无机材料学报 ›› 2020, Vol. 35 ›› Issue (5): 525-531.DOI: 10.15541/jim20190300 CSTR: 32189.14.10.15541/jim20190300

收稿日期:2019-06-20

修回日期:2019-07-29

出版日期:2020-05-20

网络出版日期:2019-09-12

作者简介:王堋人(1990-), 男, 博士研究生. E-mail: nudtwpr@163.com<br/>WANG Pengren(1990-), male, PhD candidate. E-mail: nudtwpr@163.com

基金资助:

WANG Pengren,GOU Yanzi( ),WANG Hao

),WANG Hao

Received:2019-06-20

Revised:2019-07-29

Published:2020-05-20

Online:2019-09-12

Supported by:摘要:

第三代SiC纤维具有近化学计量比的元素组成和高结晶致密的特性, 与第一、第二代SiC纤维相比, 在耐高温、抗氧化、抗蠕变及抗辐射等性能上均有明显的提升, 因此在工程应用上尤其在核能领域拥有更明显的优势和更广阔的前景。本文对第三代SiC纤维的制备工艺、性能特点进行了介绍和比较, 综述了第三代SiC纤维在核能领域的应用, 并对其发展前景进行了展望。

中图分类号:

王堋人, 苟燕子, 王浩. 第三代SiC纤维及其在核能领域的应用现状[J]. 无机材料学报, 2020, 35(5): 525-531.

WANG Pengren, GOU Yanzi, WANG Hao. Third Generation SiC Fibers for Nuclear Applications[J]. Journal of Inorganic Materials, 2020, 35(5): 525-531.

| Trade mark | Tensile strength/GPa | Young’s modulus/GPa | Diameter/μm | C/Si | |

|---|---|---|---|---|---|

| First generation | Nicalon 200 | 3.0 | 200 | 14 | 1.33 |

| Tyranno Lox-M | 3.3 | 185 | 11 | 1.38 | |

| KD-I | >2.5 | >170 | 11.5 | 1.29 | |

| Second generation | Hi-Nicalon | 2.8 | 270 | 12 | 1.39 |

| Tyranno ZE | 3.5 | 233 | 11 | 1.34 | |

| KD-II | >2.7 | >250 | 11.5 | 1.35-1.40 | |

| Third generation | Hi-Nicalon S | 2.6 | 340 | 12.0 | 1.05 |

| KD-S | 2.7 | 310 | 11.0 | 1.08 | |

| Tyranno SA | 2.8 | 375 | 8.0&10.0 | 1.08 | |

| KD-SA | 2.5 | 350 | 10.5 | 1.05 | |

| Sylramic | 3.2 | 400 | 10.0 | 1.01 |

表1 三代SiC纤维的组成和力学特性[5,13-18]

Table 1 Compositions and mechanical properties of three generations SiC fibers[5,13-18]

| Trade mark | Tensile strength/GPa | Young’s modulus/GPa | Diameter/μm | C/Si | |

