无机材料学报 ›› 2021, Vol. 36 ›› Issue (9): 919-928.DOI: 10.15541/jim20200742 CSTR: 32189.14.10.15541/jim20200742

收稿日期:2020-12-29

修回日期:2021-02-22

出版日期:2021-09-20

网络出版日期:2021-03-12

通讯作者:

张青红, 教授 E-mail: zhangqh@dhu.edu.cn

作者简介:郭隐犇(1990-), 女, 讲师. E-mail: guoyb@sues.edu.cn

基金资助:

GUO Yinben1( ), CHEN Zixi1, WANG Hongzhi2, ZHANG Qinghong3(

), CHEN Zixi1, WANG Hongzhi2, ZHANG Qinghong3( )

)

Received:2020-12-29

Revised:2021-02-22

Published:2021-09-20

Online:2021-03-12

Contact:

ZHANG Qinghong, professor. E-mail: zhangqh@dhu.edu.cn

About author:GUO Yinben(1990-), female, lecturer. E-mail: guoyb@sues.edu.cn

Supported by:摘要:

摩擦纳米发电机(Triboelectric Nanogenerator, TENG)是一种将微小机械能转化为电能并加以收集利用的绿色能源器件, 具有活性材料种类广泛、器件结构简单以及易于集成等特点。较低的输出功率密度是目前阻碍其实际应用的主要因素之一。如何通过材料组分设计与制备提高其输出功率密度及能量转化效率, 是目前该领域研究者关注的热点问题。在摩擦纳米发电机常用的活性材料-高分子聚合物中引入功能性填料是一种简便且高效的改性方法, 不仅能够对薄膜摩擦电性能进行优化、提高输出性能, 还能够赋予其新功能, 可谓一举多得。因此, 此类复合薄膜已广泛应用于TENG领域, 例如TiO2、SiO2、BaTiO3、ZnSnO3、MoS2、石墨烯、二维黑磷等无机填料对复合材料的性能均有不同程度的优化, TENG的输出功率密度最高提升了数十倍。本文结合国内外研究现状, 按照填料对基体材料表面性能以及电学性能优化作用两个方面进行阐述, 综述了复合材料薄膜在摩擦纳米发电机中的研究进展, 并展望了未来复合材料用于提高TENG输出性能研究的发展方向。

中图分类号:

郭隐犇, 陈子曦, 王宏志, 张青红. 基于无机填料复合薄膜的摩擦纳米发电机研究进展[J]. 无机材料学报, 2021, 36(9): 919-928.

GUO Yinben, CHEN Zixi, WANG Hongzhi, ZHANG Qinghong. Progress of Inorganic Filler Based Composite Films for Triboelectric Nanogenerators[J]. Journal of Inorganic Materials, 2021, 36(9): 919-928.

图1 用于TENG的不同复合材料薄膜以及所制备的器件示意图[20,21,22,23,24,25,26,27]

Fig. 1 Schematic diagram of various composite films and devices for TENGs[20,21,22,23,24,25,26,27]

