无机材料学报 ›› 2014, Vol. 29 ›› Issue (7): 673-680.DOI: 10.3724/SP.J.1077.2014.13507 CSTR: 32189.14.SP.J.1077.2014.13507

• • 下一篇

王 义, 刘海韬, 程海峰, 王 军

收稿日期:2013-10-08

修回日期:2014-01-11

出版日期:2014-07-20

网络出版日期:2014-06-20

作者简介:王 义(1985-), 男, 博士研究生. E-mail:wycfcnudt@163.com

基金资助:WANG Yi, LIU Hai-Tao, CHENG Hai-Feng, WANG Jun

Received:2013-10-08

Revised:2014-01-11

Published:2014-07-20

Online:2014-06-20

About author:WANG Yi. E-mail:wycfcnudt@163.com

Supported by:摘要:

氧化物/氧化物陶瓷基复合材料(CMCs )具有很多优良的性能, 如高比强度、高比模量、优异的抗氧化性能等, 可应用于航空发动机燃烧室和尾喷管等热端部件。本文概述了氧化物/氧化物CMCs的增强纤维和陶瓷基体, 指出单晶氧化物纤维和莫来石陶瓷基体应用潜力较大; 从改善纤维/基体界面结合程度的角度出发, 综述了从界面相和多孔基体角度提高力学性能的方案; 分析了限制其应用的三个关键问题(缺口敏感度、蠕变容忍度和耐烧蚀性能), 最后对其未来发展进行了展望。

中图分类号:

王 义, 刘海韬, 程海峰, 王 军. 氧化物/氧化物陶瓷基复合材料的研究进展[J]. 无机材料学报, 2014, 29(7): 673-680.

WANG Yi, LIU Hai-Tao, CHENG Hai-Feng, WANG Jun. Research Progress on Oxide/Oxide Ceramic Matrix Composites[J]. Journal of Inorganic Materials, 2014, 29(7): 673-680.

