无机材料学报 ›› 2024, Vol. 39 ›› Issue (8): 920-928.DOI: 10.15541/jim20240002 CSTR: 32189.14.10.15541/jim20240002

收稿日期:2024-01-02

修回日期:2024-03-13

出版日期:2024-08-20

网络出版日期:2024-03-30

通讯作者:

王 松, 研究员. E-mail: wangs0731@163.com作者简介:全文心(2000-), 男, 硕士研究生. E-mail: quanwenxin18@nudt.edu.cn

基金资助:

QUAN Wenxin( ), YU Yiping, FANG Bing, LI Wei, WANG Song(

), YU Yiping, FANG Bing, LI Wei, WANG Song( )

)

Received:2024-01-02

Revised:2024-03-13

Published:2024-08-20

Online:2024-03-30

Contact:

WANG Song, professor. E-mail: wangs0731@163.comAbout author:QUAN Wenxin (2000-), male, Master candidate. E-mail: quanwenxin18@nudt.edu.cn

Supported by:摘要:

氧化损伤是影响火箭发动机用C/SiC复合材料喷管寿命的主要因素之一。为准确评估C/SiC复合材料喷管的氧化损伤, 本研究以近似喷管结构的管状C/SiC复合材料为实验对象, 研究了管状C/SiC复合材料在高温(900~1300 ℃)空气环境下的氧化行为, 包括其组成、结构及力学性能的演变规律, 发现管状C/SiC复合材料在该高温空气环境下表现出受扩散控制的氧化特征, 质量与剩余强度随时间呈幂函数下降趋势, 下降速率与温度正相关。在此基础上, 从氧化动力学与传质学理论角度出发, 建立了管状C/SiC复合材料细观/宏观尺度氧化模型, 模拟了管状C/SiC复合材料高温空气氧化过程, 并预测了材料的质量与剩余强度。模型预测结果与实验数据拟合程度较高, 可为C/SiC复合材料喷管的寿命评估提供参考。

中图分类号:

全文心, 余艺平, 方冰, 李伟, 王松. 管状C/SiC复合材料高温空气氧化行为与宏细观建模研究[J]. 无机材料学报, 2024, 39(8): 920-928.

QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment[J]. Journal of Inorganic Materials, 2024, 39(8): 920-928.

