无机材料学报 ›› 2019, Vol. 34 ›› Issue (4): 349-357.DOI: 10.15541/jim20180347 CSTR: 32189.14.10.15541/jim20180347

• 综述 • 下一篇

谭毅1,2,王凯1,2

收稿日期:2018-07-25

修回日期:2018-11-24

出版日期:2019-04-20

网络出版日期:2019-04-15

作者简介:谭 毅(1961-), 男, 博士, 教授. E-mail:tanyi@dlut.edu.cn

Yi TAN1,2,Kai WANG1,2

Received:2018-07-25

Revised:2018-11-24

Published:2019-04-20

Online:2019-04-15

摘要:

硅的理论嵌锂比容量是石墨材料比容量的十倍以上, 脱锂电位低, 资源丰富, 倍率特性较好, 故高比能量的硅基材料成为了电动汽车?可再生能源储能系统等领域的研究热点?但由于其在脱嵌锂过程中巨大的体积膨胀效应会导致硅电极材料粉化和结构崩塌, 并且在电解液中硅表面重复形成的固相电解质层(SEI)使极化增大?库伦效率降低, 最终导致电化学性能的恶化?为了解决上述问题, 加快实现硅基电极的商业化应用, 本文系统总结了通过硅基材料的选择和结构设计来解决充放电过程中体积效应的工作, 并深入分析和讨论了具有代表性的硅基复合材料的制备方法?电化学性能和相应机理, 重点介绍了硅碳复合材料和SiOx(0<x≤2)基复合材料?最后对硅基负极材料存在的问题进行了分析, 并展望了其研究前景?

中图分类号:

谭毅, 王凯. 高比能量锂离子电池硅基负极材料研究进展[J]. 无机材料学报, 2019, 34(4): 349-357.

Yi TAN, Kai WANG. Silicon-based Anode Materials Applied in High Specific Energy Lithium-ion Batteries: a Review[J]. Journal of Inorganic Materials, 2019, 34(4): 349-357.