|---|---|---|---|---|---|

| First generation | Nicalon 200 | 3.0 | 200 | 14 | 1.33 |

| Tyranno Lox-M | 3.3 | 185 | 11 | 1.38 | |

| KD-I | >2.5 | >170 | 11.5 | 1.29 | |

| Second generation | Hi-Nicalon | 2.8 | 270 | 12 | 1.39 |

| Tyranno ZE | 3.5 | 233 | 11 | 1.34 | |

| KD-II | >2.7 | >250 | 11.5 | 1.35-1.40 | |

| Third generation | Hi-Nicalon S | 2.6 | 340 | 12.0 | 1.05 |

| KD-S | 2.7 | 310 | 11.0 | 1.08 | |

| Tyranno SA | 2.8 | 375 | 8.0&10.0 | 1.08 | |

| KD-SA | 2.5 | 350 | 10.5 | 1.05 | |

| Sylramic | 3.2 | 400 | 10.0 | 1.01 |

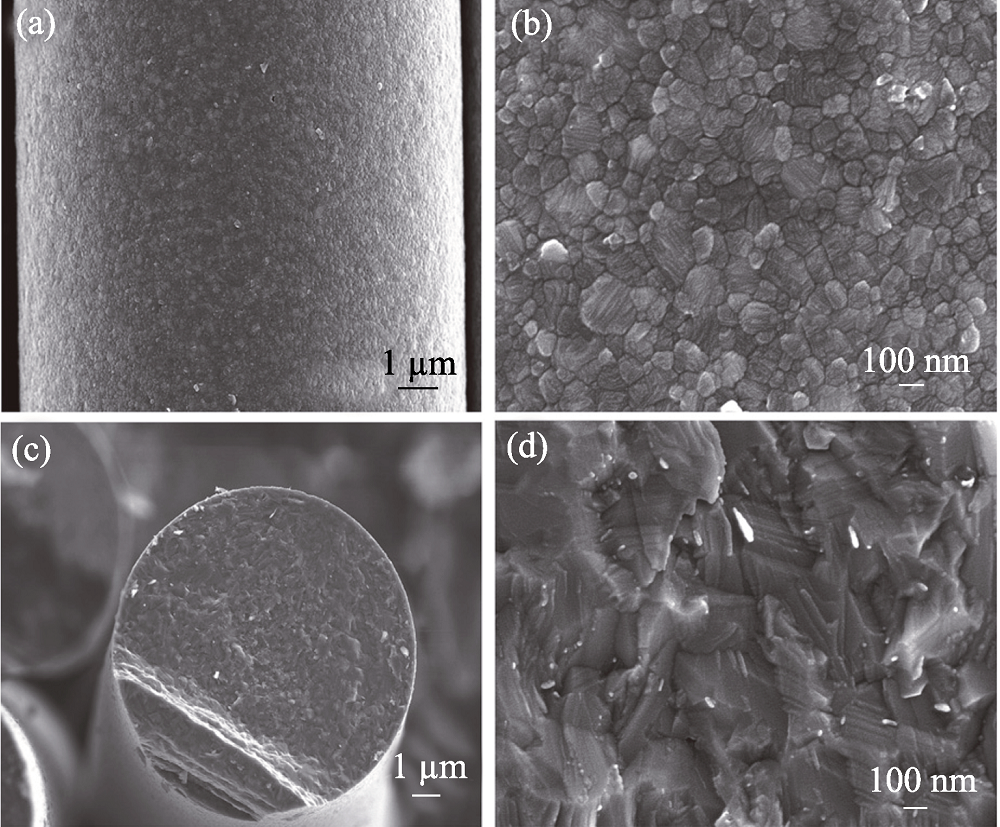

图5 在氩气中1900 ℃处理KD-SA纤维1 h后的SEM照片[14]

Fig. 5 Surface (a, b) and cross section (c, d) SEM images of KD-SA fibers after exposure under argon at 1900 ℃ for 1 h[14]

| Brand name | Fiber type | Preparation technology | Tensile strength at room temperature / MPa | Failure duration |

|---|---|---|---|---|

| Hypercomp PP-HN | Hi-Nicalon | MI | 321 | >1000 h/1200 ℃ |

| Hypercomp SC-HN | Hi-Nicalon | MI | 358 | >1000 h/1200 ℃ |

| N22 | Sylramic | CVI+MI | 400 | ~500 h/1204 ℃ |

| N24-A | Sylramic-iBN | CVI+MI | 450 | ~500 h/1315 ℃ |

| N24-B | Sylramic-iBN | CVI+MI | 450 | ~500 h/1315 ℃ |

| N24-C | Sylramic-iBN | CVI+MI | 310 | >1000 h/1315 ℃ |

| N26 | Sylramic-iBN | CVI+PIP | 330 | ~300 h/1450 ℃ |

| A410 | Hi-Nicalon | CVI | 200-315 | 600 h/1200 ℃ |

| A416 | Hi-Nicalon S | CVI | 200-315 | 200 h/1400 ℃ |

表2 不同型号SiCf/SiC复合材料及性能[46]

