无机材料学报 ›› 2024, Vol. 39 ›› Issue (7): 819-827.DOI: 10.15541/jim20230597 CSTR: 32189.14.10.15541/jim20230597

所属专题: 【能源环境】燃料电池(202506)

叶梓滨( ), 邹高昌, 吴琪雯, 颜晓敏, 周明扬, 刘江(

), 邹高昌, 吴琪雯, 颜晓敏, 周明扬, 刘江( )

)

收稿日期:2023-12-27

修回日期:2024-02-18

出版日期:2024-07-20

网络出版日期:2024-03-08

通讯作者:

刘 江, 教授. E-mail: Jiangliu@scut.edu.cn作者简介:叶梓滨(1998-), 男, 硕士研究生. E-mail: 1193676345@qq.com

基金资助:

YE Zibin( ), ZOU Gaochang, WU Qiwen, YAN Xiaomin, ZHOU Mingyang, LIU Jiang(

), ZOU Gaochang, WU Qiwen, YAN Xiaomin, ZHOU Mingyang, LIU Jiang( )

)

Received:2023-12-27

Revised:2024-02-18

Published:2024-07-20

Online:2024-03-08

Contact:

LIU Jiang, professor. E-mail: Jiangliu@scut.edu.cnAbout author:YE Zibin (1998-), male, Master candidate. E-mail: 1193676345@qq.com

Supported by:摘要:

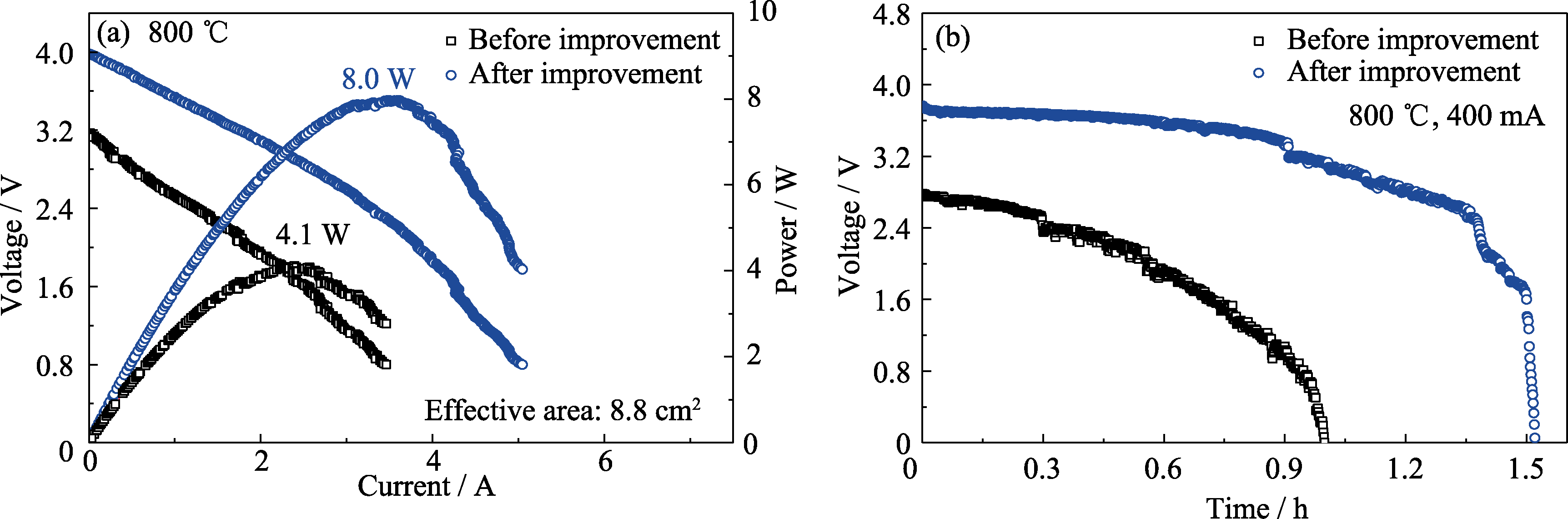

针对阳极支撑型直接碳固体氧化物燃料电池(DC-SOFC)的浓差极化阻抗大的问题, 本研究采用改进后的凝胶注模法制备了阳极支撑型锥管状固体氧化物燃料电池(SOFC)。通过适当增加溶剂的含量, 改善了浆料的流动性, 提高了成品的质量; 通过增大造孔剂的含量, 提高了阳极的孔隙率, 减小了气体的扩散阻力。改进后的SOFC以氢气为燃料, 在800 ℃运行时, 开路电压为1.05 V, 电化学阻抗谱的极化阻抗更小, 电池的最大功率密度为0.67 W•cm-2(阴极有效面积为2.2 cm2), 明显优于改进前的SOFC。改进后的SOFC直接采用担载质量分数5% K的活性炭为燃料, 在800 ℃运行时, 开路电压为1.030 V, 接近理论电压, 最大功率密度达0.74 W•cm-2, 以400 mA进行恒流放电, 碳燃料的有效利用率为31%, 高于改进前电池的碳燃料的有效利用率17%。将改进后的4个锥管状单电池串联成电池组, 直接采用担载质量分数5% K催化剂的活性炭为燃料, 在800 ℃运行时, 最大功率达8.0 W, 高于改进前的4节DC-SOFC电池组(4.1 W), 该电池组碳燃料的有效利用率为15%, 峰值功率密度可达0.91 W•cm-2, 超过了文献报道的最高值。