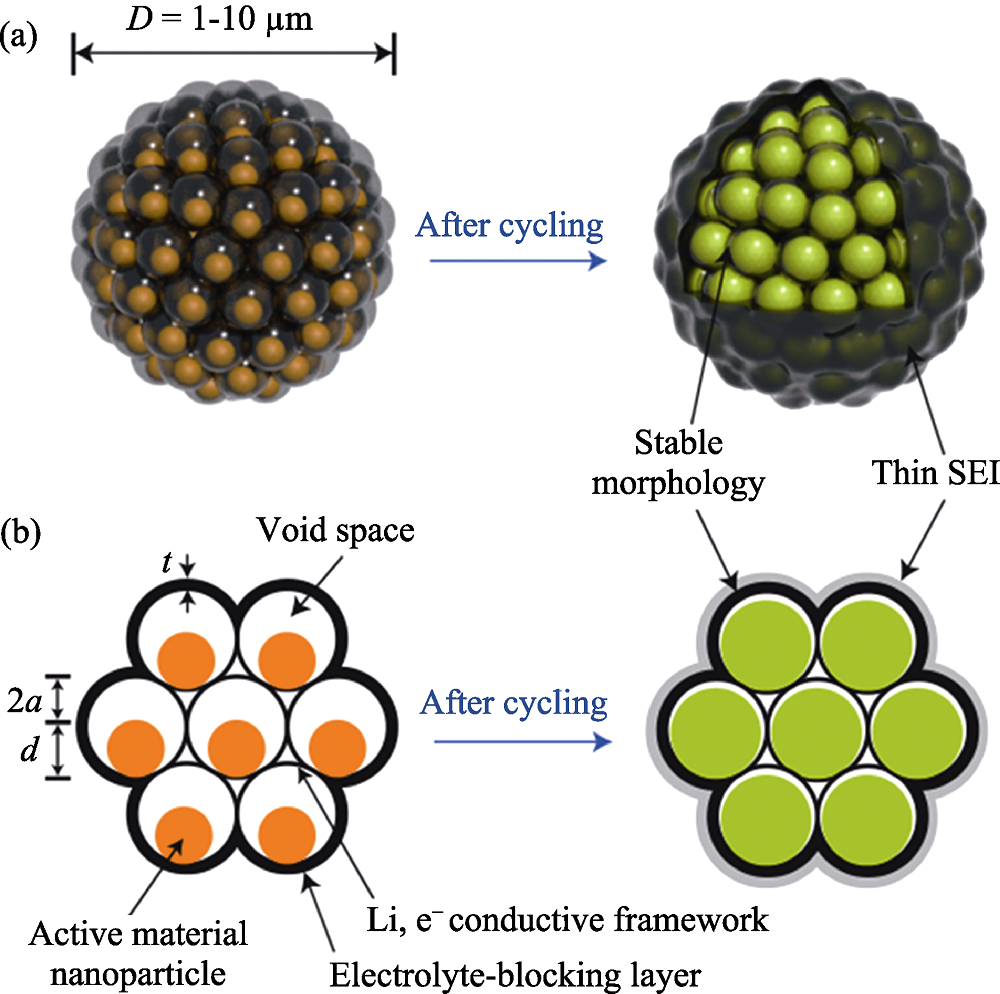

图5 石榴状纳米硅碳材料设计示意图[25]

Fig. 5 Schematic of the pomegranate-inspired design[25](a) Three dimensional view and (b) simplified two-dimensional cross-section view

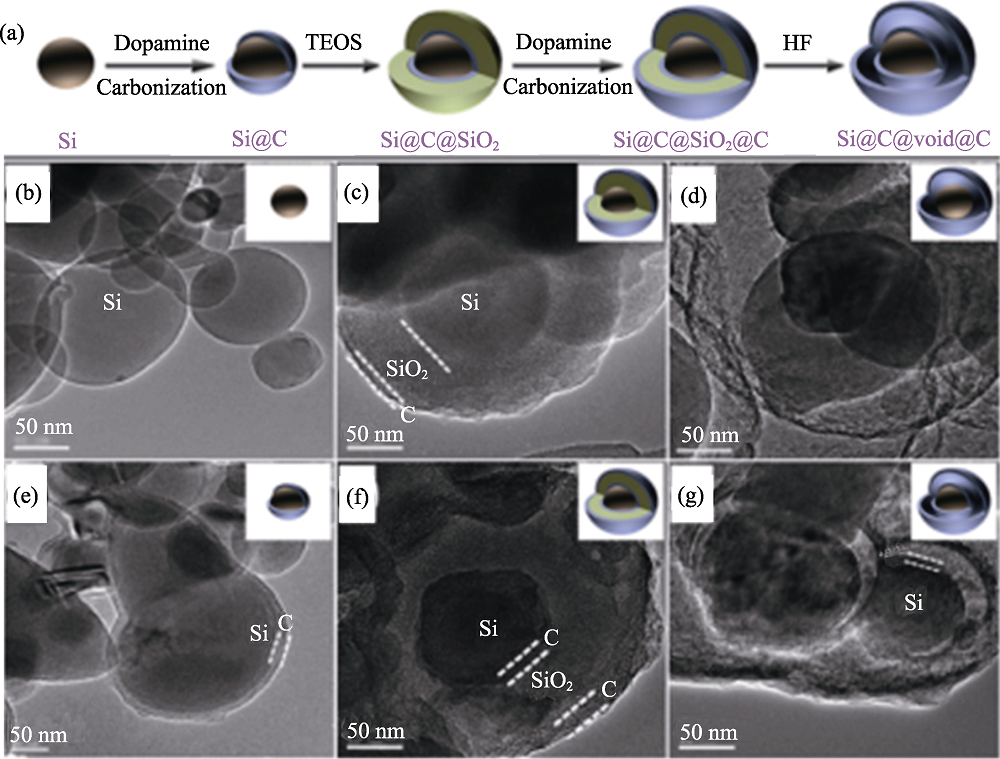

图6 (a)新型实心核壳Si@C@void@C的形成过程示意图, (b)原料Si、(c)Si@SiO2@C、(d) Si@void@C、(e) Si@C、(f) Si@C@SiO2@C和(g) Si@C@void@C的TEM照片[26]

