Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (3): 257-262.DOI: 10.15541/jim20150411

• RESEARCH PAPER • Previous Articles Next Articles

ZHANG Bing1( ), JIANG Yuan1, WU Yong-Hong1, LU Yun-Hua2(

), JIANG Yuan1, WU Yong-Hong1, LU Yun-Hua2( ), ZHAO Dan-Dan1, WANG Tong-Hua3(

), ZHAO Dan-Dan1, WANG Tong-Hua3( )

)

Received:2015-08-31

Revised:2015-10-10

Published:2016-03-20

Online:2016-02-24

Supported by:CLC Number:

ZHANG Bing, JIANG Yuan, WU Yong-Hong, LU Yun-Hua, ZHAO Dan-Dan, WANG Tong-Hua. Fabrication of Zeolite Hybrid Supported Carbon Membranes with High Hydrogen Permselective Performance[J]. Journal of Inorganic Materials, 2016, 31(3): 257-262.

| Sample codes | Permeability /Barrer a | Selectivity | |||

|---|---|---|---|---|---|

| H2 | CO2 | N2 | H2/N2 | H2/CO2 | |

| CMZ-0-650 | 47.2 | 41.9 | 3.6 | 13.1 | 1.1 |

| CMZ-0.1wt%-650 | 1474.6 | 324.6 | 15.7 | 93.9 | 4.6 |

| CMZ-0.1wt%-750 | 119.4 | 48.2 | 4.1 | 29.1 | 2.5 |

| CMZ-0.1wt%-850 | 51.8 | 37.9 | 2.7 | 19.1 | 1.4 |

| CMZ-0.3wt%-650 | 776.6 | 96.5 | 11.0 | 70.5 | 8.0 |

| CMZ-0.5wt%-650 | 1029.1 | 102.3 | 15.3 | 67.2 | 10.0 |

| [ | 628.0 | 302.0 | 38.6 | 16.2 | 2.1 |

| [ | 298.1 | 106.8 | 48.9 | 6.1 | 2.8 |

| [ | 308.0 | -- | -- | 2.0 | -- |

Table 1 Data of gas separation performance of carbon membranes

| Sample codes | Permeability /Barrer a | Selectivity | |||

|---|---|---|---|---|---|

| H2 | CO2 | N2 | H2/N2 | H2/CO2 | |

| CMZ-0-650 | 47.2 | 41.9 | 3.6 | 13.1 | 1.1 |

| CMZ-0.1wt%-650 | 1474.6 | 324.6 | 15.7 | 93.9 | 4.6 |

| CMZ-0.1wt%-750 | 119.4 | 48.2 | 4.1 | 29.1 | 2.5 |

| CMZ-0.1wt%-850 | 51.8 | 37.9 | 2.7 | 19.1 | 1.4 |

| CMZ-0.3wt%-650 | 776.6 | 96.5 | 11.0 | 70.5 | 8.0 |

| CMZ-0.5wt%-650 | 1029.1 | 102.3 | 15.3 | 67.2 | 10.0 |

| [ | 628.0 | 302.0 | 38.6 | 16.2 | 2.1 |

| [ | 298.1 | 106.8 | 48.9 | 6.1 | 2.8 |

| [ | 308.0 | -- | -- | 2.0 | -- |

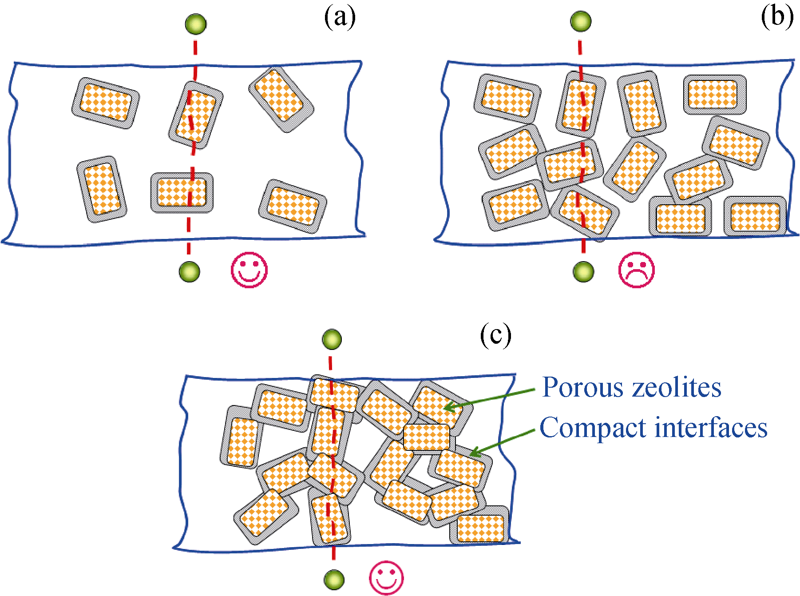

Fig. 5 Schematic of the effect of zeolite content on the permeability for hybrid carbon membranes(a) Low content; (b) Moderate content; (c) High content

| [1] | ABEDINI R, OMIDKHAH M, DOROSTI F.Hydrogen separation and purification with poly (4-methyl-1-pentyne)/MIL 53 mixed matrix membrane based on reverse selectivity.Int. J. Hydrogen Energ., 2014, 39(15): 7897-7909. |

