Guobin, CHEN Deqin, LIU Laijun, SHI Xiaodong, LI Chunchun. Low-temperature Sintering of LiBxAl1-xSi2O6 Microwave Dielectric Ceramics with Ultra-low Permittivity [J]. Journal of Inorganic Materials, 2025, 40(5): 536-544. |

| [10] | YANG Mingkai, HUANG Zeai, ZHOU Yunxiao, LIU Tong, ZHANG Kuikui, TAN Hao, LIU Mengying, ZHAN Junjie, CHEN Guoxing, ZHOU Ying. Co-production of Few-layer Graphene and Hydrogen from Methane Pyrolysis Based on Cu and Metal Oxide-KCl Molten Medium [J]. Journal of Inorganic Materials, 2025, 40(5): 473-480. |

| [11] | FAN Xiaoxuan, ZHENG Yonggui, XU Lirong, YAO Zimin, CAO Shuo, WANG Kexin, WANG Jiwei. Organic Pollutant Fenton Degradation Driven by Self-activated Afterglow from Oxygen-vacancy-rich LiYScGeO4: Bi3+ Long Afterglow Phosphor [J]. Journal of Inorganic Materials, 2025, 40(5): 481-488. |

| [12] | LI Jianjun, CHEN Fangming, ZHANG Lili, WANG Lei, ZHANG Liting, CHEN Huiwen, XUE Changguo, XU Liangji. Peroxymonosulfate Activation by CoFe2O4/MgAl-LDH Catalyst for the Boosted Degradation of Antibiotic [J]. Journal of Inorganic Materials, 2025, 40(4): 440-448. |

| [13] | XUE Ke, CAI Changkun, XIE Manyi, LI Shuting, AN Shengli. Pr1+xBa1-xFe2O5+δ Cathode Materials for Solid Oxide Fuel Cells: Preparation and Electrochemical Performance [J]. Journal of Inorganic Materials, 2025, 40(4): 363-371. |

| [14] | WANG Yue, WANG Xin, YU Xianli. Room-temperature Ferromagnetic All-carbon Films Based on Reduced Graphene Oxide [J]. Journal of Inorganic Materials, 2025, 40(3): 305-313. |

| [15] | HAO Yongxin, SUN Jun, YANG Jinfeng, ZHAO Chencheng, LIU Ziqi, LI Qinglian, XU Jingjun. Twinning Defects in Near-stoichiometric Lithium Niobate Single Crystals [J]. Journal of Inorganic Materials, 2025, 40(2): 196-204. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||