无机材料学报 ›› 2025, Vol. 40 ›› Issue (4): 405-414.DOI: 10.15541/jim20240439 CSTR: 32189.14.10.15541/jim20240439

所属专题: 【结构材料】陶瓷基复合材料(202512)

收稿日期:2024-10-18

修回日期:2024-11-18

出版日期:2025-04-20

网络出版日期:2024-11-25

作者简介:苟燕子(1984-), 副研究员. E-mail: y.gou2012@hotmail.com

基金资助:

GOU Yanzi1( ), KANG Weifeng1, WANG Pengren2

), KANG Weifeng1, WANG Pengren2

Received:2024-10-18

Revised:2024-11-18

Published:2025-04-20

Online:2024-11-25

About author:GOU Yanzi (1984-), associate professor. E-mail: y.gou2012@hotmail.com

Supported by:摘要:

细直径连续SiC纤维是先进陶瓷基复合材料的最佳增强纤维之一, 在航空航天和核工业领域具有重要的应用价值, 其中高结晶近化学计量比SiC纤维的耐温性能最好, 但是高温烧结条件对该纤维元素组成与微观结构的影响规律还不清楚。本工作研究了烧结温度和时间对纤维中SiCxOy相分解、晶粒长大以及纤维致密化的影响规律, 发现SiCxOy相分解和纤维的致密化过程均是由表层逐渐向芯部进行, 并且只有在适当的烧结温度(1800 ℃)下, 才能通过生长β-SiC晶粒来弥补SiCxOy相分解产生的孔隙缺陷, 最终实现纤维的致密化。值得注意的是, 过高的烧结温度会造成β-SiC晶粒分解。虽然延长烧结时间有助于消除纤维中的残余氧, 但会使β-SiC晶界处的石墨相变得更加集中, 且纤维芯部产生更多的孔隙缺陷。通过优化条件最终成功制备了致密的高结晶近化学计量比SiC纤维, 其组成为SiC1.04O0.02Al<0.01, 纤维中的β-SiC晶粒均匀分布, 尺寸达到100~200 nm。纤维的拉伸强度和杨氏模量分别为1.88 GPa和373 GPa, 并且密度高达3.1 g/cm3。上述研究结果可以为进一步提升SiC纤维的综合性能奠定坚实的基础。

中图分类号:

苟燕子, 康伟峰, 王堋人. 烧结条件对制备高结晶近化学计量比SiC纤维的影响[J]. 无机材料学报, 2025, 40(4): 405-414.

GOU Yanzi, KANG Weifeng, WANG Pengren. Influence of Sintering Conditions on Preparation of Nearly Stoichiometric SiC Fibers with Highly Crystalline Microstructure[J]. Journal of Inorganic Materials, 2025, 40(4): 405-414.

| Sample | O content/(%, in mass) | C/Si atomic ratio | Tensile strength/GPa | Young’s modulus/GPa | Diameter/μm |

|---|---|---|---|---|---|

| Si-C-O-Al fiber | 8.93 | 1.33 | 2.27 | 204 | 11.6 |

| Intermediate SiC fiber | 0.98 | 1.06 | 1.54 | 283 | 10.8 |

表1 Si-C-O-Al纤维及中间纤维的化学组成和力学性能

Table 1 Chemical composition and mechanical properties of Si-C-O-Al fibers and intermediate fibers

| Sample | O content/(%, in mass) | C/Si atomic ratio | Tensile strength/GPa | Young’s modulus/GPa | Diameter/μm |

