Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (5): 502-508.DOI: 10.15541/jim20160429

• Orginal Article • Previous Articles Next Articles

ZHANG Cui-Ping, GAO Xiang-Wei, RU Hong-Qiang, SUN Wei-Kang, ZHU Jing-Hui, ZONG Hui

Received:2016-07-18

Revised:2016-10-08

Published:2017-05-20

Online:2017-05-02

About author:ZHANG CUI-PING. E-mail: zhangcp@smm.neu.edu.cn

Supported by:CLC Number:

ZHANG Cui-Ping, GAO Xiang-Wei, RU Hong-Qiang, SUN Wei-Kang, ZHU Jing-Hui, ZONG Hui. Effect of Forming Pressure on Microstructure and Mechanical Properties of SiC/TiB2 Composites[J]. Journal of Inorganic Materials, 2017, 32(5): 502-508.

Fig. 3 Backscattered SEM micrographs of SiC/TiB2 composites prepared at various forming pressures (a) 50 MPa; (b) 100 MPa; (c) 150 MPa; (d) 200 MPa; (e) 250 MPa

| Number | Forming pressures/ MPa | Compositions and densities of SiC/TiB2 composites | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| \(\rho_{TiB_2}/\%\) | vSiC/ % | vSi/ % | \(w_{TiB_2}/\%\) | wSiC/ % | wSi/ % | ρt/ (g·cm-3) | ρv/ g·cm-3 | ρr/ % | ε/ % | ||

| 1# | 50 | 46.83 | 19.11 | 34.06 | 60.07 | 17.41 | 22.52 | 3.52 | 3.45 | 98.01 | 0.48 |

| 2# | 100 | 50.81 | 20.74 | 28.45 | 63.35 | 18.36 | 18.29 | 3.62 | 3.54 | 97.79 | 0.69 |

| 3# | 150 | 53.33 | 21.77 | 24.90 | 65.34 | 18.94 | 15.72 | 3.69 | 3.56 | 96.48 | 0.62 |

| 4# | 200 | 54.19 | 22.12 | 23.69 | 66.00 | 19.13 | 14.87 | 3.71 | 3.63 | 97.84 | 0.89 |

| 5# | 250 | 54.31 | 22.17 | 23.52 | 66.09 | 19.15 | 14.76 | 3.71 | 3.61 | 97.30 | 0.71 |

Table 1 Compositions and densities of SiC/TiB2 composites

| Number | Forming pressures/ MPa | Compositions and densities of SiC/TiB2 composites | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| \(\rho_{TiB_2}/\%\) | vSiC/ % | vSi/ % | \(w_{TiB_2}/\%\) | wSiC/ % | wSi/ % | ρt/ (g·cm-3) | ρv/ g·cm-3 | ρr/ % | ε/ % | ||

| 1# | 50 | 46.83 | 19.11 | 34.06 | 60.07 | 17.41 | 22.52 | 3.52 | 3.45 | 98.01 | 0.48 |

| 2# | 100 | 50.81 | 20.74 | 28.45 | 63.35 | 18.36 | 18.29 | 3.62 | 3.54 | 97.79 | 0.69 |

| 3# | 150 | 53.33 | 21.77 | 24.90 | 65.34 | 18.94 | 15.72 | 3.69 | 3.56 | 96.48 | 0.62 |

| 4# | 200 | 54.19 | 22.12 | 23.69 | 66.00 | 19.13 | 14.87 | 3.71 | 3.63 | 97.84 | 0.89 |

| 5# | 250 | 54.31 | 22.17 | 23.52 | 66.09 | 19.15 | 14.76 | 3.71 | 3.61 | 97.30 | 0.71 |