中图分类号:

叶梓滨, 邹高昌, 吴琪雯, 颜晓敏, 周明扬, 刘江. 阳极支撑型锥管串接式直接碳固体氧化物燃料电池组的制备及性能[J]. 无机材料学报, 2024, 39(7): 819-827.

YE Zibin, ZOU Gaochang, WU Qiwen, YAN Xiaomin, ZHOU Mingyang, LIU Jiang. Preparation and Performances of Tubular Cone-shaped Anode-supported Segmented-in-series Direct Carbon Solid Oxide Fuel Cell[J]. Journal of Inorganic Materials, 2024, 39(7): 819-827.

| 化学试剂 | 生产公司 | 纯度 |

|---|---|---|

| NiO | 加拿大Inco公司 | 98% |

| YSZ | 宜兴市熠辉耐磨材料有限公司 | 99.9% |

| 丙烯酰胺 | 上海阿拉丁生化科技有限公司 | 分析纯 |

| N, N'-亚甲基双丙烯酰胺 | 上海阿拉丁生化科技有限公司 | 分析纯 |

| 柠檬酸铵 | 上海麦克林生化科技有限公司 | 分析纯 |

| 聚乙二醇 | 上海阿拉丁生化科技有限公司 | 99.0% |

| 邻苯二甲酸二辛酯 | 上海麦克林生化科技有限公司 | 99.0% |

| 三乙醇胺 | 上海麦克林生化科技有限公司 | 99.0% |

| 聚乙烯醇缩丁醛 | 上海阿拉丁生化科技有限公司 | 99.0% |

| Al2O3 | 淄博信富盟化工有限公司 | 99.0% |

| GDC | 中国科学院宁波材料技术与工程研究所 | 99.50% |

| 银导电胶DAD-87 | 上海合成树脂研究所 | 99.99% |

| 粒状活性炭 | 上海阿拉丁试剂有限公司 | 触媒载体用 |

| 碳酸钾 | 上海麦克林生化科技有限公司 | 99% |

表S1 原料和化学试剂

Table S1 Raw materials and chemical reagents

| 化学试剂 | 生产公司 | 纯度 |

|---|---|---|

| NiO | 加拿大Inco公司 | 98% |

| YSZ | 宜兴市熠辉耐磨材料有限公司 | 99.9% |

