无机材料学报 ›› 2019, Vol. 34 ›› Issue (8): 885-892.DOI: 10.15541/jim20180514 CSTR: 32189.14.10.15541/jim20180514

张丽艳1,李洪2,胡丽丽1,王亚杰1,3

收稿日期:2018-10-31

修回日期:2019-01-07

出版日期:2019-08-20

网络出版日期:2019-05-22

作者简介:张丽艳(1971-), 女, 副研究员. E-mail: jndxzly@hotmail.com

ZHANG Li-Yan1,LI Hong2,HU Li-Li1,WANG Ya-Jie1,3

Received:2018-10-31

Revised:2019-01-07

Published:2019-08-20

Online:2019-05-22

摘要:

介绍了一种基于玻璃结构性质而建立的玻璃成分(C)-结构(S)-性能(P)的统计模拟方法。分析了常用的成分-性质(C-P)模拟法的局限性以及结构-性质(S-P)模拟法的特点, 并利用磷酸盐激光钕玻璃化学稳定性改良实验比较了C-P与S-P模型的差异, 表明对于组分微调设计, 结构模拟可以给出更好的模拟结果。叙述了C-S-P模型的建模步骤, 通过模拟案例演示了使用C-S与S-P模型反演玻璃成分的具体过程。除常规性质外, C-S-P模拟法还可以对玻璃的光谱激光性质及化学性质等C-P模型难以准确模拟的性质进行预测和模拟。目的是探索一种对玻璃设计普遍适用的, 可以为新型玻璃的研发和玻璃工业生产提供高效、准确设计的便捷模拟方法。

中图分类号:

张丽艳, 李洪, 胡丽丽, 王亚杰. 玻璃成分-结构-性质的“基因结构”模拟法[J]. 无机材料学报, 2019, 34(8): 885-892.

ZHANG Li-Yan, LI Hong, HU Li-Li, WANG Ya-Jie. Structure Modeling of Genes in Glass: Composition-structure-property Approach[J]. Journal of Inorganic Materials, 2019, 34(8): 885-892.

