Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (3): 283-291.DOI: 10.15541/jim20200243

Special Issue: 【虚拟专辑】层状MAX,MXene及其他二维材料

• RESEARCH PAPER • Previous Articles Next Articles

Received:2020-05-08

Revised:2020-08-25

Published:2021-03-20

Online:2020-09-09

Contact:

LI Haibo, associate professor. E-mail: lihaibo@nxu.edu.cn

About author:XI Wen(1994-), male, Master candidate. E-mail: xiwen_1994@yeah.net

Supported by:CLC Number:

XI Wen, LI Haibo. Preparation of TiO2/Ti3C2Tx Composite for Hybrid Capacitive Deionization[J]. Journal of Inorganic Materials, 2021, 36(3): 283-291.

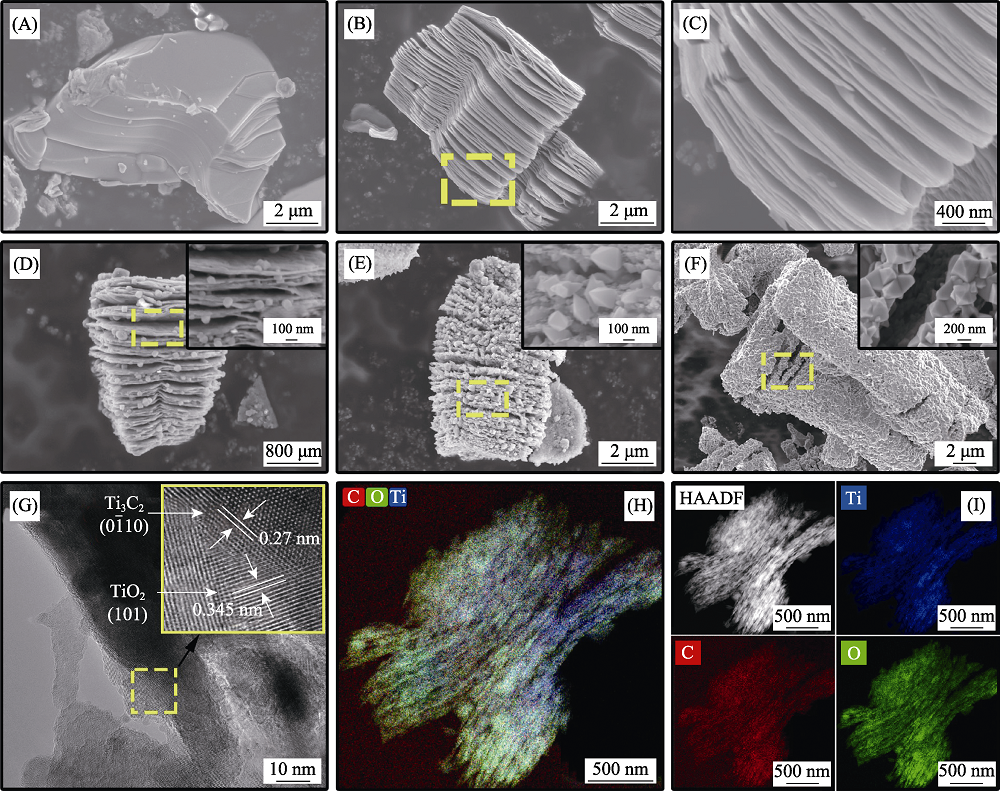

Fig. 3 SEM images of Ti3AlC2(A), Ti3C2Tx(B, C), TiO2/Ti3C2Tx-350(D), TiO2/Ti3C2Tx-450(E) and TiO2/Ti3C2Tx-550(F), HRTEM (G) and elemental mapping(H, I) of TiO2/Ti3C2Tx-450