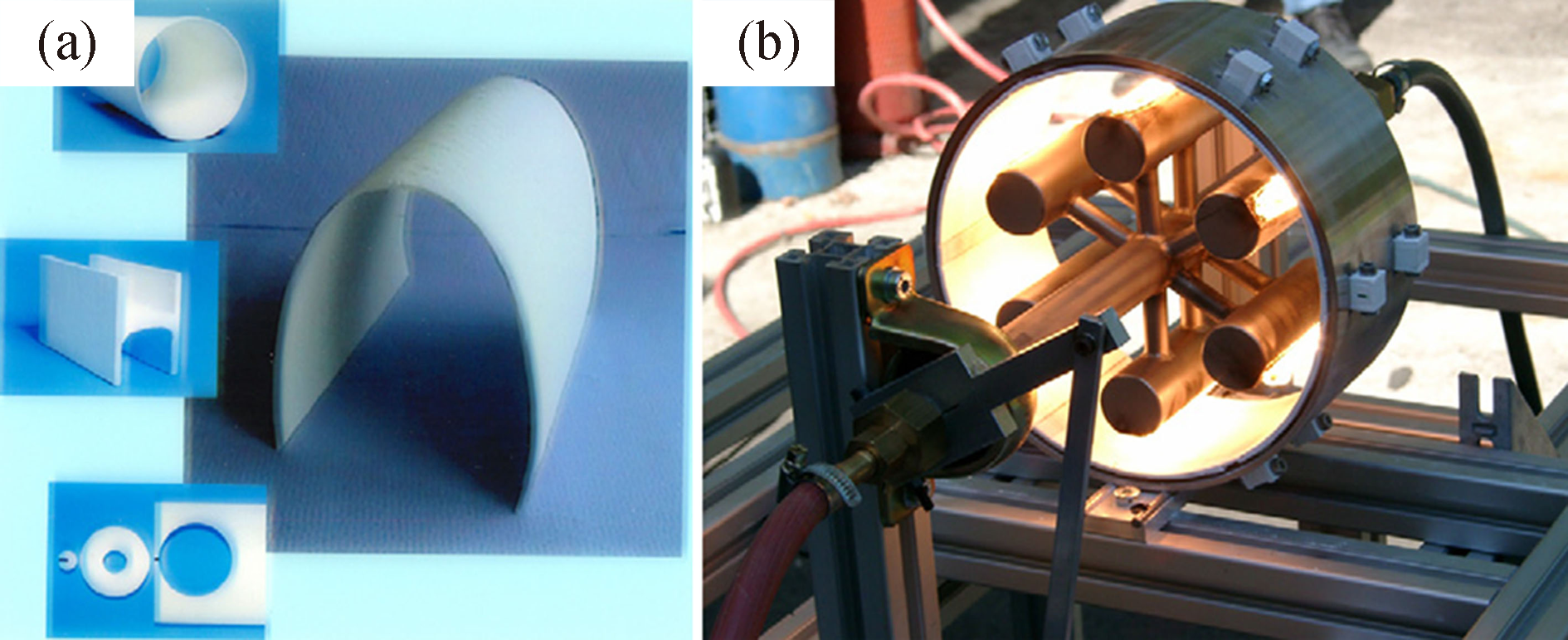

图1 Muf/Mullite CMCs应用实例[5]

Fig. 1 Application examples for Muf/Mullite CMCs[5] Products with complex shape (a), and segmented combustor tiles for the use as thermal protection systems (b)

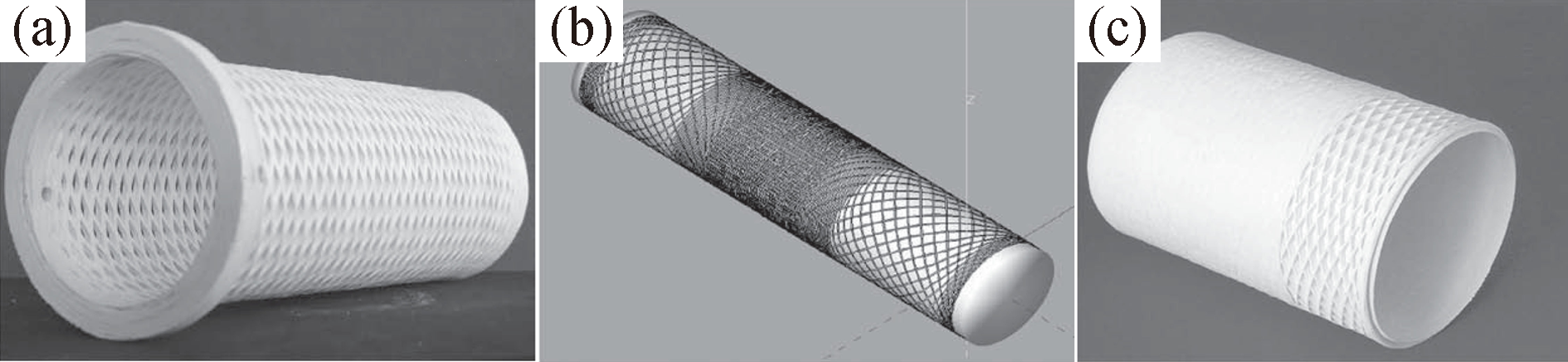

图2 浆料浸渍-缠绕工艺制备的异形氧化物/氧化物CMCs构件[9]

Fig. 2 Several Oxide/Oxide CMCs with complex shapes prepared by ceramic slurry infiltration and winding process[9] (a) Rotation-symmetric WHIPOX component (protection tube); (b) Winding pattern with variable fiber orientation (computer simulation); (c) Combination of continuous fiber layers and grid-type structures as a result of special winding sequence

