Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (3): 298-304.DOI: 10.15541/jim20150365

• RESEARCH PAPER • Previous Articles Next Articles

TANG Zhe-Peng1( ), ZHANG Zhong-Wei2, FANG Jin-Ming2, PENG Yu-Qing1, LI Ai-Jun1, ZHANG Dan3

), ZHANG Zhong-Wei2, FANG Jin-Ming2, PENG Yu-Qing1, LI Ai-Jun1, ZHANG Dan3

Received:2015-08-06

Revised:2015-10-10

Published:2016-03-20

Online:2016-02-24

Supported by:CLC Number:

TANG Zhe-Peng, ZHANG Zhong-Wei, FANG Jin-Ming, PENG Yu-Qing, LI Ai-Jun, ZHANG Dan. Modeling of Chemical Vapor Infiltration for Pyrocarbon within Capillaries[J]. Journal of Inorganic Materials, 2016, 31(3): 298-304.

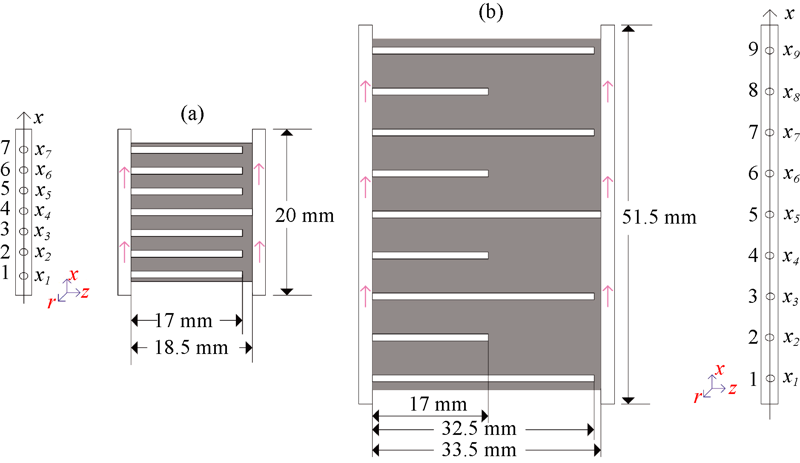

Fig. 1 Sketch of the substrates of capillaries with a diameter of 1.0 mm(a) Small reactor; (b) Large reactorNo.4 of small reactor and No.5 of large reactor are transition capillaries

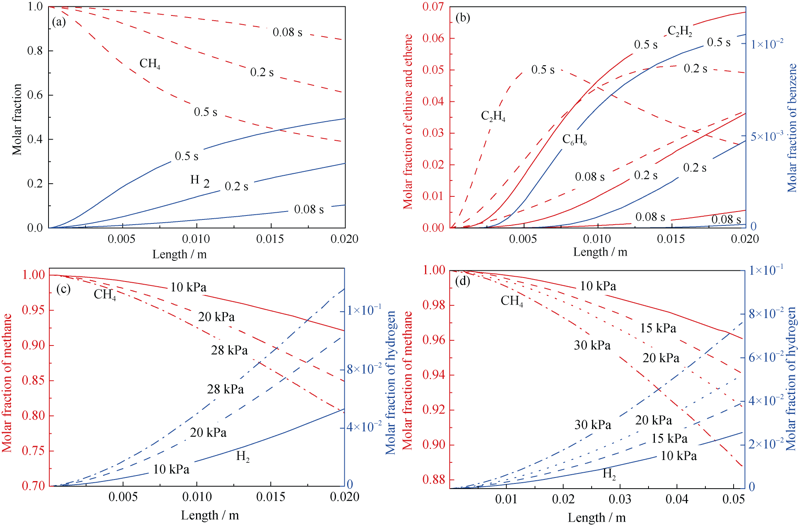

Fig. 2 Computed molar fraction profiles of major gas-phase species during the methane pyrolysis(a,b) 20 kPa, 1398 K and with various residence times in small reactor; (c) 0.08 s, 1398 K and with various pressures in small reactor; (d) 0.08 s, 1373 K and with various pressures in large reactor

