无机材料学报 ›› 2022, Vol. 37 ›› Issue (3): 289-296.DOI: 10.15541/jim20210518 CSTR: 32189.14.10.15541/jim20210518

所属专题: 增材制造专题(2022)

李琪1( ), 黄羿1, 钱滨2, 许贝贝1, 陈莉英1, 肖文戈1(

), 黄羿1, 钱滨2, 许贝贝1, 陈莉英1, 肖文戈1( ), 邱建荣1(

), 邱建荣1( )

)

收稿日期:2021-08-23

修回日期:2021-09-24

出版日期:2022-03-20

网络出版日期:2021-11-01

通讯作者:

肖文戈, 助理研究员. E-mail: wengsee@zju.edu.cn; 邱建荣, 教授. Email: qjr@zju.edu.cn

作者简介:李 琪(1998-), 女, 硕士研究生. E-mail: 22030030@zju.edu.cn

基金资助:

LI Qi1( ), HUANG Yi1, QIAN Bin2, XU Beibei1, CHEN Liying1, XIAO Wenge1(

), HUANG Yi1, QIAN Bin2, XU Beibei1, CHEN Liying1, XIAO Wenge1( ), QIU Jianrong1(

), QIU Jianrong1( )

)

Received:2021-08-23

Revised:2021-09-24

Published:2022-03-20

Online:2021-11-01

Contact:

XIAO Wenge, lecturer. E-mail: wengsee@zju.edu.cn; QIU Jianrong, professor. Email: qjr@zju.edu.cn

About author:LI Qi (1998-), female, Master candidate. E-mail: 22030030@zju.edu.cn

Supported by:摘要:

传统“荧光粉+有机硅脂”荧光转换体的热导率低, 且物理化学稳定性差, 不能应用于高功率白光LED领域。全无机荧光块体材料可以规避有机封装, 具有更高的热导率, 但这类材料面临着成本高且极难实现立体结构的问题。本工作基于非晶态纳米二氧化硅, 得到一种包含(Gd,Y)AG:Ce荧光粉、可在紫外光下固化的浆料, 并通过光固化成型、空气排脂、无压烧结, 制备了一种(Gd,Y)AG:Ce荧光粉-石英玻璃复合材料。该荧光玻璃陶瓷在蓝光激发下发射峰值位于575 nm的宽带橙黄光, 且内量子效率大于90%。研究结果表明, 在致密化烧结过程中, (Gd,Y)AG:Ce荧光粉与石英玻璃之间的界面反应非常微弱, 因此荧光粉能够完好地嵌入到石英玻璃中。该全无机荧光转换体可以用于封装相关色温小于4500 K、显色指数大于75和流明效率为74 lm·W-1的高功率暖白光LED。所构建的激光照明器件的饱和激光功率密度可达2.84 W·mm-2, 此时光通量为180 lm。此外, 所提出的制备方法与3D打印兼容, 可以批量化制造出具有复杂立体结构的荧光转换体。该技术有望推动高功率白光LED朝着个性化和模块化发展。

中图分类号:

李琪, 黄羿, 钱滨, 许贝贝, 陈莉英, 肖文戈, 邱建荣. 橙黄光玻璃陶瓷的光固化成型与无压烧结[J]. 无机材料学报, 2022, 37(3): 289-296.

LI Qi, HUANG Yi, QIAN Bin, XU Beibei, CHEN Liying, XIAO Wenge, QIU Jianrong. Photo Curing and Pressureless Sintering of Orange-emitting Glass-ceramics[J]. Journal of Inorganic Materials, 2022, 37(3): 289-296.