Table 2 Different SiCf/SiC composites and their properties[46]

| Brand name | Fiber type | Preparation technology | Tensile strength at room temperature / MPa | Failure duration |

|---|---|---|---|---|

| Hypercomp PP-HN | Hi-Nicalon | MI | 321 | >1000 h/1200 ℃ |

| Hypercomp SC-HN | Hi-Nicalon | MI | 358 | >1000 h/1200 ℃ |

| N22 | Sylramic | CVI+MI | 400 | ~500 h/1204 ℃ |

| N24-A | Sylramic-iBN | CVI+MI | 450 | ~500 h/1315 ℃ |

| N24-B | Sylramic-iBN | CVI+MI | 450 | ~500 h/1315 ℃ |

| N24-C | Sylramic-iBN | CVI+MI | 310 | >1000 h/1315 ℃ |

| N26 | Sylramic-iBN | CVI+PIP | 330 | ~300 h/1450 ℃ |

| A410 | Hi-Nicalon | CVI | 200-315 | 600 h/1200 ℃ |

| A416 | Hi-Nicalon S | CVI | 200-315 | 200 h/1400 ℃ |

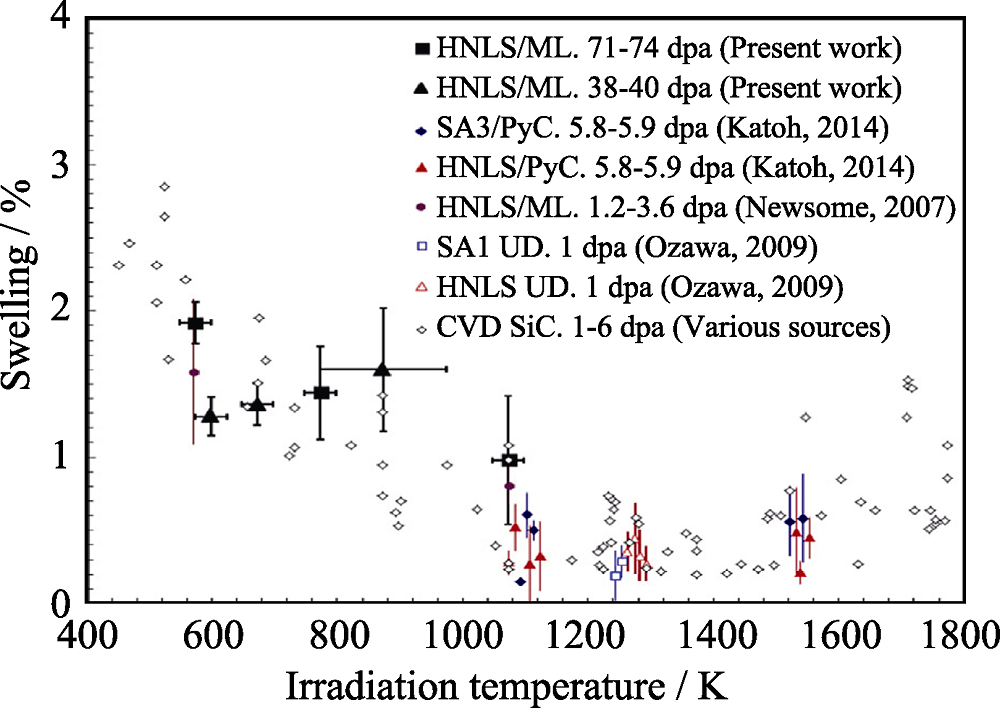

图7 辐照后CVI-Hi-Nicalon S /SiC复合材料和CVD-SiC的体积膨胀率[54]

Fig. 7 Swelling of Hi-Nicalon S, CVI SiC-matrix composites plotted against irradiation temperature[54]

