无机材料学报 ›› 2026, Vol. 41 ›› Issue (1): 119-128.DOI: 10.15541/jim20250052 CSTR: 32189.14.10.15541/jim20250052

袁旺1,2,3( ), 胡建宝1,2(

), 胡建宝1,2( ), 周亮1,2,3, 阚艳梅1,2, 张翔宇1,2, 董绍明1,2(

), 周亮1,2,3, 阚艳梅1,2, 张翔宇1,2, 董绍明1,2( )

)

收稿日期:2025-02-12

修回日期:2025-04-02

出版日期:2026-01-20

网络出版日期:2025-04-09

通讯作者:

胡建宝, 研究员. E-mail: hujianbao@mail.sic.ac.cn;作者简介:袁 旺(2001-), 男, 博士研究生. E-mail: yuanwang22@mails.ucas.ac.cn

YUAN Wang1,2,3( ), HU Jianbao1,2(

), HU Jianbao1,2( ), ZHOU Liang1,2,3, KAN Yanmei1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2(

), ZHOU Liang1,2,3, KAN Yanmei1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2( )

)

Received:2025-02-12

Revised:2025-04-02

Published:2026-01-20

Online:2025-04-09

Contact:

HU Jianbao, professor. E-mail: hujianbao@mail.sic.ac.cn;About author:YUAN Wang (2001-), male, PhD candidate. E-mail: yuanwang22@mails.ucas.ac.cn

Supported by:摘要:

碳化硅纤维因其优异的力学性能和高温特性, 成为陶瓷基复合材料的理想增强材料。由于不同型号纤维在组分和制备工艺上的差异,有必要进行单独研究。本研究系统探讨了Shicolon-II纤维在1300~1700 ℃氩气热处理条件下力学性能、表面微观结构和成分的演变规律。Shicolon-II纤维由小尺寸的β-SiC晶粒、SiCxOy非晶相及少量石墨微晶组成。经1300 ℃氩气气氛处理后,纤维的单丝拉伸强度保持在3.620 GPa(保留率为98.32%), 而经1500 ℃氩气气氛处理后, 强度下降至2.875 GPa(保留率为78.08%)。纤维力学性能下降可归因于非晶相的分解和β-SiC晶粒的生长。抗蠕变性能是复合材料长期性能的关键因素。在1400 ℃以上温度处理, 由于β-SiC晶粒生长, 纤维的高温抗蠕变性能显著增强。这项研究为第二代纤维的高温应用提供了有价值的理论依据。

中图分类号:

袁旺, 胡建宝, 周亮, 阚艳梅, 张翔宇, 董绍明. 氩气气氛热处理对Shicolon-II SiC纤维机械性能和微观结构演变的影响[J]. 无机材料学报, 2026, 41(1): 119-128.

YUAN Wang, HU Jianbao, ZHOU Liang, KAN Yanmei, ZHANG Xiangyu, DONG Shaoming. Effect of Argon Atmosphere Heat Treatment on Mechanical Properties and Microstructural Evolution of Shicolon-II SiC Fibers[J]. Journal of Inorganic Materials, 2026, 41(1): 119-128.

| Fiber | Diameter/μm | C/Si | Oxygen/% (in atom) | Young's modulus/GPa | Average tensile strength/GPa |

|---|---|---|---|---|---|

| Shincolon-II | 8.1±1.0 | 1.46 | 1.4 | 326.6 | 3.682 |

Table 1 Relevant parameters of Shincolon-II SiC fibers

| Fiber | Diameter/μm | C/Si | Oxygen/% (in atom) | Young's modulus/GPa | Average tensile strength/GPa |