|---|---|---|---|---|---|

| Si-C-O-Al fiber | 8.93 | 1.33 | 2.27 | 204 | 11.6 |

| Intermediate SiC fiber | 0.98 | 1.06 | 1.54 | 283 | 10.8 |

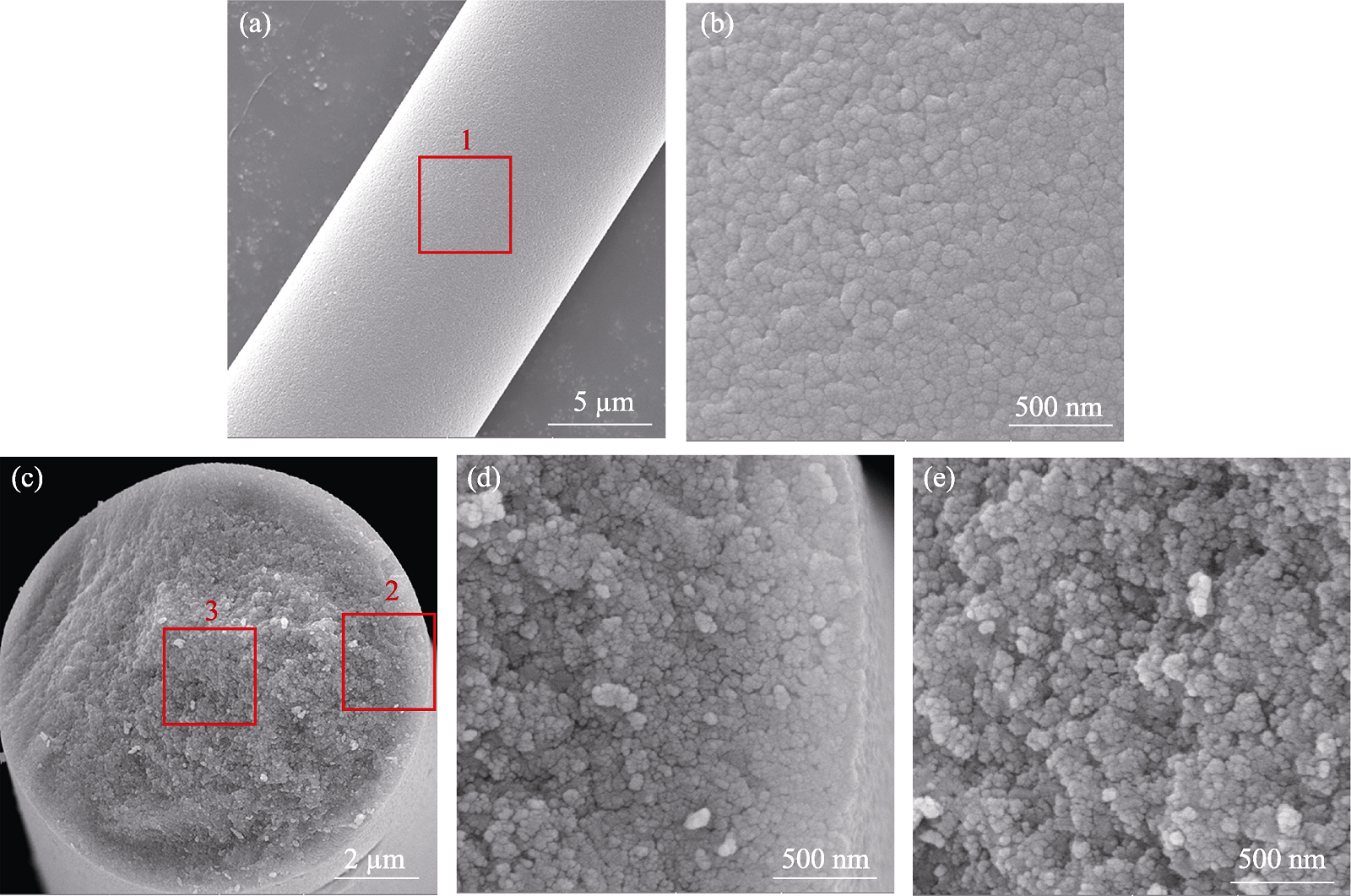

图1 中间纤维的SEM照片

Fig. 1 SEM images of the intermediate fibers (a) Fiber surface; (b) Magnified region 1; (c) Fiber cross section; (d) Magnified region 2; (e) Magnified region 3

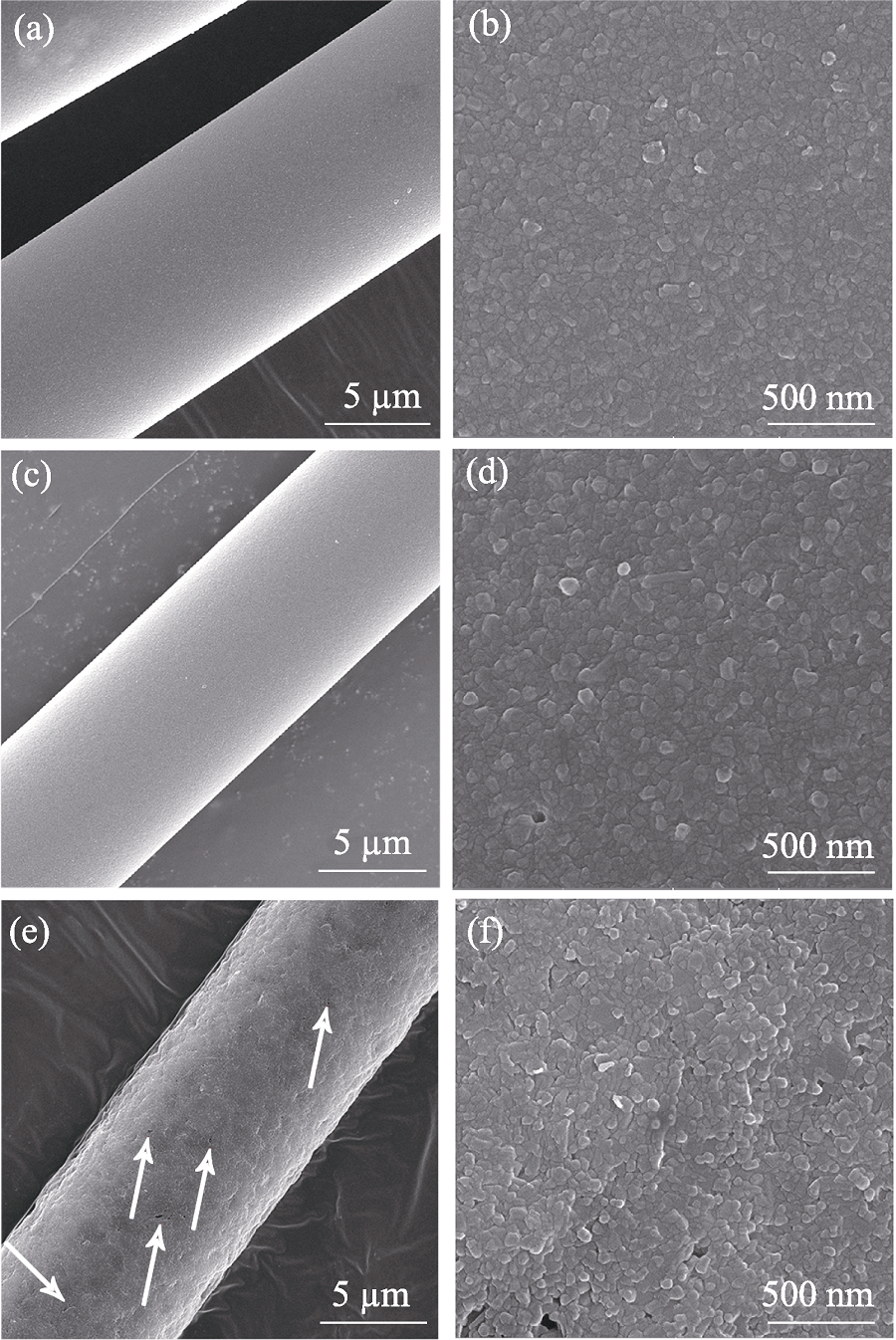

图2 烧结SiC (SF)纤维的表面形貌

Fig. 2 Surface morphologies of the sintered SiC (SF) fibers (a, b) SiC (SF)-1600-1 h; (c, d) SiC (SF)-1800-1 h; (e, f) SiC (SF)-2000-1 h