| Sample | WL /(mg?cm-2) | nd | n2 /(×10-13, esu) | α300 ℃/(×10-6, K-1) | Tg/℃ |

|---|---|---|---|---|---|

| BL | 1.29 | 1.50466 | 1.05 | 12.51 | 493.1 |

| S1 | 0.89 | 1.50574 | 0.99 | 12.75 | 471.9 |

| S2 | 1.07 | 1.50650 | 0.99 | 12.56 | 471.6 |

| S3 | 1.30 | 1.50600 | 0.98 | 12.62 | 482.7 |

| S4 | 1.11 | 1.50554 | 0.99 | 12.27 | 486.1 |

| B1 | 0.65 | 1.50734 | 1.00 | 12.53 | 471.1 |

| B2 | 1.04 | 1.50708 | 0.99 | 12.58 | 472.8 |

| B3 | 0.67 | 1.50841 | 0.99 | 12.48 | 476.8 |

| B4 | 1.11 | 1.50814 | 1.01 | 12.04 | 492.2 |

| L1 | 0.79 | 1.50836 | 0.99 | 12.80 | 466.5 |

| L2 | 0.70 | 1.51001 | 1.03 | 12.48 | 476.8 |

| L3 | 0.65 | 1.51165 | 1.06 | 12.60 | 480.4 |

| L4 | 0.69 | 1.51332 | 1.08 | 12.32 | 484.4 |

表1 实验玻璃编号及性质

Table 1 Number of glass samples and their properties

| Sample | WL /(mg?cm-2) | nd | n2 /(×10-13, esu) | α300 ℃/(×10-6, K-1) | Tg/℃ |

|---|---|---|---|---|---|

| BL | 1.29 | 1.50466 | 1.05 | 12.51 | 493.1 |

| S1 | 0.89 | 1.50574 | 0.99 | 12.75 | 471.9 |

| S2 | 1.07 | 1.50650 | 0.99 | 12.56 | 471.6 |

| S3 | 1.30 | 1.50600 | 0.98 | 12.62 | 482.7 |

| S4 | 1.11 | 1.50554 | 0.99 | 12.27 | 486.1 |

| B1 | 0.65 | 1.50734 | 1.00 | 12.53 | 471.1 |

| B2 | 1.04 | 1.50708 | 0.99 | 12.58 | 472.8 |

| B3 | 0.67 | 1.50841 | 0.99 | 12.48 | 476.8 |

| B4 | 1.11 | 1.50814 | 1.01 | 12.04 | 492.2 |

| L1 | 0.79 | 1.50836 | 0.99 | 12.80 | 466.5 |

| L2 | 0.70 | 1.51001 | 1.03 | 12.48 | 476.8 |

| L3 | 0.65 | 1.51165 | 1.06 | 12.60 | 480.4 |