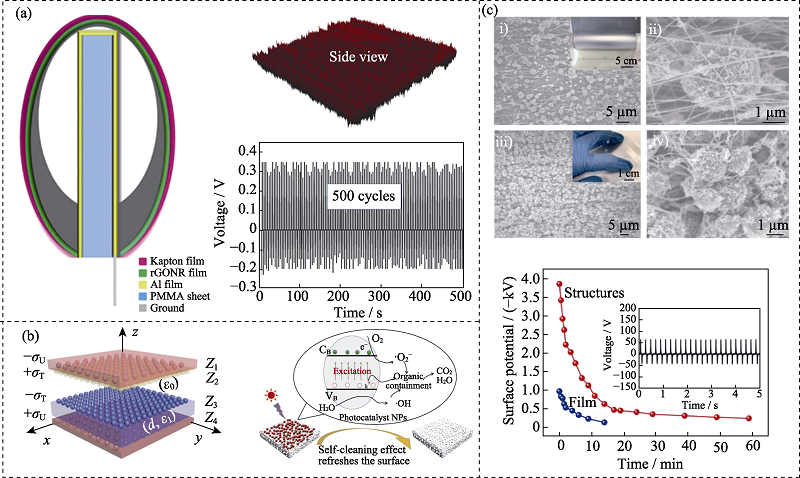

图2 基于rGONRs/PVDF复合薄膜的TENG器件示意图、复合薄膜的3D-AFM图片以及器件工作500个循环的输出电压图谱(a)[20]; 海绵状TiO2/PDMS的TENG器件示意图, TiO2/PDMS薄膜光催化原理图(b)[21]; 静电纺丝制备分层结构SiO2/P(VDF-TrFE)复合薄膜的SEM照片以及纯P(VDF-TrFE)膜(蓝色)和SiO2/P(VDF-TrFE)复合薄膜(红色)的表面电势对比(c)[40]

Fig. 2 Schematic diagram of rGONRs /PVDF based TENG, 3D-AFM image of the rGONRs/PVDF thin film, and output voltage of the rGONRs/PVDF based TENG for 500 cycles (a)[20], schematic diagram of TiO2/PDMS sponge based TENG, schematic of organic containment degradation by photocatalyst NPs in TiO2/PDMS sponge (b)[21], and SEM images of hierarchical structures for SiO2/P(VDF-TrFE) composite fabricated by electrospinning process, and the surface potentials of pure P(VDF-TrFE) film (blue) and SiO2/P(VDF-TrFE) composite film (red) (c)[40] (Colorful figures are available on website)

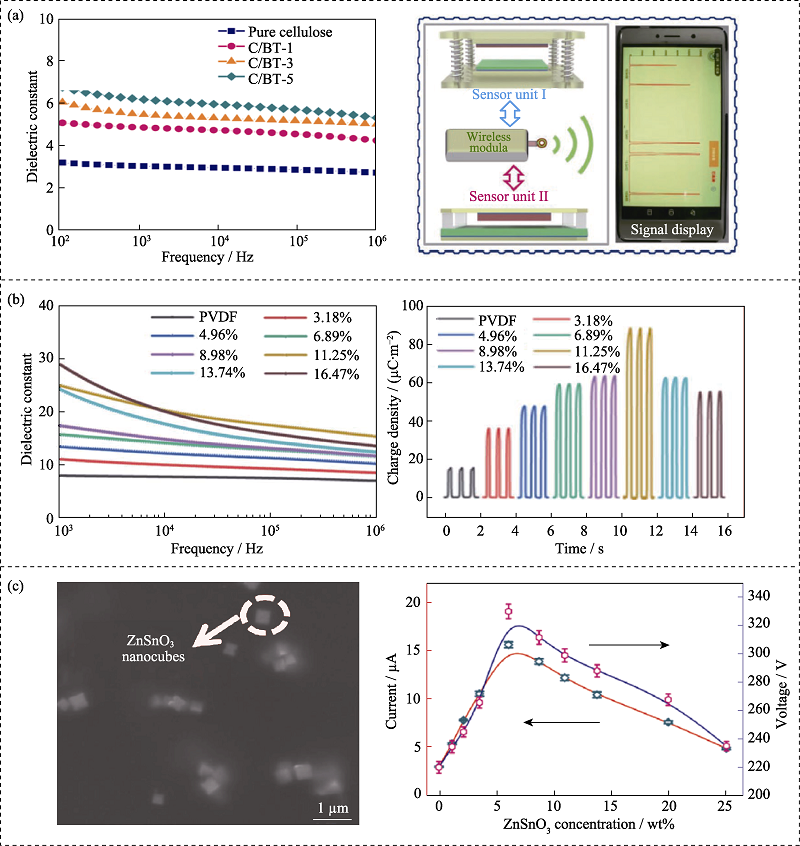

图3 不同BaTiO3含量的纤维素纸复合薄膜介电常数曲线(C/BT-1、 C/BT-3和C/BT-5样品中BaTiO3质量含量分别为50%、75%和83.3%)以及器件用于无线通讯的示意图(a)[22]; 不同BaTiO3含量的PVDF复合薄膜介电常数以及所组成器件表面电荷密度对比图(b)[23]; ZnSnO3@PDMS 复合薄膜的表面扫描电镜照片及其不同含量时的输出电流与电压曲线(c)[24]