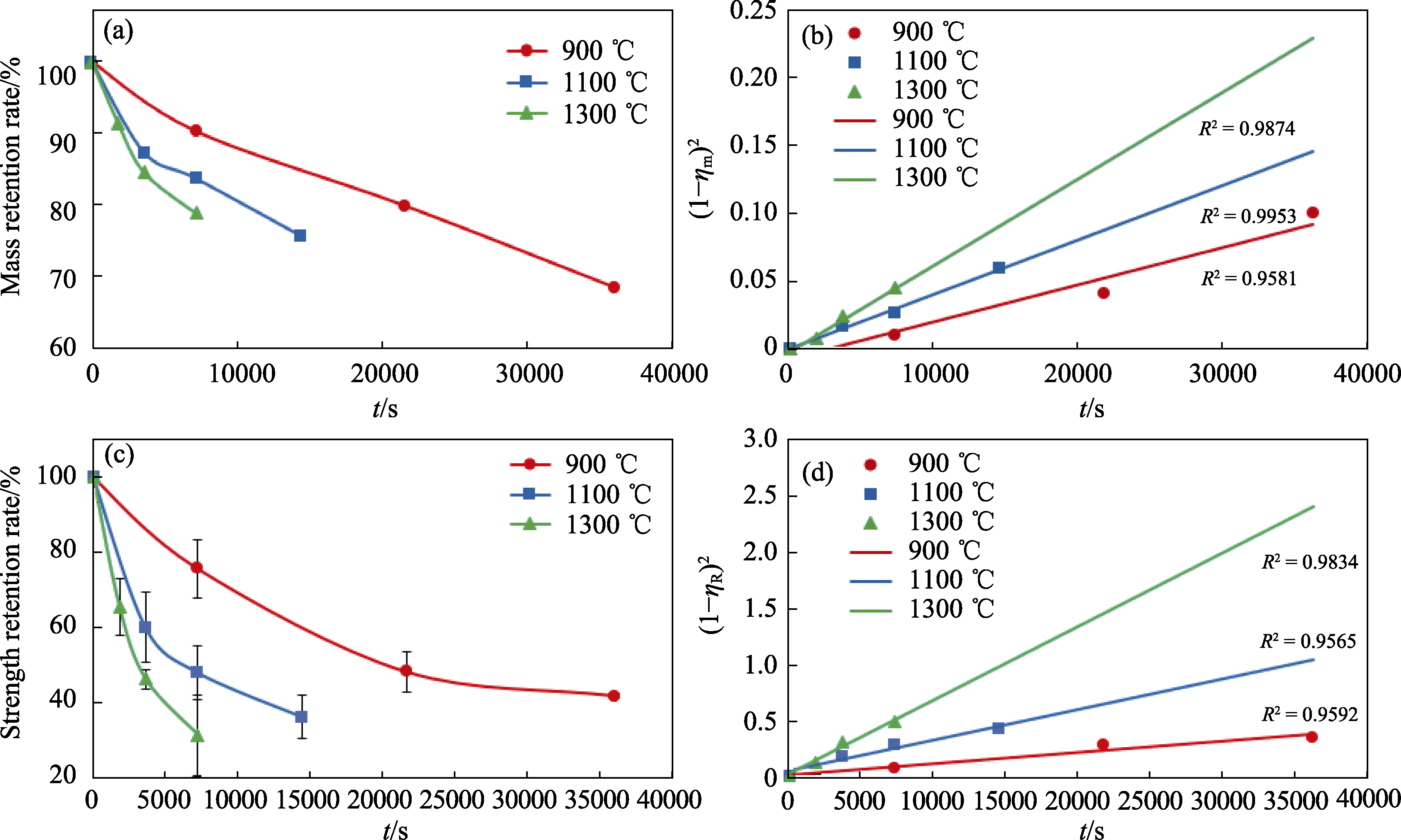

图6 管状C/SiC复合材料高温空气氧化质量保留率(a)、$ \left(1-\eta_{\mathrm{m}}\right)^{2}-t$关系曲线(b)、强度保留率(c)和$ \left(1-\eta_{\mathrm{R}}\right)^{2}-t$关系曲线(d)

Fig. 6 Mass retention rate (a), function fitting of $ \left(1-\eta_{\mathrm{m}}\right)^{2}$ with t (b), strength retention rate (c), and function fitting of $ \left(1-\eta_{\mathrm{R}}\right)^{2}$ with t (d) for tubular C/SiC composites after high-temperature air oxidation

图11 在1100 ℃-1 h(a)、1300 ℃-0.5 h(b)和1300 ℃-1 h(c)高温空气氧化后管状C/SiC复合材料的截面氧元素含量的EDS分布

Fig. 11 EDS distributions of oxygen contents at cross sections of tubular C/SiC composites after 1100 ℃-1 h (a), 1300 ℃-0.5 h (b) and 1300 ℃-1 h (c) high-temperature air oxidation