|---|---|---|---|---|---|

| Shincolon-II | 8.1±1.0 | 1.46 | 1.4 | 326.6 | 3.682 |

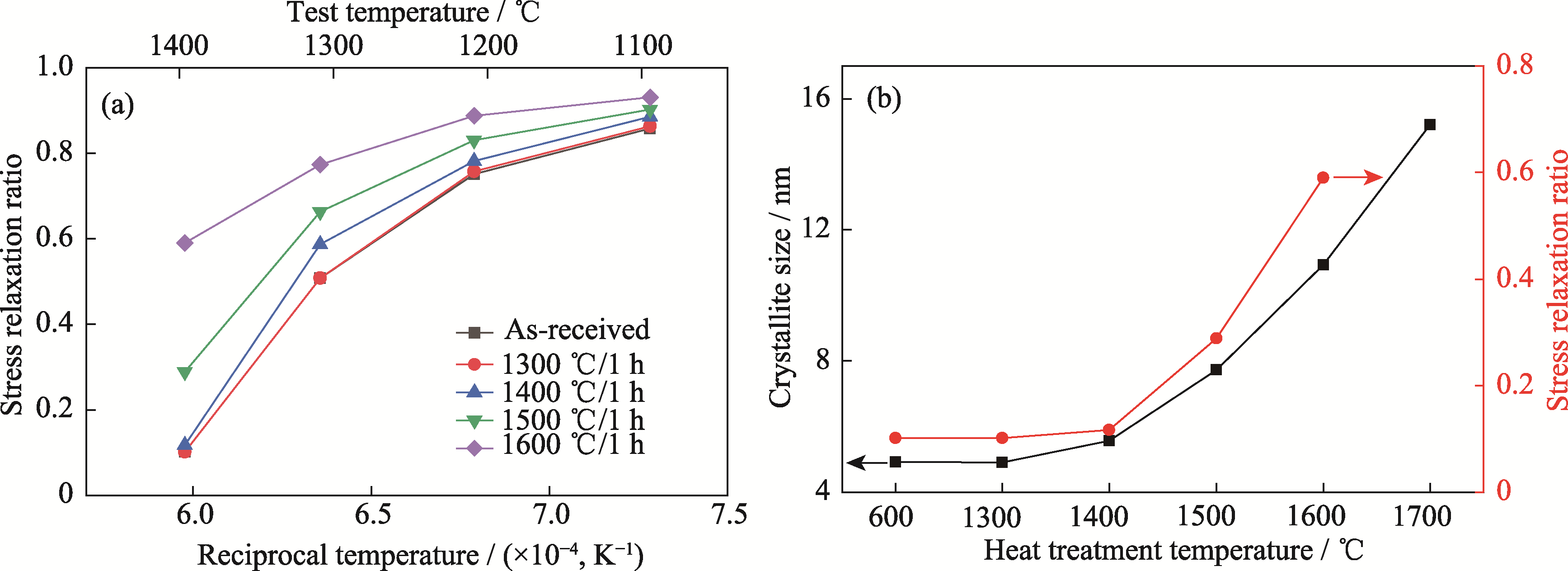

Fig. 3 (a) Stress relaxation ratio of heat-treated fibers at different test temperature; (b) β-SiC grain size and 1400 ℃ BSR results of different heat-treated fibers