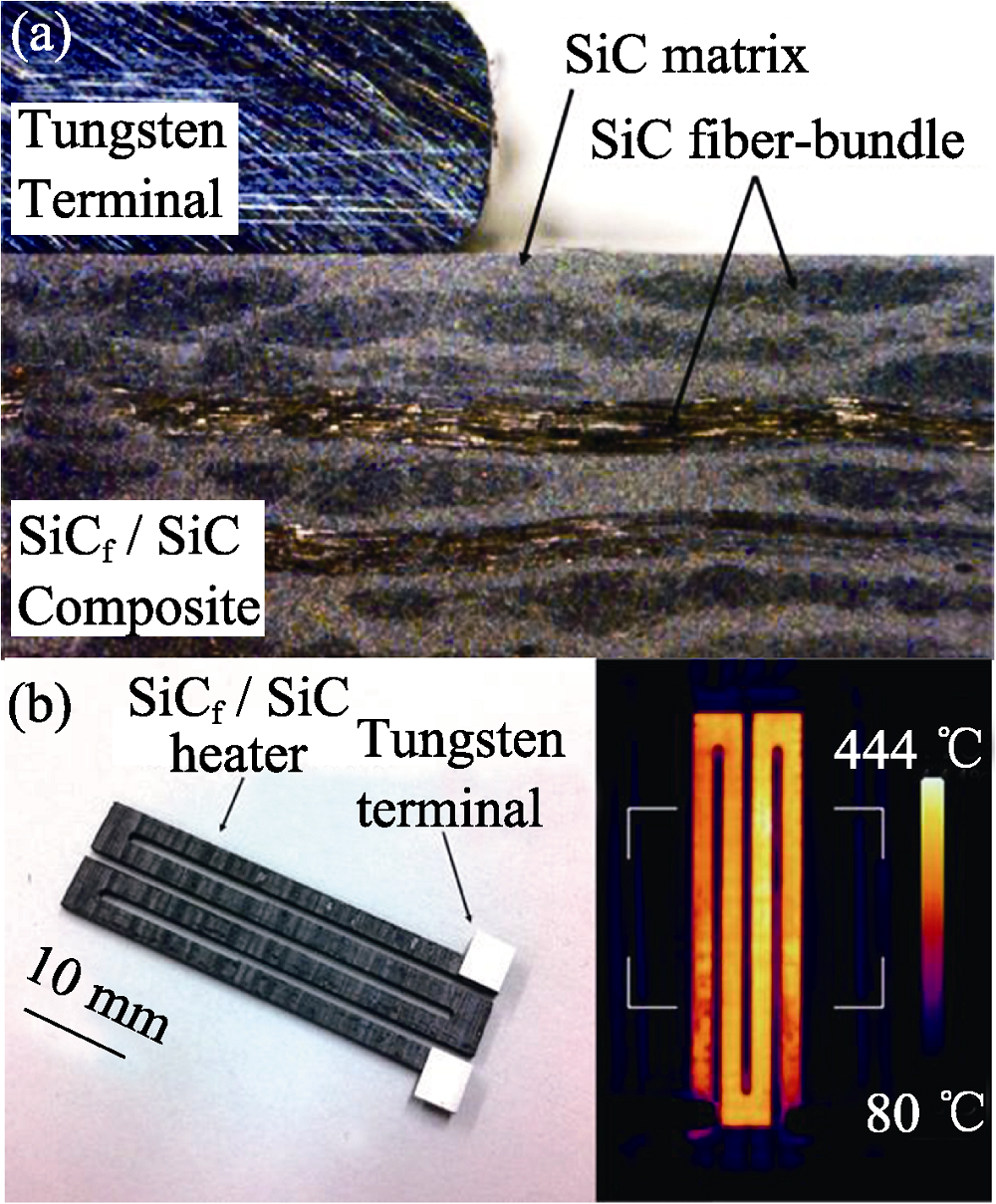

图9 SiCf/SiC复合材料加热器的剖面照片(a)和实物照片及红外图像(b)[68]

Fig. 9 (a) Sectional view of SiCf/SiC heater with tungsten terminal, (b) SiCf/SiC heater for BR2 with IR image[68]

| [1] |

ICHIKAWA H . Polymer-derived ceramic fibers. Annual Review of Materials Research, 2016,46(1):335-356.

