Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (4): 431-436.DOI: 10.15541/jim20160384

• Orginal Article • Previous Articles Next Articles

WANG Dong-Wei, DONG Ying-Hao, ZHOU Jie, DUAN Ke, LU Xiong, WANG Jian-Xin, FENG Bo, QU Shu-Xin, WENG Jie

Received:2016-06-17

Revised:2016-10-09

Published:2017-04-20

Online:2017-03-24

About author:WANG Dong-Wei. E-mail: wdw_swjtu@163.com

Supported by:CLC Number:

WANG Dong-Wei, DONG Ying-Hao, ZHOU Jie, DUAN Ke, LU Xiong, WANG Jian-Xin, FENG Bo, QU Shu-Xin, WENG Jie. Low-temperature Preparation of Cu-containing Aluminum Phosphate Coatings on Stainless Steel and Antibacterial Properties[J]. Journal of Inorganic Materials, 2017, 32(4): 431-436.

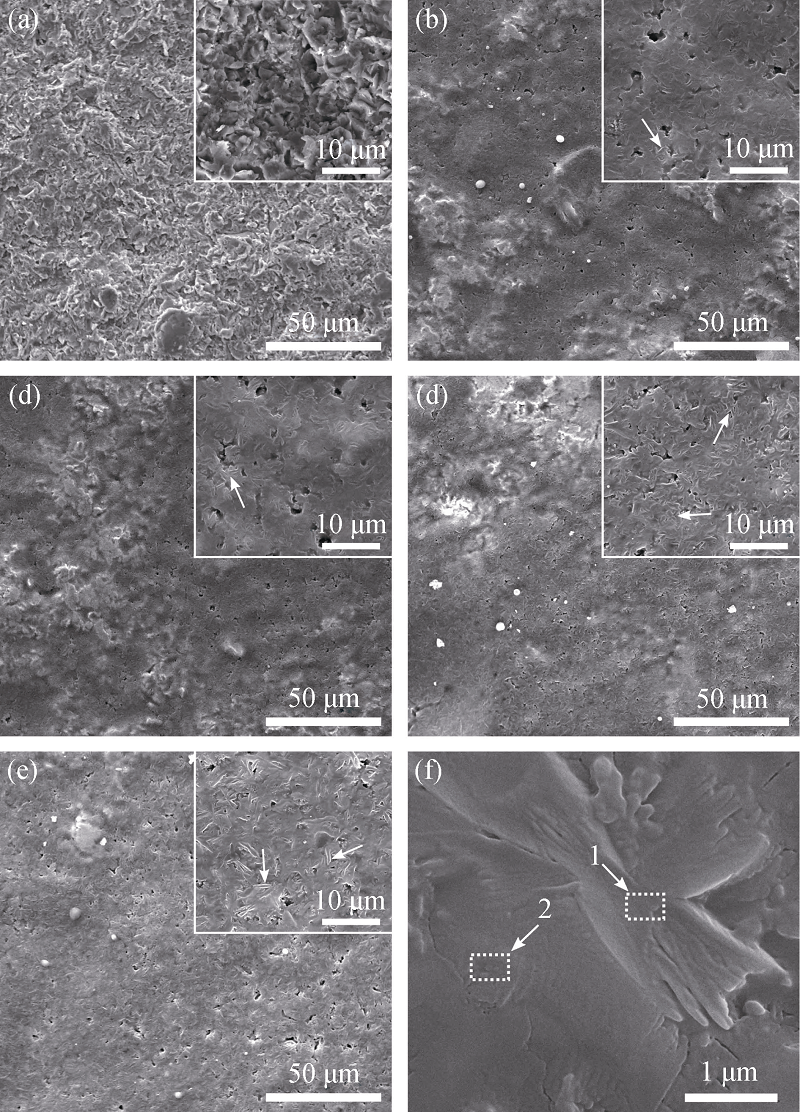

Fig. 3 SEM micrographs of (a) 316 stainless steel (grit- blasted), (b) 316-AlP, (c) 316-AlP-0.025Cu, (d) 316-AlP- 0.05Cu, and (e) 316-AlP-0.1Cu; (f) regions of EDS micro- analysis

| [1] | KASSEM I I.Chinks in the armor: The role of the nonclinical environment in the transmission of Staphylococcus bacteria. American Journal of Infection Control, 2011, 39(7): 539-541. |