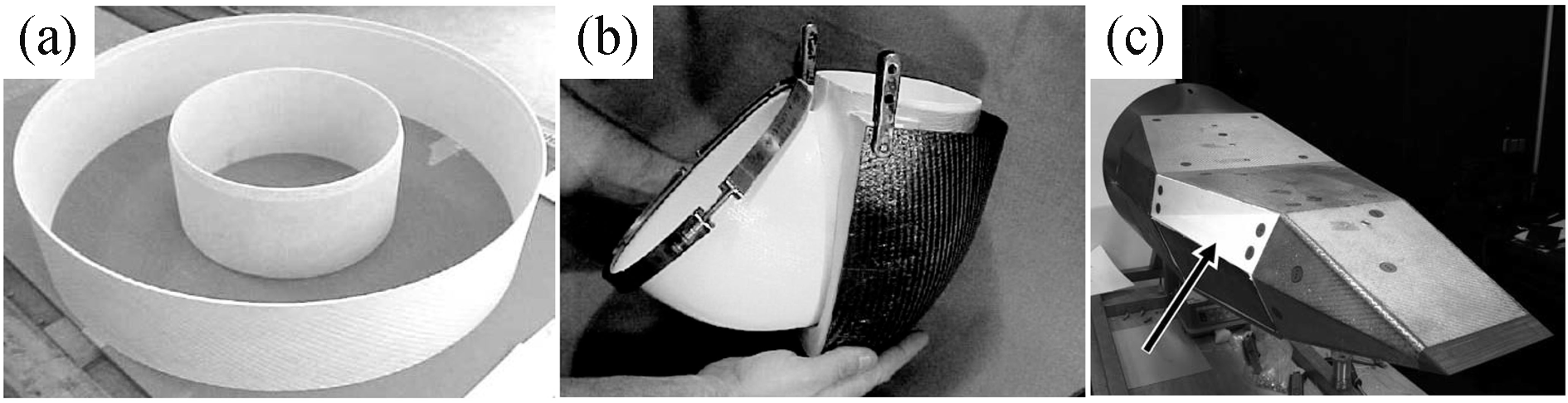

图3 氧化物/氧化物CMCs应用实例[9-10]

Fig. 3 Application examples for Oxide/Oxide CMCs[9-10] (a) Combustor inner and outer liners fabricated by ATK-COI ceramics; (b) A lightweight helicopter exhaust duct; (c) Nose cap of DLR’s SHEFEX space vehicle

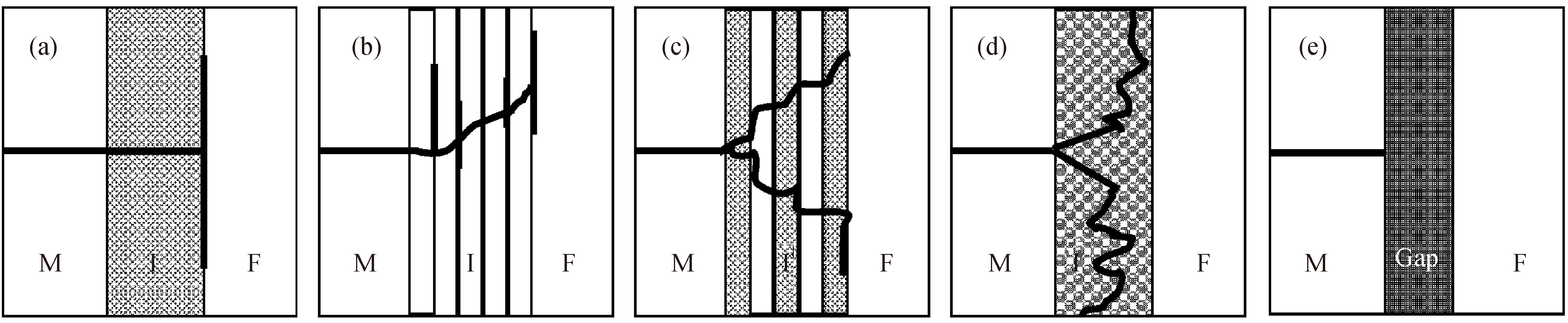

图4 氧化物/氧化物CMCs的界面相类型以及裂纹扩展模式[2, 35-36]

Fig. 4 Interphase types and crack extending modes of Oxide/Oxide CMCs[2, 35-36] M: Matrix; I: Interphase; F: Fiber

| Samples | Interphases | Mechanical properties/MPa | Reference | |

|---|---|---|---|---|

| Composition | Fabrication | |||

| 2D-N480/M* | None BN | None CVD | 104 (FS, RT); 322 (FS, RT) | [48] |

| 2D-N550/M | BN/SiC | CVD | 182 (FS, RT) | [51] |

| 2D-N720/M | NdPO4 | EPD | 279 (FS, RT); 266 (FS, 1300 ℃); 142 (TS, RT) | [52] |

| 2D-N720/M | Porous AlPO4 | EPD | 175 (FS, RT); 160 (FS, 1300 ℃-100 h) | [40] |

| 2D-N720/CAS | None fugitive carbon | None CVD | 21 (FS, RT); 85 (FS, RT) | [53] |