DOI URL |

| [2] |

ZHAO S, ZHOU X G, YU J S , et al. Research and development in fabrication and properties of SiC/SiC composites. Materials Reports, 2013,27(1):66-70.

DOI URL PMID |

| [3] |

GOU Y Z, WANG H, JIAN K , et al. Preparation and characterization of SiC fibers with diverse electrical resistivity through pyrolysis under reactive atmospheres. Journal of the European Ceramic Society, 2017,37:517-522.

DOI URL |

| [4] |

YAJIMA S, HAYASHI J, OMORI M . Continuous SiC fiber of high tensile strength. Chemistry Letters, 1975,4(9):931-934.

DOI URL PMID |

| [5] |

BUNSELL A R, PIANT A . A review of the development of three generations of small diameter silicon carbide fibres. Journal of Materials Science, 2006,41(3):823-839.

DOI URL |

| [6] | ISHIKAWA T . Recent developments of the SiC fiber Nicalon and its composites, including properties of the SiC fiber Hi-Nicalon for ultra-high temperature. Composites Science & Technology, 1994,51(2):135-144. |

| [7] | YAMAMURA T, ISHIKAWA T, SHIBUYA M , et al. Development of a new continuous Si-Ti-C-O fibre using an organometallic polymer precursor. Journal of Materials Science, 1988,23(7):2589-2594. |

| [8] |

VAHLAS C, MONTHIOUX M . On the thermal degradation of lox-M tyranno ® fibres. Journal of the European Ceramic Society, 1995,15(5):445-453.

DOI URL |

| [9] | SHIBUYA M, YAMAMURA T . Characteristics of a continuous Si-Ti-C-O fibre with low oxygen content using an organometallic polymer precursor. Journal of Materials Science, 1996,31(12):3231-3235. |

| [10] |

SHIMOO T, HAYATSU T, TAKEDA M , et al. High-temperature decomposition of low-oxygen SiC fiber under N2 atmosphere. Journal of the Ceramic Society of Japan, 2010,102(1192):1142-1147.

DOI URL |

| [11] | TAKEDA M, IMAI Y, ICHIKAWA H , et al. Thermal stability of SiC fiber prepared by an irradiation-curing process. Composites Science & Technology, 1999,59(6):793-799. |

| [12] | CHOLLON G, PAILLER R, NASLAIN R , et al. Thermal stability of a PCS-derived SiC fibre with a low oxygen content (Hi-Nicalon). Journal of Materials Science, 1997,32(2):327-347. |

| [13] | CHEN D R, HAN W J, LI S W , et al. Fabrication, microstructure, properties and applications of continuous ceramic fibers: a review of present status and further directions. Advanced Ceramics, 2018,39(3):151-222. |

| [14] |

GOU Y Z, JIAN K, WANG H , et al. Fabrication of nearly stoichiometric polycrystalline SiC fibers with excellent high-temperature stability up to 1900 ℃. Journal of the American Ceramic Society, 2017,101(5):1-10.

DOI URL |

| [15] | 曹适意 . KD系列连续碳化硅纤维组成、结构与性能关系研究. 长沙: 国防科技大学博士学位论文, 2017. |

| [16] | 王军, 宋永才, 王浩 , 等. 先驱体转化法制备碳化硅纤维. 北京: 科学出版社, 2018: 82-83. |

| [17] | ZU M, ZOU S M, HAN S , et al. Effects of heat treatment on the microstructures and properties of KD-I SiC fibres. Materials Research Innovations, 2015,19:437-441. |

| [18] | BAI W C, JIAN K . The microstructure and elctrical resistivity of near-stoichiometric SiC fiber. IOP Conf. Series: Materials Science and Engineering, 2019,490(Chapter 1):22057-22065. |

| [19] |

COUSTUMER P L, MONTHIOUX M, OBERLIN A . Understanding Nicalon Fibre. Journal of the European Ceramic Society, 1993,11(2):95-103.