| Parameter | 900 ℃ | 1000 ℃ | 1100 ℃ | 1200 ℃ | 1300 ℃ |

|---|---|---|---|---|---|

| B/(nm2∙min-1) | 1.05 | 10.29 | 39.48 | 84.84 | 163.17 |

表1 SiC空气氧化抛物线速率常数

Table 1 Parabolic rate constant of SiC in air oxidation

| Parameter | 900 ℃ | 1000 ℃ | 1100 ℃ | 1200 ℃ | 1300 ℃ |

|---|---|---|---|---|---|

| B/(nm2∙min-1) | 1.05 | 10.29 | 39.48 | 84.84 | 163.17 |

| Parameter | 900 ℃ | 1100 ℃ | 1300 ℃ |

|---|---|---|---|

| 3.18×10-5 | 3.53×10-5 | 3.86×10-5 | |

| B/(nm2∙s-1) | 0.0175 | 0.658 | 2.720 |

| Z/μm | 0.0251 | 0.1539 | 0.3129 |

| e/μm | 1.980 | 1.835 | 1.658 |

| 1.937×10-2 | 1.128×10-2 | 2.880×10-1 |

表2 氧化10 h的参数计算结果

Table 2 Parameters of oxidation for 10 h

| Parameter | 900 ℃ | 1100 ℃ | 1300 ℃ |

|---|---|---|---|

| 3.18×10-5 | 3.53×10-5 | 3.86×10-5 | |

| B/(nm2∙s-1) | 0.0175 | 0.658 | 2.720 |

| Z/μm | 0.0251 | 0.1539 | 0.3129 |

| e/μm | 1.980 | 1.835 | 1.658 |

| 1.937×10-2 | 1.128×10-2 | 2.880×10-1 |

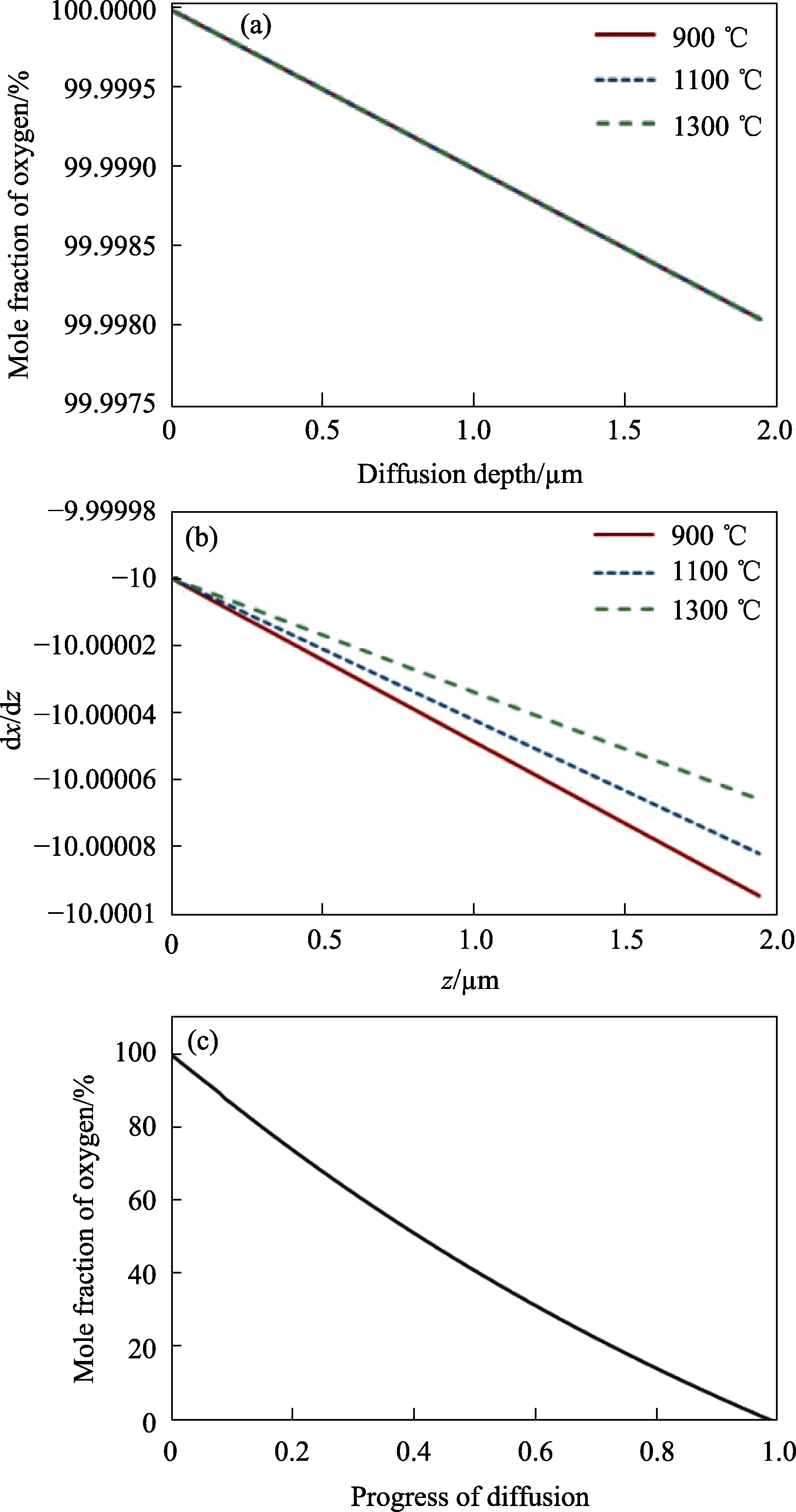

图12 SiC基体微裂纹中氧气的摩尔分数分布(a)、氧气摩尔分数的梯度分布(b)及氧气摩尔分数随扩散进度的分布(c)

Fig. 12 Distributions of mole fraction of oxygen (a), gradient of mole fraction (b) and mole fraction with diffusion progress (c) in microcracks of SiC matrix

| Modifying factor | 900 ℃ | 1100 ℃ | 1300 ℃ |

|---|---|---|---|

| 1.2×10-5 | 3.1×10-5 | 6.0×10-5 |

表3 等效氧化深度修正因子

Table 3 Modifying factor of equivalent oxidation depth

| Modifying factor | 900 ℃ | 1100 ℃ | 1300 ℃ |

|---|---|---|---|

| 1.2×10-5 | 3.1×10-5 | 6.0×10-5 |

| [1] | 栾新刚. 3D C/SiC在复杂耦合环境中的损伤机理与寿命预测. 西安: 西北工业大学博士学位论文, 2007. |

| [2] | 张紫煜. 陶瓷基复合材料应用. 中国科技投资, 2016, 18: 308. |

| [3] | XU Y, ZHANG W. Numerical modelling of oxidized microstructure and degraded properties of 2D C/SiC composites in air oxidizing environments below 800 ℃. Materials Science and Engineering, 2011, 528(27): 7974. |