| 丙烯酰胺 | 上海阿拉丁生化科技有限公司 | 分析纯 |

| N, N'-亚甲基双丙烯酰胺 | 上海阿拉丁生化科技有限公司 | 分析纯 |

| 柠檬酸铵 | 上海麦克林生化科技有限公司 | 分析纯 |

| 聚乙二醇 | 上海阿拉丁生化科技有限公司 | 99.0% |

| 邻苯二甲酸二辛酯 | 上海麦克林生化科技有限公司 | 99.0% |

| 三乙醇胺 | 上海麦克林生化科技有限公司 | 99.0% |

| 聚乙烯醇缩丁醛 | 上海阿拉丁生化科技有限公司 | 99.0% |

| Al2O3 | 淄博信富盟化工有限公司 | 99.0% |

| GDC | 中国科学院宁波材料技术与工程研究所 | 99.50% |

| 银导电胶DAD-87 | 上海合成树脂研究所 | 99.99% |

| 粒状活性炭 | 上海阿拉丁试剂有限公司 | 触媒载体用 |

| 碳酸钾 | 上海麦克林生化科技有限公司 | 99% |

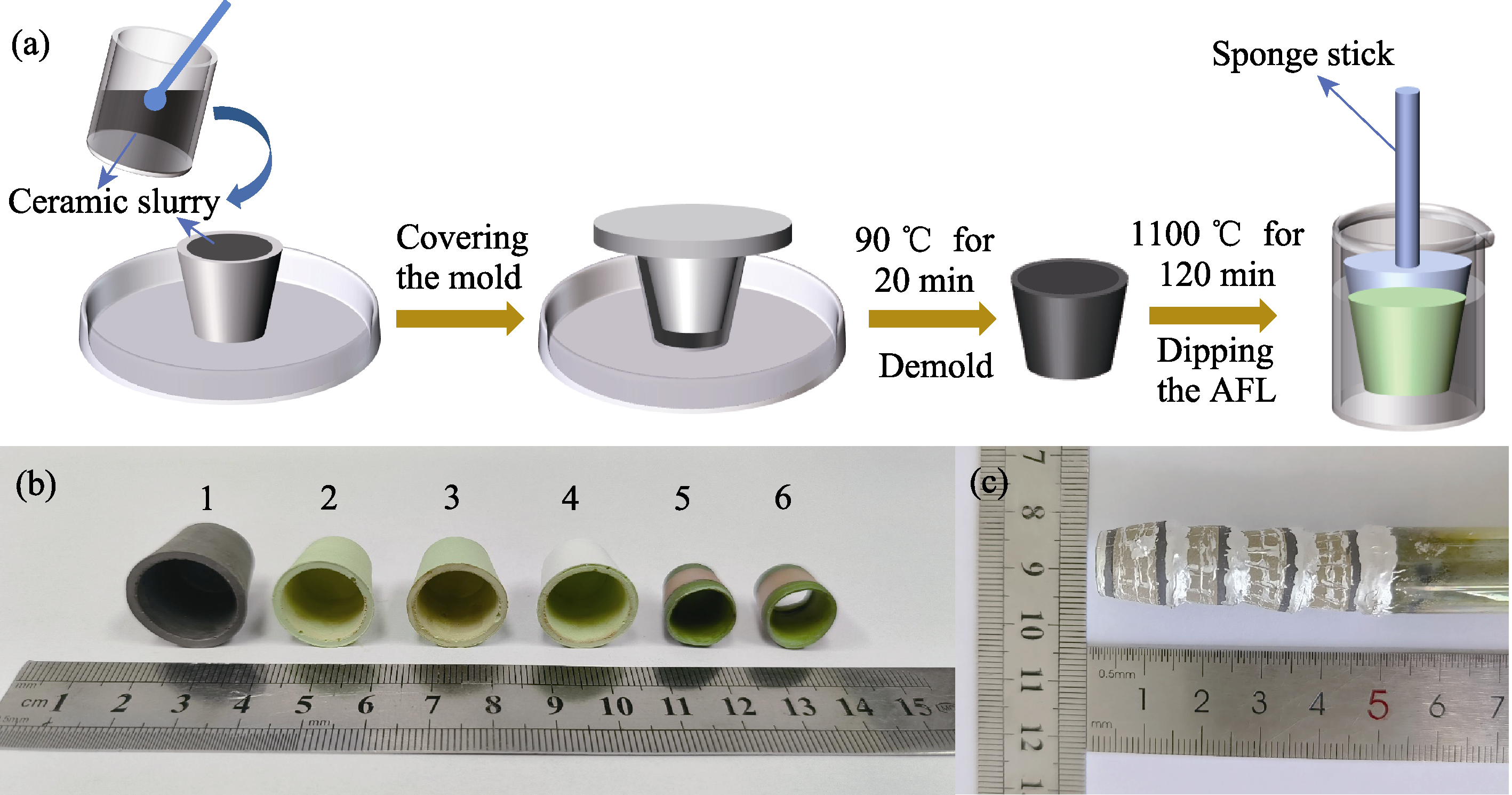

图1 固体氧化物燃料电池的制备过程

Fig. 1 Preparation of solid oxide fuel cells (a) Illustration of process for preparing anode supports; (b) Photo of a series of tubular cone-shaped SOFCs at different preparation stages (2-6) in contrast to green anode support (1); (c) The segmented-in-series four-cell stack; The tubular cone-shaped SOFCs marked with 2-6 are pre-sintered anode support, anode support with a co-sintered functional layer, anode support coated with electrolyte layer, completed tubular cone-shaped cell with one end closed, and completed tubular cone-shaped cell with both ends open, respectively