| Species | Index | Ri |

|---|---|---|

| CH4 | c1 | c1*(-k1-Ic1*k5*Sv) |

| C2H4 | c2 | 0.5*k1*c1-k2*c2- Ic2*k6*Sv*c2 |

| C2H2 | c3 | k2*c2-k3*c3- Ic3*k7*Sv*c3 |

| C6H6 | c4 | k3*c3/3- Ic4*k8*Sv*c4 |

| H2 | c5 | k1*c1+k2*c2+0.5*k4*c4+2*Ic1*k5*Sv*c1+2*Ic2*k6*Sv*c2+ Ic3*k7*Sv*c3 +3* Ic4*k8*Sv*c4 |

Table 1 Reaction terms of related species

| Species | Index | Ri |

|---|---|---|

| CH4 | c1 | c1*(-k1-Ic1*k5*Sv) |

| C2H4 | c2 | 0.5*k1*c1-k2*c2- Ic2*k6*Sv*c2 |

| C2H2 | c3 | k2*c2-k3*c3- Ic3*k7*Sv*c3 |

| C6H6 | c4 | k3*c3/3- Ic4*k8*Sv*c4 |

| H2 | c5 | k1*c1+k2*c2+0.5*k4*c4+2*Ic1*k5*Sv*c1+2*Ic2*k6*Sv*c2+ Ic3*k7*Sv*c3 +3* Ic4*k8*Sv*c4 |

| Species | C | H | H2 |

|---|---|---|---|

| Diffusion volume /(cm3·mol-1) | 16.50 | 1.98 | 7.07 |

Table 2 Atom/molecular volume increment[12]

| Species | C | H | H2 |

|---|---|---|---|

| Diffusion volume /(cm3·mol-1) | 16.50 | 1.98 | 7.07 |

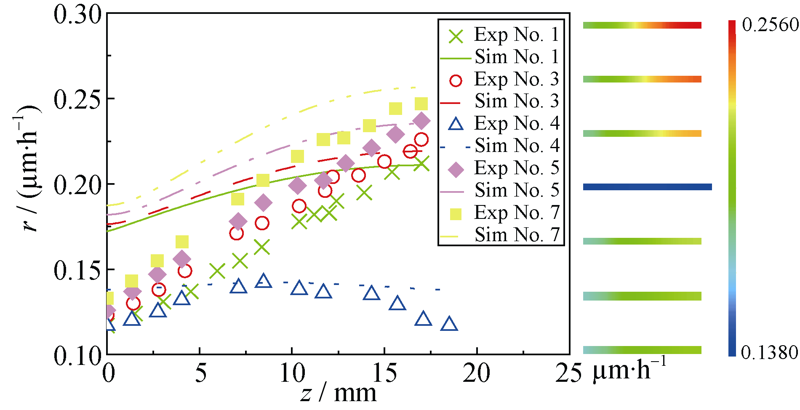

Fig. 4 Comparison of the computational predictions with the experimental data of the mean deposition rates as a function of the capillary depth in small reactor under the reaction conditions of 1398 K, 0.08 s, 10 kPa, and the cloud chart (right) of the related deposition rate for the substrate No.4 is a transition capillary