Fig. 3 Dielectric constants of the cellulose/ BaTiO3 aerogel paper with different BaTiO3 contents (the mass ratios of BaTiO3 in C/BT-1, C/BT-3 and C/BT-5 were 50%, 75% and 83.3%, respectively) and schematic image of wireless application of the TENG(a)[22], dielectric constants and charge densities of the BaTiO3/PVDF nanocomposite films with different BaTiO3 volume fractions (b)[23], and SEM image of ZnSnO3@PDMS composite film, and output currents and voltages of the corresponding TENGs with different ZnSnO3 contents (c)[24] (Colorful figures are available on website)

图4 P(VDF-TrFE)、PDMS、PDMS-30wt% BTO(30BTO)和PDMS-30wt% CCTO (30CCTO)薄膜的开尔文探针力显微镜(KPFM)图像(a)以及其输出功率密度(b)[46]; 基于PDMS以及PDMS@F-MOF薄膜器件的电场分布(有限元模拟)(c)及其实际输出功率密度(d)[49]

Fig. 4 KPFM images (a) and power densities (b) of P(VDF-TrFE), PDMS, 30BTO and 30CCTO films[46], electrical field distributions (finite-element simulation) (c) and power densities as a function of the external resistance (d) of the devices based on PDMS and PDMS@F-MOF[49]

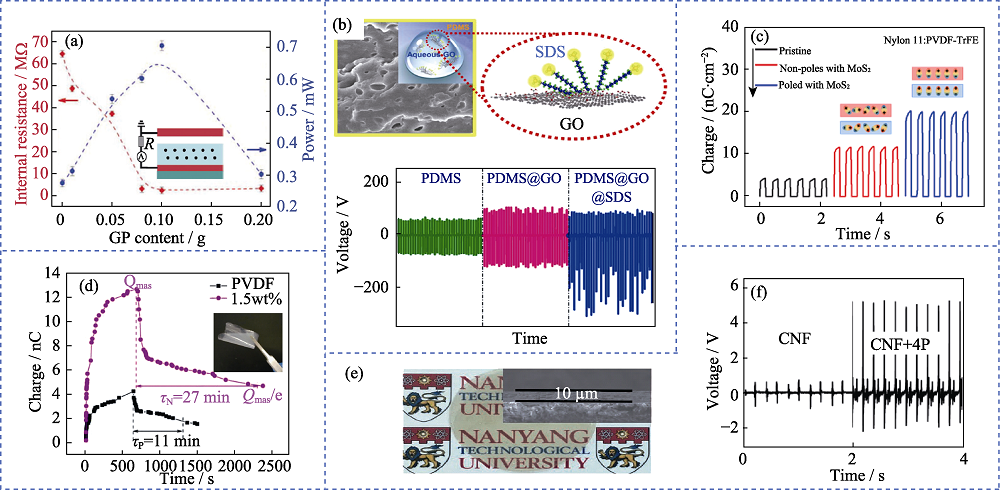

图5 不同GP含量的复合薄膜的TENG内阻以及输出功率, 插图为器件结构示意图(a)[25]; PDMS@GO@SDS复合薄膜的示意图, 基于不同薄膜的TENG输出电压对比图(b)[50]; 纯Nylon-11和PVDF-TrFE(黑色), Nylon-11@MoS2和P(VDF-TrFE)@MoS2复合薄膜组成的器件的未极化状态(红色)和极化状态(蓝色)的TENG的电荷密度比较(c)[51]; 纯PVDF薄膜和PVDF/TOML复合膜的TENG表面电荷对比图, 以及PVDF/TOML复合膜照片(d)[26]; CNF/黑磷复合薄膜的照片(e), 及单纯CNF与CNF/黑磷复合薄膜所制备的TENG输出电压对比图(f)[27]