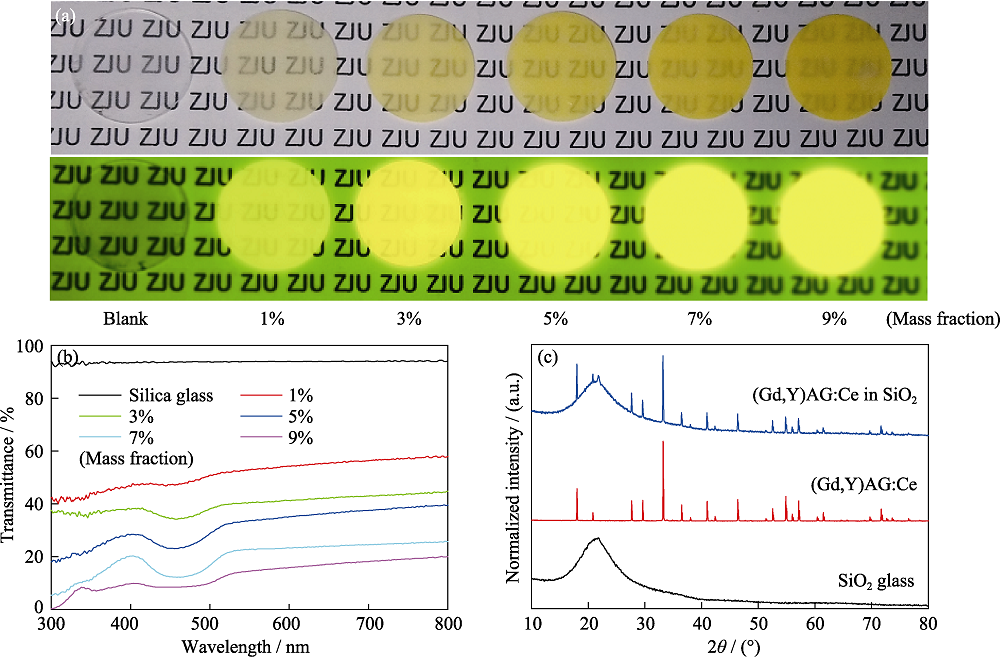

图1 (Gd,Y)AG:Ce-PiG的照片、透过率曲线和XRD图谱

Fig. 1 Photographs, transmittance spectra, and XRD patterns of (Gd,Y)AG:Ce-PiG (a) (Gd,Y)AG:Ce-PiG (0.5 mm in thickness) with different doping concentrations under daylight and blue light (using a 480 nm filter to filter out blue light when taking pictures); (b) Transmittance spectra of (Gd,Y)AG:Ce-PiG samples; (c) XRD patterns of silica glass, (Gd,Y)AG:Ce phosphors and (Gd,Y)AG:Ce-PiG Colorful figures are availuable on the website

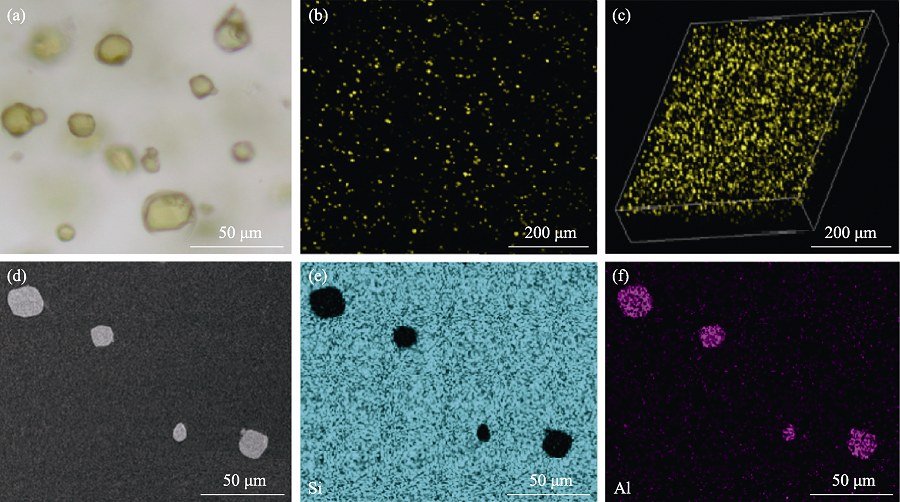

图2 3%(质量分数)掺杂(Gd,Y)AG:Ce-PiG的光学照片和能谱分析

Fig. 2 Optical photos and EDS images of 3% (mass fraction) (Gd,Y)AG:Ce-PiG (a) Fluorescence microscope image; (b, c) 2D and 3D confocal laser scanning microscope images; (d) SEM image; (e, f) EDS spectra of Si and Al