Fig. 6 (a) Schematic diagram of the novel core-shell Si@C@void@C, TEM images of (b) raw Si, (c) Si@SiO2@C, (d) Si@void@C, (e) Si@C, (f) Si@C@SiO2@C, and (g) Si@C@void@C[26]

| Composite type | Si source | Carbon source | Electrochemical performance | Method | Ref. |

|---|---|---|---|---|---|

| Si/Porous-C | Nano-silicon powder | Pitch | 723.8 mAh/g (1st)600 mAh/g (100 mA/g, 100 )a | Spray drying + High-temperature pyrolysis | [35] |

| Si@C@RGO | Silicon powder (80 nm) | Sucrose | 1599 mAh/g (1st)1517 mAh/g (100 mA/g, 100 ) | Spray drying + High-temperature pyrolysis | [36] |

| Si/C/G | Silicon powder (325 mesh) | Phenol-formaldehyde resin (PFR) | 700 mAh/g (1st)550 mAh/g (100 mA/g, 40 ) | High-temperature pyrolysis | [37] |

| Silicon-sponge | Si wafer (>20 μm) | Acetylene | 790 mAh/g (1st)726 mAh/g (100 mA/g, 300 ) | Electrochemical etching+ High-temperature pyrolysis | [38] |

| PS@C | Si powder (5 μm) | Propylene | 1980 mAh/g (1st)1287 mAh/g (100 mA/g, 100) | Chemical etching + CVD | [39] |

| Si/C | Al-Si alloy (2-10 μm) | Polyacrylonitrile (PAN) | 952 mAh/g (1st)826.3 mAh/g (200 mA/g, 300) | Chemical etching + High-temperature pyrolysis | [30] |

表1 硅/碳锂离子电池负极材料的电化学性能

Table 1 Electrochemical performance of some silicon/carbon composite anodes for lithium-ion batteries

| Composite type | Si source | Carbon source | Electrochemical performance | Method | Ref. |

|---|---|---|---|---|---|

| Si/Porous-C | Nano-silicon powder | Pitch | 723.8 mAh/g (1st)600 mAh/g (100 mA/g, 100 )a | Spray drying + High-temperature pyrolysis | [35] |

| Si@C@RGO | Silicon powder (80 nm) | Sucrose | 1599 mAh/g (1st)1517 mAh/g (100 mA/g, 100 ) | Spray drying + High-temperature pyrolysis | [36] |

| Si/C/G | Silicon powder (325 mesh) | Phenol-formaldehyde resin (PFR) | 700 mAh/g (1st)550 mAh/g (100 mA/g, 40 ) | High-temperature pyrolysis | [37] |

| Silicon-sponge | Si wafer (>20 μm) | Acetylene | 790 mAh/g (1st)726 mAh/g (100 mA/g, 300 ) | Electrochemical etching+ High-temperature pyrolysis | [38] |

| PS@C | Si powder (5 μm) | Propylene | 1980 mAh/g (1st)1287 mAh/g (100 mA/g, 100) | Chemical etching + CVD | [39] |

| Si/C | Al-Si alloy (2-10 μm) | Polyacrylonitrile (PAN) | 952 mAh/g (1st)826.3 mAh/g (200 mA/g, 300) | Chemical etching + High-temperature pyrolysis | [30] |