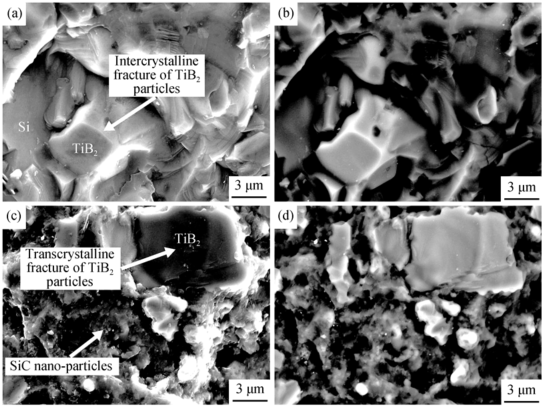

Fig. 6 SEM micrographs of fracture surfaces of SiC/TiB2 composites prepared at various forming pressures 50 Mpa; (a) Secondary electron micrograph; (b) Backscattered electron micrograph. 250 Mpa; (c) Secondary electron micrograph; (d) Backscattered electron micrograph

| [1] | MUNRO R G.Material properties of titanium diboride.J. Res. Natl. Inst. Stan., 2000, 105(5): 709-720. |

| [2] | MURTHY T S R CH, SONBER J K, VISHWANADH B, et al. Densification, characterization and oxidation studies of novel TiB2+EuB6 compounds.J. Alloys Compd., 2016, 670(4): 85-95. |

| [3] | LUO X T, XIE X L, YUAN R Z.Microstructure and mechanical properties of hot-pressed TiB2 ceramics.J. Inorg. Mater., 2000, 15(3): 541-545. |

| [4] | NAMINI A S, GOGANI S N S, ASL M S, et al. Microstructural development and mechanical properties of hot pressed SiC reinforced TiB2 based composite.Int. J. Refract. Met. H., 2015, 51: 169-179. |

| [5] | ZHAO G L, HUANG C Z, LIU H L, et al.Microstructure and mechanical properties of hot pressed TiB2-SiC composite ceramic tool materials at room and elevated temperatures.Mat. Sci. Eng. A-Struct., 2014, 606: 108-116. |

| [6] | CHEN H B, WANG Z, WU Z J.Investigation and characterization of densification, processing and mechanical properties of TiB2-SiC ceramics.Mater. Design, 2014, 64(9): 9-14. |

| [7] | LIN J, YANG Y H, ZHANG H A, et al.Microstructure and mechanical properties of TiB2 ceramics enhanced by SiC particles and carbon nanotubes.Ceram. Int., 2016, 42(3): 4627-4631. |

| [8] | WEN G, LI S B, ZHANG B S, et al.Reaction synthesis of TiB2-TiC composites with enhanced toughness.Acta Mater., 2001, 49(8): 1463-1470. |

| [9] | WANG H, WANG W M, GU P, et al.Mechanical properties and structure of TiB2-NbB2 composite prepared by hot pressing.J. Inorg. Mater., 2002, 17(3): 703-707. |

| [10] | WYZGA P, JAWORSKA L, BUCKO M M, et al.TiB2-TiN composites prepared by various sintering techniques.Int. J. Refract. Met. H., 2013, 41(3): 571-576. |

| [11] | TIAN W B, KITA H, HYUGA H, et al.Synthesis, microstructure and mechanical properties of reaction-infiltrated TiB2-SiC-Si composites.J. Alloy. Compd., 2011, 5(9): 1819-1823. |

| [12] | ZHANG C P, RU H Q, HE R P, et al.Preparation and properties of TiB2-SiC-Si composites fabricated by reaction bonding.Key Eng. Mater., 2016, 697: 539-546. |

| [13] | VOYTOVYCH R, BOUGIOURI V, CALDERON N R, et al.Reactive infiltration of porous graphite by NiSi alloys.Acta Mater., 2008, 56(10): 2237-2246. |

| [14] | WANG Y X, TAN S H, JIANG D L.The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC.Carbon, 2004, 42(8-9): 1833-1839. |