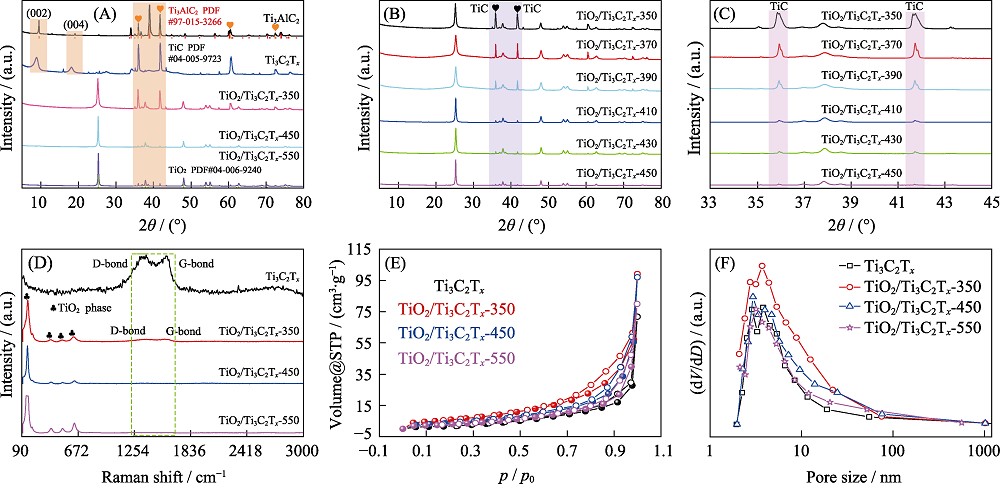

Fig. 4 XRD patterns (A) of various samples, XRD patterns (B, C) of TiO2/Ti3C2Tx calcined at different temperatures, Raman spectra (D), N2 adsorption-desorption isotherms (E) and pore size distributions (F) of various samples (A)Ti3AlC2, Ti3C2Tx, TiO2/Ti3C2Tx-350, TiO2/Ti3C2Tx-450 and TiO2/Ti3C2Tx-550; (B-D) Ti3C2Tx and TiO2/Ti3C2Tx-350, TiO2/Ti3C2Tx-450 and TiO2/Ti3C2Tx-550

| Sample | Specific surface area/(m2·g-1) | Pore size /nm | Pore volume /(cm3·g-1) |

|---|---|---|---|

| Ti3C2Tx | 8.542 | 51.979 | 0.111 |

| TiO2-Ti3C2Tx-350 | 23.227 | 26.394 | 0.153 |

| TiO2-Ti3C2Tx-450 | 14.630 | 41.005 | 0.150 |

| TiO2-Ti3C2Tx-550 | 12.324 | 40.134 | 0.124 |

Table 1 Comparison of specific surface areas, pore sizes and pore volumes of Ti3C2Tx, TiO2/Ti3C2Tx-350, TiO2/Ti3C2Tx-450 and TiO2/Ti3C2Tx-550

| Sample | Specific surface area/(m2·g-1) | Pore size /nm | Pore volume /(cm3·g-1) |

|---|---|---|---|

| Ti3C2Tx | 8.542 | 51.979 | 0.111 |

| TiO2-Ti3C2Tx-350 | 23.227 | 26.394 | 0.153 |

| TiO2-Ti3C2Tx-450 | 14.630 | 41.005 | 0.150 |

| TiO2-Ti3C2Tx-550 | 12.324 | 40.134 | 0.124 |

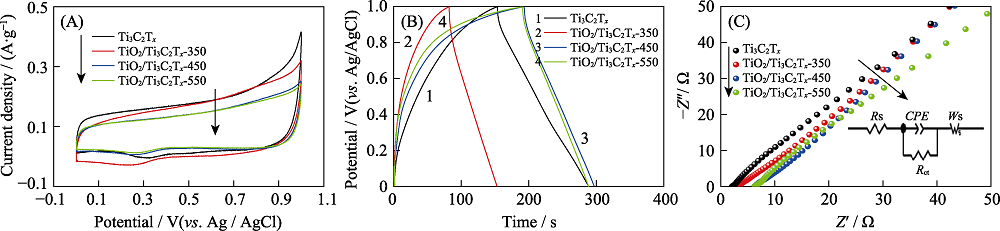

Fig. 6 CV curves(A), GCD(B) and EIS(C) of Ti3C2Tx, TiO2/Ti3C2Tx-350, TiO2/Ti3C2Tx-450 and TiO2/Ti3C2Tx-550 with inset in (C) representing the equivalent circuit