| [4] | LACOMBE A, PICHON T, LACOSTE M. High temperature composite nozzle extensions: a mature and efficient technology to improve upper stage liquid rocket engine performance. 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, 2007: 5471. |

| [5] | 张立同, 成来飞, 梅辉, 等. 陶瓷基复合材料. 北京: 中国铁道出版社, 2020: 12- 42. |

| [6] | 张立同, 成来飞. 连续纤维增韧陶瓷基复合材料可持续发展战略探讨. 复合材料学报, 2007, 2: 1. |

| [7] | HALBIG M C, MCGUFFIN-CAWLEY J D, ECKEL A J, et al. Oxidation kinetics and stress effects for the oxidation of continuous carbon fibers within a microcracked C/SiC ceramic matrix composite. Journal of the American Ceramic Society, 2008, 2: 519. |

| [8] | 成来飞, 栾新刚, 张立同, 等. 超高温结构复合材料服役行为模拟:理论与方法. 北京: 化学工业出版社, 2020: 174-237. |

| [9] | CHEN X, SUN Z, CHEN P, et al. Modeling thermal expansion behavior of 2.5D C/SiC composites in air oxidizing environments between 400 ℃ and 800 ℃. Applied Composite Materials, 2020, 6: 861. |

| [10] | MEI H, TAN Y, CHANG P, et al. Simplified approach to study oxidative damage of C/SiC composites induced from notch defects. Ceramics International, 2019, 45(17): 22464. |

| [11] | LAMOUROUX F, CAMUS G, THEBAULT J. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: I. experimental approach. Journal of the American Ceramic Society, 1994, 8: 2049. |

| [12] | LAMOUROUX F, NASLAIN R, JOUIN J. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: II, theoretical approach. Journal of the American Ceramic Society, 1994, 8: 2058. |

| [13] | SULLIVAN R M. A model for the oxidation of carbon silicon carbide composite structures. Carbon, 2005, 43(2): 275. |

| [14] | ZHAO C, TU Z, MAO J. The dynamic thermophysical properties evolution and multi-scale heat transport mechanisms of 2.5D C/SiC composite under high-temperature air oxidation environment. Composites Part B, 2023, 263: 110831. |

| [15] | DING J, SUN Z, CHEN X, et al. A progressive oxidative damage model of C/SiC composites under stressed oxidation environments. Applied Composite Materials, 2021, 28(5): 1609. |

| [16] | 颜淮. C/SiC复合材料微细观氧化损伤分析. 哈尔滨: 哈尔滨工业大学硕士学位论文, 2021. |

| [17] | CHEN P, NIU X, CHEN X, et al. Modeling the failure time and residual strength of C/SiC composites under stress-oxidation environment. Transactions of the Indian Ceramic Society, 2020, 4: 212. |

| [18] | ZHAO C, TU Z, MAO J. Thermal-oxidation coupled analysis method for unidirectional fiber-reinforced C/SiC composites in air oxidizing environments below 1000 ℃. International Communications in Heat and Mass Transfer, 2023, 143: 106678. |

| [19] | ECKEL A J, CAWLEY J D, PARTHASARATHY T A. Oxidation kinetics of a continuous carbon phase in a nonreactive matrix. Journal of the American Ceramic Society, 1995, 4: 972. |

| [20] | OPILA E J, SERRA J L. Oxidation of carbon fiber-reinforced silicon carbide matrix composites at reduced oxygen partial pressures. Journal of the American Ceramic Society, 2011, 7: 2185. |

| [21] | XIANG Y, CAO F, PENG Z, et al. Evolution of microstructure and mechanical properties of PIP-C/SiC composites after high- temperature oxidation. Journal of Asian Ceramic Societies, 2017, 3: 370. |

| [22] | SU F, HUANG P, WU J, et al. Creep behavior of C/SiC composite in hot oxidizing atmosphere and its mechanism. Ceramics International, 2017, 12: 9355. |

| [23] | DRAWIN S, BACOS M, DORVAUX J, et al. Oxidation model for carbon-carbon composites. 4th Symposium on Multidisciplinary Analysis and Optimization, Cleveland, 1992: 5016. |