| [2] | ESCOLASTICO S, SOLIS C, SERRA J M.Hydrogen separation and stability study of ceramic membranes based on the system Nd(5)LnWO(12).Int. J. Hydrogen Energ., 2011, 36(18): 11946-11954. |

| [3] | LEWIS A E, ZHAO H B, SYED H, et al. PdAu and PdAuAg composite membranes for hydrogen separation from synthetic water- gas shift streams containing hydrogen sulfide. J. Membr. Sci., 2014, 465: 167-176. |

| [4] | YUN S, OYAMA S T.Correlations in palladium membranes for hydrogen separation: a review.J. Membr. Sci., 2011, 375(1/2): 28-45. |

| [5] | SALLEH W N W, ISMAIL A F, MATSUURA T, et al. Precursor selection and process conditions in the preparation of carbon membrane for gas separation: a review. Sep. Purif. Rev., 2011, 40(4): 261-311. |

| [6] | SAUFI S M, ISMAIL A F.Fabrication of carbon membranes for gas separation--a review.Carbon, 2004, 42(2): 241-259. |

| [7] | ISMAIL A F, DAVID L I B. A review on the latest development of carbon membranes for gas separation.J. Membr. Sci., 2001, 193(1): 1-18. |

| [8] | CHEUNG O, HEDIN N.Zeolites and related sorbents with narrow pores for CO2 separation from flue gas.RSC Adv., 2014, 4(28): 14480-14494. |

| [9] | PAUL D R.Creating new types of carbon-based membranes.Science, 2012, 335(6067): 413-414. |

| [10] | TIN P S, XIAO Y, CHUNG T S.Polyimide‐carbonized membranes for gas separation: structural, composition, and morphological control of precursors.Sep. Purif Rev., 2006, 35(4): 285-318. |

| [11] | ZHANG X, HU H, ZHU Y, et al. Carbon molecular sieve membranes derived from phenol formaldehyde novolac resin blended with poly(ethylene glycol). J. Membr. Sci., 2007, 289(1/2): 86-91. |

| [12] | KABURAGI Y, HISHIYAMA Y, OKA H, et al. Growth of iron clusters and change of magnetic property with carbonization of aromatic polyimide film containing iron complex. Carbon, 2001, 39(4): 593-603. |

| [13] | ZHANG X, LIU H, WANG T, et al. Modification of carbon membranes and preparation of carbon-zeolite composite membranes with zeolite growth. Carbon, 2006, 44(3): 501-507. |

| [14] | TEIXEIRA M, RODRIGUES S C, CAMPO M, et al. Boehmite- phenolic resin carbon molecular sieve membranes— permeation and adsorption studies. Chem. Eng. Res. Des., 2014, 92(11): 2668-2680. |