表1 界面相在氧化物/氧化物CMCs中的应用概况

Table 1 Applications of interphases in Oxide/Oxide CMCs

| Samples | Interphases | Mechanical properties/MPa | Reference | |

|---|---|---|---|---|

| Composition | Fabrication | |||

| 2D-N480/M* | None BN | None CVD | 104 (FS, RT); 322 (FS, RT) | [48] |

| 2D-N550/M | BN/SiC | CVD | 182 (FS, RT) | [51] |

| 2D-N720/M | NdPO4 | EPD | 279 (FS, RT); 266 (FS, 1300 ℃); 142 (TS, RT) | [52] |

| 2D-N720/M | Porous AlPO4 | EPD | 175 (FS, RT); 160 (FS, 1300 ℃-100 h) | [40] |

| 2D-N720/CAS | None fugitive carbon | None CVD | 21 (FS, RT); 85 (FS, RT) | [53] |

| Samples | Fabrication | Mechanical properties/MPa | Reference | |

|---|---|---|---|---|

| Original | After heat-treatment | |||

| 2D-N720/(M+A+PDA)* | SI-HP+PIP | 177(FS) | 189(FS )(1200 ℃-100 h) | [6] |

| 2D-N720/(M+A+PDA) | SI-HP+PIP | 148(TS) | 145(TS )(1200 ℃-1000 h) | [58-59] |

| 2D-N720/(A+S) | SI-HP+PIP | 175(TS) | 50(TS )(1200 ℃-1000 h) | [59] |

| 2D-N720/(M+PDA) | CR | 200(TS) | 220(TS )(1200 ℃-1000 h) | [60] |

| 2D-N720/AS | Sol-Gel | 204(FS) | 180(FS )(1000 ℃-100 h) | [61] |

| 1D-N720/M | SI-W | 165(FS) | 148(FS )(1250 ℃-400 h) | [7] |

Table 2 Mechanical properties of porous oxide CMCs

| Samples | Fabrication | Mechanical properties/MPa | Reference | |

|---|---|---|---|---|

| Original | After heat-treatment | |||

| 2D-N720/(M+A+PDA)* | SI-HP+PIP | 177(FS) | 189(FS )(1200 ℃-100 h) | [6] |

| 2D-N720/(M+A+PDA) | SI-HP+PIP | 148(TS) | 145(TS )(1200 ℃-1000 h) | [58-59] |

| 2D-N720/(A+S) | SI-HP+PIP | 175(TS) | 50(TS )(1200 ℃-1000 h) | [59] |

| 2D-N720/(M+PDA) | CR | 200(TS) | 220(TS )(1200 ℃-1000 h) | [60] |

| 2D-N720/AS | Sol-Gel | 204(FS) | 180(FS )(1000 ℃-100 h) | [61] |

| 1D-N720/M | SI-W | 165(FS) | 148(FS )(1250 ℃-400 h) | [7] |

| [1] | MA QING-SONG, LIU HAI-TAO, PAN YU, et al. Research progress on the application of C/SiC composites in scramjet. Journal of Inorganic Materials, 2013, 28(3): 247-255. |

| [2] | NASLAIN R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Composites Science and Technology, 2004, 64(2): 155-170. |

| [3] | NASLAIN R, GUETTE A, REBILLAT F, et al. Oxidation mecha-n-isms and kinetics of SiC-matrix composites and their constituents. Journal of Materials Science, 2004, 39(24): 7303-7316. |

| [4] | MEDVEDOVSKI E. Alumina-mullite ceramics for structural applications. Ceramics International, 2006, 32(4): 369-375. |

| [5] | SCHNEIDER H, SCHREUER J, HILDMANN B. Structure and properties of mullite-a review. Journal of the European Ceramic Society, 2008, 28(2): 329-344. |