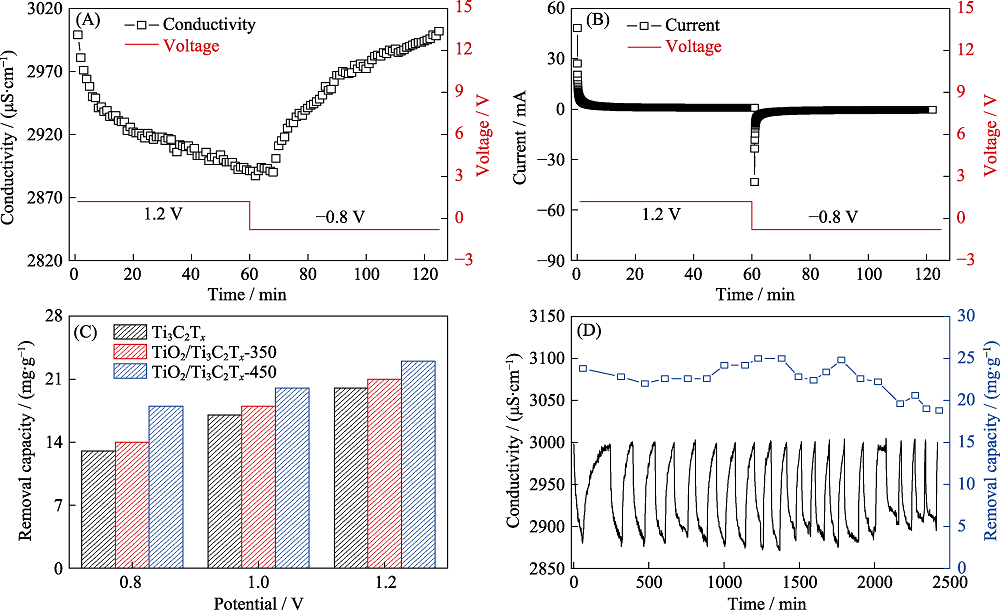

Fig. 7 Desalination performance of TiO2/Ti3C2Tx-450‖AC device (A, B) Conductivity and current transient of TiO2/Ti3C2Tx-450‖AC device in NaCl solution with an initial conductivity of 3000 μS·cm-1 at 1.2 V; (C) Salt removal capacity of Ti3C2Tx, TiO2/Ti3C2Tx-350 and TiO2/Ti3C2Tx-450 at various voltages; (D) Regeneration curves of TiO2/Ti3C2Tx-450‖AC device

| Sample | Specific surface area/(m2·g-1) | Initial conductivity /(mg·L-1) | Voltage/V | Desalination capacity/(mg·g-1) | Ref. |

|---|---|---|---|---|---|

| Pre-conditioned Ti3C2Tx MXene | - | 585.0 | -1.2 (discharge potential) | 9.19 | [42] |

| Ti3C2 MXene | 6.0 | 292.5 | 1.2 | 13.00 | [39] |

| Ar plasma modified Ti3C2Tx | - | 500.0 | 1.4 | 26.80 | [43] |

| LiH/HCl-etched Ti3C2Tx MXene | 2.1 | 585.0 | 1.2 | 67.70 | [44] |

| Porous Ti3C2Tx MXene | 293.0 | 10000.0 | 1.2 | 45.00 | [40] |

| Porous nitrogen-doped MXene sheets (N-Ti3C2Tx) | 368.8 | 5000.0 | 1.2 | 43.50±1.70 | [45] |

| TiO2/Ti3C2Tx-450 | 14.6 | 1500.0 | 1.2 | 22.00 | This work |

Table 2 Comparison of salt removal capacity among various CDI electrodes

| Sample | Specific surface area/(m2·g-1) | Initial conductivity /(mg·L-1) | Voltage/V | Desalination capacity/(mg·g-1) | Ref. |

|---|---|---|---|---|---|

| Pre-conditioned Ti3C2Tx MXene | - | 585.0 | -1.2 (discharge potential) | 9.19 | [42] |

| Ti3C2 MXene | 6.0 | 292.5 | 1.2 | 13.00 | [39] |

| Ar plasma modified Ti3C2Tx | - | 500.0 | 1.4 | 26.80 | [43] |

| LiH/HCl-etched Ti3C2Tx MXene | 2.1 | 585.0 | 1.2 | 67.70 | [44] |

| Porous Ti3C2Tx MXene | 293.0 | 10000.0 | 1.2 | 45.00 | [40] |

| Porous nitrogen-doped MXene sheets (N-Ti3C2Tx) | 368.8 | 5000.0 | 1.2 | 43.50±1.70 | [45] |