| [15] | ZHANG B, WANG T, WU Y, et al. Preparation and gas permeation of composite carbon membranes from poly(phthalazinone ether sulfone ketone). Sep. Purif. Technol., 2008, 60(3): 259-263. |

| [16] | ZHANG B, SHI Y, WU Y, et al. Preparation and characterization of supported ordered nanoporous carbon membranes for gas separation. J. Appl. Polym. Sci., 2014, 131(4): 2136-2146. |

| [17] | LI Y, CHUNG T S.Exploratory development of dual-layer carbon- zeolite nanocomposite hollow fiber membranes with high performance for oxygen enrichment and natural gas separation.Micropor. Mesopor. Mat., 2008, 113(1/2/3): 315-324. |

| [18] | ZHANG B, SHI Y, WU Y H, et al. Towards the preparation of ordered mesoporous carbon/carbon composite membranes for gas separation. Sep. Sci. Technol., 2014, 49(2): 171-178. |

| [19] | LUA A C, SHEN Y.Preparation and characterization of polyimide- silica composite membranes and their derived carbon-silica composite membranes for gas separation.Chem. Eng. J., 2013, 220: 441-451. |

| [20] | ZHANG B, WU Y, LU Y, et al. Preparation and characterization of carbon and carbon/zeolite membranes from ODPA-ODA type polyetherimide. J. Membr. Sci., 2015, 474: 114-121. |

| [21] | MA X L, LIN B K, WEI X T, et al. Gamma-alumina supported carbon molecular sieve membrane for propylene/propane separation. Ind. Eng. Chem. Res., 2013, 52(11): 4297-4305. |

| [22] | ITTA A K, TSENG H H, WEY M Y.Effect of dry/wet-phase inversion method on fabricating polyetherimide-derived CMS membrane for H2/N2 separation.Int. J. Hydrogen Energ., 2010, 35(4): 1650-1658. |

| [23] | TSENG H H, SHIU P T, LIN Y S.Effect of mesoporous silica modification on the structure of hybrid carbon membrane for hydrogen separation.Int. J. Hydrogen Energ., 2011, 36(23): 15352-15363. |

| [24] | TIN P S, CHUNG T S, JIANG L, et al. Carbon-zeolite composite membranes for gas separation. Carbon, 2005, 43(9): 2025-2027. |

| [25] | LIU Q, WANG T, GUO H, et al. Controlled synthesis of high performance carbon/zeolite T composite membrane materials for gas separation. Micropor. Mesopor. Mat., 2009, 120(3): 460-466. |

| [26] | WANG T, ZHANG B, QIU J, et al. Effects of sulfone/ketone in poly(phthalazinone ether sulfone ketone) on the gas permeation of their derived carbon membranes. J. Membr. Sci., 2009, 330(1/2): 319-325. |

| [1] | WANG Lei, LI Jianjun, NING Jun, HU Tianyu, WANG Hongyang, ZHANG Zhanqun, WU Linxin. Enhanced Degradation of Methyl Orange with CoFe2O4@Zeolite Catalyst as Peroxymonosulfate Activator: Performance and Mechanism [J]. Journal of Inorganic Materials, 2023, 38(4): 469-476. |

| [2] | DAI Jieyan, FENG Aihu, MI Le, YU Yang, CUI Yuanyuan, YU Yun. Adsorption Mechanism of NaY Zeolite Molecular Adsorber Coating on Typical Space Contaminations [J]. Journal of Inorganic Materials, 2023, 38(10): 1237-1244. |

| [3] | LI Ziyi, ZHANG Jiajia, ZOU Xiaoqin, ZUO Jiayu, LI Jun, LIU Yingshu, PUI David Youhong. Synthesis and Gas Separation of Chabazite Zeolite Membranes [J]. Journal of Inorganic Materials, 2021, 36(6): 579-591. |

| [4] | GAO Jiming, YANG Yang, LEI Ting, WANG Jin, LIU Jie, ZHANG Limin. Synthesis and Characterization of SiC@SiO2/BN/PI Composites by in-situ Polymerization [J]. Journal of Inorganic Materials, 2021, 36(1): 36-42. |