| [6] | HOLMQUIST M G, LANGE F F. Processing and properties of a porous oxide matrix composite reinforced with continuous oxide fibers. Journal of the American Ceramic Society, 2003, 86(10): 1733-1740. |

| [7] | KANKA B, SCHNEIDER H. Aluminosilicate fiber/mullite matrix composites with favorable high-temperature properties. Journal of the European Ceramic Society, 2000, 20(5): 619-623. |

| [8] | CARELLI E A V, FUJITA H, YANG J Y, et al. Effects of thermal aging on the mechanical properties of a porous-matrix ceramic composite. Journal of the American Ceramic Society, 2002, 85(3): 595-602. |

| [9] | KRENKEL W (Eds.). Ceramic Matrix Composites: Fiber Reinforced Ceramics and Their Applications. WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim, 2008: 205-229. |

| [10] | JURF R A, BUTNER S C. Advances in all-oxide CMC. Journal of Engineering for Gas Turbines and Power, 2000, 122(2): 202-205. |

| [11] | RUGGLES-WRENN M B, MUSIL S S, MALL S, et al. Creep behavior of NextelTM610/monazite/alumina composite at elevated temperatures. Composites Science and Technology, 2006, 66(13): 2089-2099. |

| [12] | CHEN Z F, ZHU X R, LIU Z L, et al. Microstructure and mullitization of aluminosilicate matrix in Nextel 720/aluminosi-licate composites prepared by LPCVI at 550℃. Ceramics International, 2006, 32(6): 687-690. |

| [13] | WANG Y, CHENG H F, LIU H T, et al. Effects of sintering temperature on mechanical properties of 3D mullite fiber (ALF FB3) reinforced mullite composites. Ceramics International, 2013, 39(8): 9229-9235. |

| [14] | 3M Nextel™ Ceramic Textiles Technical Notebook. 3M Center, 2004. |

| [15] | SCHNEIDER H, KOMARNENI S (EDS.). Mullite. WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim, 2005: 141-156. |

| [16] | CHAWLA K K. Interface Engineering in Oxide Fiber/Oxide Matrix Composites. Contract No. N0014-89-J1459, annual report for the period 1992 to 1993. |

| [17] | KAUFMANN H, MORTENSEN A. Wetting of Saffil alumina fiber preforms by aluminum at 973 K. Metallurgical Transactions A, 1992, 23A(7): 2071-2073. |

| [18] | SCHMÜCKER M, FLUCHT F, MECHNICH P. Degradation of oxide fibers by thermal overload and environmental effects. Materials Science and Engineering A, 2012, 557(15): 10-16. |

| [19] | WANG Y, CHENG H F, LIU H T, et al. Microstructure and room temperature mechanical properties of mullite fibers afterheat-treatment at elevated temperatures. Materials Science and Engineering A, 2013, 578(20): 287-293. |

| [20] | DASSIOS K G, STEEN M, FILIOU C. Mechanical properties of alumina NextelTM 720 fibres at room and elevated temperatures: tensile bundle testing. Materials Science and Engineering A, 2003, 349(12): 63-72. |

| [21] | SCHMÜCKER M, SCHNEIDER H, MAUER T, et al. Kinetics of mullite grain growth in alumino silicate fibers. Journal of the American Ceramic Society, 2005, 88(2): 488-490. |

| [22] | DELÉGLISE F, BERGER M H, JEULIN D, et al. Microstructural stability and room temperature mechanical properties of the Nextel 720 fibre. Journal of the European Ceramic Society, 2001, 21(5): 569-580. |

| [23] | TOWATA A, HWANG H J, YASUOKA M, et al. Fabrication of fine YAG-particulate-dispersed alumina fiber. Journal of the American Ceramic Society, 1998, 81(9): 2469-2472. |

| [24] | TOWATA A, HWANG H J, YASUOKA M, et al. Preparation of polycrystalline YAG/alumina composite fibers and YAG fiber by Sol-Gel method. Composites PartA, 2001, 32(8): 1127-1131. |

| [25] | QUISPE-CANCAPA J J, DE ARELLANO-LÓPEZ A R, Martínez- Fernández J. Tensile strength of directionally solidified chromia- doped sapphire. Journal of the European Ceramic Society, 2005, 25(8): 1259-1268. |