DOI URL |

| [20] |

PORTE L, SARTRE A . Evidence for a silicon oxycarbide phase in the Nicalon silicon carbide fibre. Journal of Materials Science, 1989,24(1):271-275.

DOI URL |

| [21] | ISHIKAWA T, KOHTOKU Y, KUMAGAWA K , et al. High-strength alkali-resistant sintered SiC fibre stable to 2,200 ℃. Nature, 1998,391(6669):773-775. |

| [22] | TAKEDA M, SAKAMOTO J, IMAI Y , et al. Properties of Stoichiometric Silicon Carbide Fiber Derived from Polycarbosilane. Proceedings of the 18th Annual Conference on Composites and Advanced Ceramic Materials - A: Ceramic Engineering and Science Proceedings, Cocoa Beach, Florida, U.S., 1994: 133-141. |

| [23] | YUN H M, DICARLO J A, BHATT R T , et al. Processing and Structural Advantages of the Sylramic-iBN SiC Fiber for SiC/SiC Components. 27th Annual Cocoa Beach Conference on Advanced Ceramics and Composites-B: Ceramic Engineering and Science Proceedings, Cocoa Beach, Florida, U.S., 2008: 247-253. |

| [24] | ISHIKAWA T, KAJII S, HISAYUKI T , et al. New type of SiC- sintered fiber and its composite material. Key Engineering Materials, 2008,164(3):283-290. |

| [25] | ISHIKAWA T . Advances in inorganic fibers. Polymeric and Inorganic Fibers, 2005,178:109-144. |

| [26] |

DICARLO J A . Creep limitations of current polycrystalline ceramic fibers. Composites Science & Technology, 1994,51(2):213-222.

URL PMID |

| [27] | 赵大方 . SA型碳化硅纤维的连续化技术研究. 长沙: 国防科学技术大学博士学位论文, 2008. |

| [28] |

SUGIMOTO M, SHIMOO T, OKAMURA K , et al. Reaction mechanisms of silicon carbide fiber synthesis by heat treatment of polycarbosilane fibers cured by radiation, part 1evolved gas analysis. Journal of the American Ceramic Society, 1995,78(4):1013-1017.

DOI URL |

| [29] | ICHIKAWA H . Recent advances in Nicalon ceramic fibres including Hi-Nicalon type S. Annales de Chimie-Sciences des Materiaux, 2000,25(7):523-528. |

| [30] |

ZHANG Y, WU C, WANG Y , et al. A detailed study of the microstructure and thermal stability of typical SiC fibers. Materials Characterization, 2018,146:91-100.

DOI URL |

| [31] |

XIE Z F, GOU Y Z . Polyaluminocarbosilane as precursor for aluminium- containing SiC fiber from oxygen-free sources. Ceramics International, 2016,42:10439-10443.

DOI URL |

| [32] |

GOU Y Z, WANG H, JIAN K , et al. Facile synthesis of melt- spinnablepolyaluminocarbosilane using low-softening-point polycarbosilane for Si-C-Al-O fibers. Journal of Materials Science, 2016,51:8240-8249.

DOI URL |

| [33] | YUN H M, DICARLO J A . Comparison of the Tensile, Creep, and Rupture Strength Properties of Stoichiometric SiC Fibers. 23rd Annual Conference on Composites, Advanced Ceramics, Materials, and structures: A: Ceramic Engineering and Science Proceedings, Cocoa Beach, Florida, U.S., 1999. |

| [34] |

MORSCHER G N, HURST J, BREWER D . Intermediate-temperature stress rupture of a woven Hi-Nicalon, BN-interphase, SiC- matrix composite in air. Journal of the American Ceramic Society, 2010,83(6):1441-1449.