| TiO2/Ti3C2Tx-450 | 14.6 | 1500.0 | 1.2 | 22.00 | This work |

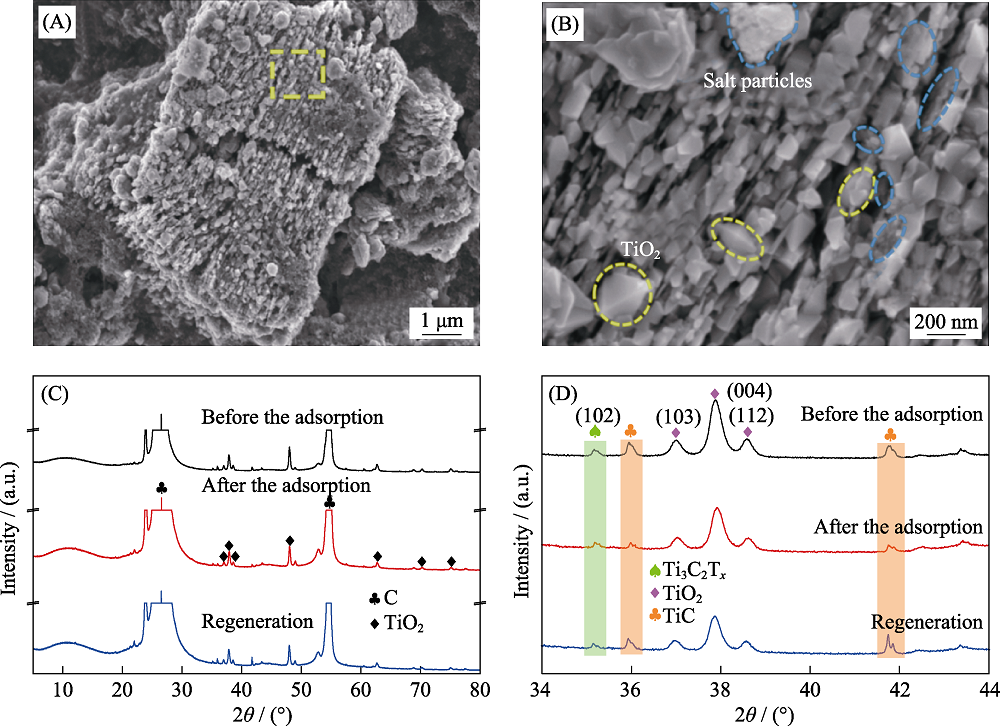

Fig. 8 SEM (A) and the enlarged (B) images of TiO2/Ti3C2Tx-450 after 20 cycling, XRD patterns(C, D) of TiO2/Ti3C2Tx-450 before and after desalting and regeneration (B) Enlarged image of (A); (D) Enlarged image of (C) within 2θ = 34°-44°

| [1] |

XU X, TAN H, WANG Z, et al. Extraordinary capacitive deionization performance of highly-ordered mesoporous carbon nano- polyhedra for brackish water desalination. Environmental Science: Nano, 2019,6(3):981-989.

DOI URL |

| [2] |

SHANNON M A, BOHN P W, ELIMELECH M, et al. Science and technology for water purification in the coming decades. Nature, 2008,452(7185):301-310.

DOI URL PMID |

| [3] | LI L, ZHAO J, SUN Y, et al. Ionically cross-linked sodium alginate/ ĸ-carrageenan double-network gel beads with low-swelling, enhanced mechanical properties, and excellent adsorption performance. Chemical Engineering Journal, 2019,372:1091-1103. |

| [4] | XU X, ALLAH A E, WANG C, et al. Capacitive deionization using nitrogen-doped mesostructured carbons for highly efficient brackish water desalination. Chemical Engineering Journal, 2019,362:887-896. |

| [5] | CUI T, YANG T, XU C Y, et al. Assessment of the impact of climate change on flow regime at multiple temporal scales and potential ecological implications in an alpine river. Stochastic Environmental Research and Risk Assessment, 2018,32(6):1849-1866. |

| [6] | ZHAO F, YUAN Z. H, ZHONG L B, et al. Review on electrode materials and Capacitive Deionization (CDI) technology for desalination. Technology of Water Treatment, 2016,42(5):38-44. |

| [7] | PEÑATE B, GARCÍA-RODRÍGUEZ L. Current trends and future prospects in the design of seawater reverse osmosis desalination technology. Desalination, 2012,284:1-8. |

| [8] | ZHAO D, LEE L Y, ONG S L, et al. Electrodialysis reversal for industrial reverse osmosis brine treatment. Separation and Purification Technology, 2019,213:339-347. |