| [26] | CLAUSS B, GRÜB A, OPPERMANN W. Continuous yttria-stab-ilized zirconia fibers. Advanced Materials, 1996, 8(2): 142-146. |

| [27] | MARSHALL D B, LANGE F F, MORGAN P D. High-strength zirconia fibers. Journal of the American Ceramic Society, 1987, 70(8): C-187-C-188. |

| [28] | EL-BUAISHI N M, JANKOVIC-CASTVAN I, JOKIC B, et al. Crystallization behavior and sintering of cordierite synthesized by an aqueous Sol-Gel route. Ceramics International, 2012, 38(3): 1835-1841. |

| [29] | OCHIAI S, UEDA T, SATO K, et al. Deformation and fracture behavior of an Al2O3/YAG composite from room temperature to 2023 K. Composites Science and Technology, 2001, 61(14): 2117-2128. |

| [30] | ARVIND A, KUMAR R, DEO M N, et al. Preparation, structural and thermo-mechanical properties of lithium aluminum silicate glass-ceramics. Ceramics International, 2009, 35(4): 1661-1666. |

| [31] | EICHLER K, SOLOW G, OTSCHIK P, et al. BAS (BaO·Al2O3·SiO2)- glasses for high temperature applications. Journal of the European Ceramic Society, 1999, 19(67): 1101-1104. |

| [32] | MA W M, WEN L, GUAN R G, et al. Sintering densification, microstructure and transformation behavior of Al2O3/ZrO2(Y2O3) composites. Materials Science and Engineering A, 2008, 477(12): 100-106. |

| [33] | JIMÉNEZ-MELENDO M, HANEDA H, NOZAWA H. Ytterbium cation diffusion in yttrium aluminum garnet (YAG)-implications for creep mechanisms. Journal of the American Ceramic Society, 2001, 84(10): 2356-2360. |

| [34] | MARTIN E, PETERS P W M, LEGUILLON D, et al. Conditions for matrix crack deflection at an interface in ceramic matrix composites. Materials Science and Engineering A, 1998, 250(2): 291-302. |

| [35] | NASLAIN R. The design of the fibre-matrix interfacial zone in ceramic matrix composites. Composites Part A, 1998, 29(9/10): 1145-1155. |

| [36] | ZOK F W. Developments in oxide fiber composites. Journal of the American Ceramic Society, 2006, 89(11): 3309-3324. |

| [37] | KUO D H, KRIVEN W M, MACKIN T J. Control of interfacial properties through fiber coatings: monazite coatings in oxide-oxide composites. Journal of the American Ceramic Society, 1997, 80(12): 2987-2996. |

| [38] | CINIBULK M K. Hexaluminates as a cleavable fiber-matrix interphase: synthesis, texture development, and phase compatibility. Journal of the European Ceramic Society, 2000, 20(5): 569-582. |

| [39] | CHAWLA K K. Interface engineering in mullite fiber/mullite matrix composites. Journal of the European Ceramic Society, 2008, 28(2): 447-453. |

| [40] | BAO Y H, NICHOLSON P S. AlPO4-coated mullite/alumina fiber reinforced reaction-bonded mullite composites. Journal of the European Ceramic Society, 2008, 28(16): 3041-3048. |

| [41] | DAVIS J B, MARSHALL D B, MORGAN P E D. Monazite- containing oxide/oxide composites. Journal of the European Ceramic Society, 2000, 20(5): 583-587. |

| [42] | CHAWLA K K, LIU H, JANCZAK-RUSCHC J, et al. Microstr-ucture and properties of monazite (LaPO4) coated saphikon fiber/alumina matrix composites. Journal of the European Ceramic Society, 2000, 20(5): 551-559. |

| [43] | REIG P, DEMAZEAU G, NASLAIN R. KMg2AlSi4O12 phyllosi-loxide as a potential interphase material for ceramic-matrix comp-osites. Journal of Materials Science, 1997, 32(16): 4195-4200. |