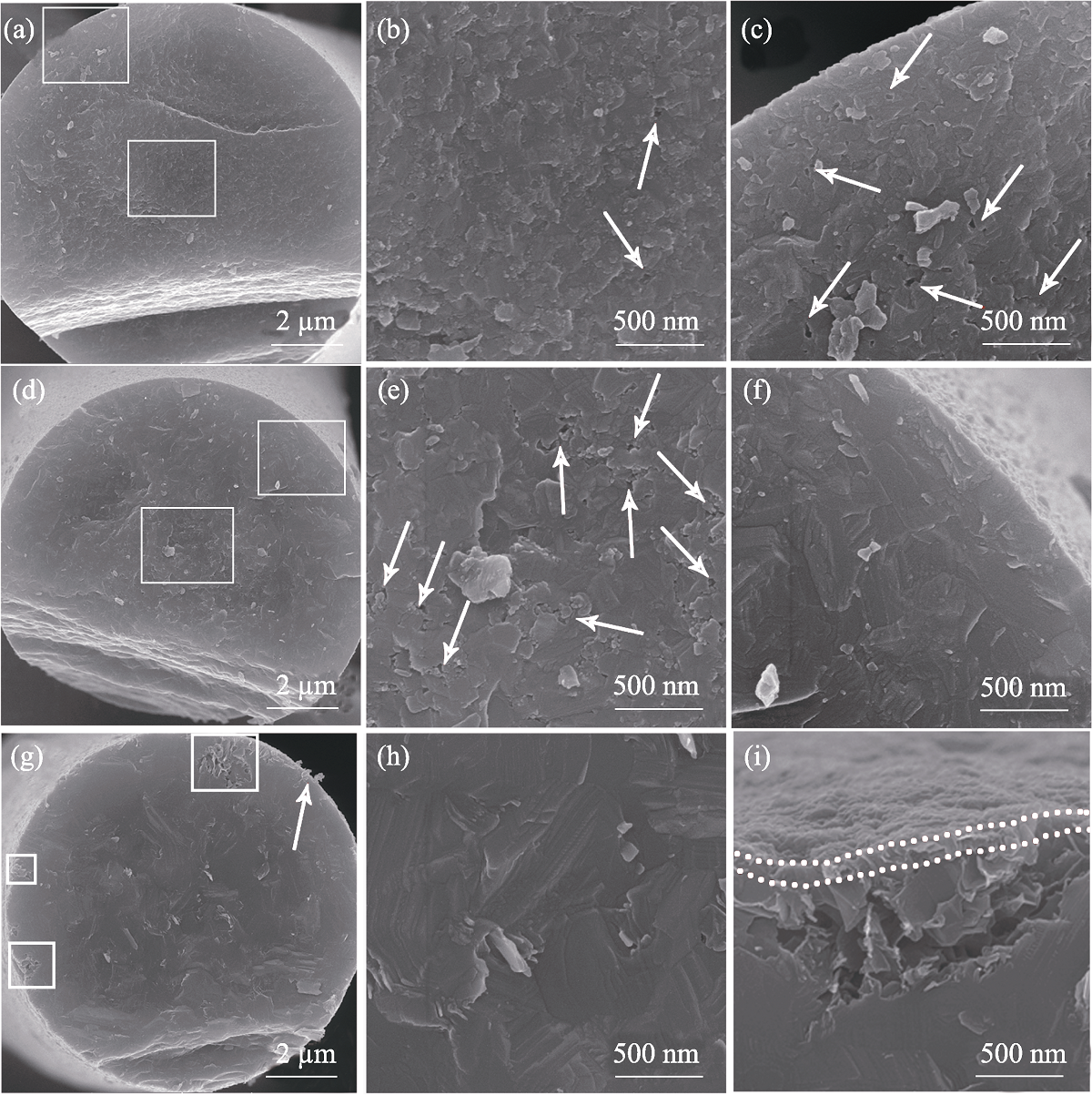

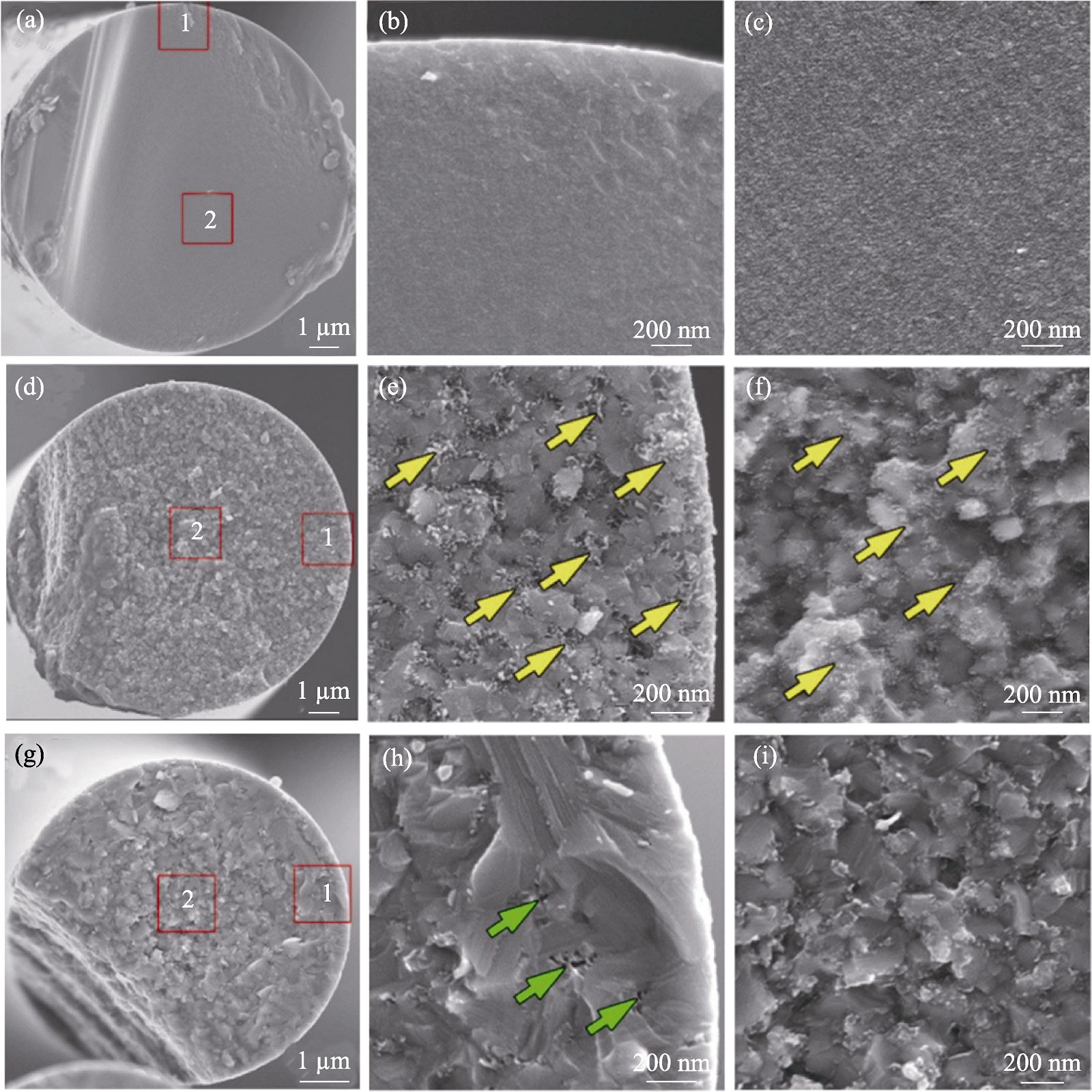

图3 烧结SiC (SF)纤维的截面形貌

Fig. 3 Cross-sectional morphologies of the sintered SiC (SF) fibers (a-c) SiC (SF)-1600-1 h; (d-f) SiC (SF)-1800-1 h; (g-i) SiC (SF)-2000-1 h