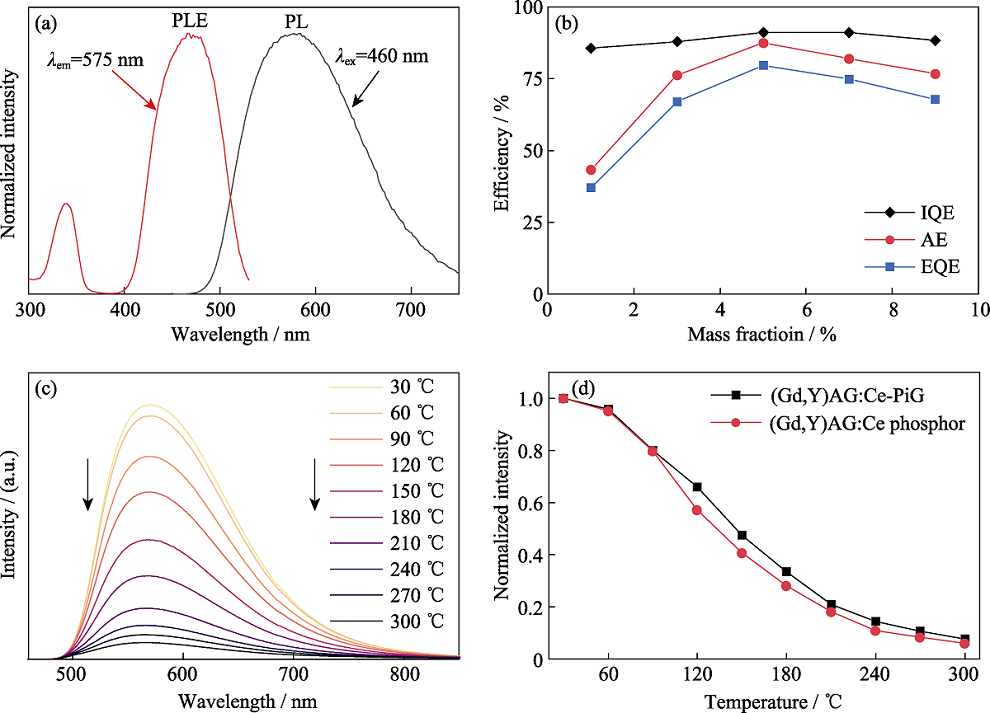

图3 (Gd,Y)AG:Ce-PiG的发光性能

Fig. 3 Luminous performance of (Gd,Y)AG:Ce-PiG (a) Excitation and emission spectra of 5% (mass fraction) (Gd,Y)AG:Ce-PiG; (b) Values of internal quantum efficiency (IQE), absorption efficiency (AE) and external quantum efficiency (EQE) of (Gd,Y)AG:Ce-PiG with different doping concentrations; (c) Temperature-dependent emission spectrum of 5% (mass fraction) (Gd,Y)AG:Ce-PiG PiG; (d) Temperature dependences of integrated emission intensity of (Gd,Y)AG:Ce-PiG and (Gd,Y)AG:Ce phosphor