Fig. 5 Internal resistances and output powers of PDMS@GPs composite membranes with different GP contents with inset showing structural schematic of corresponding TENG device (a)[25], schematic image of PDMS@GO@SDS composite film and the output voltages of different TENGs (b)[50], comparison of charge densities for TENGs : pure Nylon-11 and PVDF-TrFE (black), Nylon-11@MoS2 and P(VDF-TrFE)@MoS2 composite films in non-poled state (red) and poled state (blue) (c)[51], comparison of charges for PVDF and PVDF/TOML nanocomposite films based TENGs with inset showing the picture of PVDF/TOML nanocomposite film (d)[26], optical image of the CNF/phosphorene hybrid paper (e), and the comparison of voltages between pure CNF based TENG and CNF/ phosphorene hybrid paper based TENG (f)[27]

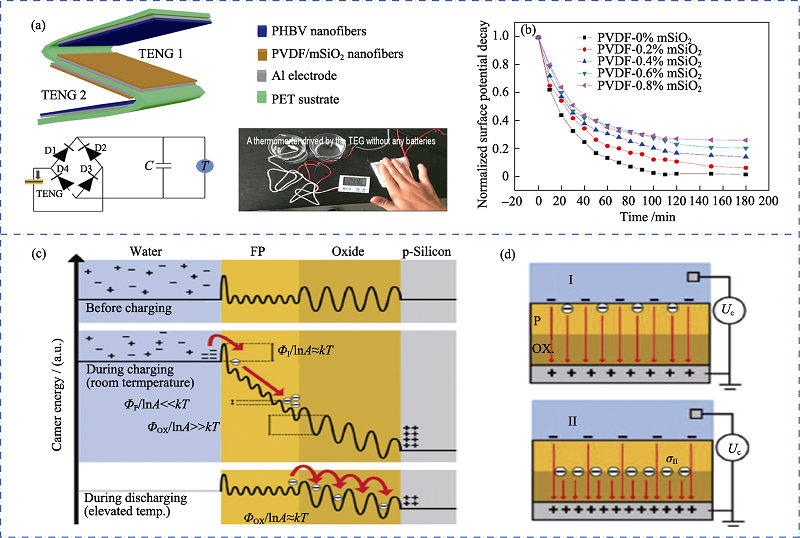

图6 书形TENG的制备过程示意图(a), 具有不同mSiO2浓度的PVDF/mSiO2纳米纤维的表面电势衰减曲线(b)[55]; SiO2-FP在充电前、充电过程中电荷载流子的能量分布图, 以及高温下的表面电势衰减(c); 充电过程中在注入电荷位于水-FP界面(I), 注入电荷位于FP-氧化物界面(II)两种竞争情况下的电场分布(d)[57]

Fig. 6 Illustration of the fabrication process of a book-shaped TENG (a), normalized surface potential decay of PVDF/mSiO2 nanofibers with different concentrations of mSiO2 (b)[55]; energy landscapes for (injected) charge carriers for SiO2-FP before and during charging, and surface potential decays at elevated temperatures (c), electric field distributions during charging for two competing scenarios with injected charge residing at the aqueous-FP interface (I), and injected charge residing at the FP-oxide interface (II) (d)[57]

| Filler | Matrix | Optimal fillers ratio | Dielectric constant | Shape/Size | Increased percentage of output/% | Ref. | |

|---|---|---|---|---|---|---|---|

| wt% | vol% | ||||||

| rGONRs | PVDF | 97 | — | — | Nanoribbon | 200 (Voltage) | [ |

| TiO2 | PDMS | 0.05 | — | — | Nanopaticle | — | [ |

| SiO2 | P(VDF-TrFE) | 30 | — | — | Nanopaticle (D=10-20 nm) | 300 (Voltage) | [ |

| BaTiO3 | Cellulose paper | 16.7 | — | 6.25 | Nanopaticle (D=200 nm) | 300 (Power) | [ |

| BaTiO3 | PVDF | — | 11.25 | 25 | Nanopaticle (D=100 nm) | 650 (Voltage) | [ |

| ZnSnO3 | PDMS | 6 | — | — | Nanocube | 620 (Current) | [ |

| CaCu3Ti4O12 | PDMS | 30 | — | — | Nanopaticle | 1000 (Power) | [ |

| KUAST-8 | PDMS | 0.5 | — | 4.23 | Nanopaticle | 1100 (Power) | [ |

| Graphite particle | PDMS | 3 | — | 3 | Nanopaticle (D=20-40 nm) | 260 (Power) | [ |