| Sample | C/% | Si/% | O/% | Al/% | C/Si atomic ratio |

|---|---|---|---|---|---|

| SiC (SF)-1600-1 h | 31.88 | 67.50 | 0.80 | <1.00 | 1.10 |

| SiC (SF)-1700-1 h | 32.37 | 66.31 | 0.82 | <1.00 | 1.14 |

| SiC (SF)-1800-1 h | 31.48 | 67.41 | 0.61 | <1.00 | 1.09 |

| SiC (SF)-1900-1 h | 33.04 | 66.14 | 0.32 | <1.00 | 1.17 |

| SiC (SF)-2000-1 h | 38.27 | 61.13 | 0.10 | <1.00 | 1.46 |

表2 不同温度烧结制备的SiC (SF)纤维的化学组成(质量分数)

Table 2 Chemical composition (mass fraction) of the SiC (SF) fibers sintered at different temperatures

| Sample | C/% | Si/% | O/% | Al/% | C/Si atomic ratio |

|---|---|---|---|---|---|

| SiC (SF)-1600-1 h | 31.88 | 67.50 | 0.80 | <1.00 | 1.10 |

| SiC (SF)-1700-1 h | 32.37 | 66.31 | 0.82 | <1.00 | 1.14 |

| SiC (SF)-1800-1 h | 31.48 | 67.41 | 0.61 | <1.00 | 1.09 |

| SiC (SF)-1900-1 h | 33.04 | 66.14 | 0.32 | <1.00 | 1.17 |

| SiC (SF)-2000-1 h | 38.27 | 61.13 | 0.10 | <1.00 | 1.46 |

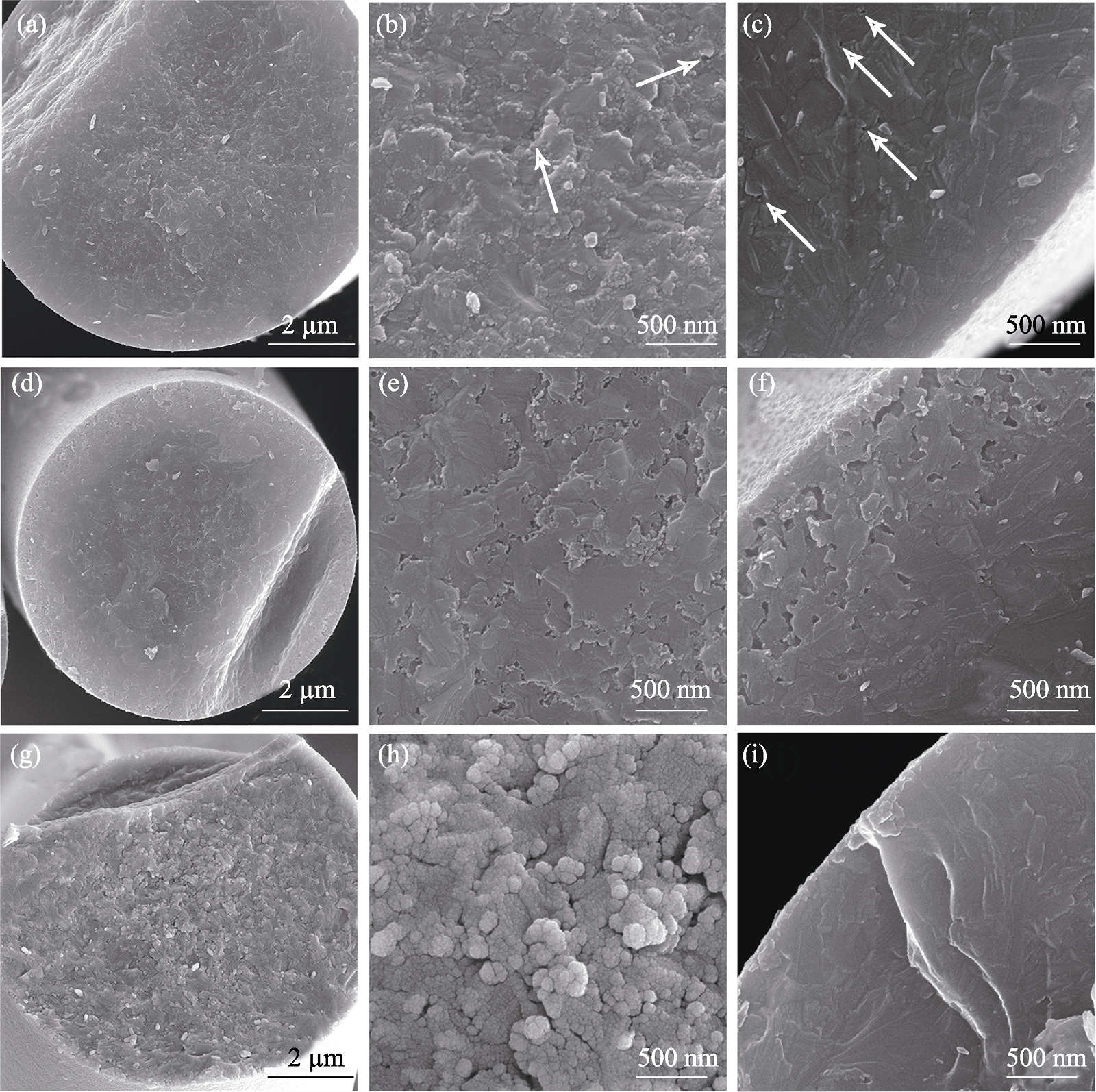

图7 1800 ℃下烧结不同时间的SiC (SF)纤维的截面形貌

Fig. 7 Cross-sectional morphologies of the SiC (SF) fibers sintered at 1800 ℃ for different durations (a-c) SiC (SF)-1800-10 min; (d-f) SiC (SF)-1800-30 min; (g-i) SiC (SF)-1800-2 h

| Sample | C/% | Si/% | O/% | Al/% | C/Si atomic ratio |

|---|---|---|---|---|---|

| SiC (SF)-1800-10 min | 31.82 | 66.93 | 0.75 | <1.00 | 1.11 |

| SiC (SF)-1800-1 h | 31.48 | 67.41 | 0.61 | <1.00 | 1.09 |

| SiC (SF)-1800-2 h | 31.54 | 67.96 | 0 | <1.00 | 1.08 |

表3 1800 ℃下烧结不同时间的SiC (SF)纤维的化学组成(质量分数)