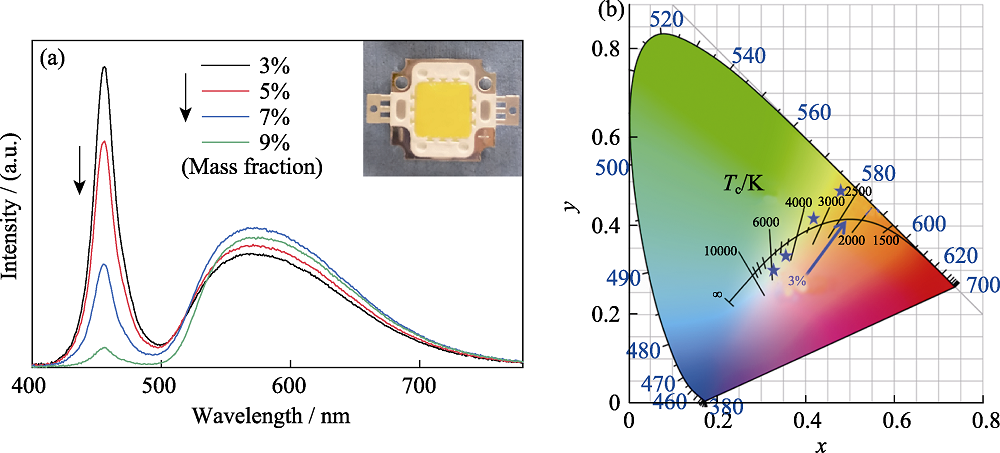

图4 白光LED器件的电致发光光谱及其相应的CIE色坐标

Fig. 4 Electroluminescence spectra and their corresponding CIE color coordinates of white LEDs (a) Electroluminescence spectra; (b) Corresponding CIE color coordinates. White LEDs fabricated by using (Gd,Y)AG:Ce-PiG (0.8 mm in thickness) with different doping concentrations under the current of 100 mA; The inset shows the picture of LED device