| [24] | 国义军, 石卫波, 曾磊, 等. 高超声速飞行器烧蚀防热理论与应用. 北京: 科学出版社, 2019: 112. |

| [25] | DEAL B E, GROVE A S. General relationship for the thermal oxidation of silicon. Journal of Applied Physics, 1965, 12: 3770. |

| [26] | FILIPUZZI L, NASLAIN R, JAUSSAUD C. Oxidation kinetics of SiC deposited from CH3SiCl3/H2 under CVI conditions. Journal of Materials Science, 1992, 12: 3331. |

| [27] | SONG Y, DHAR S, FELDMAN L C. Modified deal grove model for the thermal oxidation of silicon carbide. Journal of Applied Physics, 2004, 9: 4953. |

| [28] | FULLER E N, SCHETTLER P D, GIDDINGS J C. New method for prediction of binary gas-phase diffusion coefficients. Industrial & Engineering Chemistry, 1966, 5: 18. |

| [29] | KNUDSEN M. The laws of molecular flow and of inner friction flow of gases through tubes. Journal of Membrane Science, 1995, 1: 23. |

| [1] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [2] | 穆爽, 马沁, 张禹, 沈旭, 杨金山, 董绍明. Yb2Si2O7改性SiC/SiC复合材料的氧化行为研究[J]. 无机材料学报, 2025, 40(3): 323-328. |

| [3] | 王文婷, 徐敬军, 马科, 李美栓, 李兴超, 李同起. 原位反应/热压合成Ti2AlC-20TiB2复合材料在1000~1300 ℃空气中的高温氧化行为[J]. 无机材料学报, 2025, 40(1): 31-38. |

| [4] | 陈乾, 苏海军, 姜浩, 申仲琳, 余明辉, 张卓. 超高温氧化物陶瓷激光增材制造及组织性能调控研究进展[J]. 无机材料学报, 2024, 39(7): 741-753. |

| [5] | 王洪达, 冯倩, 游潇, 周海军, 胡建宝, 阚艳梅, 陈小武, 董绍明. SiC/SiC-哈氏合金异质连接机制及其氟熔盐腐蚀特性分析[J]. 无机材料学报, 2022, 37(4): 452-458. |

| [6] | 罗艺, 夏书海, 牛波, 张亚运, 龙东辉. 柔性有机硅气凝胶的制备及其高温无机化转变研究[J]. 无机材料学报, 2022, 37(12): 1281-1288. |

| [7] | 马登浩, 侯振华, 李军平, 孙新, 金恩泽, 尹健. 界面相对3D-SiC/SiC复合材料静态力学性能及内耗特征的影响[J]. 无机材料学报, 2021, 36(1): 55-60. |

| [8] | 张冰玉,王岭,王晓猛,邱海鹏. 不同先驱体制备C/SiC复合材料及其浸渍行为[J]. 无机材料学报, 2020, 35(9): 1017-1022. |

| [9] | 黄喜鹏, 王波, 杨成鹏, 潘文革, 刘小瀛. 基于声发射信号的三维针刺C/SiC复合材料拉伸损伤演化研究[J]. 无机材料学报, 2018, 33(6): 609-616. |

| [10] | 何 飞, 李 亚, 骆 金, 方旻翰, 赫晓东. 具有气凝胶结构特征的C/SiO2和C/SiC复合材料研究进展[J]. 无机材料学报, 2017, 32(5): 449-458. |

| [11] | 赵 爽, 杨自春, 周新贵. 不同界面SiC/SiC复合材料的断裂行为研究[J]. 无机材料学报, 2016, 31(1): 58-62. |

| [12] | 王 浩, 周卿军, 简 科, 邵长伟, 朱旖华. C/SiC复合材料有序多孔陶瓷接头的制备及其连接技术研究[J]. 无机材料学报, 2013, 28(7): 763-768. |

| [13] | 马青松, 刘海韬, 潘 余, 刘卫东, 陈朝辉. C/SiC复合材料在超燃冲压发动机中的应用研究进展[J]. 无机材料学报, 2013, 28(3): 247-255. |

| [14] | 刘 顾, 汪刘应, 陈桂明, 魏皖宁, 华绍春, 朱二雷. CNTs-SiC/Al2O3-TiO2复合涂层的制备及其性能[J]. 无机材料学报, 2011, 26(11): 1187-1192. |

| [15] | 李思维, 张立同, 刘永胜, 成来飞, 冯祖德, 栾新刚, 张伟华, 杨文彬. CVI B-C基体改性2D C/SiC在低温湿氧中的自愈合行为[J]. 无机材料学报, 2010, 25(11): 1199-1203. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||