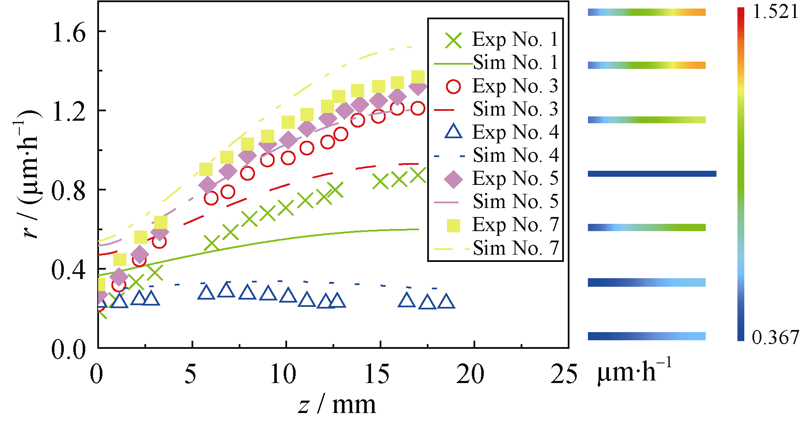

Fig. 5 Comparison of the computational predictions with the experimental data of the mean deposition rates as a function of the capillary depth in small reactor under the reaction conditions of 1398 K; 0.08 s; 20 kPa, and the cloud chart (right) of the related deposition rate for the substrate No.4 is a transition capillary

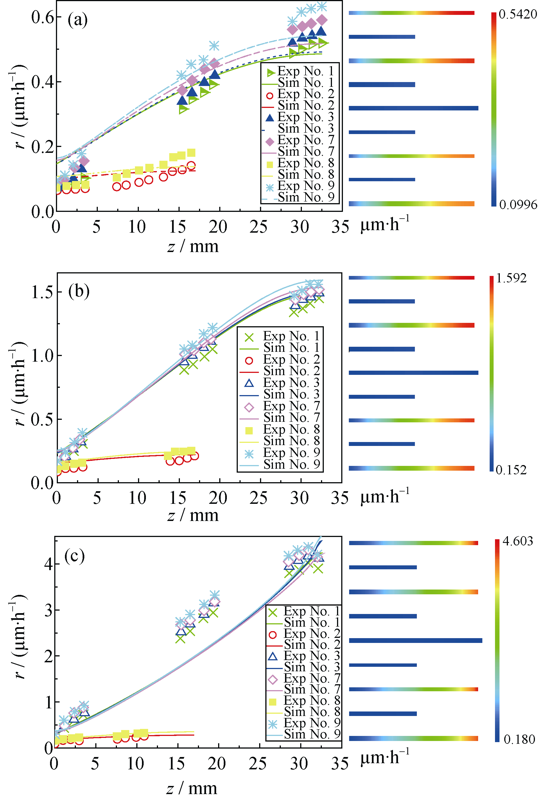

Fig. 6 Comparison of the computational predictions with the experimental data of the mean deposition rates as a function of the capillary depth in large reactor under the reaction conditions of 1398 K, 0.08 s and 10 kPa (a), 15 kPa (b) or 20 kPa (c), and the cloud chart (right) of the related deposition rate for the substrateNo.5 is a transition capillary

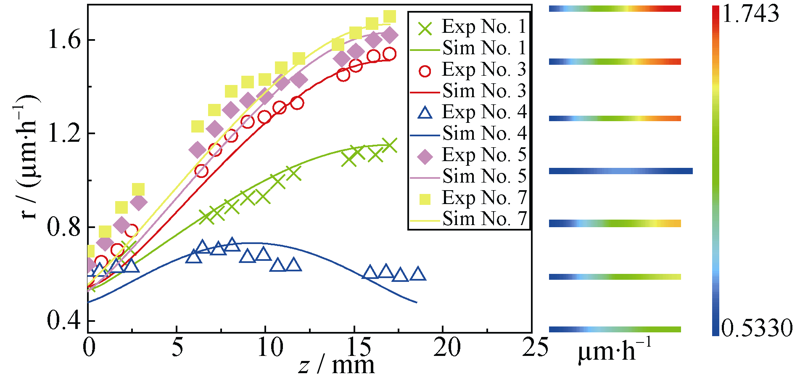

Fig. 7 Comparison of the computational predictions with the experimental data of the mean deposition rates as a function of the capillary depth in small reactor under the reaction conditions of 1398 K, 0.2 s and 20 kPa, and the cloud chart (right) of the related deposition rate for the substrate No.4 is a transition capillary