| [2] | CHERNOUSOVA S, MATTHIAS E.Silver as antibacterial agent: ion, nanoparticle, and metal. Angewandte Chemie International Edition, 2013, 52(6): 1636-1653. |

| [3] | HE H, WANG J, GO Q, et al.Ag-silica composite nanotubes with controlled wall structures for biomedical applications. Colloids and Surfaces B: Biointerfaces, 2013, 111: 693-698. |

| [4] | GRASS G, RENSING C, SOLIOZ M.Metallic copper as an antimicrobial surface. Applied and Environmental Micribiology, 2011, 77(5): 1541-1547. |

| [5] | WU Q, LI J, ZHANG W, et al.Antibacterial property, angiogenic and osteogenic activity of Cu-incorporated TiO2 coating. Journal of Materials Chemistry B, 2014, 39(2): 6738-6748. |

| [6] | NAN L, YANG W, LIU Y, et al.Antibacterial mechanism of copper-bearing antibacterial stainless steel against E. Coli. Journal of Materials Science and Technology, 2008, 24(2): 197-201. |

| [7] | ZHANG X Y, JIANG L, HUANG X B, et al.Improvement of antibacterial properties of stainless steel by combining plasma Cu and thermal diffusion. Journal of Inorganic Materials, 2012, 27(5): 519-523. |

| [8] | DAN Z, NI H, XU B, et al.Microstructure and antibacterial properties of AISI 420 stainless steel implanted by copper ions. Thin Solid Films, 2005, 492(1): 93-100. |

| [9] | TRAPALIS C C, KOKKORIS M, PERDIKAKIS G, et al.Study of antibacterial composite Cu/SiO2 thin coatings. Journal of Sol-Gel Science and Technology, 2003, 26(1/2/3): 1213-1218. |

| [10] | VASCONCELOS D C L, CARVALHO J A N, MANTEL M, et al. Corrosion resistance of stainless steel coated with Sol-Gel silica, Journal of Non-Crystalline Solids, 2000, 271(1): 135-139. |

| [11] | JAIN S, BUDIANSKY N D, HUDSON J L, et al.Surface spreading of intergranular corrosion on stainless steels. Corrosion Science, 2010, 52(3): 873-885. |

| [12] | HAN H, KIM D.Studies on curing chemistry of aluminum-chromium-phosphates as low temperature curable binders. Journal of Sol-Gel Science and Technology, 2003, 26(1/2/3): 223-228. |

| [13] | HE L, CHEN D, SHANG S.Fabrication and wear properties of Al2O3-SiC ceramic coatings using aluminum phosphate as binder. Journal of Materials Science, 2004, 39(15): 4887-4892. |

| [14] | HAWTHORNE H M, NEVILLE A, TROCZYNSKI T, et al.Characterization of chemically bonded composite-Sol-Gel based alumina coatings on steel substrates. Surface and Coatings Technology. 2004, 176(2): 243-252. |

| [15] | MUNOZ T, PRAKASH A M, KEVAN L, et al.Synthesis and characterization of CuAPO-5 molecular sieves: evidence for the framework incorporation of Cu (II) ions. Journal of Physical Chemistry, 1998, 102(8): 1379-1386. |

| [16] | LIUD M, YANG Q, TROCZYNSKI T.Sol-Gel hydroxyapatite coatings on stainless steel substrates. Biomaterials, 2002, 23(3): 691-698. |

| [17] | MORRIS J H, PERKINS P G, ROSE A E A, et al. The chemistry and binding properties of aluminium phosphates. Chemical Society Reviews, 1977, 6(2): 173-194. |

| [18] | GILMORE R. Phosphoric Acid, Purification, Uses, Technology, and Economics. Boca Raton: CRC Press, 2014: 280. |

| [19] | 周长林. 微生物学与基础免疫学, 2版. 南京: 东南大学出版社, 2008: 123. |

| [20] | KURODA A, NOMURA K, OHTOMO R, et al.Role of inorganic polyphosphate in promoting ribosomal protein degradation by the Lon protease in E. coli. Science, 2001, 293(5530): 705-708. |

| [21] | MATHEWS S, HANS M, MUCKLICH F, et al.Contact killing of bacteria on copper is suppressed if bacteria-metal contact is prevented and is induced on iron by copper ions. Applied and Environmental Microbiology, 2013, 79(8): 2605-2611. |