Table 3 Chemical composition (mass fraction) of the SiC (SF) fibers sintered at 1800 ℃ for different durations

| Sample | C/% | Si/% | O/% | Al/% | C/Si atomic ratio |

|---|---|---|---|---|---|

| SiC (SF)-1800-10 min | 31.82 | 66.93 | 0.75 | <1.00 | 1.11 |

| SiC (SF)-1800-1 h | 31.48 | 67.41 | 0.61 | <1.00 | 1.09 |

| SiC (SF)-1800-2 h | 31.54 | 67.96 | 0 | <1.00 | 1.08 |

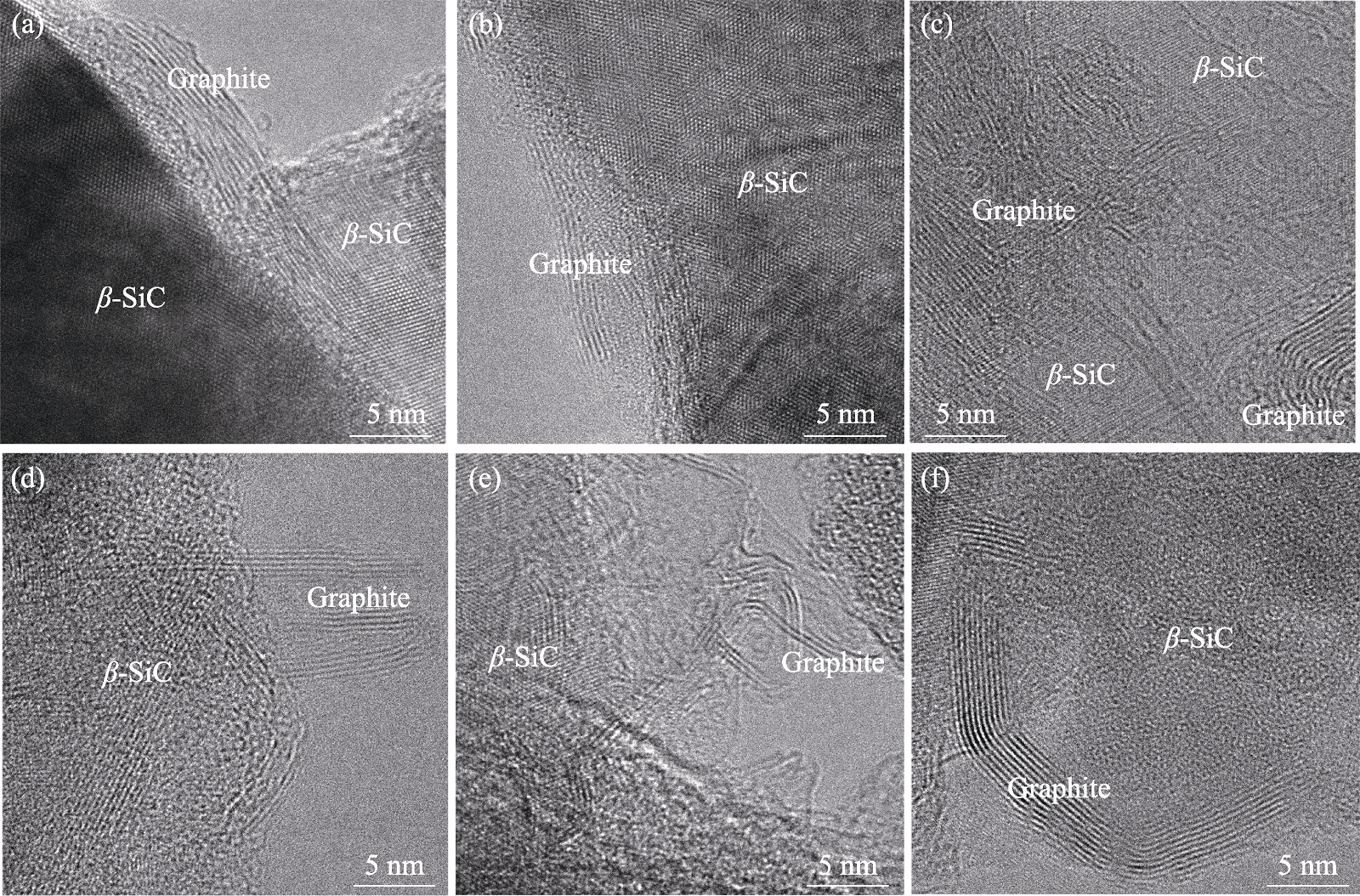

图8 1800 ℃烧结不同时间的SiC (SF)纤维的HRTEM照片

Fig. 8 HRTEM images of the SiC (SF) fibers sintered at 1800 ℃ for different durations (a, b) SiC (SF)-1800-10 min; (c, d) SiC (SF)-1800-30 min; (e, f) SiC (SF)-1800-2 h

| Sample | Tensile strength/ GPa | Young’s modulus/ GPa | Fiber diameter/ μm | Chemical formula |

|---|---|---|---|---|

| SiC (SF) | 1.88 | 373 | 11.2 | SiC1.04O0.02Al<0.01 |

| SiC (SG) | 2.96 | 268 | 11.6 | SiC1.31O0.05 |

表4 SiC (SF)和SiC (SG)纤维的力学性能

Table 4 Mechanical properties of SiC (SF) and SiC (SG) fibers

| Sample | Tensile strength/ GPa | Young’s modulus/ GPa | Fiber diameter/ μm | Chemical formula |