| L4 | 0.69 | 1.51332 | 1.08 | 12.32 | 484.4 |

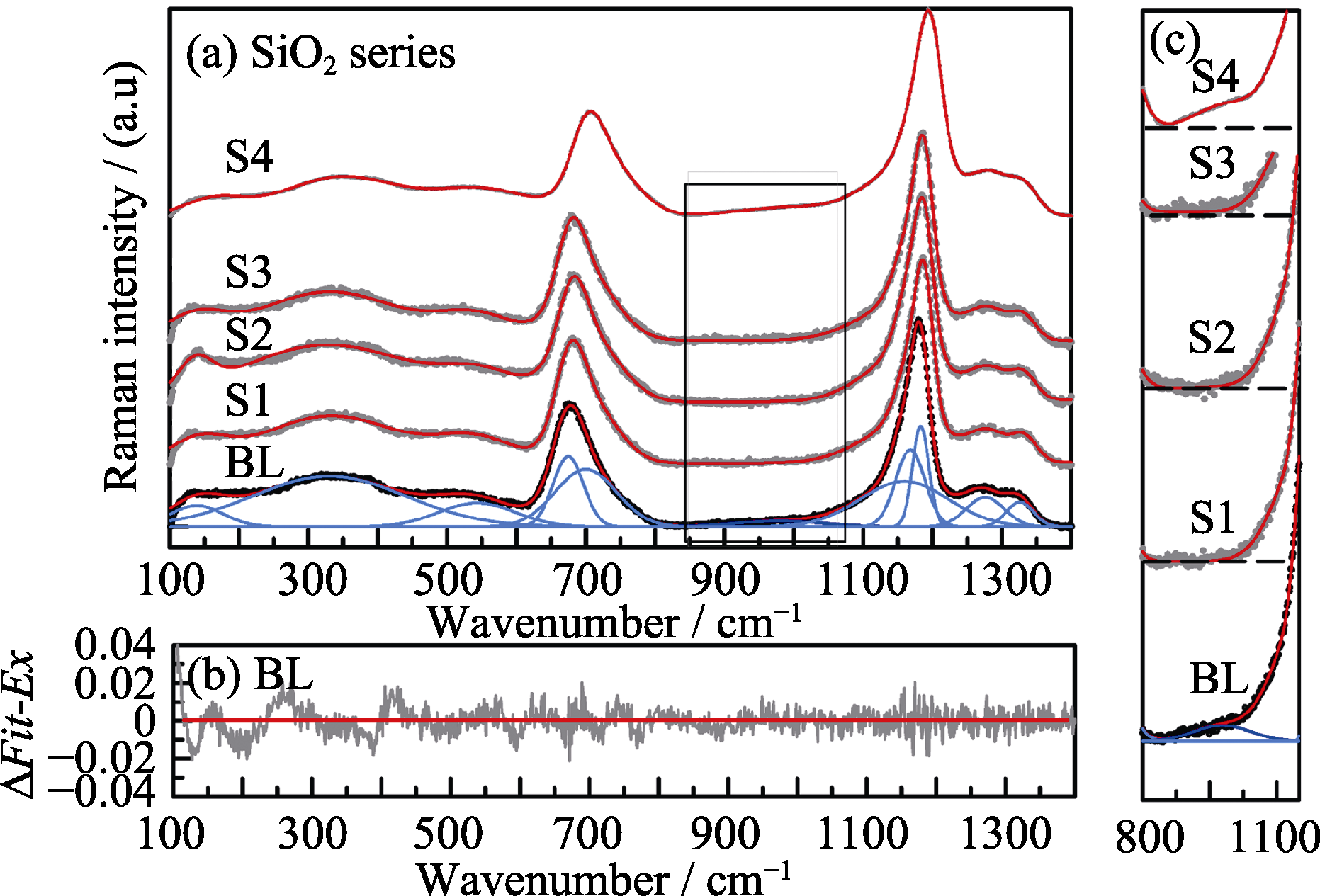

图1 BL与含SiO2的玻璃拉曼光谱对比(包含测试与拟合谱图对比)及BL拉曼分峰结果细节描述(a~b)为拟合误差, (c)为虚框处的拟合细节

Fig. 1 Raman spectra of BL glass and SiO2 modified glasses, comparing the measured and the simulated spectra (a) along with the corresponding error in detail curve fitting results for BL glass (b), and the fitting detail of gridlines (c) in Fig.1(a)

| No. | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BL | 3.6 | 29.0 | 6.9 | 8.2 | 13.5 | 1.9 | 15.3 | 8.7 | 6.3 | 4.3 | 2.5 |

| S1 | 4.4 | 27.6 | 8.1 | 9.2 | 13.1 | 0.0 | 14.2 | 9.1 | 7.7 | 4.3 | 2.4 |

| S2 | 3.3 | 36.8 | 6.6 | 6.3 | 14.2 | 0.0 | 12.5 | 9.3 | 5.1 | 4.2 | 1.9 |

| S3 | 4.2 | 28.1 | 7.6 | 7.4 | 14.9 | 0.0 | 13.0 | 10.5 | 7.5 | 4.8 | 2.0 |

| S4 | 3.4 | 19.2 | 10.4 | 6.8 | 13.0 | 3.1 | 18.8 | 8.0 | 9.3 | 5.2 | 2.7 |

| B1 | 3.7 | 27.6 | 7.8 | 7.4 | 13.4 | 2.8 | 12.7 | 10.2 | 5.9 | 7.2 | 1.1 |

| B2 | 3.7 | 29.0 | 6.7 | 8.0 | 13.6 | 1.8 | 15.3 | 8.6 | 6.4 | 4.2 | 2.6 |

| B3 | 3.6 | 29.1 | 10.7 | 4.6 | 16.3 | 2.8 | 15.4 | 10.8 | 5.1 | 6.9 | 0.9 |

| B4 | 3.5 | 28.4 | 8.0 | 3.5 | 16.4 | 2.3 | 17.8 | 7.4 | 5.7 | 5.0 | 1.7 |

| L1 | 3.7 | 27.1 | 7.4 | 8.8 | 12.3 | 2.5 | 13.5 | 11.1 | 5.8 | 5.8 | 1.9 |

| L2 | 3.7 | 27.4 | 7.4 | 8.5 | 12.3 | 2.4 | 12.8 | 11.5 | 5.7 | 6.5 | 1.7 |

| L3 | 3.8 | 27.1 | 7.4 | 9.3 | 11.2 | 2.4 | 16.2 | 10.0 | 6.3 | 4.2 | 2.2 |

| L4 | 5.0 | 23.5 | 9.4 | 9.3 | 11.0 | 2.7 | 13.7 | 11.4 | 6.1 | 6.7 | 1.4 |

表2 拉曼光谱分峰拟合后各分峰的积分面积(A=Area)