| [5] | ZHANG Bo,ZHANG Ning,YANG Jianhua,LAN Jiancheng,WANG Jinqu. High Performance a&b Oriented T Zeolite Membrane by a Two-stage Crystallization Synthesis [J]. Journal of Inorganic Materials, 2020, 35(8): 939-946. |

| [6] | LI Hao-Geng,GU Hong-Yu,ZHANG Yu-Zhi,SONG Li-Xin,WU Ling-Nan,QI Zhen-Yi,ZHANG Tao. Surface Protection of Polymer Materials from Atomic Oxygen: a Review [J]. Journal of Inorganic Materials, 2019, 34(7): 685-693. |

| [7] | CHEN Meng-Qiu, WANG Yu, YANG Deng-Yao, WU Hong-Juan, GUO Li-Min. Pt Supported Hierarchical ZSM-5 Zeolite as Adsorbent/Catalytic Combustion Catalyst for o-xylene Elimination [J]. Journal of Inorganic Materials, 2019, 34(2): 173-178. |

| [8] | KONG Xiang-Li, QIU Ming-Hui, YANG Lu, WANG An-Ran, FAN Yi-Qun, KONG De-Shuang, GU Chang-Jun, HUAN Xiu-Hua, KONG Ling-Ren. Preparation of High-performance Cu-SAPO-34 Catalysts without Removal of Templating Agents [J]. Journal of Inorganic Materials, 2018, 33(9): 956-962. |

| [9] | FENG Shou-Ai, ZHOU Jun, YANG Xuan-Yu, LIU Hong, HUANG Jiang-Feng, BAI Jia-Feng, CHENG Xiao-Wei, DENG Yong-Hui. Synthesis of Pure-silica BETA Zeolite by the Method of Seed-direct Steam-assisted Crystallization [J]. Journal of Inorganic Materials, 2018, 33(9): 963-968. |

| [10] | LI Hong-Ji, ZHOU Xiao-De, ZHANG Jian-Min, YANG Jing, WANG Fa-Liang, WANG Xiang-Yang. CTAB on Synthesis and Pore Structure of Hierarchical Zeolite [J]. Journal of Inorganic Materials, 2018, 33(6): 629-634. |

| [11] | WANG Xiao-Lei, ZHANG Yu-Ting, GAO Bing, ZHANG Chun, GU Xue-Hong. Preparation and Characterization of NaA Zeolite Membranes on Inner-surface of Four-channel Ceramic Hollow Fibers [J]. Journal of Inorganic Materials, 2018, 33(3): 339-344. |

| [12] | HUANG Pan, ZHOU Liang, LI Hua-Zheng, LI Hong-Jian, YANG Jian-hua, WANG Jin-Qu. Preparation and Characterization of High Performance MFI Zeolite Membrane in Ultradilute Solution [J]. Journal of Inorganic Materials, 2018, 33(3): 345-351. |

| [13] | CHEN Hang-Rong, ZHOU Xiao-Xia, SHI Jian-Lin. Research Progress on Hierarchically Porous Zeolites: Structural Control, Synthesis and Catalytic Applications [J]. Journal of Inorganic Materials, 2018, 33(2): 113-128. |

| [14] | CHEN Meng-Qiu, CHEN Yun, SHU Zhu, WANG Yu, WU Hong-Juan, GUO Li-Min. Template-free Synthesis of Mesoporous Silica with High Specific Surface Area from Natural Halloysite and Its Application in Methylene Blue Adsorption [J]. Journal of Inorganic Materials, 2018, 33(12): 1365-1370. |

| [15] | WANG You-He, WANG Xiao-Dong, XU Jing-Wei, SUN Hong-Man, WU Cheng-Cheng, YAN Zi-Feng, JI Sheng-Fu. Hierarchical ZSM-5 Zeolite: Preparation by Sequential Desilication-dealumination and Catalytic Performance in Methanol to Gasoline Reaction [J]. Journal of Inorganic Materials, 2018, 33(11): 1193-1200. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||