| Concentration (mass fraction) | Luminous efficiency/(lm·W-1) | CCT/K | CRI |

|---|---|---|---|

| 3% | 70.7 | 5717 | 84.1 |

| 5% | 74.2 | 4444 | 78.4 |

| 7% | 81.9 | 3398 | 67.7 |

| 9% | 72.9 | 2907 | 60.5 |

表1 白光LED器件的光学性能

Table 1 Optical performance of the packaged white LED devices

| Concentration (mass fraction) | Luminous efficiency/(lm·W-1) | CCT/K | CRI |

|---|---|---|---|

| 3% | 70.7 | 5717 | 84.1 |

| 5% | 74.2 | 4444 | 78.4 |

| 7% | 81.9 | 3398 | 67.7 |

| 9% | 72.9 | 2907 | 60.5 |

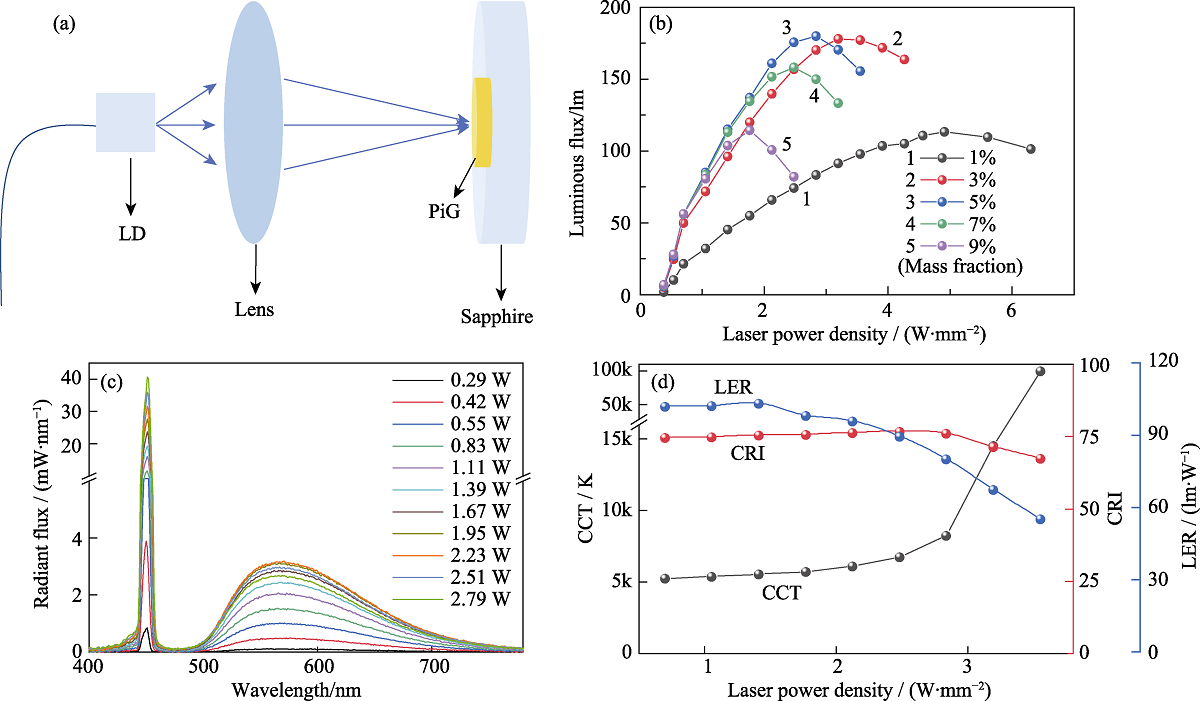

图5 高功率下(Gd,Y)AG:Ce-PiG的光学性能

Fig. 5 Optical performance of (Gd,Y) AG:Ce-PiG under high power (a) Schematic of reflective LD device; (b) Luminous flux of (Gd,Y)AG:Ce-PiG (0.8 mm in thickness) with different doping concentrations as a function of the laser power density; (c) Emission spectra of 5% (mass fraction) (Gd,Y)AG:Ce-PiG under different laser powers densities; (d) Values of CCT, CRI and luminous efficacy of radiation (LER) of 5% (mass fraction) (Gd,Y)AG:Ce-PiG under different laser power densities Colorful figures are availuable on the website

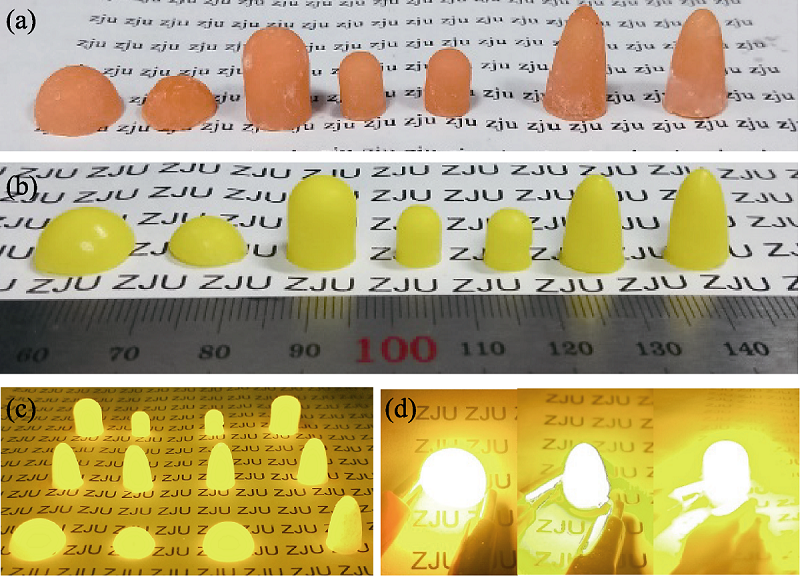

图6 3D打印荧光转换体

Fig. 6 3D printed fluorescence converter (a) Photos of 5% (mass fraction) doped 3D printed precursor; (b) Photos of sintered (Gd,Y)AG:Ce-PiG; (c) Sintered (Gd,Y)AG:Ce-PiG under 450 nm blue light irradiation; (d) Device demonstration of white LED when combined with blue LED chip

| [1] |

PATTISON P M, TSAO J Y, BRAINARD G C, et al. LEDs for photons, physiology and food. Nature, 2018, 563(7732): 493-500.

DOI URL |

| [2] | CAO X, CAO C C, SUN G Y. Recent progress of single-phase white light-emitting diodes phosphors. Journal of Inorganic Materials, 2019, 34(11): 1145-1155. |

| [3] | ZHAO M, LIAO H, MOLOKEEV M S, et al. Emerging ultra- narrow-band cyan-emitting phosphor for white LEDs with enhanced color rendition. Light: Science & Applications, 2019, 8: 38. |

| [4] |

BASORE E T, WU H, XIAO W, et al. High-power broadband NIR LEDs enabled by highly efficient blue-to-NIR conversion. Advanced Optical Materials, 2021, 9(7): 2001660.