| Component | Ref.[ | Ref.[ | This work |

|---|---|---|---|

| NiO-YSZ | 49.7% | 57.5% | 44.2% |

| AM | 7.9% | 11.5% | 7.1% |

| MBAM | 0.8% | 0.6% | 0.9% |

| Deionized water | 20.7% | 17.2% | 26% |

| Graphite | 10% | 11.5% | 13.2% |

| AC | 1.7% | - | 1.3% |

| Polyacrylic acid | - | 1.7% | - |

| TEA | 1.0% | - | - |

| PEG-600 | 8.2% | - | 7.3% |

表1 凝胶注模成型浆料成分对比

Table 1 Comparison of the composition of gel-casting slurries

| Component | Ref.[ | Ref.[ | This work |

|---|---|---|---|

| NiO-YSZ | 49.7% | 57.5% | 44.2% |

| AM | 7.9% | 11.5% | 7.1% |

| MBAM | 0.8% | 0.6% | 0.9% |

| Deionized water | 20.7% | 17.2% | 26% |

| Graphite | 10% | 11.5% | 13.2% |

| AC | 1.7% | - | 1.3% |

| Polyacrylic acid | - | 1.7% | - |

| TEA | 1.0% | - | - |

| PEG-600 | 8.2% | - | 7.3% |

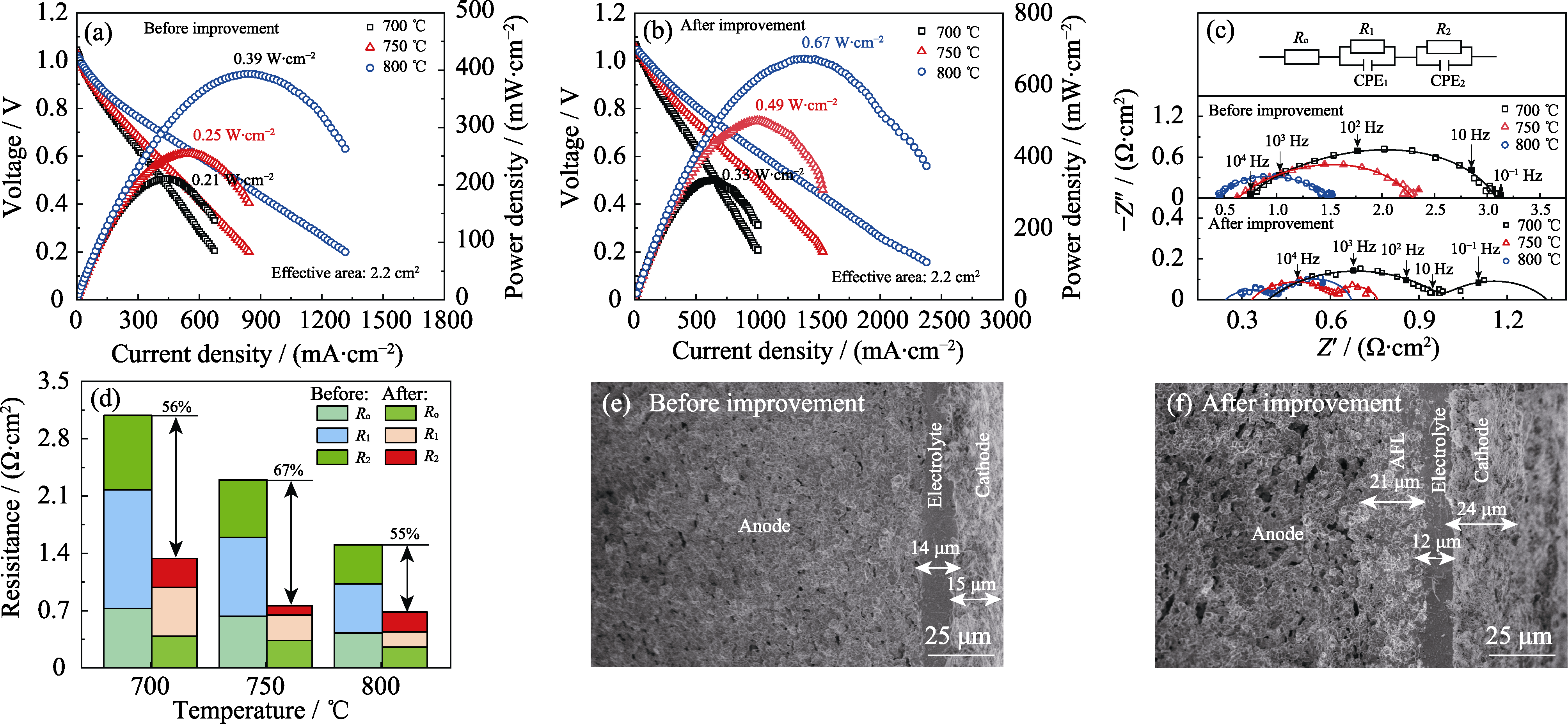

图3 工艺改进前后以氢气为燃料的SOFC单电池的电化学性能及其微观结构

Fig. 3 Electrochemical performance and microstructure of hydrogen-fueled SOFC single cell before and after process improvement (a, b) Output performances; (c) Electrochemical impedance spectra; (d) Comparison of the corresponding fitted resistances; (e, f) Microstructures of the SOFC observated by SEM. Colorful figures are available on website