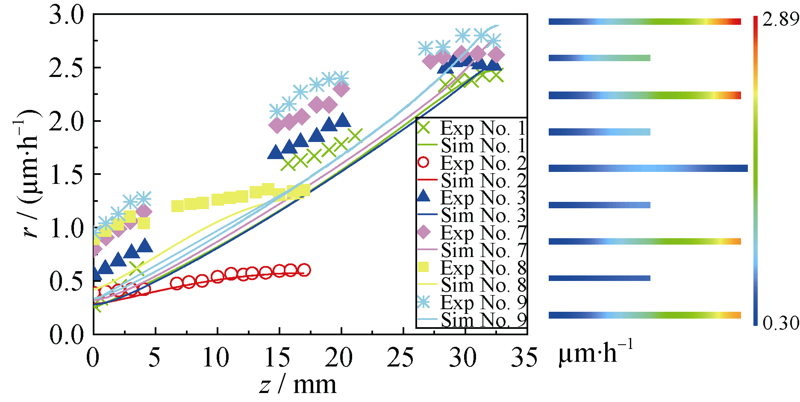

Fig. 8 Comparison of the computational predictions with the experimental data of the mean deposition rates as a function of the capillary depth in large reactor under the reaction conditions of 1373 K, 0.2 s and 20 kPa, and the cloud chart (right) of the related deposition rate for the substrate No.5 is a transition capillary

| [1] | FITZER E, MANOCHA L M.Carbon Reinforcements and Carbon/ Carbon Composites. Berlin, Heidelberg: Springer, 1998. |

| [2] | SUN L, LI H, ZHANG S.Microstructural characteristics of pitch-based carbon-carbon composites. Journal of Inorganic Materials, 2000, 15(6): 1111-1116. |

| [3] | LUO R, LI H, YANG Z, et al. A study of properties for carbon/carbon composites fabricated by chemical vapour deposition. Journal of Inorganic Materials, 1996, 11(1): 107-112. |

| [4] | ZHANG W G, HÜETTINGER K J. Simulation studies on chemical vapor infiltration of carbon.Composites Science and Technology, 2002, 62(15): 1947-1955. |

| [5] | HU Z J, HÜETTINGER K J. Chemical vapor infiltration of carbon- revised, Part II: Experimental results.Carbon, 2001, 39(7): 1023-1032. |

| [6] | ZHANG W, HUETTINGER K J.Chemical vapor infiltration of carbon-revised, Part I: Model simulations.Carbon, 2001, 39(7): 1013-1022. |

| [7] | HU Z, SCHOCH G, HUETTINGER K J.Chemistry and kinetics of chemical vapor infiltration of pyrocarbon: VII: infiltration of capillaries of equal size.Carbon, 2000, 38(7): 1059-1065. |

| [8] | XU W, ZHANG Z, BAI R, et al. Kinetic modeling of gas-phase reactions for CVD from propane. New Carbon Materials, 2014, 29: 67-77. |

| [9] | LI A J, DEUTSCHMANN O.Transient modeling of chemical vapor infiltration of methane using multi-step reaction and deposition models.Chemistry Engineering Science, 2007, 62(18/19/20): 4976-4982. |

| [10] | LI A J, NORINAGA K, ZHANG W, et al. Modeling and simulation of materials synthesis: chemical vapor deposition and infiltration of pyrolytic carbon. Composites Science Technology, 2008, 68(5): 1097-1104. |

| [11] | LI H, LI A J, BAI R, et al. Numerical simulation of chemical vapor infiltration of propylene into C/C composites with reduced multi-step kinetic models. Carbon, 2005, 43(14): 2937-2950. |

| [12] | IBRAHIM J, PAOLUCCI S.Transient solution of chemical vapor infiltration/deposition in a reactor.Carbon, 2011, 49(3): 915-930. |