|---|---|---|---|---|

| SiC (SF) | 1.88 | 373 | 11.2 | SiC1.04O0.02Al<0.01 |

| SiC (SG) | 2.96 | 268 | 11.6 | SiC1.31O0.05 |

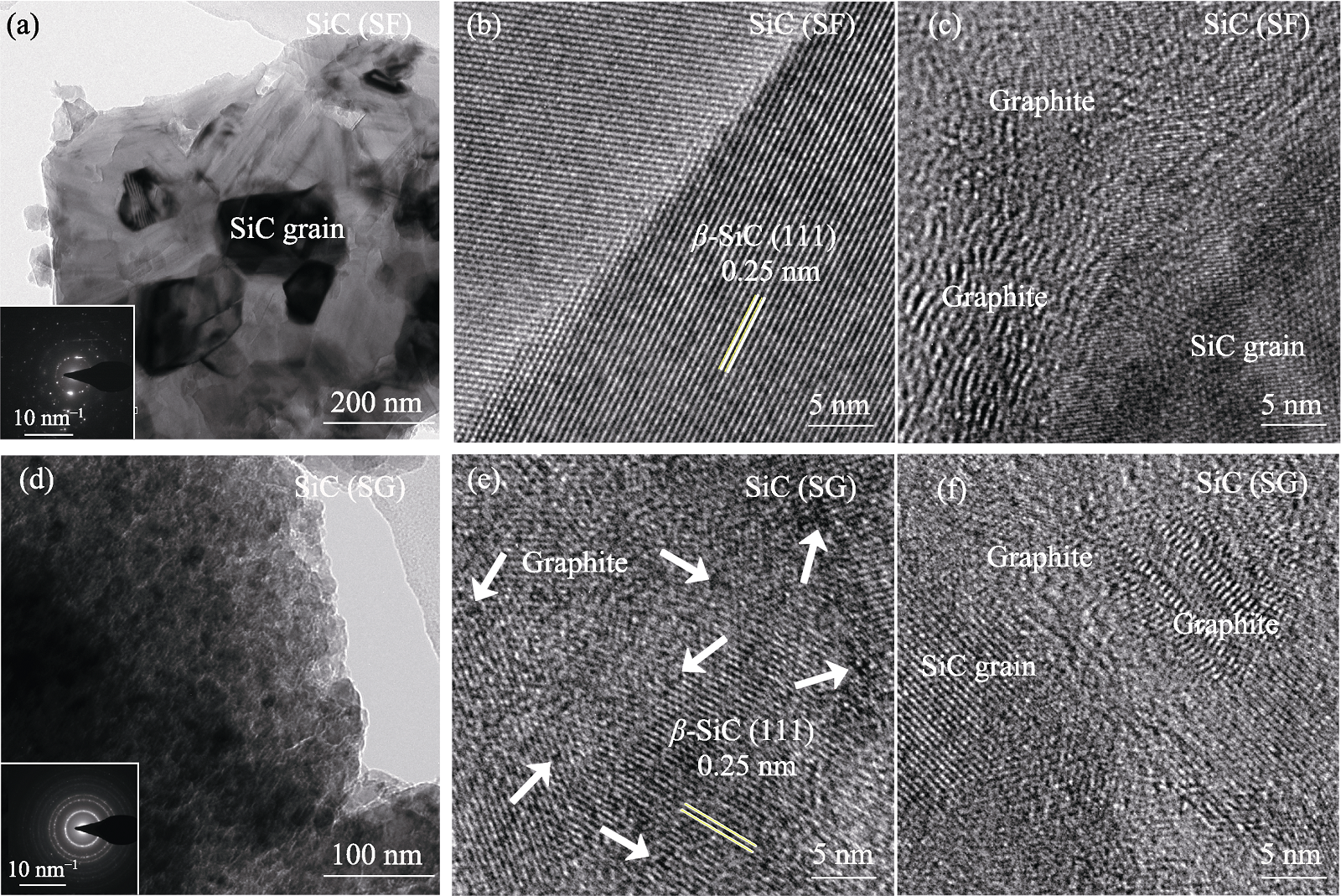

图11 SiC (SF)和SiC (SG)纤维的SAED图案、TEM和HRTEM照片

Fig. 11 SAED patterns, TEM and HRTEM images of SiC (SF) and SiC (SG) fibers (a-c) SiC (SF) fiber; (d-f) SiC (SG) fiber