Table 2 Integral area of Raman bands derived from the Raman curve fitting (A=Area)

| No. | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | A10 | A11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| BL | 3.6 | 29.0 | 6.9 | 8.2 | 13.5 | 1.9 | 15.3 | 8.7 | 6.3 | 4.3 | 2.5 |

| S1 | 4.4 | 27.6 | 8.1 | 9.2 | 13.1 | 0.0 | 14.2 | 9.1 | 7.7 | 4.3 | 2.4 |

| S2 | 3.3 | 36.8 | 6.6 | 6.3 | 14.2 | 0.0 | 12.5 | 9.3 | 5.1 | 4.2 | 1.9 |

| S3 | 4.2 | 28.1 | 7.6 | 7.4 | 14.9 | 0.0 | 13.0 | 10.5 | 7.5 | 4.8 | 2.0 |

| S4 | 3.4 | 19.2 | 10.4 | 6.8 | 13.0 | 3.1 | 18.8 | 8.0 | 9.3 | 5.2 | 2.7 |

| B1 | 3.7 | 27.6 | 7.8 | 7.4 | 13.4 | 2.8 | 12.7 | 10.2 | 5.9 | 7.2 | 1.1 |

| B2 | 3.7 | 29.0 | 6.7 | 8.0 | 13.6 | 1.8 | 15.3 | 8.6 | 6.4 | 4.2 | 2.6 |

| B3 | 3.6 | 29.1 | 10.7 | 4.6 | 16.3 | 2.8 | 15.4 | 10.8 | 5.1 | 6.9 | 0.9 |

| B4 | 3.5 | 28.4 | 8.0 | 3.5 | 16.4 | 2.3 | 17.8 | 7.4 | 5.7 | 5.0 | 1.7 |

| L1 | 3.7 | 27.1 | 7.4 | 8.8 | 12.3 | 2.5 | 13.5 | 11.1 | 5.8 | 5.8 | 1.9 |

| L2 | 3.7 | 27.4 | 7.4 | 8.5 | 12.3 | 2.4 | 12.8 | 11.5 | 5.7 | 6.5 | 1.7 |

| L3 | 3.8 | 27.1 | 7.4 | 9.3 | 11.2 | 2.4 | 16.2 | 10.0 | 6.3 | 4.2 | 2.2 |

| L4 | 5.0 | 23.5 | 9.4 | 9.3 | 11.0 | 2.7 | 13.7 | 11.4 | 6.1 | 6.7 | 1.4 |

| n2/(×10-13, esu) | WL/ (mg?cm-2) | Tg/℃ | CTE /(×10-6, K-1) | SiO2/wt% | B2O3/wt% | La2O3 /wt% | RO*/wt% | R2O*/wt% | Al2O3 /wt% | P2O5/wt% | Obj |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.029 | 0.90 | 486.9 | 12.18 | 2.16 | 2.81 | 0.91 | 13.59 | 10.74 | 11.58 | 59.17 | 0.99 |

| 1.023 | 0.92 | 486.7 | 12.28 | 1.93 | 2.96 | 1.08 | 13.61 | 10.77 | 11.60 | 59.27 | 0.99 |

| 1.027 | 0.88 | 487.0 | 12.26 | 1.89 | 3.04 | 1.27 | 13.59 | 10.74 | 11.58 | 59.15 | 0.98 |

| 1.024 | 0.94 | 488.0 | 12.21 | 2.05 | 2.97 | 0.89 | 13.60 | 10.75 | 11.59 | 59.21 | 0.98 |

| 1.027 | 0.90 | 487.4 | 12.22 | 2.19 | 2.95 | 1.08 | 13.57 | 10.73 | 11.56 | 59.09 | 0.98 |

| 1.027 | 0.93 | 486.0 | 12.28 | 2.03 | 2.78 | 1.21 | 13.62 | 10.77 | 11.60 | 59.30 | 0.98 |