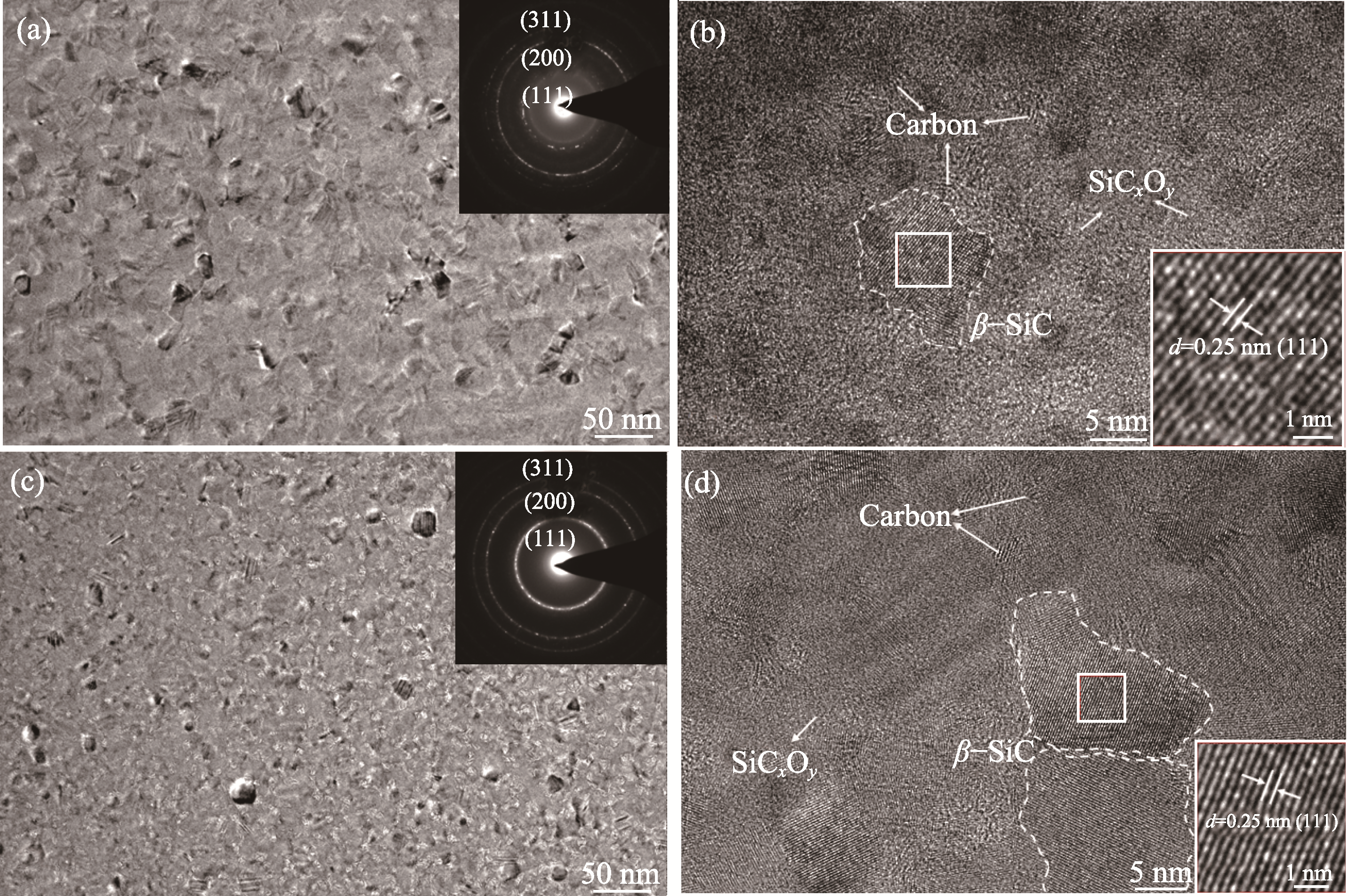

Fig. 4 TEM and HRTEM images of as-received fiber (a, b), fiber after heat treatment at 1500 ℃ (c, d), and corresponding SAED images (insets in (a, c))