DOI URL |

| [5] | ZHENG G, XIAO W, WU H, et al. Near-unity and zero-thermal- quenching far-red-emitting composite ceramics via pressureless glass crystallization. Laser & Photonics Reviews, 2021, 15(7): 2100060. |

| [6] | WEI Y, XING G, LIU K, et al. New strategy for designing orangish- red-emitting phosphor via oxygen-vacancy-induced electronic localization. Light: Science & Applications, 2019, 8: 15. |

| [7] |

HUANG J, GOLUBOVIC D S, KOH S, et al. Rapid degradation of mid-power white-light LEDs in saturated moisture conditions. IEEE Transactions on Device and Materials Reliability, 2015, 15(4): 478-485.

DOI URL |

| [8] | LI S, WANG L, HIROSAKI N, et al. Color conversion materials for high-brightness laser-driven solid-state lighting. Laser & Photonics Reviews, 2018, 12(12): 1800173. |

| [9] |

LI J, ZOU J, XIA C, et al. Ce:YAG transparent ceramics enabling high luminous efficacy for high-power LEDs/LDs. Journal of Inorganic Materials, 2021, 36(8): 883-892.

DOI URL |

| [10] | HU T, NING L, GAO Y, et al. Glass crystallization making red phosphor for high-power warm white lighting. Light: Science & Applications, 2021, 10(1): 56. |

| [11] |

DING H, LIU Z, HU P, et al. High efficiency green-emitting LuAG:Ce ceramic phosphors for laser diode lighting. Advanced Optical Materials, 2021, 9(8): 2002141.

DOI URL |

| [12] |

ARJOCA S, INOMATA D, MATSUSHITA Y, et al. Growth and optical properties of (Y1-xGdx)3Al5O12:Ce single crystal phosphors for high-brightness neutral white LEDs and LDs. CrystEngComm, 2016, 18(25): 4799-4806.

DOI URL |

| [13] |

LIU X, HUANG Z, XIE R, et al. Phosphor ceramics for high- power solid-state lighting. Journal of Inorganic Materials, 2021, 36(8): 807-819.

DOI URL |

| [14] |

ZHANG D, XIAO W, LIU C, et al. Highly efficient phosphor-glass composites by pressureless sintering. Nature Communications, 2020, 11(1): 2805.

DOI URL |

| [15] | LIN H, HU T, CHENG Y, et al. Glass ceramic phosphors: towards long-lifetime high-power white light-emitting-diode applications-a review. Laser & Photonics Reviews, 2018, 12(6): 1700344. |

| [16] |

LEE Y K, LEE J S, HEO J, et al. Phosphor in glasses with Pb-free silicate glass powders as robust color-converting materials for white LED applications. Optics Letters, 2012, 37(15): 3276-3278.

DOI URL |

| [17] | YOU S, LI S, ZHENG P, et al. A thermally robust La3Si6N11:Ce-in- glass film for high-brightness blue-laser-driven solid state lighting. Laser & Photonics Reviews, 2019, 13(2): 1800216. |

| [18] |

ZHANG X, SI S, YU J, et al. Improving the luminous efficacy and resistance to blue laser irradiation of phosphor-in-glass based solid state laser lighting through employing dual-functional sapphire plate. Journal of Materials Chemistry C, 2019, 7(2): 354-361.

DOI URL |

| [19] |

MA X, LI X, LI J, et al. Pressureless glass crystallization of transparent yttrium aluminum garnet-based nanoceramics. Nature Communications, 2018, 9(1): 1175.

DOI URL |

| [20] |

SUN B, ZHANG L, ZHOU T, et al. Protected-annealing regulated defects to improve optical properties and luminescence performance of Ce:YAG transparent ceramics for white LEDs. Journal of Materials Chemistry C, 2019, 7(14): 4057-4065.

DOI URL |

| [21] | WANG L, XIE R J, LI Y, et al. Ca1-xLixAl1-xSi1+xN3:Eu2+ solid solutions as broadband, color-tunable and thermally robust red phosphors for superior color rendition white light-emitting diodes. Light: Science & Applications, 2016, 5(10): e16155. |

| [22] |

HOERDER G J, SEIBALD M, BAUMANN D, et al. Sr[Li2Al2O2N2]:Eu2+-a high performance red phosphor to brighten the future. Nature Communications, 2019, 10(1): 1824.

DOI URL |

| [23] |

RONGJUN X I E, DELIANG C, SETSUHISA T, et al. Advance in red-emitting Mn4+-activated oxyfluoride phosphors. Journal of Inorganic Materials, 2020, 35(8): 847-856.