| [9] | LEE K P, ARNOT T C, MATTIA D. A review of reverse osmosis membrane materials for desalination-development to date and future potential. Journal of Membrane Science, 2011,370(1/2):1-22. |

| [10] | GAO C J, ZHOU Y, LIU L F. Recent development and prospect of seawater reverse osmosis desalination technology. Journal of Ocean Technology, 2016,35(1):1-12. |

| [11] | ZHOU Y, YU S C, GAO C J. Reverse osmosis composite membrane (Ⅰ) chemical structure and performance. Journal of Chemical Industry and Engineering, 2006,57(6):1370-1373. |

| [12] | CHEN Y, YUE M, HUANG Z H, et al. Electrospun carbon nanofiber networks from phenolic resin for capacitive deionization. Chemical Engineering Journal, 2014,252:30-37. |

| [13] | TIAN X L, WANG L, CHI B, et al. Formation of a tubular assembly by ultrathin Ti0.8Co0.2N nanosheets as efficient oxygen reduction electrocatalysts for hydrogen-/metal-air fuel cells. ACS Catalysis, 2018,8(10):8970-8975. |

| [14] |

GALAMA A H, SAAKES M, BRUNING H, et al. Seawater predesalination with electrodialysis. Desalination, 2014,342:61-69.

DOI URL |

| [15] | DENG D, AOUAD W, BRAFF W A, et al. Water purification by shock electrodialysis: deionization, filtration, separation, and disinfection. Desalination, 2015,357:77-83. |

| [16] | YAN H Y, WANG Y M, JIANG C X, et al. Ion exchange membrane electrodialysis for high salinity wastewater “zero liquid discharge”: applications, opportunities and challenges. Chemical Industry and Engineering Progress, 2019,38(328):672-681. |

| [17] | AN X, LIU Z, HU Y. Amphiphobic surface modification of electrospun nanofibrous membranes for anti-wetting performance in membrane distillation. Desalination, 2018,432:23-31. |

| [18] | LIU L F, ZHOU Y S, XUE J, et al. Enhanced antipressure ability through graphene oxide membrane by intercalating g-C3N4 nanosheets for water purification. AICHE Journal, 2019, 65(10): e16699- 1-13. |

| [19] |

HOU Q Q, WU Y, ZHOU SH, et al. Ultra-tuning of the aperture size in stiffened ZIF-8_Cm frameworks with mixd-linker strategy for enhanced CO2/CH4 separation. Angewandte Chemie- International Edition, 2019,58(1):327-331.

DOI URL PMID |

| [20] | AL-MUTAZ I S, WAZEER I. Comparative performance evaluation of conventional multi-effect evaporation desalination processes. Applied Thermal Engineering, 2014,73(1):1194-1203. |

| [21] | PORADA S, ZHAO R, VAN DER WAL A, et al. Review on the science and technology of water desalination by capacitive deionization. Progress in Materials Science, 2013,58(8):1388-1442. |

| [22] | YAN J J, SHAO S F, WANG J H, et al. Improvement of a multi- stage flash seawater desalination system for cogeneration power plants. Desalination, 2007,217(1/2/3):191-202. |

| [23] | AVLONITIS S A, KOUROUMBAS K, VLACHAKIS N. Energy consumption and membrane replacement cost for seawater RO desalination plants. Desalination, 2003,157(1):151-158. |

| [24] | WU Y C, YING D W, WANG Y L, et al. Capacitive desalination technology and its application in wastewater treatment. Technology of Water Treatment, 2019,45(8):1-15. |

| [25] | LEE J, KIM S, KIM C, et al. Hybrid capacitive deionization to enhance the desalination performance of capacitive techniques. Energy & Environmental Science, 2014,7:3683-3689. |

| [26] | WANG S Y, WANG G, CHE X P, et al. Enhancing the capacitive deionization performance of NaMnO2 by interface engineering and redox-reaction. Environmental Science: Nano, 2019,6:2379-2388. |

| [27] |

NAGUIB M, KURTOGLU M, PRESSER V, et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Advanced Materials, 2011,23(37):4248-4253.