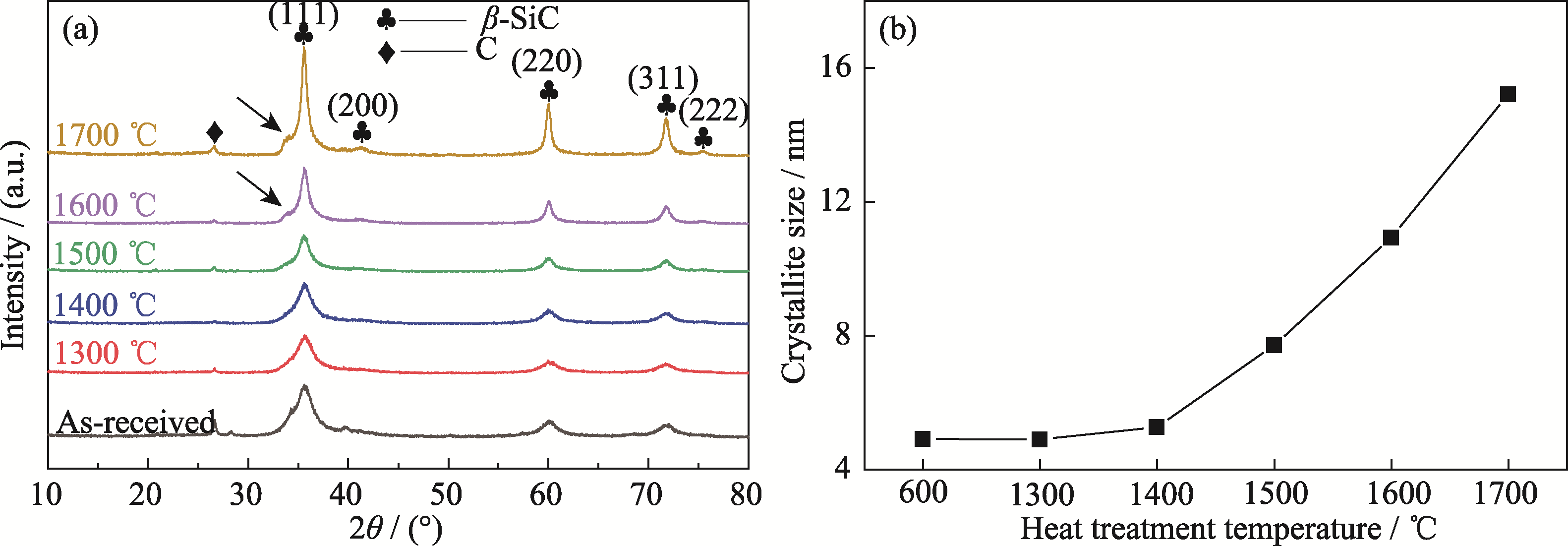

Fig. 5 XRD patterns of Shicolon-II SiC fibers after argon treatment at different temperatures (a) and size of β-SiC crystallites versus heat treatment temperature (b)

| [1] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8): 804.

DOI |

| [2] |

VIX-GUTERL C, EHRBURGER P. Effect of thermal treatment on the reactivity of SiC-based fibres. Journal of Materials Science, 1996, 31(20): 5363.

DOI URL |

| [3] |

IVEKOVIĆ A, NOVAK S, DRAŽIĆ G, et al. Current status and prospects of SiCf/SiC for fusion structural applications. Journal of the European Ceramic Society, 2013, 33(10): 1577.

DOI URL |

| [4] |

MAZERAT S, PAILLER R. Simulating the variability and scale effect for slow crack growth in Hi-Nicalon SiC-based tows: a parametric study. Journal of the European Ceramic Society, 2021, 41(14): 6834.

DOI URL |

| [5] |

SOMMERS A, WANG Q, HAN X, et al. Ceramics and ceramic matrix composites for heat exchangers in advanced thermal systems—a review. Applied Thermal Engineering, 2010, 30(11/12): 1277.

DOI URL |

| [6] | WANG P R, LIU F Q, WANG H, et al. A review of third generation SiC fibers and SiCf/SiC composites. Journal of Materials Science & Technology, 2019, 35(12): 2743. |

| [7] |

KATOH Y, SNEAD L L, HENAGER C H, et al. Current status and recent research achievements in SiC/SiC composites. Journal of Nuclear Materials, 2014, 455(1/2/3): 387.

DOI URL |

| [8] |

CHOLLON G, PAILLER R, NASLAIN R, et al. Thermal stability of a PCS-derived SiC fibre with a low oxygen content (Hi-Nicalon). Journal of Materials Science, 1997, 32(2): 327.

DOI |

| [9] |

SMITH P R, GAMBONE M L, WILLIAMS D S, et al. Heat treatment effects on SiC fiber. Journal of Materials Science, 1998, 33(24): 5855.

DOI |

| [10] |

SACKS M D. Effect of composition and heat treatment conditions on the tensile strength and creep resistance of SiC-based fibers. Journal of the European Ceramic Society, 1999, 19(13/14): 2305.

DOI URL |

| [11] |

BHATT R T, ELDRIDGE J I. Heat treatment effects on microstructure and properties of CVI SiC/SiC composites with Sylramic™-iBN SiC fibers. Journal of the European Ceramic Society, 2023, 43(6): 2376.

DOI URL |

| [12] |

BHATT R T, JASKOWIAK M H. Creep and cyclic durability of CVI SiC/SiC composites. Journal of the European Ceramic Society, 2024, 44(7): 4437.