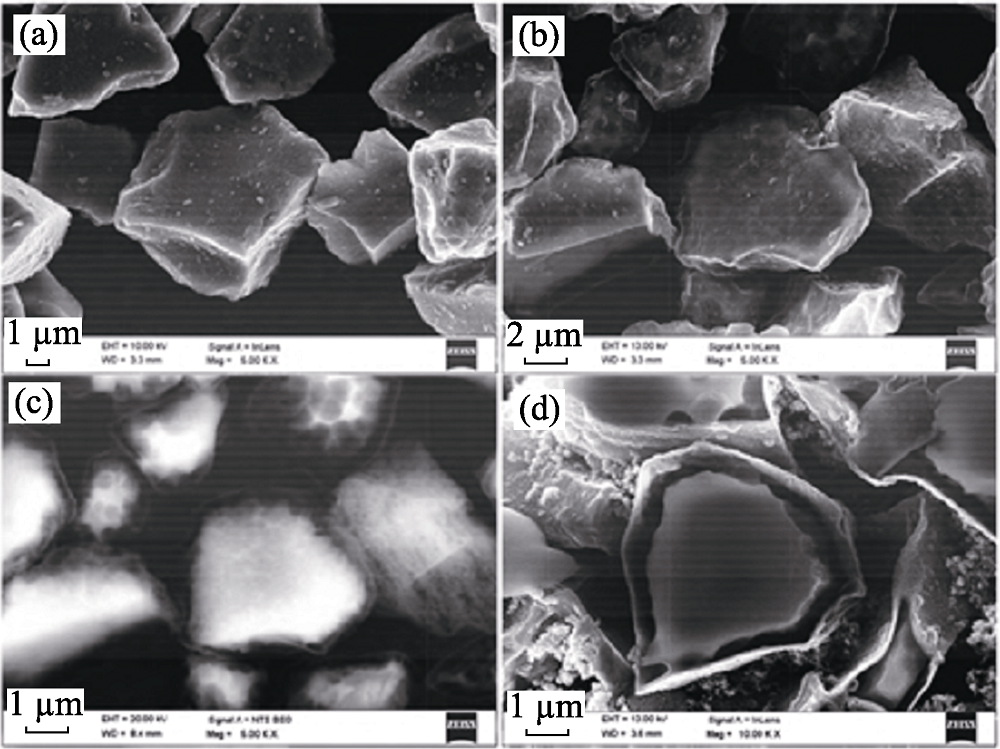

图12 (a)初始SiO@C原料与中空SiO@void@C材料的表面((b)二次电子相, (c)背散射相)及(d)截面SEM照片[59]

Fig. 12 SEM images of (a) initial SiO@C, surface ((b) secondary electron phase, (c) back scattered) and (d) cross-section of hollow SiO@void@C material[59]

| [1] | GOODENOUGH J B, PARK K S . The Li-ion rechargeable battery: a perspective.[J]. Am. Chem. Soc., 2013,135(4):1167-1176. |

| [2] | TAN Y, XUE B . Research progress on lithium titanate as anode material in lithium-ion battery.[J]. Inorg. Mater., 2018,33(5):475-482. |

| [3] | LUO W, CHEN X, XIA Y , et al. Surface and interface engineering of silicon-based anode materials for lithium-ion batteries. Adv. Energy Mater., 2017, 7(24): 1701083-1-28. |

| [4] | XIAO Q Z, FAN Y, WANG X H , et al. A multilayer Si/CNT coaxial nano fiber LiB anode with a high areal capacity. Energy Environ. Sci., 2014,7(2):655-661. |

| [5] | HUANG S, FAN F, LI J , et al. Stress generation during lithiation of high-capacity electrode particles in lithium ion batteries. Acta Mater., 2013,61(12):4354-4364. |

| [6] | LI J, DAHN J R . An in situ X-ray diffraction study of the reaction of Li with crystalline Si.[J]. Electrochem. Soc., 2007,154(3):A156-A161. |

| [7] | WANG F, WU L J, KEY B , et al. Electrochemical reaction of lithium with nanostructure silicon anodes: a study by in-situ synchrotron X-ray diffraction and electron energy-loss spectroscopy. Adv. Energy Mater., 2013,3(10):1324-1331. |

| [8] | OBROVAC M N, KRAUSE L J . Reversible cycling of crystalline silicon powder.[J]. Electrochem. Soc., 2007,154(2):A103-A108. |

| [9] | DING N, XU J, YAO Y X , et al. Improvement of cyclability of Si as anode for Li-ion batteries.[J]. Power Sources, 2009,192(2):644-651. |