DOI URL PMID |

| [28] | ANASORI B, LUKATSKAYA M R, GOGOTSI Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nature Reviews Materials, 2017,2:16098. |

| [29] | NAGUIB M, MOCHALIN V N, BARSOUM M W, et al. Two- dimensional materials: 25th anniversary article: MXenes: a new family of two-dimensional materials. Advanced Materials, 2014,26(7):982-982. |

| [30] | ALHABEB M, MALESKI K, ANASORI B, et al. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chemistry of Materials, 2017,29(18):7633-7644. |

| [31] | DING L, LI L B, LIU Y C, et al. Effective ion sieving with Ti3C2Tx MXene membranes for production of drinking water from seawater. Nature Sustainability, 2020,3(4):296. |

| [32] |

DING L, XIAO D, LU Z, et al. Oppositely charged Ti3C2Tx MXene membranes with 2D nanofluidic channels for osmotic energy harvesting. Angewandte Chemie-International Edition, 2020,59(22):8720-8726.

DOI URL PMID |

| [33] | GUO J, PENG Q, FU H, et al. Heavy-metal adsorption behavior of two-dimensional alkalization-intercalated MXene by first-principles calculations. The Journal of Physical Chemistry C, 2015,119(36):20923-20930. |

| [34] |

REN C E, HATZELL K B, ALHABEB M, et al. Charge-and size- selective ion sieving through Ti3C2Tx MXene membranes. The Journal of Physical Chemistry Letters, 2015,6(20):4026-4031.

URL PMID |

| [35] |

TANG Q, ZHOU Z, SHEN P. Are MXenes promising anode materials for Li ion batteries? computational studies on electronic properties and Li storage capability of Ti3C2 and Ti3C2X2 (X=F, OH) monolayer. Journal of the American Chemical Society, 2012,134(40):16909-16916.

DOI URL PMID |

| [36] |

GUO X, ZHANG X, ZHAO S, et al. High adsorption capacity of heavy metals on two-dimensional MXenes: an ab initio study with molecular dynamics simulation. Physical Chemistry Chemical Physics, 2016,18(1):228-233.

URL PMID |

| [37] |

ANASORI B, XIE Y, BEIDAGHI M, et al. Two-dimensional, ordered, double transition metals carbides (MXenes). ACS Nano, 2015,9(10):9507-9516.

DOI URL PMID |

| [38] | LU ZONG, WEI Y Y, DENG J J, et al. Self-crosslinked MXene (Ti3C2Tx) membranes with good antiswelling property for monovalent metal ion exclusion. ACS Nano, 2019,3:10535-10544. |

| [39] | SRIMUK P, KAASIK F, KRÜNER B, et al. MXene as a novel intercalation-type pseudocapacitive cathode and anode for capacitive deionization. Journal of Materials Chemistry, 2016,4(47):18265-18271. |

| [40] | BAO W, TANG X, GUO X, et al. Porous cryo-dried MXene for efficient capacitive deionization. Joule, 2018,2(4):778-787. |

| [41] | LOW J X, ZHANG L Y, TONG T, et al. TiO2/MXene Ti3C2 composite with excellent photocatalytic CO2 reduction activity. Journal of Catalysis, 2018,361:255-266. |

| [42] | AGARTAN L, HANTANASIRISAKUL K, BUCZEK S, et al. Influence of operating conditions on the desalination performance of a symmetric pre-conditioned Ti3C2Tx-MXene membrane capacitive deionization system. Desalination, 2020,477:114267. |

| [43] | GUO L, WANG X, LEONG Z Y, et al. Ar plasma modification of 2D MXene Ti3C2Tx nanosheets for efficient capacitive desalination. Flat. Chem., 2018,8:17-24. |

| [44] | MA J, CHENG Y, WANG L, et al. Free-standing Ti3C2Tx MXene film as binder-free electrode in capacitive deionization with an ultrahigh desalination capacity. Chemical Engineering Journal, 2020,384:123329. |

| [45] | AMIRI A, CHEN Y, TENG C B, et al. Porous nitrogen-doped MXene-based electrodes for capacitive deionization. Energy Storage Mater., 2020,25:731-739. |

| [46] | XI W, LI H B. Pseudo-capacitive deionization behavior of CuAl- mixed metal. Environmental Science: Water Research & Technology, 2020,6(2):296-302. |

| [1] | WEI Jianwen, ZHANG Lijuan, GENG Linlin, LI Yu, LIAO Lei, WANG Dunqiu. Novel CO2 Adsorbent Prepared with ZSM-5/MCM-48 as Support: High Adsorption Property and Its Mechanism [J]. Journal of Inorganic Materials, 2025, 40(7): 833-839. |