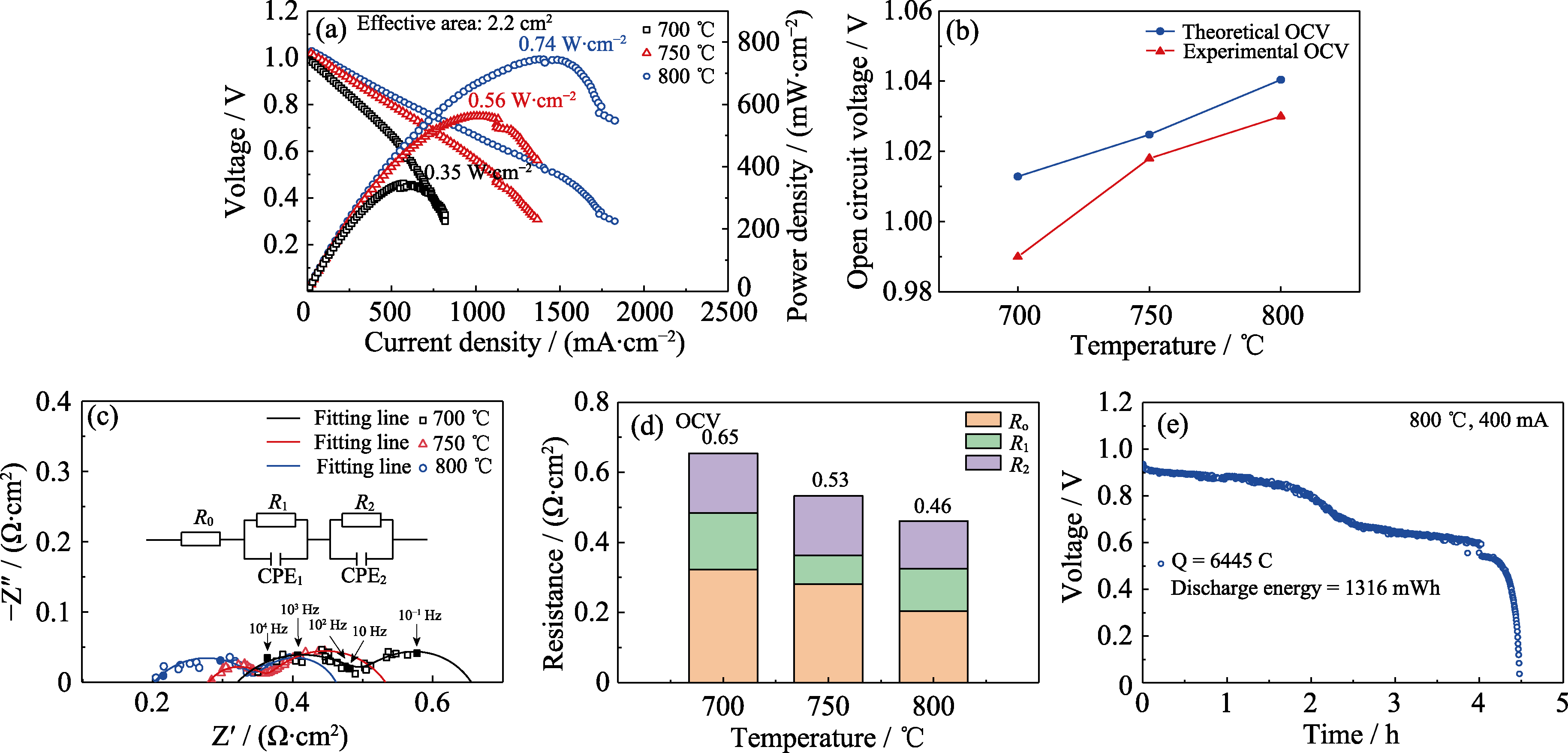

图4 以担载质量分数5% K的活性炭为燃料的DC-SOFC单电池的电化学性能

Fig. 4 Electrochemical performance of a single DC-SOFC using 5% (in mass) K activated carbon (a) Output performances; (b) Open circuit voltages; (c) Electrochemical impedance spectra; (d) Comparison of the corresponding fitted resistances; (e) Discharge characteristics. Colorful figures are available on website