| GO | PDMS | — | 16.7 | — | Nanosheet | 300 (Voltage) | [ |

| MoS2 | Nylon-11/P(VDF-TrFE) | — | — | — | Nanosheet | 800 (Power) | [ |

| Monolayer titania | PVDF | 1.5 | — | 11.51 | Thickness=1.2 nm | 5000 (Power) | [ |

| Phosphorene | CNF | 0.2 | — | — | Nanosheet | 4600 (Power) | [ |

| Hydrophobic SiO2 | PVDF | 0.8 | — | — | Nanopaticle | 530 (Power) | [ |

| SiO2 | Thermoplastic nanofiber membranes | — | — | — | Nanopaticle | — | [ |

表1 用于TENG复合材料的填料种类

Table 1 Fillers used in composite materials for TENGs

| Filler | Matrix | Optimal fillers ratio | Dielectric constant | Shape/Size | Increased percentage of output/% | Ref. | |

|---|---|---|---|---|---|---|---|

| wt% | vol% | ||||||

| rGONRs | PVDF | 97 | — | — | Nanoribbon | 200 (Voltage) | [ |

| TiO2 | PDMS | 0.05 | — | — | Nanopaticle | — | [ |

| SiO2 | P(VDF-TrFE) | 30 | — | — | Nanopaticle (D=10-20 nm) | 300 (Voltage) | [ |

| BaTiO3 | Cellulose paper | 16.7 | — | 6.25 | Nanopaticle (D=200 nm) | 300 (Power) | [ |

| BaTiO3 | PVDF | — | 11.25 | 25 | Nanopaticle (D=100 nm) | 650 (Voltage) | [ |

| ZnSnO3 | PDMS | 6 | — | — | Nanocube | 620 (Current) | [ |

| CaCu3Ti4O12 | PDMS | 30 | — | — | Nanopaticle | 1000 (Power) | [ |

| KUAST-8 | PDMS | 0.5 | — | 4.23 | Nanopaticle | 1100 (Power) | [ |

| Graphite particle | PDMS | 3 | — | 3 | Nanopaticle (D=20-40 nm) | 260 (Power) | [ |

| GO | PDMS | — | 16.7 | — | Nanosheet | 300 (Voltage) | [ |

| MoS2 | Nylon-11/P(VDF-TrFE) | — | — | — | Nanosheet | 800 (Power) | [ |

| Monolayer titania | PVDF | 1.5 | — | 11.51 | Thickness=1.2 nm | 5000 (Power) | [ |

| Phosphorene | CNF | 0.2 | — | — | Nanosheet | 4600 (Power) | [ |

| Hydrophobic SiO2 | PVDF | 0.8 | — | — | Nanopaticle | 530 (Power) | [ |

| SiO2 | Thermoplastic nanofiber membranes | — | — | — | Nanopaticle | — | [ |

| [1] |

FAN F R, TIAN Z Q, WANG Z L. Flexible triboelectric generator. Nano Energy, 2012, 1(2):328-334.

DOI URL |

| [2] |

WANG J, ZHANG H, XIE Y, et al. Smart network node based on hybrid nanogenerator for self-powered multifunctional sensing. Nano Energy, 2017, 33:418-426.

DOI URL |

| [3] |

ZHANG L, ZHANG B, CHEN J, et al. Lawn structured triboelectric nanogenerators for scavenging sweeping wind energy on rooftops. Adv. Mater., 2016, 28(8):1650-1656.

DOI URL |

| [4] |

CHEN B, YANG Y, WANG Z L. Scavenging wind energy by triboelectric nanogenerators. Adv. Energy Mater., 2018, 8(10):1702649.

DOI URL |

| [5] |

CHEN B D, TANG W, HE C, et al. Water wave energy harvesting and self-powered liquid-surface fluctuation sensing based on bionic-jellyfish triboelectric nanogenerator. Mater. Today, 2018, 21(1):88-97.

DOI URL |

| [6] |

WANG X, WEN Z, GUO H, et al. Fully packaged blue energy harvester by hybridizing a rolling triboelectric nanogenerator and an electromagnetic generator. ACS Nano, 2016, 10(12):11369-11376.