| [44] | CHEN Z C, TAMACHI T, KULKARNI R, et al. Interfacial reaction behavior and thermal stability of barium zirconate-coated alumina fiber/alumina matrix composites. Journal of the European Ceramic Society, 2008, 28(6): 1149-1160. |

| [45] | BERTRAND S, DROILLARD C, PAILLER R, et al. TEM structure of (PyC/SiC)n multilayered interphases in SiC/SiC composites. Journal of the European Ceramic Society, 2000, 20(1): 1-13. |

| [46] | YU H J, ZHOU X G, ZHANG W, et al. Mechanical properties of 3D KD-I SiCf/SiC composites with engineered fibre-matrix interfaces. Composites Science and Technology, 2011, 71(5): 699-704. |

| [47] | BHATT R T, CHEN Y L, MORSCHER G N. Microstructure and tensile properties of BN/SiC coated Hi-Nicalon, and Sylramic SiC fiber preforms. Journal of Materials Science, 2002, 37(18): 3991-3998. |

| [48] | SCHMÜCKER M, SCHNEIDER H, CHAWLA K K. Thermal degradation of fiber coatings in mullite-fiber-reinforced mullite composites. Journal of the American Ceramic Society, 1997, 80(8): 2136-2140. |

| [49] | CINIBULK M K, PARTHASARATHY T A, KELLER K A, et al. Porous yttrium aluminum garnet fiber coatings for oxide composites. Journal of the American Ceramic Society, 2002, 85(11): 2703-2710. |

| [50] | KERANS R J, HAY R S, PARTHASARATHY T A, et al. Interface design for oxidation-resistant ceramic composites. Journal of the American Ceramic Society, 2002, 85(11): 2599-2632. |

| [51] | CHAWLA K K, XU Z R, HA J S. Processing, structure, and properties of mullite fiber/mullite matrix composites. Journal of the European Ceramic Society, 1996, 16(2): 293-299. |

| [52] | KAYA C, KAYA F, BUTLER E G, et al. Development and characterisation of high-density oxide fibre-reinforced oxide ceramic matrix composites with improved mechanical properties. Journal of the European Ceramic Society, 2009, 29(9): 1631-1639. |

| [53] | KELLER K A, MAH T, PARTHASARATHY T A, et al. Fugitive interfacial carbon coatings for oxide/oxide composites. Journal of the American Ceramic Society, 2000, 83(2): 329-336. |

| [54] | BOCCACCINI A R, KAYA C, CHAWLA K K. Use of electrophoretic deposition in the processing of fibre reinforced ceramic and glass matrix composites: a review. Composites Part A, 2001, 32(8): 997-1006. |

| [55] | STOLL E, MAHR P, KRÜGER H G, et al. Progress in the characterisation of structural oxide/oxide ceramic matrix compo-sites fabricated by electrophoretic deposition (EPD). Advanced Engine-ering Materials, 2006, 8(4): 282-285. |

| [56] | GOUSHEGIR S M, GUGLIELMI P O, SILVA J G P D, et al. Fiber-matrix compatibility in an all-oxide ceramic composite with RBAO matrix. Journal of the American Ceramic Society, 2012, 95(1): 159-164. |

| [57] | SCHMÜCKER M, MECHNICH P. Improving the microstructural stability of NextelTM 610 alumina fibers embedded in a porous alumina matrix. Journal of the American Ceramic Society, 2010, 93(7): 1888-1890. |

| [58] | CARELLI E V A, FUJITA H, YANG J Y, et al. Effects of thermal aging on the mechanical properties of a porous-matrix ceramic composite. Journal of the American Ceramic Society, 2002, 85(3): 595-602. |

| [59] | ZOK F W, LEVI C G. Mechanical properties of porous-matrix ceramic composites. Advanced Engineering Materials, 2001, 3(1/2): 15-23. |

| [60] | SIMON R A. Progress in processing and performance of porous-matrix oxide/oxide composites. International Journal of Applied Ceramic Technology, 2005, 2(2): 141-149. |

| [61] | ANTTI M L, CURZIO E L, WARREN R. Thermal degradation of an oxide fibre (Nextel 720)/aluminosilicates composite. Journal of the European Ceramic Society, 2004, 24(3): 565-578. |