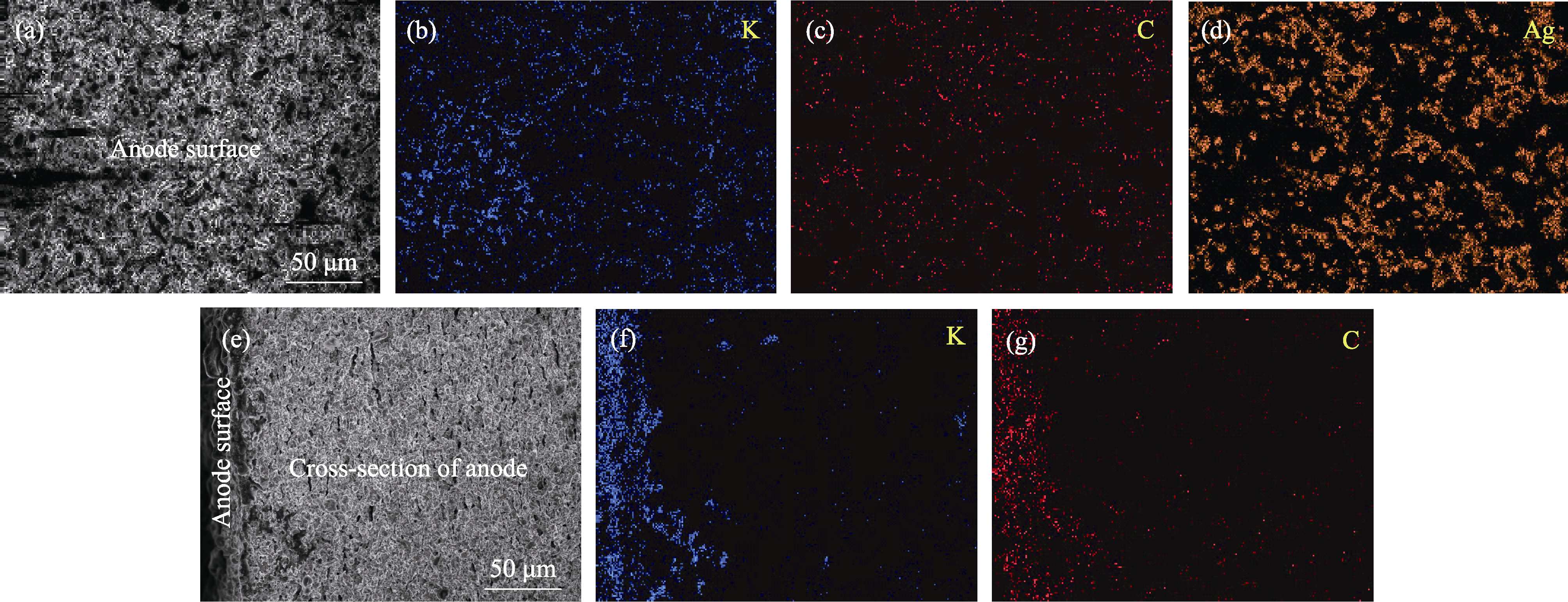

图5 测试后的DC-SOFC阳极微观结构

Fig. 5 Microstructure of the DC-SOFC anode after testing (a-d) Surface SEM image (a) and EDS mappings of K (b), C (c) and Ag (d); (e-g) Cross-sectional SEM image (e) and EDS mappings of K (f) and C (g)

图6 采用担载质量分数5% K活性炭作为燃料的锥管串接式电池组的(a)输出性能及(b)放电特性

Fig. 6 (a) Output performance and (b) discharge characteristic of the tubular cone-shaped segmented-in-series stack fueled by 5% (in mass) K-loaded activated carbon

| [1] | KILKIS S, KRAJACIC G, DUIC N, et al. Advances in integration of energy, water and environment systems towards climate neutrality for sustainable development. Energy Conversion and Management, 2020, 225: 113410. |

| [2] | XU G Y, SCHWARZ P, YANG H L. Adjusting energy consumption structure to achieve China’s CO2emissions peak. Renewable & Sustainable Energy Reviews, 2020, 122: 109737. |

| [3] | SIVABALAN K, HASSAN S, YA H, et al. A review on the characteristic of biomass and classification of bioenergy through direct combustion and gasification as an alternative power supply. Journal of Physics: Conference Series, 2021, 1831: 012033. |

| [4] | TANG Y B, LIU J, SUI J. A novel direct carbon solid oxide fuel cell. 11th International Symposium on Solid Oxide Fuel Cells (SOFC), Vienna, 2009. |

| [5] | LIU R Z, ZHAO C H, LI J L, et al. A novel direct carbon fuel cell by approach of tubular solid oxide fuel cells. Journal of Power Sources, 2010, 195(2): 480. |

| [6] | LIU G Y, ZHOU A N, QIU J S, et al. Utilization of bituminous coal in a direct carbon fuel cell. International Journal of Hydrogen Energy, 2016, 41(20): 8576. |

| [7] | RADY A C, GIDDEY S, BADWAL S P S, et al. Review of fuels for direct carbon fuel cells. Energy & Fuels, 2012, 26(3): 1471. |

| [8] | GIDDEY S, BADWAL S P S, KULKARNI A, et al. A comprehensive review of direct carbon fuel cell technology. Progress in Energy and Combustion Science, 2012, 38(3): 360. |

| [9] | DEEPI A S, PRIYA S D, NESARAJ A S, et al. Component fabrication techniques for solid oxide fuel cell (SOFC) — a comprehensive review and future prospects. International Journal of Green Energy, 2022, 19(14): 1600. |

| [10] | NAKAGAWA N, ISHIDA M. Performance of an internal direct- oxidation carbon fuel cell and its evaluation by graphic exergy analysis. Industrial & Engineering Chemistry Research, 1988, 27(7): 1181. |

| [11] | XIE Y M, TANG Y B, LIU J. A verification of the reaction mechanism of direct carbon solid oxide fuel cells. Journal of Solid State Electrochemistry, 2013, 17(1): 121. |