DOI URL |

| [7] |

MA Y F, TONG Z M, WANG M, et al. Triboelectric nanogenerator based on graphene forest electrodes. J. Inorg. Mater., 2019, 34(8):839-843.

DOI URL |

| [8] |

FENG X, ZHANG Y, KANG L, et al. Integrated energy storage system based on triboelectric nanogenerator in electronic devices. Front. Chem. Sci. Eng., 2021, 15(2):238-250.

DOI URL |

| [9] |

MAMUN M A A, YUCE M R. Recent progress in nanomaterial enabled chemical sensors for wearable environmental monitoring applications. Adv. Funct. Mater., 2020, 30(51):2005703.

DOI URL |

| [10] |

ZHU M, HE T, LEE C. Technologies toward next generation human machine interfaces: from machine learning enhanced tactile sensing to neuromorphic sensory systems. Appl. Phys. Rev., 2020, 7(3):031305.

DOI URL |

| [11] |

CHEN A, ZHANG C, ZHU G, et al. Polymer materials for high-performance triboelectric nanogenerators. Adv. Sci., 2020, 7(14):2000186.

DOI URL |

| [12] |

BURGO T A, DUCATI T R, FRANCISCO K R, et al. Triboelectricity: macroscopic charge patterns formed by self-arraying ions on polymer surfaces. Langmuir, 2012, 28(19):7407-7416.

DOI URL |

| [13] |

ZHU G, ZHOU Y S, BAI P, et al. A shape-adaptive thin-film-based approach for 50% high-efficiency energy generation through micro-grating sliding electrification. Adv. Mater., 2014, 26(23):3788-3796.

DOI URL |

| [14] |

XIE Y, WANG S, NIU S, et al. Grating-structured freestanding triboelectric-layer nanogenerator for harvesting mechanical energy at 85% total conversion efficiency. Adv. Mater., 2014, 26(38):6599-6607.

DOI URL |

| [15] |

DENG W, ZHANG B, JIN L, et al. Enhanced performance of ZnO microballoon arrays for a triboelectric nanogenerator. Nanotechnology, 2017, 28(13):135401.

DOI URL |

| [16] |

SU L, ZHAO Z X, LI H Y, et al. High-performance organolead halide perovskite-based self-powered triboelectric photodetector. ACS Nano, 2015, 9(11):11310-11316.

DOI URL |

| [17] |

YUE X, XI Y, HU C, et al. Enhanced output-power of nanogenerator by modifying PDMS film with lateral ZnO nanotubes and Ag nanowires. RSC Adv., 2015, 5(41):32566-32571.

DOI URL |

| [18] |

WU C, KIM T W, PARK J H, et al. Enhanced triboelectric nanogenerators based on MoS2 monolayer nanocomposites acting as electron-acceptor layers. ACS Nano, 2017, 11(8):8356-8363.

DOI URL |

| [19] |

LI G Z, WANG G G, YE D M, et al. High-performance transparent and flexible triboelectric nanogenerators based on PDMS-PTFE composite films. Adv. Electron. Mater., 2019, 5(4):1800846.

DOI URL |

| [20] |

KAUR N, BAHADUR J, PANWAR V, et al. Effective energy harvesting from a single electrode based triboelectric nanogenerator. Sci. Rep., 2016, 6(1):38835.

DOI URL |

| [21] |

LIU H, FENG Y, SHAO J, et al. Self-cleaning triboelectric nanogenerator based on TiO2 photocatalysis. Nano Energy, 2020, 70:104499.

DOI URL |

| [22] |

SHI K, ZOU H, SUN B, et al. Dielectric modulated cellulose paper/PDMS-based triboelectric nanogenerators for wireless transmission and electropolymerization applications. Adv. Funct. Mater., 2019, 30(4):1904536.

DOI URL |

| [23] |

KANG X, PAN C, CHEN Y, et al. Boosting performances of triboelectric nanogenerators by optimizing dielectric properties and thickness of electrification layer. RSC Adv., 2020, 10(30):17752-17759.

DOI URL |

| [24] |

WANG G, XI Y, XUAN H, et al. Hybrid nanogenerators based on triboelectrification of a dielectric composite made of lead-free ZnSnO3 nanocubes. Nano Energy, 2015, 18:28-36.