| Sample | D peak/cm-1 | G peak/cm-1 | ID/IG | ||

|---|---|---|---|---|---|

| Position | FWHM | Position | FWHM | ||

| SiC (SF)-1600-1 h | 1357 | 56.0 | 1590 | 47.0 | 1.41 |

| SiC (SF)-1800-1 h | 1358 | 51.4 | 1593 | 42.2 | 1.01 |

| SiC (SF)-2000-1 h | 1357 | 49.3 | 1585 | 28.8 | 0.31 |

表S1 在1600~2000 ℃烧结1 h得到的SiC (SF)纤维的Raman结果

Table S1 Raman results of the SiC (SF) fibers sintered at 1600-2000 ℃ for 1 h

| Sample | D peak/cm-1 | G peak/cm-1 | ID/IG | ||

|---|---|---|---|---|---|

| Position | FWHM | Position | FWHM | ||

| SiC (SF)-1600-1 h | 1357 | 56.0 | 1590 | 47.0 | 1.41 |

| SiC (SF)-1800-1 h | 1358 | 51.4 | 1593 | 42.2 | 1.01 |

| SiC (SF)-2000-1 h | 1357 | 49.3 | 1585 | 28.8 | 0.31 |

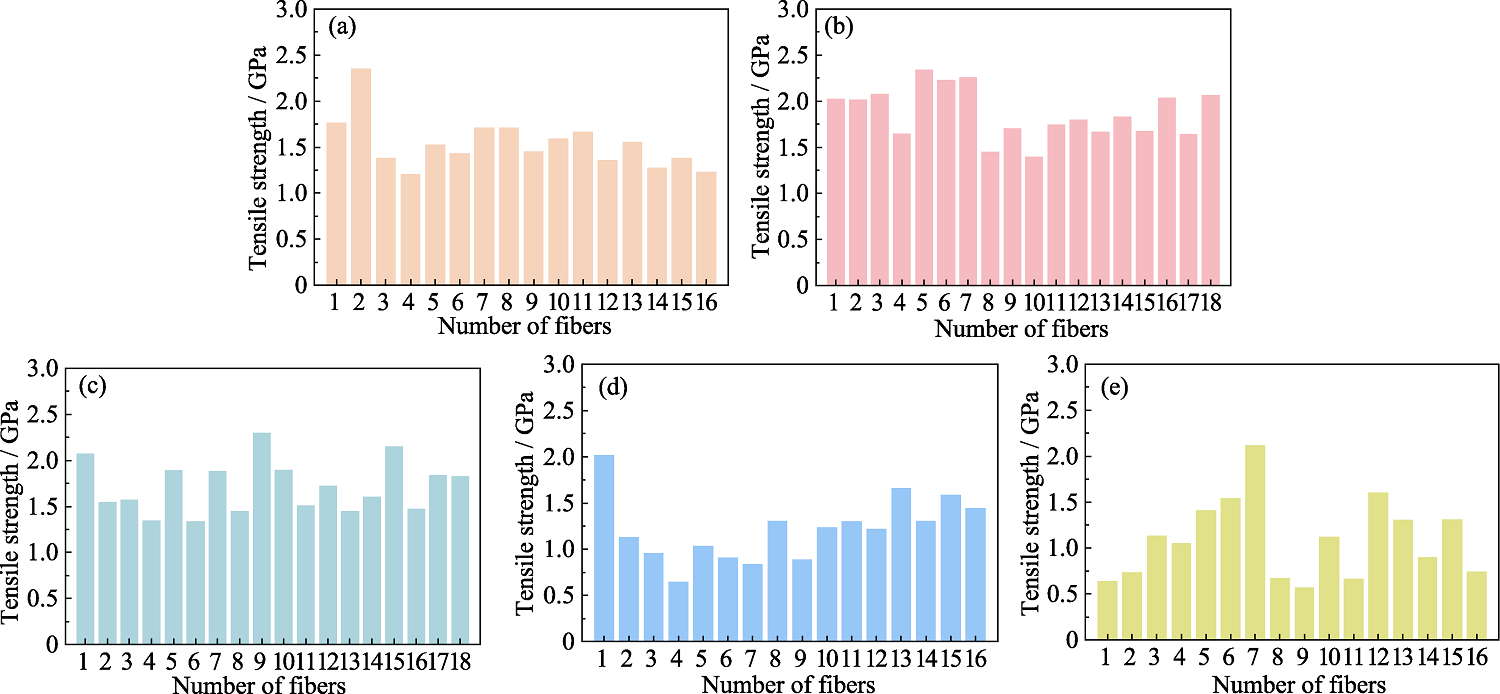

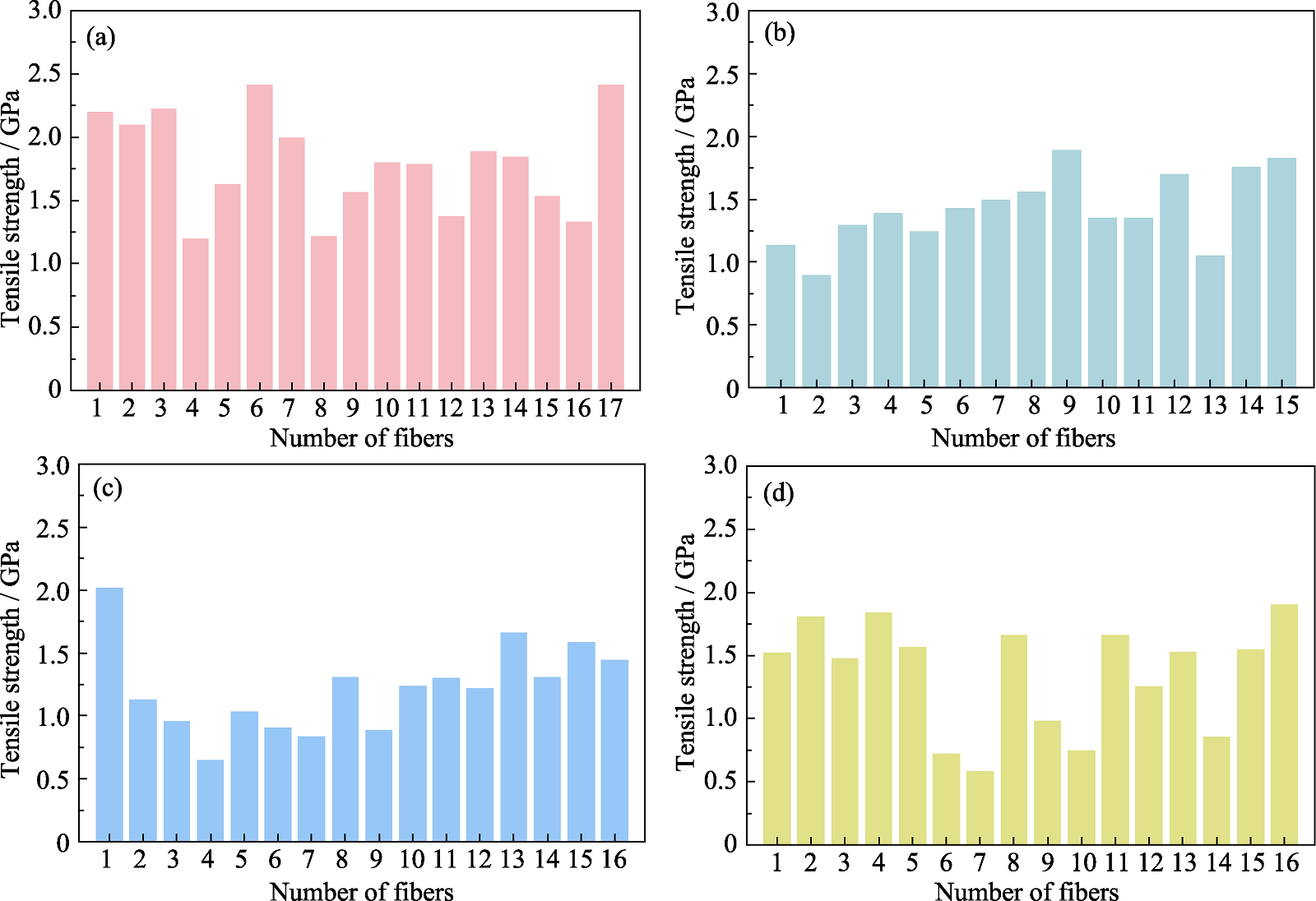

图S3 SiC (SF)纤维在不同温度烧结后的拉伸强度

Fig. S3 Tensile strength of SiC (SF) fibers after sintered at different temperatures (a) 1500 ℃; (b) 1600 ℃; (c) 1700 ℃; (d) 1800 ℃; (e) 1900 ℃