表3 C-S-P模型预测的玻璃成分及相应性质

Table 3 Compositions and properties of the glass predicted by C-S-P model

| n2/(×10-13, esu) | WL/ (mg?cm-2) | Tg/℃ | CTE /(×10-6, K-1) | SiO2/wt% | B2O3/wt% | La2O3 /wt% | RO*/wt% | R2O*/wt% | Al2O3 /wt% | P2O5/wt% | Obj |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.029 | 0.90 | 486.9 | 12.18 | 2.16 | 2.81 | 0.91 | 13.59 | 10.74 | 11.58 | 59.17 | 0.99 |

| 1.023 | 0.92 | 486.7 | 12.28 | 1.93 | 2.96 | 1.08 | 13.61 | 10.77 | 11.60 | 59.27 | 0.99 |

| 1.027 | 0.88 | 487.0 | 12.26 | 1.89 | 3.04 | 1.27 | 13.59 | 10.74 | 11.58 | 59.15 | 0.98 |

| 1.024 | 0.94 | 488.0 | 12.21 | 2.05 | 2.97 | 0.89 | 13.60 | 10.75 | 11.59 | 59.21 | 0.98 |

| 1.027 | 0.90 | 487.4 | 12.22 | 2.19 | 2.95 | 1.08 | 13.57 | 10.73 | 11.56 | 59.09 | 0.98 |

| 1.027 | 0.93 | 486.0 | 12.28 | 2.03 | 2.78 | 1.21 | 13.62 | 10.77 | 11.60 | 59.30 | 0.98 |