DOI URL |

| [25] |

HE X, GUO H, YUE X, et al. Improving energy conversion efficiency for triboelectric nanogenerator with capacitor structure by maximizing surface charge density. Nanoscale, 2015, 7(5):1896-1903.

DOI URL |

| [26] |

WEN R, GUO J, YU A, et al. Remarkably enhanced triboelectric nanogenerator based on flexible and transparent monolayer titania nanocomposite. Nano Energy, 2018, 50:140-147.

DOI URL |

| [27] |

CUI P, PARIDA K, LIN M F, et al. Transparent, flexible cellulose nanofibril-phosphorene hybrid paper as triboelectric nanogenerator. Adv. Mater. Interfaces, 2017, 4(22):1700651.

DOI URL |

| [28] |

DIAZ A F, FELIX-NAVARRO R M. A semi-quantitative triboelectric series for polymeric materials: the influence of chemical structure and properties. J. Electrost., 2004, 62(4):277-290.

DOI URL |

| [29] |

WANG Z L, WANG A C. On the origin of contact-electrification. Mater. Today, 2019, 30:34-51.

DOI URL |

| [30] |

WU C, WANG A C, DING W, et al. Triboelectric nanogenerator: a foundation of the energy for the new era. Adv. Energy Mater., 2019, 9(1):1802906.

DOI URL |

| [31] |

BAYTEKIN H T, PATASHINSKI A Z, BRANICKI M, et al. The mosaic of surface charge in contact electrification. Science, 2011, 333(6040):308-12.

DOI URL |

| [32] |

GUO Y, LI K, HOU C, et al. Fluoroalkylsilane-modified textile-based personal energy management device for multifunctional wearable applications. ACS Appl. Mater. Interfaces, 2016, 8(7):4676-4683.

DOI URL |

| [33] |

CHEN X, PU X, JIANG T, et al. Tunable optical modulator by coupling a triboelectric nanogenerator and a dielectric elastomer. Adv. Funct. Mater., 2017, 27(1):1603788.

DOI URL |

| [34] |

KIM D, PARK S J, JEON S B, et al. A triboelectric sponge fabricated from a cube sugar template by 3D soft lithography for superhydrophobicity and elasticity. Adv. Electron. Mater., 2016, 2(4):1500331.

DOI URL |

| [35] |

SRIPHAN S, VITTAYAKORN N. Facile roughness fabrications and their roughness effects on electrical outputs of the triboelectric nanogenerator. Smart Mater. Struct., 2018, 27(10):105026.

DOI URL |

| [36] |

SINGH H H, KHARE N. Improved performance of ferroelectric nanocomposite flexible film based triboelectric nanogenerator by controlling surface morphology, polarizability, and hydrophobicity. Energy, 2019, 178:765-771.

DOI URL |

| [37] |

GONG W, HOU C, GUO Y, et al. A wearable, fibroid, self-powered active kinematic sensor based on stretchable sheath-core structural triboelectric fibers. Nano Energy, 2017, 39:673-683.

DOI URL |

| [38] |

YANG W, GONG W, HOU C, et al. All-fiber tribo-ferroelectric synergistic electronics with high thermal-moisture stability and comfortability. Nat. Commun., 2019, 10:5541.

DOI URL |

| [39] |

GONG W, HOU C, ZHOU J, et al. Continuous and scalable manufacture of amphibious energy yarns and textiles. Nat. Commun., 2019, 10(1):868.

DOI URL |

| [40] |

CHEN X, XIONG J, PARIDA K, et al. Transparent and stretchable bimodal triboelectric nanogenerators with hierarchical micro- nanostructures for mechanical and water energy harvesting. Nano Energy, 2019, 64:103904.

DOI URL |

| [41] |

SEUNG W, YOON H J, KIM T Y, et al. Boosting power-generating performance of triboelectric nanogenerators via artificial control of ferroelectric polarization and dielectric properties. Adv. Energy Mater., 2017, 7(2):1600988.

DOI URL |

| [42] |

NIU S M, WANG Z L. Theoretical systems of triboelectric nanogenerators. Nano Energy, 2015, 14:161-192.