| [2] | JIANG Zongyu, HUANG Honghua, QING Jiang, WANG Hongning, YAO Chao, CHEN Ruoyu. Aluminum Ion Doped MIL-101(Cr): Preparation and VOCs Adsorption Performance [J]. Journal of Inorganic Materials, 2025, 40(7): 747-753. |

| [3] | HONG Peiping, LIANG Long, WU Lian, MA Yingkang, PANG Hao. Structure Regulation of ZIF-67 and Adsorption Properties for Chlortetracycline Hydrochloride [J]. Journal of Inorganic Materials, 2025, 40(4): 388-396. |

| [4] | WU Guangyu, SHU Song, ZHANG Hongwei, LI Jianjun. Enhanced Styrene Adsorption by Grafted Lactone-based Activated Carbon [J]. Journal of Inorganic Materials, 2024, 39(4): 390-398. |

| [5] | XIE Tian, SONG Erhong. Effect of Elastic Strains on Adsorption Energies of C, H and O on Transition Metal Oxides [J]. Journal of Inorganic Materials, 2024, 39(11): 1292-1300. |

| [6] | CHAO Shaofei, XUE Yanhui, WU Qiong, WU Fufa, MUHAMMAD Sufyan Javed, ZHANG Wei. Efficient Potassium Storage through Ti-O-H-O Electron Fast Track of MXene Heterojunction [J]. Journal of Inorganic Materials, 2024, 39(11): 1212-1220. |

| [7] | MA Xiaosen, ZHANG Lichen, LIU Yanchao, WANG Quanhua, ZHENG Jiajun, LI Ruifeng. 13X@SiO2: Synthesis and Toluene Adsorption [J]. Journal of Inorganic Materials, 2023, 38(5): 537-543. |

| [8] | GUO Chunxia, CHEN Weidong, YAN Shufang, ZHAO Xueping, YANG Ao, MA Wen. Adsorption of Arsenate in Water by Zirconia-halloysite Nanotube Material [J]. Journal of Inorganic Materials, 2023, 38(5): 529-536. |

| [9] | WANG Shiyi, FENG Aihu, LI Xiaoyan, YU Yun. Pb (II) Adsorption Process of Fe3O4 Supported Ti3C2Tx [J]. Journal of Inorganic Materials, 2023, 38(5): 521-528. |

| [10] | YU Yefan, XU Ling, NI Zhongbing, SHI Dongjian, CHEN Mingqing. Prussian Blue Modified Biochar: Preparation and Adsorption of Ammonia Nitrogen from Sewage [J]. Journal of Inorganic Materials, 2023, 38(2): 205-212. |

| [11] | LING Jie, ZHOU Anning, WANG Wenzhen, JIA Xinyu, MA Mengdan. Effect of Cu/Mg Ratio on CO2 Adsorption Performance of Cu/Mg-MOF-74 [J]. Journal of Inorganic Materials, 2023, 38(12): 1379-1386. |

| [12] | TANG Ya, SUN Shengrui, FAN Jia, YANG Qingfeng, DONG Manjiang, KOU Jiahui, LIU Yangqiao. PEI Modified Hydrated Calcium Silicate Derived from Fly Ash and Its adsorption for Removal of Cu (II) and Catalytic Degradation of Organic Pollutants [J]. Journal of Inorganic Materials, 2023, 38(11): 1281-1291. |

| [13] | DAI Jieyan, FENG Aihu, MI Le, YU Yang, CUI Yuanyuan, YU Yun. Adsorption Mechanism of NaY Zeolite Molecular Adsorber Coating on Typical Space Contaminations [J]. Journal of Inorganic Materials, 2023, 38(10): 1237-1244. |

| [14] | WANG Hongning, HUANG Li, QING Jiang, MA Tengzhou, HUANG Weiqiu, CHEN Ruoyu. Mesoporous Organic-inorganic Hybrid Siliceous Hollow Spheres: Synthesis and VOCs Adsorption [J]. Journal of Inorganic Materials, 2022, 37(9): 991-1000. |

| [15] | LIU Cheng, ZHAO Qian, MOU Zhiwei, LEI Jiehong, DUAN Tao. Adsorption Properties of Novel Bismuth-based SiOCNF Composite Membrane for Radioactive Gaseous Iodine [J]. Journal of Inorganic Materials, 2022, 37(10): 1043-1050. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||