| [62] | KRAMB V A, JOHN R, ZAWADA L P. Notched fracture behavior of an oxide/oxide ceramic-matrix composite. Journal of the American Ceramic Society, 1999, 82(11): 3087-3096. |

| [63] | RUGGLES-WRENN M B, MALL S, EBER C A, et al. Effects of steam environment on high-temperature mechanical behavior of NextelTM 720/alumina (N720/A) continuous fiber ceramic composite. Composites Part A, 2006, 37(11): 2029-2040. |

| [64] | RUGGLES-WRENN M B, BRAUN J C. Effects of steam environment on creep behavior of NextelTM 720/alumina ceramic composite at elevated temperature. Materials Science and Engineering A, 2008, 497(12): 101-110. |

| [65] | RUGGLES-WRENN M B, LAFFEY P D. Creep behavior in interlaminar shear of NextelTM 720/alumina ceramic composite at elevated temperature in air and in steam. Composites Science and Technology, 2008, 68(1011): 2260-2266. |

| [66] | RUGGLES-WRENN M B, KOUTSOUKOS P, BAEK S S. Effects of environment on creep behavior of two oxide/oxide ceramic- matrix composites at 1200℃. Journal of Materials Science, 2008, 43(20): 6734-6746. |

| [67] | RUGGLES-WRENN M B, GENELIN C L. Creep of NextelTM 720/alum-ina-mullite ceramic composite at 1200℃ in air, argon, and steam. Composites Science and Technology, 2009, 69(5): 663-669. |

| [68] | MATTONI M A, YANG J Y, LEVI C G, et al. Effects of combustor rig exposure on a porous-matrix oxide composite. International Journal of Applied Ceramic Technology, 2005, 2(2): 133-140. |

| [69] | OPILA E J, MYERS D L. Alumina volatility in water vapor at elevated temperatures. Journal of the American Ceramic Society, 2004, 87(9): 1701-1705. |

| [70] | CAO X Q, VASSEN R, STOEVER D. Ceramic materials for thermal barrier coatings. Journal of the European Ceramic Society, 2004, 24(1): 1-10. |

| [71] | HUA JIA-JIE, ZHANG LI-PENG, LIU ZI-WEI. Progress of research on the failure mechanism of thermal barrier coatings. Journal of Inorganic Materials, 2012, 27(7): 680-686. |

| [72] | MECHNICH P, BRAUE W. Air plasma-sprayed Y2O3 coatings for Al2O3/Al2O3 ceramic matrix composites. Journal of the European Ceramic Society, 2013, 33(13/14): 2645-2653. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 柴润宇, 张镇, 王孟龙, 夏长荣. 直接组装法制备氧化铈基金属支撑固体氧化物燃料电池[J]. 无机材料学报, 2025, 40(7): 765-771. |

| [3] | 陈相杰, 李玲, 雷添福, 王佳佳, 汪尧进. 相界工程和畴工程调控(1-x)(0.8PZT-0.2PZN)-xBZT陶瓷的压电性能[J]. 无机材料学报, 2025, 40(6): 729-734. |

| [4] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [5] | 李文元, 徐佳楠, 邓瀚澳, 常爱民, 张博. 钒取代对LaTaO4陶瓷微观结构和微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 697-703. |

| [6] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [7] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [8] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [9] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [10] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [11] | 尹长志, 成名飞, 雷微程, 蔡弋炀, 宋小强, 付明, 吕文中, 雷文. Ga3+掺杂对SrAl2Si2O8陶瓷晶体结构及微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 704-710. |

| [12] | 孙雨萱, 王政, 时雪, 史颖, 杜文通, 满振勇, 郑嘹赢, 李国荣. 缺陷偶极子热稳定性对Fe掺杂PZT陶瓷机电性能影响研究[J]. 无机材料学报, 2025, 40(5): 545-551. |

| [13] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [14] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [15] | 熊思宇, 莫尘, 朱肖伟, 朱国斌, 陈德钦, 刘来君, 施晓东, 李纯纯. 超低介电常数LiBxAl1-xSi2O6微波介质陶瓷的低温烧结[J]. 无机材料学报, 2025, 40(5): 536-544. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||