| [13] | BECKER A, HUETTINGER K J.Chemistry and kinetics of chemical vapor deposition of Pyrocarbon: IV. Pyrocarbon deposition from methane in the low temperature regime.Carbon, 1998, 36(3): 213-224. |

| [14] | BENZINGER W H, HUETTINGER K J.Chemistry and kinetics of chemical vapor infiltration of pyrocarbon: IV. Investigation of methane/hydrogen mixtures.Carbon, 1999, 37(6): 931-940. |

| [15] | VIGNOLES G L, GOYHENECHE J, SEBASTIAN P, et al. The film-boiling densification process for C/C composites fabrication: from local scale to overall optimization. Chemistry Engineering Science, 2006, 61(17): 5636-5653. |

| [16] | NORINAGA K, JANARDHANAN V, DEUTSCHMANN O.Detailed chemical kinetic modeling of pyrolysis of ethylene, acetylene, and propylene at 1073 - 1373 K with a plug-flow reactor model.International Journal of Chemical Kinetics, 2008, 40(4): 199-208. |

| [17] | HUETTINGER K J.CVD in hot wall reactors - the interaction between homogeneous gas-phase and heterogeneous surface reactions.Chemical Vapor Deposition, 1998, 4(4): 151-158. |

| [18] | DEUTSCHMANN O, TISCHER S, CORREA C, et al. DETCHEM Software Package 2.1 Ed, 2007. |

| [19] | BENZINGER W H, HUETTINGER K J.Chemistry and kinetics of chemical vapor deposition of Pyrocarbon: II. Pyrocarbon deposition from ethylene, acetylene and 1,3-butadiene in the low temperature regime.Carbon, 1998, 36(3): 23. |

| [20] | NORINAGA K, DEUTSCHMANN O.Detailed kinetic modeling of gas-phase reactions in the chemical vapor deposition of carbon from light hydrocarbons.Indistrial Engineering Chemistry Research, 2007, 46(11): 3547-3557. |

| [21] | HU Z, ZHANG W, HUETTINGER K J, et al. Influence of pressure, temperature and surface area/volume ratio on the texture of pyrolytic carbon deposited from methane. Carbon, 2003, 41(4): 749-758. |

| [22] | LACROIX R, FOURNET R, ZIEGLER D I, et al. Kinetic modeling of surface reactions involved in CVI of pyrocarbon obtained by propane pyrolysis. Carbon, 2010, 48(1): 132-144. |

| [23] | TANG Z, LI A J, ZHANG Z, et al. Chemistry and kinetics of heterogeneous reaction mechanism for chemical vapor infiltration of pyrolytic carbon from propane. Industrial Engineering Chemistry Research, 2014, 53(45): 17537-17546. |

| [1] | YANG Mingkai, HUANG Zeai, ZHOU Yunxiao, LIU Tong, ZHANG Kuikui, TAN Hao, LIU Mengying, ZHAN Junjie, CHEN Guoxing, ZHOU Ying. Co-production of Few-layer Graphene and Hydrogen from Methane Pyrolysis Based on Cu and Metal Oxide-KCl Molten Medium [J]. Journal of Inorganic Materials, 2025, 40(5): 473-480. |

| [2] | PAN Jianlong, MA Guanjun, SONG Lemei, HUAN Yu, WEI Tao. High Stability/Catalytic Activity Co-based Perovskite as SOFC Anode: In-situ Preparation by Fuel Reducing Method [J]. Journal of Inorganic Materials, 2024, 39(8): 911-919. |

| [3] | YOU Bojie, LI Bo, LI Xuqin, MA Xuehan, ZHANG Yi, CHENG Laifei. Thermal Shock Damage and In-plane Shear Performance Degradation of 2D SiCf/SiC at Medium Temperature [J]. Journal of Inorganic Materials, 2024, 39(12): 1367-1376. |