DOI URL |

| [43] |

SHAO Y, FENG C P, DENG B W, et al. Facile method to enhance output performance of bacterial cellulose nanofiber based triboelectric nanogenerator by controlling micro-nano structure and dielectric constant. Nano Energy, 2019, 62:620-627.

DOI URL |

| [44] |

CHEN J, GUO H, HE X, et al. Enhancing performance of triboelectric nanogenerator by filling high dielectric nanoparticles into sponge PDMS film. ACS Appl. Mater. Interfaces, 2016, 8(1):736-744.

DOI URL |

| [45] |

LEE K Y, KIM D, LEE J H, et al. Unidirectional high-power generation via stress-induced dipole alignment from ZnSnO3 nanocubes/polymer hybrid piezoelectric nanogenerator. Adv. Funct. Mater., 2014, 24(1):37-43.

DOI URL |

| [46] |

FANG Z, CHAN K H, LU X, et al. Surface texturing and dielectric property tuning toward boosting of triboelectric nanogenerator performance. J. Mater. Chem. A, 2018, 6(1):52-57.

DOI URL |

| [47] |

WEN R, GUO J, YU A, et al. Humidity-resistive triboelectric nanogenerator fabricated using metal organic framework composite. Adv. Funct. Mater., 2019, 29(20):1807655.

DOI URL |

| [48] |

KHANDELWAL G, CHANDRASEKHAR A, MARIA JOSEPH RAJ N P, et al. Metal-organic framework: a novel material for triboelectric nanogenerator-based self-powered sensors and systems. Adv. Energy Mater., 2019, 9(14):1803581.

DOI URL |

| [49] |

GUO Y, CAO Y, CHEN Z, et al. Fluorinated metal-organic framework as bifunctional filler toward highly improving output performance of triboelectric nanogenerators. Nano Energy, 2020, 70:104517.

DOI URL |

| [50] |

HARNCHANA V, NGOC H V, HE W, et al. Enhanced power output of a triboelectric nanogenerator using poly(dimethylsiloxane) modified with graphene oxide and sodium dodecyl sulfate. ACS Appl. Mater. Interfaces, 2018, 10(30):25263-25272.

DOI URL |

| [51] |

KIM M, PARK D, ALAM M M, et al. Remarkable output power density enhancement of triboelectric nanogenerators via polarized ferroelectric polymers and bulk MoS2 composites. ACS Nano, 2019, 13(4):4640-4646.

DOI URL |

| [52] |

TAO K, YI H, YANG Y, et al. Origami-inspired electret-based triboelectric generator for biomechanical and ocean wave energy harvesting. Nano Energy, 2020, 67:104197.

DOI URL |

| [53] |

HINCHET R, GHAFFARINEJAD A, LU Y, et al. Understanding and modeling of triboelectric-electret nanogenerator. Nano Energy, 2018, 47:401-409.

DOI URL |

| [54] |

LIU L, TANG W, WANG Z L. Inductively-coupled-plasma-induced electret enhancement for triboelectric nanogenerators. Nanotechnology, 2017, 28(3):035405.

DOI URL |

| [55] |

HUANG T, YU H, WANG H, et al. Hydrophobic SiO2 electret enhances the performance of poly(vinylidene fluoride) nanofiber- based triboelectric nanogenerator. J. Phys. Chem. C, 2016, 120(47):26600-26608.

DOI URL |

| [56] |

YAN S, DONG K, LU J, et al. Amphiphobic triboelectric nanogenerators based on silica enhanced thermoplastic polymeric nanofiber membranes. Nanoscale, 2020, 12(7):4527-4536.

DOI URL |

| [57] |

MENDEL N, WU H, MUGELE F. Electrowetting-assisted generation of ultrastable high charge densities in composite silicon oxide- fluoropolymer electret samples for electric nanogenerators. Adv. Funct. Mater., 2021, 31:2007872.

DOI URL |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [13] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [14] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| [15] | 周帆, 田志林, 李斌. 热防护系统用碳化物超高温陶瓷抗烧蚀涂层研究进展[J]. 无机材料学报, 2025, 40(1): 1-16. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||