| [12] | CARBONELL M S, VILLAGRACIA A C, ONG H L, et al. Review- bibliometrics and current research trends on direct carbon-solid oxide fuel cells utilizing biomass as fuel. Journal of the Electrochemical Society, 2023, 170(4): 044510. |

| [13] | 刘江, 颜晓敏. 直接碳固体氧化物燃料电池. 电化学, 2020, 26(2): 175. |

| [14] | 唐玉宝, 刘江. 以活性炭为燃料的固体氧化物燃料电池. 物理化学学报, 2010, 26(5): 1191. |

| [15] | TANG Y B, LIU J. Effect of anode and boudouard reaction catalysts on the performance of direct carbon solid oxide fuel cells. International Journal of Hydrogen Energy, 2010, 35(20): 11188. |

| [16] | 谢永敏. 直接碳固体氧化物燃料电池的反应机理及其在电-气联产方面的应用. 广州: 华南理工大学博士学位论文, 2015. |

| [17] | YAN X M, ZHOU M Y, ZHANG Y P, et al. An all-solid-state carbon-air battery reaching an output power over 10 W and a specific energy of 3600 Wh kg-1. Chemical Engineering Journal, 2021, 404: 127057. |

| [18] | ELLEUCH A, BOUSSETTA A, YU J S, et al. Experimental investigation of direct carbon fuel cell fueled by almond shell biochar: Part I. Physicochemical characterization of the biochar fuel and cell performance examination. International Journal of Hydrogen Energy, 2013, 38(36): 16590. |

| [19] | ZHOU Q, CAI W Z, ZHANG Y P, et al. Electricity generation from corn cob char though a direct carbon solid oxide fuel cell. Biomass & Bioenergy, 2016, 91: 250. |

| [20] | CAI W Z, ZHOU Q, XIE Y M, et al. A direct carbon solid oxide fuel cell operated on a plant derived biofuel with natural catalyst. Applied Energy, 2016, 179: 1232. |

| [21] | CAI W Z, LIU J, YU F Y, et al. A high performance direct carbon solid oxide fuel cell fueled by Ca-loaded activated carbon. International Journal of Hydrogen Energy, 2017, 42(33): 21167. |

| [22] | QIU Q Y, ZHOU M Y, CAI W Z, et al. A comparative investigation on direct carbon solid oxide fuel cells operated with fuels of biochar derived from wheat straw, corncob, and bagasse. Biomass & Bioenergy, 2019, 121: 56. |

| [23] | LI X, ZHU Z H, DE MARCO R, et al. Evaluation of raw coals as fuels for direct carbon fuel cells. Journal of Power Sources, 2010, 195(13): 4051. |

| [24] | HUIJSMANS J P P. Ceramics in solid oxide fuel cells. Current Opinion in Solid State and Materials Science, 2001, 5(4): 317. |

| [25] | LI C J, LI C X, XING Y Z, et al. Influence of YSZ electrolyte thickness on the characteristics of plasma-sprayed cermet supported tubular SOFC. Solid State Ionics, 2006, 177(19-25): 2065. |

| [26] | MOON H, KIM S D, HYUN S H, et al. Development of IT-SOFC unit cells with anode-supported thin electrolytes via tape casting and co-firing. International Journal of Hydrogen Energy, 2008, 33(6): 1758. |

| [27] | DING J, LIU J, YUAN W S, et al. Slip casting combined with colloidal spray coating in fabrication of tubular anode-supported solid oxide fuel cells. Journal of the European Ceramic Society, 2008, 28(16): 3113. |

| [28] | BAI Y H, LIU J, WANG C L. Performance of cone-shaped tubular anode-supported segmented-in-series solid oxide fuel cell stack fabricated by dip coating technique. International Journal of Hydrogen Energy, 2009, 34(17): 7311. |

| [29] | XIAO J, CAI W Z, LIU J, et al. A novel low-pressure injection molding technique for fabricating anode supported solid oxide fuel cells. International Journal of Hydrogen Energy, 2014, 39(10): 5105. |

| [30] | PILLAI M R, GOSTOVIC D, KIM I, et al. Short-period segmented- in-series solid oxide fuel cells on flattened tube supports. Journal of Power Sources, 2007, 163(2): 960. |

| [31] | YOUNG A C, OMATETE O O, JANNEY M A, et al. Gelcasting of alumina. Journal of the American Ceramic Society, 1991, 74(3): 612. |

| [32] | MORALES M, LAGUNA-BERCERO M A. Microtubular solid oxide fuel cells fabricated by gel-casting: the role of supporting microstructure on the mechanical properties. RSC Advances, 2017, 7(29): 17620. |