| [15] | 黄培云. 粉末冶金原理, 2版. 北京: 冶金工业出版社, 1997, 173-195. |

| [16] | HUMPHREYS F J.Quantitative metallography by electron backscattered diffraction.J. Microsc-oxford, 1999, 195(3): 170-185. |

| [17] | YURKOV A L, STARCHENKO A M, SKIDAN B S.Reaction sintering of boron carbide.Refract. Ind. Ceram., 1989, 30(11/12): 731-736. |

| [18] | MOON H, KIM B, KANG S J L. Growth mechanism of round-edged NbC grains in Co liquid.Acta Mater., 2001, 49(7): 1293-1299. |

| [19] | MALLICK D, KAYAL T K, GHOSH J, et al.Development of multi-phase B-Si-C ceramic composite by reaction sintering.Ceram. Int., 2009, 35(4): 1667-1669. |

| [20] | 赵祖德. 复合材料固-液成形理论与工艺. 北京: 冶金工业出版社, 2008: 5-6. |

| [21] | ENGEL U, HUBNER H.Strength improvement of cemented carbides by hot isostatic pressing (HIP).J. Mater. Sci., 1978, 13(9): 2003-2012. |

| [22] | KRUZIC J J, SATET R L, HOFFMANN M J, et al.The utility of R-curves for understanding fracture toughness-strength.J. Am. Ceram. Soc., 2008, 91(6): 1986-1994. |

| [23] | SKOROKHOD V, KRSTIC V D.High strength-high toughness B4C-TiB2 composites.J. Mater. Sci. Lett., 2000, 19(3): 237-239. |

| [24] | CHANTIKUL P, BENNISON S J, LAWN B R.Role of grain size in the strength and R-curve properties of alumina. J. Am. Ceram. Soc., 1990, 73(8): 2419-2427. |

| [25] | 龚江宏. 陶瓷材料断裂力学. 北京: 清华大学出版社, 2001: 138-141. |

| [26] | CHOI S R, SANDERS W A, SALEM J A, et al.Young’s modulus, strength and fracture toughness as a function of density of in situ toughened silicon nitride with 4wt% scandia.J. Mater. Sci. Lett., 1995, 14(4): 276-278. |

| [27] | HUTCHINSON J W, SUO Z.Mixed mode cracking in layered materials.Adv. Appl. Mech., 1991, 29(08): 63-191. |

| [28] | KING D S, FAHRENHOLTZ W G, HILMAS G E.Silicon carbide- titanium diboride ceramic composites.J. Eur. Ceram. Soc., 2013, 33(s15-16): 2943-2951. |

| [29] | HAYUN S, DILMAN H, DARIEL M P, et al.The effect of aluminum on the microstructure and phase composition of boron carbide infiltrated with silicon.Mater. Chem. Phys., 2009, 118(2): 490-495. |

| [30] | RICE R W, WU C C, BOICHELT F.Hardness-grain-size relations in ceramics.J. Am. Ceram. Soc., 1994, 77(10): 2539-2553. |

| [1] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [2] | XU Puhao, ZHANG Xiangzhao, LIU Guiwu, ZHANG Mingfen, GUI Xinyi, QIAO Guanjun. Microstructure and Mechanical Properties of SiC Joint Brazed by Al-Ti Alloys as Filler Metal [J]. Journal of Inorganic Materials, 2022, 37(6): 683-690. |

| [3] | LI Longbin, XUE Yudong, HU Jianbao, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Influence of SiC Nanowires on the Damage Evolution of SiCf/SiC Composites [J]. Journal of Inorganic Materials, 2021, 36(10): 1111-1117. |

| [4] | ZHANG Xiao-Yang, PENG Hai-Bo, LIU Feng-Fei, ZHAO Yan, SUN Meng-Li, GUAN Ming, ZHANG Bing-Tao, DU Xin, YUAN Wei, WANG Tie-Shan. Mechanical Properties of Borosilicate Glass with Different Irradiation of Heavy Ions [J]. Journal of Inorganic Materials, 2019, 34(7): 741-747. |