DOI URL |

| [13] |

DONG H N, GAO X G, ZHANG S, et al. Effects of heat treatment on the mechanical properties at elevated temperatures of plain- woven SiC/SiC composites. Journal of the European Ceramic Society, 2022, 42(2): 412.

DOI URL |

| [14] |

YAJIMA S, HAYASHI J, OMORI M. Continuous silicon carbide fiber of high tensile strength. Chemistry Letters, 1975, 4(9): 931.

DOI URL |

| [15] |

BUNSELL A R, PIANT A. A review of the development of three generations of small diameter silicon carbide fibres. Journal of Materials Science, 2006, 41(3): 823.

DOI URL |

| [16] | JONES R E, PETRAK D, RABE J, et al. SYLRAMIC™ SiC fibers for CMC reinforcement. Journal of Nuclear Materials, 2000, 283-287: 556. |

| [17] |

ZHANG Y, WU C L, WANG Y D, et al. A detailed study of the microstructure and thermal stability of typical SiC fibers. Materials Characterization, 2018, 146: 91.

DOI URL |

| [18] |

TAKEDA M, IMAI Y, ICHIKAWA H, et al. Thermal stability of SiC fiber prepared by an irradiation-curing process. Composites Science and Technology, 1999, 59(6): 793.

DOI URL |

| [19] |

SHA J J, PARK J S, HINOKI T, et al. Tensile properties and microstructure characterization of Hi-NicalonTM SiC fibers after loading at high temperature. International Journal of Fracture, 2006, 142(1): 1.

DOI URL |

| [20] |

DONG S M, CHOLLON G, LABRUGÈRE C, et al. Characterization of nearly stoichiometric SiC ceramic fibres. Journal of Materials Science, 2001, 36(10): 2371.

DOI |

| [21] |

YUAN Q, LI Y Q, SONG Y C. Microstructure and thermal stability of low-oxygen SiC fibers prepared by an economical chemical vapor curing method. Ceramics International, 2017, 43(12): 9128.

DOI URL |

| [22] |

BODET R, LAMON J, JIA N Y, et al. Microstructural stability and creep behavior of Si-C-O (Nicalon) fibers in carbon monoxide and argon environments. Journal of the American Ceramic Society, 1996, 79(10): 2673.

DOI URL |

| [23] |

KISTER G, HARRIS B. Tensile properties of heat-treated nicalon and hi-nicalon fibres. Composites Part A: Applied Science and Manufacturing, 2002, 33(3): 435.

DOI URL |

| [24] |

JIA N Y, BODET R, TRESSLER R E. Effects of microstructural instability on the creep behavior of Si-C-O (Nicalon) fibers in argon. Journal of the American Ceramic Society, 1993, 76(12): 3051.

DOI URL |

| [25] |

MO R, YIN X W, YE F, et al. Mechanical and microwave absorbing properties of Tyranno® ZMI fiber annealed at elevated temperatures. Ceramics International, 2017, 43(12): 8922.

DOI URL |

| [26] |

YOUNGBLOOD G E, LEWINSOHN C, JONES R H, et al. Tensile strength and fracture surface characterization of Hi-Nicalon™ SiC fibers. Journal of Nuclear Materials, 2001, 289(1/2): 1.

DOI URL |

| [27] |

WILSON M, OPILA E. A review of SiC fiber oxidation with a new study of Hi-Nicalon SiC fiber oxidation. Advanced Engineering Materials, 2016, 18(10): 1698.

DOI URL |

| [28] | HUGUET-GARCIA J, JANKOWIAK A, MIRO S,et al. In situ TEM annealing of ion-amorphized Hi Nicalon S and Tyranno SA 3 SiC fibers. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2016, 374: 76. |

| [29] |

CAO S Y, WANG J, WANG H. Formation mechanism of large SiC grains on SiC fiber surfaces during heat treatment. CrystEngComm, 2016, 18(20): 3674.

DOI URL |

| [30] |

MORIMOTO T, OGASAWARA T. Potential strength of Nicalon™, Hi Nicalon™, and Hi Nicalon Type S™ monofilaments of variable diameters. Composites Part A: Applied Science and Manufacturing, 2006, 37(3): 405.