| [33] | ZHANG L, JIANG S P, WANG W, et al. NiO/YSZ, anode- supported, thin-electrolyte, solid oxide fuel cells fabricated by gel casting. Journal of Power Sources, 2007, 170(1): 55. |

| [34] | 叶梓滨, 周明扬, 邹高昌, 等. 凝胶注模法制备锥管串接式阳极支撑固体氧化物燃料电池及其性能研究. 陶瓷学报, 2023, 44(4): 761. |

| [35] | YU F Y, ZHANG Y P, YU L, et al. All-solid-state direct carbon fuel cells with thin yttrium-stabilized-zirconia electrolyte supported on nickel and iron bimetal-based anodes. International Journal of Hydrogen Energy, 2016, 41(21): 9048. |

| [36] | YU J L, WANG H J, ZHANG J, et al. Gelcasting preparation of porous silicon nitride ceramics by adjusting the content of monomers. Journal of Sol-Gel Science and Technology, 2010, 53(3): 515. |

| [37] | LIU Y, TANG Y B, DING J, et al. Electrochemical performance of cone-shaped anode-supported segmented-in-series SOFCs fabricated by gel-casting technique. International Journal of Hydrogen Energy, 2012, 37(1): 921. |

| [38] | HUANG Y, MA L G, LE H R, et al. Improving the homogeneity and reliability of ceramic parts with complex shapes by pressure- assisted gel-casting. Materials Letters, 2004, 58(30): 3893. |

| [39] | MA L G, HUANG Y, YANG J L, et al. Effect of plasticizer on the cracking of ceramic green bodies in gelcasting. Journal of Materials Science, 2005, 40(18): 4947. |

| [40] | YANG J, YU J, HUANG Y. Recent developments in gelcasting of ceramics. Journal of the European Ceramic Society, 2011, 31(14): 2569. |

| [41] | XIANG J H, HUANG Y, XIE Z P. Study of gel-tape-casting process of ceramic materials. Materials Science and Engineering: A, 2002, 323(1/2): 336. |

| [42] | MINH N Q. Ceramic fuel cells. Journal of the American Ceramic Society, 1993, 76(3): 563. |

| [43] | BAI Y H, LIU Y, TANG Y B, et al. Direct carbon solid oxide fuel cell—a potential high performance battery. International Journal of Hydrogen Energy, 2011, 36(15): 9189. |

| [1] | 王晓波, 朱于良, 薛稳超, 史汝川, 骆柏锋, 罗骋韬. PT含量变化对PMN-PT单晶的大功率性能影响[J]. 无机材料学报, 2025, 40(7): 840-846. |

| [2] | 汤新丽, 丁自友, 陈俊锐, 赵刚, 韩颖超. 基于稀土铕离子荧光标记的磷酸钙纳米材料体内分布与代谢研究[J]. 无机材料学报, 2025, 40(7): 754-764. |

| [3] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [4] | 杨光, 张楠, 陈舒锦, 王义, 谢安, 严育杰. 基于多孔ITO电极的WO3薄膜的制备及其电致变色性能[J]. 无机材料学报, 2025, 40(7): 781-789. |

| [5] | 孙晶, 李翔, 毛小建, 章健, 王士维. 月桂酸改性剂对氮化铝粉体抗水解性能的影响[J]. 无机材料学报, 2025, 40(7): 826-832. |

| [6] | 柴润宇, 张镇, 王孟龙, 夏长荣. 直接组装法制备氧化铈基金属支撑固体氧化物燃料电池[J]. 无机材料学报, 2025, 40(7): 765-771. |

| [7] | 王鲁杰, 张玉新, 李彤阳, 于源, 任鹏伟, 王建章, 汤华国, 姚秀敏, 黄毅华, 刘学建, 乔竹辉. 深海服役环境下碳化硅陶瓷材料的腐蚀及磨损行为[J]. 无机材料学报, 2025, 40(7): 799-807. |

| [8] | 李文元, 徐佳楠, 邓瀚澳, 常爱民, 张博. 钒取代对LaTaO4陶瓷微观结构和微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 697-703. |

| [9] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [10] | 董晨雨, 郑维杰, 马一帆, 郑春艳, 温峥. 压电力显微镜表征Pb(Mg,Nb)O3-PbTiO3超薄膜弛豫特性[J]. 无机材料学报, 2025, 40(6): 675-682. |

| [11] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [12] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [13] | 安然, 林锶, 郭世刚, 张冲, 祝顺, 韩颖超. 铁掺杂纳米羟基磷灰石的制备及紫外吸收性能研究[J]. 无机材料学报, 2025, 40(5): 457-465. |

| [14] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [15] | 熊思宇, 莫尘, 朱肖伟, 朱国斌, 陈德钦, 刘来君, 施晓东, 李纯纯. 超低介电常数LiBxAl1-xSi2O6微波介质陶瓷的低温烧结[J]. 无机材料学报, 2025, 40(5): 536-544. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||