DOI URL |

| [35] |

KATOH Y, SNEAD L L, JR C H H , et al. Current status and critical issues for development of SiC composites for fusion applications. Journal of Nuclear Materials, 2007, 367- 370(part-PA):659-671.

DOI URL |

| [36] |

GOU Y Z, WANG H, JIAN K . Formation of carbon-rich layer on the surface of SiC fiber by sintering under vacuum for superior mechanical and thermal properties. Journal of the European Ceramic Society, 2016,37:907-914

DOI URL |

| [37] |

JI X Y, WANG S S, SHAO C W , et al. The high-temperature corrosion behavior of SiBCN fibers for aerospace applications. ACS Applied Materials & Interfaces, 2018,10(23):19712-19720.

DOI URL PMID |

| [38] |

RICCARDI B, TRENTINI E, LABANTI M , et al. Characterization of commercial grade Tyranno SA/CVI-SiC composites. Journal of Nuclear Materials, 2007, 367- 370(part-PA):672-676.

DOI URL |

| [39] | HILLIG W B . Making ceramic composites by melt infiltration. American Ceramic Society Bulletin, 1994,73(4):56-62. |

| [40] | MORSCHER G N . Stress-dependent matrix cracking in 2D woven SiC-fiber reinforced melt-infiltrated SiC matrix composites. Composites Science & Technology, 2004,64(9):1311-1319. |

| [41] | MORSCHER G N, REJI J, LARRY Z , et al. Creep in vacuum of woven Sylramic-iBN melt-infiltrated composites. Composites Science & Technology, 2011,71(1):52-59. |

| [42] |

SINGH M . Microstructure and mechanical properties of reaction- formed joints in reaction-bonded silicon carbide ceramics. Journal of Materials Science, 1998,33(24):5781-5787.

DOI URL |

| [43] |

KOHYAMA A, PARK J S, JUNG H C . Advanced SiC fibers and SiC/SiC composites toward industrialization. Journal of Nuclear Materials, 2011,417(1/2/3):340-343.

DOI URL |

| [44] |

DONG S, KATOH Y, KOHYAMA A . Processing optimization and mechanical evaluation of hot pressed 2D Tyranno-SA/SiC composites. Journal of the European Ceramic Society, 2003,23(8):1223-1231.

DOI URL |

| [45] |

KISHIMOTO H, OZAWA K, HASHITOMI O , et al. Microstructural evolution analysis of NITE SiC/SiC composite using TEM examination and dual-ion irradiation. Journal of Nuclear Materials, 2007, 367- 370(part-PA):748-752.

DOI URL |

| [46] | WANG J, LIAN Y L, HAN X F . Research and application of polyimide composites for aeroengine. Aeronautical Manufacturing Technology, 2017. |

| [47] | HINOKI T, SNEAD L L, KATOH Y , et al. The effect of high dose/high temperature irradiation on high purity fibers and their silicon carbide composites. Journal of Nuclear Materials, 2008,307(3):1157-1162. |

| [48] |

HOLLENBERG G W, JR C H H, YOUNGBLOOD G E , et al. The effect of irradiation on the stability and properties of monolithic silicon carbide and SiCf/SiC composites up to 25 dpa. Journal of Nuclear Materials, 1994,219(2):70-86.

DOI URL |

| [49] | NEWSOME G A . The effect of neutron irradiation on silicon carbide fibers. John Wiley & Sons, Inc. 1997: 579-583. |

| [50] |

KATOH Y, OZAWA K, SHIH C , et al. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects. Journal of Nuclear Materials, 2014,448(1/2/3):448-476.

DOI URL |

| [51] | EHRLICH K . Materials research towards a fusion reactor. Fusion Engineering & Design, 2001,56(1):71-82. |

| [52] | NOZAWA T, HINOKI T, HASEGAWA A , et al. Recent advances and issues in development of silicon carbide composites for fusion applications. Journal of Nuclear Materials, 2010,41(17):622-627. |

| [53] |

ZHAO S, ZHOU X G, YU H , et al. Compatibility of PIP SiCf/SiC with LiPb at 700 ℃. Fusion Engineering & Design, 2010,85(7/8/9):1624-1626.