| Sample | Yb3+ (ICP)/ (×1020, ions?cm-3) | σemi/pm2 | Tg/℃ | Stark splitting |

|---|---|---|---|---|

| PS0 | 2.40 | 0.50 | 477 | 639 |

| PS2 | 2.38 | 0.48 | 441 | 651 |

| PS5 | 2.46 | 0.50 | 462 | 769 |

| PS10 | 2.32 | 0.53 | 503 | 786 |

| PS20 | 2.17 | 0.57 | 509 | 814 |

表4 PS玻璃性质

Table 4 Properties of PS glass

| Sample | Yb3+ (ICP)/ (×1020, ions?cm-3) | σemi/pm2 | Tg/℃ | Stark splitting |

|---|---|---|---|---|

| PS0 | 2.40 | 0.50 | 477 | 639 |

| PS2 | 2.38 | 0.48 | 441 | 651 |

| PS5 | 2.46 | 0.50 | 462 | 769 |

| PS10 | 2.32 | 0.53 | 503 | 786 |

| PS20 | 2.17 | 0.57 | 509 | 814 |

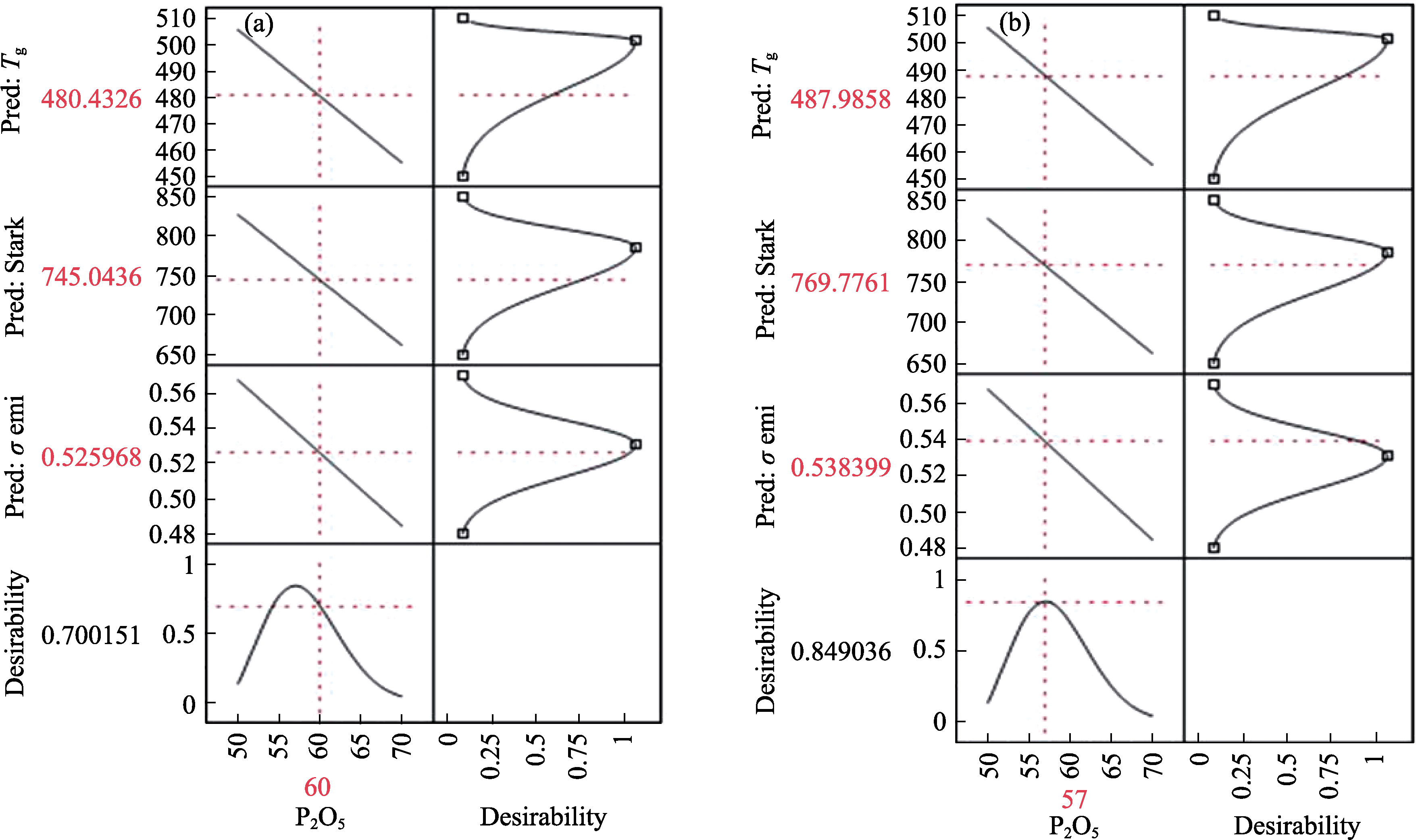

图6 设计成分为SiO2=10mol%时对应设计性质(a)和最高模拟意愿对应的P2O5值对应性质(b)的C-P模型图

Fig. 6 Designed results of C-P model (a) Properties with SiO2=10mol%, (b) Properties with P2O5 mol% under the highest aspiration

| [1] | ZHAO J C . A perspective on the materials genome initiative. Chinese Journal of Nature, 2014,36(2):89-104. |

| [2] | VOLF M . Mathematical approach to glass. Amsterdam: Elsevier Science Publishers, 1988. |

| [3] | LI H, DAVIS M J, URRUTI E H . Eye-safe laser glass development at SCHOTT. Proc. of SPIE, 2010,7686(16):1-12. |

| [4] |

VIENNA J D . Compositional models of glass/melt properties and their use for glass formulation. Procedia Materials Science, 2014,7:148-155.

DOI URL |

| [5] |

LI H, CHERYL R, WATSON J . High-performance glass fiber development for composite applications. International Journal of Applied Glass Science, 2014,5(1):65-81.

DOI URL |

| [6] | VIENNA J D, HRMA P R, SCHWEIGER M J , et al . Effect of composition and temperature on the properties of High-Level Waste (HLW) glasses melting above 1200 ℃ (Draft). Office of Scientific & Technical Information Technical Reports, 1996. |

| [7] | YAMASHITA H, YOSHINO H, NAGATA K , et al. Nuclear magnetic resonance studies of alkaline earth phosphosilicate and aluminoborosilicate glasses. Journal of Non-Crystalline Solids, 2000,270(1):48-59. |

| [8] |

GREAVES G N . EXAFS and the structure of glass. Journal of Non-Crystalline Solids, 1985,71(1):203-217.