DOI URL |

| [31] |

TOBIN Z, KERNS P, NISLY N, et al. Hi-NICALON™ type S fiber tow surface desizing and decarburization via heat treatment. Ceramics International, 2021, 47(23): 33709.

DOI URL |

| [32] |

MAH T, HECHT N L, MCCULLUM D E, et al. Thermal stability of SiC fibres (Nicalon®). Journal of Materials Science, 1984, 19(4): 1191.

DOI URL |

| [33] |

GOU Y Z, WANG H, JIAN K. Formation of carbon-rich layer on the surface of SiC fiber by sintering under vacuum for superior mechanical and thermal properties. Journal of the European Ceramic Society, 2017, 37(3): 907.

DOI URL |

| [34] |

ZHANG S N, ZHONG Z H, HUA Y, et al. Properties of super heat-resistant silicon carbide fibres with in situ BN coating. Journal of the European Ceramic Society, 2022, 42(14): 6404.

DOI URL |

| [35] |

GOSSET D, COLIN C, JANKOWIAK A, et al. X-ray diffraction study of the effect of high-temperature heat treatment on the microstructural stability of third-generation SiC fibers. Journal of the American Ceramic Society, 2013, 96(5): 1622.

DOI URL |

| [36] |

BHATT R T, SOLA’ F, EVANS L J, et al. Microstructural, strength, and creep characterization of Sylramic™, Sylramic™-iBN and super Sylramic™-iBN SiC fibers. Journal of the European Ceramic Society, 2021, 41(9): 4697.

DOI URL |

| [37] |

CHEN X H, SUN Z G, NIU X M, et al. Evolution of the structure and mechanical performance of Cansas-II SiC fibres after thermal treatment. Ceramics International, 2021, 47(19): 27217.

DOI URL |

| [38] |

CHEN Y H, CHEN Z K, ZHANG R Q, et al. Structural evolution and mechanical properties of Cansas-III SiC fibers after thermal treatment up to 1700 ℃. Journal of the European Ceramic Society, 2021, 41(10): 5036.

DOI URL |

| [39] |

XIAO Y, MA C L, XU H, et al. Mechanical properties and microstructural evolution of Cansas-III SiC fibers after thermal exposure in different atmospheres. Ceramics International, 2022, 48(22): 32804.

DOI URL |

| [40] | SHA J J, NOZAWA T, PARK J S, et al. Effect of heat treatment on the tensile strength and creep resistance of advanced SiC fibers. Journal of Nuclear Materials, 2004, 329: 592. |

| [41] |

MORSCHER G N, DICARLO J A. A simple test for thermomechanical evaluation of ceramic fibers. Journal of the American Ceramic Society, 1992, 75(1): 136.

DOI URL |

| [42] |

CAO S Y, WANG J, WANG H. High-temperature behavior and degradation mechanism of SiC fibers annealed in Ar and N2 atmospheres. Journal of Materials Science, 2016, 51(9): 4650.

DOI URL |

| [1] | 张永恒, 陈继新. 镱铝硅酸盐玻璃和SiC改性h-BN基复合材料的制备与性能研究[J]. 无机材料学报, 2026, 41(1): 37-44. |

| [2] | 陈斌, 任科, 王一光. Mini-SiCf/SiC复合材料长时间高温下的力学性能演变[J]. 无机材料学报, 2025, 40(9): 971-980. |

| [3] | 钟卫民, 赵科, 王珂玮, 刘佃光, 刘金铃, 安立楠. 振荡压力振幅对碳化钨微观结构和摩擦磨损性能的影响[J]. 无机材料学报, 2025, 40(9): 964-970. |

| [4] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [5] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [6] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [7] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [8] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [9] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [10] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [11] | 姜灵毅, 庞生洋, 杨超, 张悦, 胡成龙, 汤素芳. C/SiC-BN复合材料的制备及氧化行为[J]. 无机材料学报, 2024, 39(7): 779-786. |

| [12] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [13] | 孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670. |

| [14] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [15] | 刘国昂, 王海龙, 方成, 黄飞龙, 杨欢. B4C含量对(Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C陶瓷力学性能及抗氧化性能的影响[J]. 无机材料学报, 2024, 39(6): 697-706. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||