DOI URL |

| [24] | SENDEN T, VAN DIJK-MOES R J A, MEIJERINK A. Quenching of the red Mn4+ luminescence in Mn4+-doped fluoride LED phosphors. Light: Science & Applications, 2018, 7: 8-13. |

| [25] |

XU J, YANG Y, GUO Z, et al. Design of a CaAlSiN3:Eu/glass composite film: facile synthesis, high saturation-threshold and application in high-power laser lighting. Journal of the European Ceramic Society, 2020, 40(13): 4704-4708.

DOI URL |

| [26] | DANG P, LI G, YUN X, et al. Thermally stable and highly efficient red-emitting Eu3+-doped Cs3GdGe3O9 phosphors for WLEDs: non-concentration quenching and negative thermal expansion. Light: Science & Applications, 2021, 10(1): 29. |

| [27] |

DU Q, FENG S, QIN H, et al. Massive red-shifting of Ce3+ emission by Mg2+ and Si4+ doping of YAG:Ce transparent ceramic phosphors. Journal of Materials Chemistry C, 2018, 6(45): 12200-12205.

DOI URL |

| [28] |

SUN P, HU P, LIU Y, et al. Broadband emissions from Lu2Mg2Al2Si2O12:Ce3+ plate ceramic phosphors enable a high color- rendering index for laser-driven lighting. Journal of Materials Chemistry C, 2020, 8(4): 1405-1412.

DOI URL |

| [29] | LIU S, SUN P, LIU Y, et al. Warm white light with a high color- rendering index from a single Gd3Al4GaO12:Ce3+ transparent ceramic for high-power LEDs and LDs. ACS Applied Materials & Interfaces, 2019, 11(2): 2130-2139. |

| [30] | DIGONNET M J F, NISHIURA S, JIANG S, et al. Transparent Ce3+:GdYAG Ceramic Phosphors for White LED. Proc. SPIE, Optical Components and Materials VIII, San Francisco, 2011: 793404. |

| [31] |

LIU X, QIAN X, HU Z, et al. Al2O3-Ce:GdYAG composite ceramic phosphors for high-power white light-emitting-diode applications. Journal of the European Ceramic Society, 2019, 39(6): 2149-2154.

DOI URL |

| [32] |

CHEN J, TANG Y, YI X, et al. Fabrication of (Tb,Gd)3Al5O12:Ce3+ phosphor ceramics for warm white light-emitting diodes application. Optical Materials Express, 2019, 9(8): 3333-3341.

DOI URL |

| [33] |

DING H, LIU Z, LIU Y, et al. Gd3Al3Ga2O12:Ce, Mg2+ transparent ceramic phosphors for high-power white LEDs/LDs. Ceramics International, 2021, 47(6): 7918-7924.

DOI URL |

| [34] |

LIU Z, LIU S, WANG K, et al. Optical analysis of color distribution in white LEDs with various packaging methods. IEEE Photonics Technology Letters, 2008, 20(24): 2027-2029.

DOI URL |

| [35] |

YU R, JIN S, CEN S, et al. Effect of the phosphor geometry on the luminous flux of phosphor-converted light-emitting diodes. IEEE Photonics Technology Letters, 2010, 22(23): 1765-1767.

DOI URL |

| [36] | LIU Z, KAI W, LUO X, et al. Realization of High Spatial Color Uniformity for White Light-emitting Diodes by Remote Hemispherical YAG: Ce Phosphor Film. Electronic Components and Technology Conference, Las Vegas, 2010: 1703-1707. |

| [37] |

TSAI P Y, HUANG H K, SUNG J M, et al. High thermal stability and wide angle of white light chip-on-board package using a remote phosphor structure. IEEE Electron Device Letters, 2015, 36(3): 250-252.

DOI URL |

| [38] |

CHENG T, YU X, MA Y, et al. Angular color uniformity enhancement of white LEDs by lens wetting phosphor coating. IEEE Photonics Technology Letters, 2016, 28(14): 1589-1592.