| [10] | SETHURAMAN V A, CHON M J, SHIMSHAK M , et al. In situ, measurements of stress evolution in silicon thin films during electrochemical lithiation and delithiation.[J]. Power Sources, 2012,195(15):5062-5066. |

| [11] | NADIMPALLI S P V, SETHURAMAN V A, BUCCI G , et al. On plastic deformation and fracture in Si films during electrochemical lithiation/delithiation cycling.[J]. Electrochem. Soc., 2013,160(10):A1885-A1893. |

| [12] | GHASSEMI H, MING A, CHEN N , et al. In situ electrochemical lithiation/delithiation observation of individual amorphous Si nanorods. ACS Nano, 2011,5(10):7805-7811. |

| [13] | LIANG B, LIU Y, XU Y . Silicon-based materials as high capacity anodes for next generation lithium ion batteries.[J]. Power Sources, 2014,267:469-490. |

| [14] | WEN Z S, WANG K, XIE J Y . Interface formed on high capacity silicon anode for lithium ion batteries.[J]. Inorg. Mater., 2007,22(3):437-441. |

| [15] | CHAN C K, RUFFO R, HONG S , et al. Surface chemistry and morphology of the solid electrolyte interphase on silicon nanowire lithium-ion battery anodes.[J]. Power Sources, 2009,189(2):1132-1140. |

| [16] | KEY B, BHATTACHARYYA R, MORCRETTE M , et al. Real-time NMR investigations of structural changes in silicon electrodes for lithium-ion batteries.[J]. Am. Chem. Soc., 2009,131(26):9239-9249. |

| [17] | JI H R, KIM J W, SUNG Y E , et al. Failure modes of silicon powder negative electrode in lithium secondary batteries. Electrochem. Solid-State Lett., 2004,7(10):A306-A309. |

| [18] | HONG L, HUANG X, CHEN L , et al. The crystal structural evolution of nano-Si anode caused by lithium insertion and extraction at room temperature. Solid State Ionics, 2000,135(1):181-191. |

| [19] | LIANG J W, LI X N, ZHU Y C , et al. Hydrothermal synthesis of nano-silicon from a silica sol and its use in lithium ion batteries. Nano Res., 2015,8(5):1497-1504. |

| [20] | KIM W S, CHOI J, HONG S H . Meso-porous silicon-coated carbon nanotube as an anode for lithium-ion battery. Nano Lett., 2016,9(7):2174-2181. |

| [21] | ZHOU Y N, XUE M Z, FU Z W . Nanostructured thin film electrodes for lithium storage and all-solid-state thin-film lithium batteries.[J]. Power Sources, 2013,234(21):310-332. |

| [22] | DATTA M K, MARANCHI J, CHUNG S J , et al. Amorphous silicon- carbon based nano-scale thin film anode materials for lithium ion batteries. Electrochim. Acta, 2011,56(13):4717-4723. |

| [23] | CHENG H, XIAO R, BIAN H , et al. Periodic porous silicon thin films with interconnected channels as durable anode materials for lithium ion batteries. Mater. Chem. Phys., 2014,144(1/2):25-30. |

| [24] | TONG Y, XU Z, LIU C , et al. Magnetic sputtered amorphous Si/C multilayer thin films as anode materials for lithium ion batteries.[J]. Power Sources, 2014,247(2):78-83. |

| [25] | LIU N, LU Z, ZHAO J , et al. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat. Nanotechnol., 2014,9(3):187-192. |

| [26] | XIE J, TONG L, SU L , et al. Core-shell yolk-shell Si@C@Void@C nanohybrids as advanced lithium ion battery anodes with good electronic conductivity and corrosion resistance.[J]. Power Sources, 2017,342:529-536. |

| [27] | BANG B M, LEE J I, KIM H , et al. High-performance macro porous bulk silicon anodes synthesized by template-free chemical etching. Adv. Energy Mater., 2012,2(7):878-883. |

| [28] | GE M, LU Y, ERCIUS P , et al. Large-scale fabrication, 3D tomography, and lithium-ion battery application of porous silicon. Nano Lett., 2014,14(1):261-268. |