DOI URL |

| [54] |

KATOH Y, NOZAWA T, SHIH C , et al. High-dose neutron irradiation of Hi-Nicalon type S silicon carbide composites. Part 2: Mechanical and physical properties. Journal of Nuclear Materials, 2015,462:450-457.

DOI URL |

| [55] | JONES R H, GIANCARLI L, HASEGAWA A , et al. Promise and challenges of SiCf/SiC composites for fusion energy applications. Journal of Nuclear Materials, 2002,307(3):1057-1072. |

| [56] | UEDA S, NISHIO S, SEKI Y , et al. A fusion power reactor concept using SiC/SiC composites. Journal of Nuclear Materials, 1998, s258- 263(98):1589-1593. |

| [57] | SNEAD L L, JONES R H, KOHYAMA A , et al. Status of silicon carbide composites for fusion. Journal of Nuclear Materials, 1996, s233- 237(96):26-36. |

| [58] | HASEGAWA A, KOHYAMA A, JONES R H , et al. Critical issues and current status of SiCf/SiC composites for fusion. Journal of Nuclear Materials, 2000,s(283-287):128-137. |

| [59] |

SENOR D J, YOUNGBLOOD G E, MOORE C E , et al. Effects of neutron irradiation on thermal conductivity of SiC-based composites and monolithic ceramics. Fusion Technology, 1996,30(3):943-955.

DOI URL |

| [60] |

JONES R H, STEINER D, HEINISCH H L , et al. Radiation resistant ceramic matrix composites. Journal of Nuclear Materials, 1997,245(2/3):87-107.

DOI URL PMID |

| [61] | YAMADA R, IGAWA N, TAGUCHI T . Thermal diffusivity/conductivity of Tyranno SA fiber- and Hi-Nicalon type S fiber-reinforced 3-D SiC/SiC composites. Journal of Nuclear Materials, 2004,329(1):497-501. |

| [62] | NISHIO S, UEDA S, KURIHARA R , et al. Prototype tokamak fusion reactor based on SiC/SiC composite material focusing on easy maintenance. Fusion Engineering & Design, 2000,48(3/4):271-279. |

| [63] |

IHLI T, BASU T K, GIANCARLI L M , et al. Review of blanket designs for advanced fusion reactors. Fusion Engineering & Design, 2008,83(7/8/9):912-919.

DOI URL |

| [64] | NORAJITRA P, BUHLER L, FISCHER U , et al. The EU advanced lead lithium blanket concept using SiCf/SiC flow channel inserts as electrical and thermal insulators. Fusion Engineering & Design, 2001,s(58/59):629-634. |

| [65] |

NORAJITRA P, ABDEL-KHALIK S I, GIANCARLI L M , et al. Divertor conceptual designs for a fusion power plant. Fusion Engineering & Design, 2008,83(7):893-902.

DOI URL |

| [66] | PUMA A L, GIANCARLI L, GOLFIER H , et al. Potential performances of a divertor concept based on liquid metal cooled SiCf/SiC structures. Fusion Engineering & Design, 2003, s66- 68(3):401-405. |

| [67] | SATORI K, KISHIMOTO H, PARK J S , et al. Thermal insulator of porous SiC/SiC composites for fusion blanket system. Materials Science and Engineering Conference Series, 2011: 2150-2159. |

| [68] |

KISHIMOTO H, ABE T, PARK J S , et al. SiC/SiC and W/SiC/SiC composite heater by NITE-method for IFMIF and fission reactor irradiation rigs. IOP Conference Series: Materials Science and Engineering, 2011,18(16):162018-162022.

DOI URL |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 苟燕子, 康伟峰, 王堋人. 烧结条件对制备高结晶近化学计量比SiC纤维的影响[J]. 无机材料学报, 2025, 40(4): 405-414. |

| [9] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [10] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [11] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [12] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [13] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [14] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [15] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||