| [4] | SUN Chen, ZHAO Kunfeng, YI Zhiguo. Research Progress in Catalytic Total Oxidation of Methane [J]. Journal of Inorganic Materials, 2023, 38(11): 1245-1256. |

| [5] | JIANG Lili, XU Shuaishuai, XIA Baokai, CHEN Sheng, ZHU Junwu. Defect Engineering of Graphene Hybrid Catalysts for Oxygen Reduction Reactions [J]. Journal of Inorganic Materials, 2022, 37(2): 215-222. |

| [6] | ZHANG Li, YANG Xianfeng, XU Xiewen, GUO Jinyu, ZHOU Zhe, LIU Peng, XIE Zhipeng. 3D Printed Zirconia Ceramics via Fused Deposit Modeling and Its Mechanical Properties [J]. Journal of Inorganic Materials, 2021, 36(4): 436-442. |

| [7] | ZHANG Li-Yan, LI Hong, HU Li-Li, WANG Ya-Jie. Structure Modeling of Genes in Glass: Composition-structure-property Approach [J]. Journal of Inorganic Materials, 2019, 34(8): 885-892. |

| [8] | Xiu-Min YAO, Xiao-Jie WANG, Xue-Jian LIU, Zhong-Ming CHEN, Zheng-Ren HUANG. Friction-wear Properties and Mechanism of Hard Facing Pairs of SiC and WC [J]. Journal of Inorganic Materials, 2019, 34(6): 673-678. |

| [9] | ZHANG Peng, ZHANG Qing, LIU Jing, GAO Lian. Research Progress of Ni-based Composite Catalysts for Methane Dry Reforming [J]. Journal of Inorganic Materials, 2018, 33(9): 931-941. |

| [10] | LIU Xue-Jiao, HE Zhen-Yu, WU Hao, LUO Ting, MENG Xie, CHEN Chu-Sheng, ZHAN Zhong-Liang. Influence of Impregnated Nano-scale LaNi0.6Fe0.4O3-δ Particles on the Oxygen Permeation Performance of Zr0.84Y0.16O2-δ-La0.8Sr0.2Cr0.5Fe0.5O3-δ Composite Membranes [J]. Journal of Inorganic Materials, 2018, 33(1): 14-18. |

| [11] | ZOU Yang, ZHAO Li-Li, YOU Li-Jun, CHEN Xiao-Ying, SONG Li-Xin. Preparation and Numerical Simulation Investigation of High Reflectance Anti-laser-ablation Coating [J]. Journal of Inorganic Materials, 2016, 31(8): 869-875. |

| [12] | LI Yan, CUI Hong, ZHANG Hua-Kun, JI A-Lin, JIE Yu-Jie. Densification Behavior of Thermal Gradient CVI of Large-scale C/C Composites [J]. Journal of Inorganic Materials, 2015, 30(2): 153-158. |

| [13] | LUO Pin-Feng, ZHI Wei, ZHANG Jing-Wei, SHI Feng, DUAN Ke, WANG Jian-xin, LU Xiong, WENG Jie. Interconnectivity of Bioceramic Scaffolds with Different Porous Structures and Their Fluid Velocity Distribution Analyzed by Micro-CT Computer Modeling [J]. Journal of Inorganic Materials, 2015, 30(1): 71-76. |

| [14] | LIU Ya-Di, YUAN Chun, ZHOU Yu-Cun, ZOU Jie, XIN Xian-Shuang, WANG Shao-Rong. Composite Anodes with Ni Impregnated LST-SSZ for Direct Methane Solid Oxide Fuel Cells [J]. Journal of Inorganic Materials, 2014, 29(11): 1121-1126. |

| [15] | ZHANG Shou-Yang,YAN Xia-Feng,LI He-Jun,LI Wei,GUO Ling-Jun. Deposition of Pyrolytic Carbon using Ethanol as Precursor in Chemical Vapor Infiltration [J]. Journal of Inorganic Materials, 2009, 24(5): 1073-1076. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||