| [29] | GE M, RONG J, FANG X , et al. Scalable preparation of porous silicon nanoparticles and their application for lithium-ion battery anodes. Nano Res., 2013,6:174-181. |

| [30] | TIAN H, TAN X, XIN F , et al. Micro-sized nano-porous Si/C anodes for lithium ion batteries. Nano Energy, 2015,11:490-499. |

| [31] | LIU N, WU H, MCDOWELL M T , et al. A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes. Nano Lett., 2012,12(6):3315-3321. |

| [32] | KIM H, HAN B, CHOO J , et al. Three-dimensional porous silicon particles for use in high-performance lithium secondary batteries. Angew. Chem. Int. Ed., 2008,47(52):10151-10154. |

| [33] | JIANG H, ZHOU X, LIU G , et al. Free-standing Si/graphene paper using Si nanoparticles synthesized by acid-etching Al-Si alloy powder for high-stability Li-ion battery anodes. Electrochim. Acta, 2016,188:777-784. |

| [34] | WRODNIGG G H, WRODNIGG T M, BESENHARD J O , et al. Propylene sulfite as film-forming electrolyte additive in lithium ion batteries. Electrochem. Commun., 1999,1(3/4):148-150. |

| [35] | LI M, HOU X, SHA Y , et al. Facile spray-drying/pyrolysis synjournal of core-shell structure graphite/silicon-porous carbon composite as a superior anode for Li-ion batteries.[J]. Power Sources, 2014,248(2):721-728. |

| [36] | PAN Q, ZUO P, LOU S , et al. Micro-sized spherical silicon@carbon@graphene prepared by spray drying as anode material for lithium-ion batteries.[J]. Alloys Compd., 2017,723:434-440. |

| [37] | ZUO P, YIN G, MA Y , et al. Electrochemical stability of silicon/ carbon composite anode for lithium ion batteries. Electrochim. Acta, 2007,52(15):4878-4883. |

| [38] | LI X, GU M, HU S , et al. Mesoporous silicon sponge as an anti- pulverization structure for high-performance lithium-ion battery anodes. Nature Commun., 2014, 5(5): 4105-1-7. |

| [39] | KIM J S, HALIM M, BYUN D , et al. Amorphous carbon-coated prickle-like silicon of micro and nano hybrid anode materials for lithium-ion batteries. Solid State Ionics, 2014,260:36-42. |

| [40] | MIN K K, BO Y J, JIN S L , et al. Microstructures and electrochemical performances of nano-sized SiOx (1.18≤ x ≤1.83) as an anode material for a lithium(Li)-ion battery.[J]. Power Sources, 2013,244:115-121. |

| [41] | TAKEZAWA H, IWAMOTO K, ITO S , et al. Electrochemical behaviors of nonstoichiometric silicon suboxides (SiOx) film prepared by reactive evaporation for lithium rechargeable batteries.[J]. Power Sources, 2013,244:149-157. |

| [42] | SCHULMEISTER K, MADER W . TEM investigation on the structure of amorphous silicon monoxide. J. Non-Cryst. Solids, 2003,320(1):143-150. |

| [43] | HOHL A, WIEDER T, AKEN P A V , et al. An interface clusters mixture model for the structure of amorphous silicon monoxide (SiO). J. Non-Cryst. Solids, 2003,320(1):255-280. |

| [44] | LÜ P P, ZHAO H L, WANG J , et al. Facile preparation and electrochemical properties of amorphous SiO2/C composite as anode material for lithium ion batteries.[J]. Power Sources, 2013,237(259):291-294. |

| [45] | LIU X, ZHAO H L, JIE J Y , et al. SiOx(0<x≤2) based anode materials for lithium-ion batteries. Prog. Chem., 2015,27(4):336-348. |

| [46] | PHILIPPE B, DEDRYVÈRE R, ALLOUCHE J , et al. Nanosilicon electrodes for lithium-ion batteries: interfacial mechanisms studied by hard and soft X-ray photoelectron spectroscopy. Chem. Mater., 2017,24(24):1107-1115. |