| [5] | Jin-Jie WU, Yan LI, Ren-Chu WEI, Jian-Xin WANG, Shu-Xin QU, Jie WENG, Wei ZHI. Bioactivity and Mechanical Stability of Hydroxyapatite Ceramicsunder Micro-vibration Environment [J]. Journal of Inorganic Materials, 2019, 34(4): 417-424. |

| [6] | PANG Sheng-Yang, WANG Pei-Yao, HU Cheng-Long, ZHAO Ri-Da, TANG Su-Fang. Carbon Fiber Preform's Structure on Mechanical Property of C/C Composites and Bolts [J]. Journal of Inorganic Materials, 2019, 34(12): 1272-1278. |

| [7] | ZHANG Zhou, WANG Hao, TU Bing-Tian, XU Peng-Yu, WANG Wei-Min, FU Zheng-Yi. Characterization and Evaluation on Mechanical Property of Mg0.27Al2.58O3.73N0.27 Transparent Ceramic [J]. Journal of Inorganic Materials, 2018, 33(9): 1006-1010. |

| [8] | NIE Heng-Chang, WANG Yong-Ling, HE Hong-Liang, WANG Gen-Shui, DONG Xian-Lin. Recent Progress of Porous PZT95/5 Ferroelectric Ceramics [J]. Journal of Inorganic Materials, 2018, 33(2): 153-161. |

| [9] | WANG Meng-Qian, JIA Lin-Tao, LI Ai-Jun, PENG Yu-Qing, ZHANG Fang-Zhou. Preparation of Boron Nitride Coating from BCl3-NH3-H2-N2 Precursor by Chemical Vapor Deposition [J]. Journal of Inorganic Materials, 2018, 33(11): 1179-1185. |

| [10] | GAO Jiao-Jiao, JIANG Long-Kai, SONG Jin-Peng, LIANG Guo-Xing, AN Jing, XIE Jun-Cai, CAO Lei, LV Ming. Effects of TiC Content on Microstructure and Mechanical Property of WC-TiC-TaC Cemented Carbides [J]. Journal of Inorganic Materials, 2017, 32(8): 891-896. |

| [11] | ZHANG Chang-Song, LIU Qiang, CHEN Wei. Effect of hBN Content on Property and Microstructure of Si3N4-hBN Composite Ceramics [J]. Journal of Inorganic Materials, 2017, 32(5): 509-516. |

| [12] | QIAO Zhen-Jie, GAO Le, FENG Qian, HU Jian-Bao, DONG Shao-Ming, MA Liang-Lai. Boron Content on Microstructure and Mechanical Properties of Amorphous Boron Carbide by Chemical Vapor Deposition [J]. Journal of Inorganic Materials, 2017, 32(11): 1228-1232. |

| [13] | ZONG Peng-An, CHEN Li-Dong. Preparation and Mechanical Properties of Ce0.85Fe3CoSb12/rGO Thermoelectric Nanocomposite [J]. Journal of Inorganic Materials, 2017, 32(1): 33-38. |

| [14] | SUN Qing-Lei, ZHOU Hong-Qing, QIAN-Lei, WANG Ya-Zhou, ZHU Hai-Kui, YUE Zhen-Xing. Effects of MgO, SrO and La2O3 Co-doping on Structure and Properties of (Zr0.8Sn0.2)TiO4 Ceramics [J]. Journal of Inorganic Materials, 2016, 31(8): 812-818. |

| [15] | SONG Bo, ZHAO Li-Li, CHEN Xiao-Ying, YOU Li-Jun, SONG Li-Xin. Effects of HfO2 Interlayer on Microstructure and Mechanical Property of Al2O3 Thin Film on MgF2 Substrate [J]. Journal of Inorganic Materials, 2016, 31(7): 779-784. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||