| [22] | CHEN Z, ZHANG L, ZHOU K C.Research progress of phosphate inorganic binder for high temperature resistance. Materials Science and Engineering of Powder Metallurgy, 2009, 2(14): 74-82. |

| [1] | YANG Mingkai, HUANG Zeai, ZHOU Yunxiao, LIU Tong, ZHANG Kuikui, TAN Hao, LIU Mengying, ZHAN Junjie, CHEN Guoxing, ZHOU Ying. Co-production of Few-layer Graphene and Hydrogen from Methane Pyrolysis Based on Cu and Metal Oxide-KCl Molten Medium [J]. Journal of Inorganic Materials, 2025, 40(5): 473-480. |

| [2] | LIANG Ruihui, ZHONG Xin, HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin. High-temperature Water Vapor Corrosion Behaviors of Environmental Barrier Coatings with Yb2O3-modified Silicon Bond Layer [J]. Journal of Inorganic Materials, 2025, 40(4): 425-432. |

| [3] | HOU Jiaqi, CHEN Ruicong, ZENG Yaoying, ZHOU Lei, ZHANG Jiaping, FU Qiangang. Thermal Shock and Ablation Resistance of SiC Coating Repaired by Gaseous Silicon Infiltration [J]. Journal of Inorganic Materials, 2025, 40(2): 168-176. |

| [4] | WANG Yueyue, HUANG Jiahui, KONG Hongxing, LI Huaizhu, YAO Xiaohong. Silver Loaded Radial Mesoporous Silica: Preparation and Application in Dental Resins [J]. Journal of Inorganic Materials, 2025, 40(1): 77-83. |

| [5] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| [6] | YANG Jialin, WANG Liangjun, RUAN Siyuan, JIANG Xiulin, YANG Chang. Highly Weak-light Sensitive and Dual-band Switchable Photodetector Based on CuI/Si Unilateral Heterojunction [J]. Journal of Inorganic Materials, 2024, 39(9): 1063-1069. |

| [7] | MA Wen, SHEN Zhe, LIU Qi, GAO Yuanming, BAI Yu, LI Rongxing. Preparation of Y2O3 Coating by Suspension Plasma Spraying and Its Resistance to Plasma Etching [J]. Journal of Inorganic Materials, 2024, 39(8): 929-936. |

| [8] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [9] | FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong. Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC [J]. Journal of Inorganic Materials, 2024, 39(6): 647-661. |

| [10] | LI Chengyu, DING Ziyou, HAN Yingchao. In vitro Antibacterial and Osteogenic Properties of Manganese Doped Nano Hydroxyapatite [J]. Journal of Inorganic Materials, 2024, 39(3): 313-320. |

| [11] | GUO Xiaoyang, ZHANG Xiaolin, JIANG Yan, TIAN Yuan, GENG Zhi. Ti-doped Hf(Zr)B2-SiC Anti-ablation Coatings: Preparation and Ablation Resistance Mechanism [J]. Journal of Inorganic Materials, 2024, 39(12): 1357-1366. |

| [12] | ZHANG Zhimin, GE Min, LIN Han, SHI Jianlin. Novel Magnetoelectric Catalytic Nanoparticles: RNS Release and Antibacterial Efficiency [J]. Journal of Inorganic Materials, 2024, 39(10): 1114-1124. |

| [13] | ZHANG Shumin, XI Xiaowen, SUN Lei, SUN Ping, WANG Deqiang, WEI Jie. Sonodynamic and Enzyme-like Activities of Niobium-based Coatings: Antimicrobial, Cell Proliferation and Cell Differentiation [J]. Journal of Inorganic Materials, 2024, 39(10): 1125-1134. |

| [14] | TAO Shunyan, YANG Jiasheng, SHAO Fang, WU Yingchen, ZHAO Huayu, DONG Shaoming, ZHANG Xiangyu, XIONG Ying. Thermal Spray Coatings for Aircraft CMC Hot-end Components: Opportunities and Challenges [J]. Journal of Inorganic Materials, 2024, 39(10): 1077-1083. |

| [15] | HE Qian, TANG Wanlan, HAN Bingkun, WEI Jiayuan, LÜ Wenxuan, TANG Zhaomin. pH Responsive Copper-Doped Mesoporous Silica Nanocatalyst for Enhanced Chemo-Chemodynamic Tumor Therapy [J]. Journal of Inorganic Materials, 2024, 39(1): 90-98. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||