| [47] | PARK C M, CHOI W, HWA Y , et al. Characterizations and electrochemical behaviors of disproportionate SiO and its composite for rechargeable Li-ion batteries.[J]. Mater. Chem., 2010,20(23):4854-4860. |

| [48] | MORITA T, TAKAMI N . Nano Si cluster-SiOx-C composite material as high-capacity anode material for rechargeable lithium batteries.[J]. Electrochem. Soc., 2006,153(2):A425-A430. |

| [49] | YANG X L, ZHANG P C, WEN Z Y , et al. High performance silicon/carbon composite prepared by in situ carbon-thermal reduction for lithium ion batteries.[J]. Alloys Compd., 2010,496(1):403-406. |

| [50] | SEONG I W, KIM K T, YOON W Y , et al. Electrochemical behavior of a lithium-pre-doped carbon-coated silicon monoxide anode cell.[J]. Power Sources, 2009,189(1):511-514. |

| [51] | KIM H J, CHOI S, LEE S J , et al. Controlled prelithiation of silicon monoxide for high performance lithium-ion rechargeable full cells. Nano Lett., 2016,16(1):282-288. |

| [52] | XING A, ZHANG J, BAO Z , et al. A magnesiothermic reaction process for the scalable production of mesoporous silicon for rechargeable lithium batteries. Chem. Commun., 2013,49(60):6743-6745. |

| [53] | YU B C, HWA Y, KIM J H , et al. A new approach to synthesis of porous SiOx, anode for Li-ion batteries via chemical etching of Si crystallites. Electrochim. Acta, 2014,117(4):426-430. |

| [54] | FENG X J, YANG J, LU Q W , et al. Facile approach to SiOx/Si/C composite anode material from bulk SiO for lithium ion batteries. Phys. Chem. Chem. Phys., 2013,15(34):14420-144206. |

| [55] | YANG T, XIAO L I, TIAN X D , et al. Preparation and electrochemical performance of Si@C/SiOx as anode material for lithium-ion batteries.[J]. Inorg. Mater., 2017,32(7):699-704. |

| [56] | LIU Y H, OKANO M, MUKAI T , et al. Improvement of thermal stability and safety of lithium ion battery using SiO anode material.[J]. Power Sources, 2016,304:9-14. |

| [57] | MIYUKI T, OKUYAMA Y, SAKAMOTO T , et al. Characterization of heat treated SiO powder and development of a LiFePO4/ SiO lithium ion battery with high-rate capability and thermo stability. Electrochemistry, 2012,80(6):401-404. |

| [58] | MASAYUKI Y, KAZUTAKA U, ATSUSHI U . Performance of the “SiO”-carbon composite-negative electrodes for high-capacity lithium-ion batteries; prototype 14500 batteries.[J]. Power Sources, 2013,225:221-225. |

| [59] | LIU X . Facile synthesis and electrochemical performance of hollow SiO@void@C composite as anode material for lithium-ion batteries. Chin. Batt. Indust., 2017,21(6):3-9. |

| [60] | LIU W R, YEN Y C, WU H C , et al. Nano-porous SiO/carbon composite anode for lithium-ion batteries.[J]. Appl. Electrochem., 2009,39(9):1643-1649. |

| [61] | CHOI I, MIN J L, OH S M , et al. Fading mechanisms of carbon- coated and disproportionated Si/SiOx negative electrode (Si/SiOx/C) in Li-ion secondary batteries: dynamics and component analysis by TEM. Electrochim. Acta, 2012,85(1):369-376. |

| [62] | SHI C C, YAN X L, ZHANG L L , et al. High-performance SiO/C/G composite anode for lithium ion batteries.[J]. Inorg. Mater., 2013,28(9):943-948. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 谭博文, 耿双龙, 张锴, 郑百林. 硅电极组分梯度设计抑制力-化学耦合劣化[J]. 无机材料学报, 2025, 40(7): 772-780. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [5] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [6] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [7] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [8] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [9] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [10] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [11] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [12] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [13] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [14] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [15] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||