DOI URL |

| [39] |

LI J, LI Z, LI Z, et al. Improvement in optical performance and color uniformity by optimizing the remote phosphor caps geometry for chip-on-board light emitting diodes. Solid-State Electronics, 2016, 126: 36-45.

DOI URL |

| [40] |

MOORE D G, BARBERA L, MASANIA K, et al. Three-dimensional printing of multicomponent glasses using phase-separating resins. Nature Materials, 2020, 19(2): 212-217.

DOI URL |

| [41] |

CAMPOSEO A, PERSANO L, FARSARI M, et al. Additive manufacturing: applications and directions in photonics and optoelectronics. Advanced Optical Materials, 2019, 7(1): 1800419.

DOI URL |

| [1] | 范小暄, 郑永炅, 徐丽荣, 姚子敏, 曹硕, 王可心, 王绩伟. 基于富氧空位LiYScGeO4: Bi3+长余辉光催化剂的自激活余辉驱动有机污染物芬顿降解[J]. 无机材料学报, 2025, 40(5): 481-488. |

| [2] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [3] | 史瑞, 刘伟, 李林, 李欢, 张志军, 饶光辉, 赵景泰. BaSrGa4O8: Tb3+力致发光材料的制备及性能[J]. 无机材料学报, 2024, 39(10): 1107-1113. |

| [4] | 施哲, 刘伟业, 翟东, 谢建军, 朱钰方. 3D打印制备镁黄长石生物陶瓷骨组织工程支架及其性能[J]. 无机材料学报, 2023, 38(7): 763-770. |

| [5] | 苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488. |

| [6] | 王鲁凯, 冯军宗, 姜勇刚, 李良军, 冯坚. 直写3D打印陶瓷基多孔结构的研究进展[J]. 无机材料学报, 2023, 38(10): 1133-1148. |

| [7] | 关旭峰, 李桂芳, 卫云鸽. Na1-xMxCaEu(WO4)3 (M=Li, K)红色荧光粉的微观结构与热猝灭特性研究[J]. 无机材料学报, 2022, 37(6): 676-682. |

| [8] | 杨勇, 郭啸天, 唐杰, 常浩天, 黄政仁, 胡秀兰. 非氧化物陶瓷光固化增材制造研究进展及展望[J]. 无机材料学报, 2022, 37(3): 267-277. |

| [9] | 朱俊逸, 张成, 罗忠强, 曹继伟, 刘志远, 王沛, 刘长勇, 陈张伟. 脱脂工艺对光固化3D打印堇青石陶瓷性能的影响[J]. 无机材料学报, 2022, 37(3): 317-324. |

| [10] | 李乔磊, 顾玥, 于雪华, 张朝威, 邹明科, 梁静静, 李金国. 烧结温度对3D打印硅基陶瓷型芯表面形貌及粗糙度的影响[J]. 无机材料学报, 2022, 37(3): 325-332. |

| [11] | 孙扬善, 杨治华, 蔡德龙, 张正义, 柳琪, 房树清, 冯良, 石丽芬, 王友乐, 贾德昌. 粉末烧结法制备α-堇青石基玻璃陶瓷的析晶动力学和性能[J]. 无机材料学报, 2022, 37(12): 1351-1357. |

| [12] | 陈铖, 丁晶鑫, 王会, 王德平. 掺钕介孔硼硅酸盐生物活性玻璃陶瓷骨水泥的制备与性能表征[J]. 无机材料学报, 2022, 37(11): 1245-1258. |

| [13] | 吴重草, 郇志广, 朱钰方, 吴成铁. 3D打印HA微球支架的制备与表征[J]. 无机材料学报, 2021, 36(6): 601-607. |

| [14] | 王兆武, 姬海鹏, 王飞翔, 侯星慧, 易莎莎, 周颖, 陈德良. 调控Al2O3晶型控制MgAl2O4:Mn4+荧光粉中Mn价态研究[J]. 无机材料学报, 2021, 36(5): 513-520. |

| [15] | 张力, 杨现锋, 徐协文, 郭金玉, 周哲, 刘鹏, 谢志鹏. 熔融沉积法3D打印制备氧化锆陶瓷及其力学性能研究[J]. 无机材料学报, 2021, 36(4): 436-442. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||