DOI URL |

| [9] | SEN S, RAKHMATULLIN R, GUBAYDULLIN R , et al. A pulsed EPR study of clustering of Yb3+ ions incorporated in GeO2 glass. Journal of Non-Crystalline Solids , 2004,333(1):22-27. |

| [10] | ZHANG L Y, LI H, HU L L . Statistical structure analysis of GeO2 modified Yb 3+: phosphate glasses based on Raman and FT-IR study . Journal of Alloys & Compounds, 2017,698:103-113. |

| [11] | LI H, ZHANG L Y, HU L L , et al. Statistical Modeling Approach to Glass Research and Development: Composition-Structure- Property Relationships (Invited). 8th International Symposium on Advanced Glass, Shanghai, China, 2018. |

| [12] | CORNELL J A . Experiments with Mixtures: Designs, Models, and the Analysis of Mixture Data, 3rd ed. New York: John Wiley and Sons, 2002. |

| [13] |

DARROCH J N, WALLER J . Additive and interaction in three-component experiments with mixtures. Biometrika, 1985,72:153-163.

DOI URL |

| [14] |

PIEPEL G F, SZYCHOWSKI J M, LOEPPKY J L . Augmenting scheffe linear mixture models with squared and/or crossproduct terms. Journal of Quality Technology, 2002,34(3):297-314.

DOI URL |

| [15] | SCHEFFE H . The simplex-centroid design for experiments with mixtures. Journal of the Royal Statistical Society, 1963,25(2):235-263. |

| [16] | ZHANG L Y, LI H, HU L L . Statistical approach to modeling relationships of composition-structure-property I: Alkaline earth phosphate glasses. Journal of Alloys & Compounds, 2018,734:163-171. |

| [1] | 王晓波, 朱于良, 薛稳超, 史汝川, 骆柏锋, 罗骋韬. PT含量变化对PMN-PT单晶的大功率性能影响[J]. 无机材料学报, 2025, 40(7): 840-846. |

| [2] | 孙晶, 李翔, 毛小建, 章健, 王士维. 月桂酸改性剂对氮化铝粉体抗水解性能的影响[J]. 无机材料学报, 2025, 40(7): 826-832. |

| [3] | 汤新丽, 丁自友, 陈俊锐, 赵刚, 韩颖超. 基于稀土铕离子荧光标记的磷酸钙纳米材料体内分布与代谢研究[J]. 无机材料学报, 2025, 40(7): 754-764. |

| [4] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [5] | 杨光, 张楠, 陈舒锦, 王义, 谢安, 严育杰. 基于多孔ITO电极的WO3薄膜的制备及其电致变色性能[J]. 无机材料学报, 2025, 40(7): 781-789. |

| [6] | 柴润宇, 张镇, 王孟龙, 夏长荣. 直接组装法制备氧化铈基金属支撑固体氧化物燃料电池[J]. 无机材料学报, 2025, 40(7): 765-771. |

| [7] | 王鲁杰, 张玉新, 李彤阳, 于源, 任鹏伟, 王建章, 汤华国, 姚秀敏, 黄毅华, 刘学建, 乔竹辉. 深海服役环境下碳化硅陶瓷材料的腐蚀及磨损行为[J]. 无机材料学报, 2025, 40(7): 799-807. |

| [8] | 李文元, 徐佳楠, 邓瀚澳, 常爱民, 张博. 钒取代对LaTaO4陶瓷微观结构和微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 697-703. |

| [9] | 董晨雨, 郑维杰, 马一帆, 郑春艳, 温峥. 压电力显微镜表征Pb(Mg,Nb)O3-PbTiO3超薄膜弛豫特性[J]. 无机材料学报, 2025, 40(6): 675-682. |

| [10] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [11] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [12] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [13] | 安然, 林锶, 郭世刚, 张冲, 祝顺, 韩颖超. 铁掺杂纳米羟基磷灰石的制备及紫外吸收性能研究[J]. 无机材料学报, 2025, 40(5): 457-465. |

| [14] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [15] | 孙雨萱, 王政, 时雪, 史颖, 杜文通, 满振勇, 郑嘹赢, 李国荣. 缺陷偶极子热稳定性对Fe掺杂PZT陶瓷机电性能影响研究[J]. 无机材料学报, 2025, 40(5): 545-551. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||