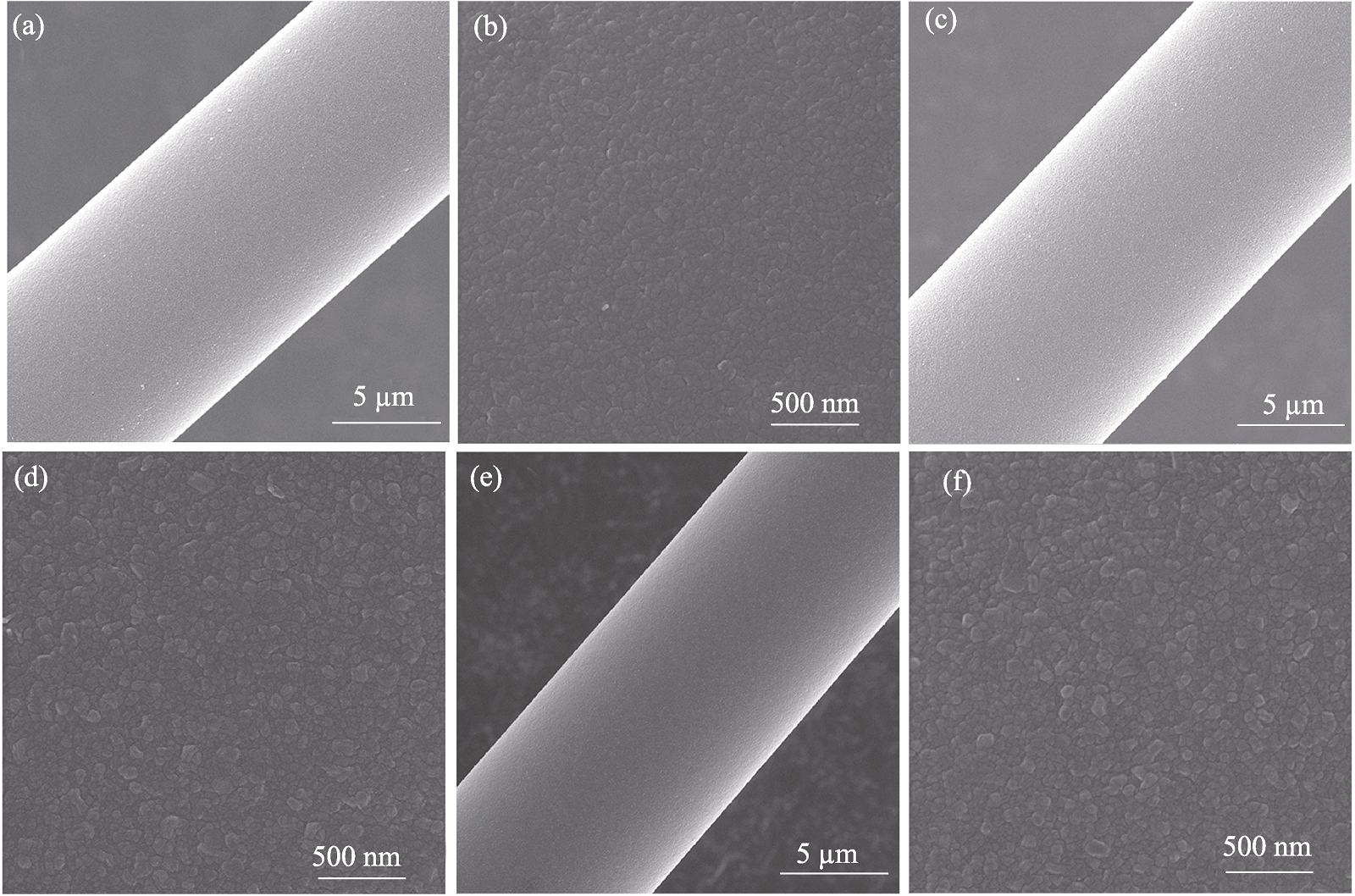

图S4 在1800 ℃烧结不同时间后SiC (SF)纤维的表面形貌

Fig. S4 Surface morphologies of the SiC (SF) fibers sintered at 1800 ℃ for different durations (a, b) SiC (SF)-1800-10 min; (c, d) SiC (SF)-1800-30 min; (e, f) SiC (SF)-1800-2 h

图S7 SiC (SF)纤维在1800 ℃不同烧结时间后的拉伸强度

Fig. S7 Tensile strength of SiC (SF) fibers sintered at 1800 ℃ for different durations (a) 10 min; (b) 30 min; (c) 1 h; (d) 2 h

图S8 F-1(a~c)、F-2(d~f)和F-3(g~i)断面的SEM照片[25]

Fig. S8 SEM images of fracture morphologies for the fibers F-1 (a-c), F-2 (d-f) and F-3 (g-i) More details of the fracture surfaces can be found in the enlarged images for the outer parts (b, e, h) as indicated by red square 1 and the core parts (c, f, i) as indicated by red square 2[25]

| [1] | KANG W, CHEN J, ZHANG Y, et al. SiC fibers with different diameters exhibiting excellent high-temperature resistance and oxidation resistance. Journal of Materials Research and Technology, 2023, 23: 1559. |

| [2] | CHEN J, ZHANG Y, YAN D, et al. Flexible ultrafine nearly stoichiometric polycrystalline SiC fibers with excellent oxidation resistance and superior thermal stability up to 1900 ℃. Journal of the European Ceramic Society, 2022, 42(5): 1938. |

| [3] | XIANG Y, WU S, YU J, et al. Long-time oxidation behavior of the nearly stoichiometric polycrystal-line SiC fibers under air atmosphere at different temperatures. Journal of the European Ceramic Society, 2024, 44(6):3569. |

| [4] | SHAN J, MO G, SUN Q, et al. Fabrication of SiC (OAl) and SiC (Al) fibers by melt-spinning, UV curing, thermolysis and sintering of photo-sensitive polyvinylaluminocarbosilane. Journal of the European Ceramic Society, 2024, 44(6):3501. |

| [5] | MORSCHER G N, HURST J, BREWER D. Intermediate- temperature stress rupture of a woven Hi-Nicalon, BN-interphase, SiC-matrix composite in air. Journal of the American Ceramic Society, 2000, 83(6):1441. |

| [6] | KATOH Y, SNEAD L L, HENAGER C H, et al. Current status and critical issues for development of SiC composites for fusion applications. Journal of Nuclear Materials, 2007, 367: 659. |

| [7] | PANAKARAJUPALLY R P, MIRZA F, EL RASSI J, et al. Solid particle erosion behavior of melt-in-filtrated SiC/SiC ceramic matrix composites (CMCs) in a simulated turbine engine environ- ment. Composites Part B: Engineering, 2021, 216: 108860. |

| [8] | ARREGUI-MENA J D, KOYANAGI T, CAKMAK E, et al. Qualitative and quantitative analysis of neutron irradiation effects in SiC/SiC composites using X-ray computed tomography. Composites Part B: Engineering, 2022, 238: 109896. |

| [9] | ZHANG S, GAO X, HAN X, et al. Prediction of strength and constitutive response of SiC/SiC composites considering fiber failure. Composites Part B: Engineering, 2019, 163: 252. |

| [10] | BHATT R, ELDRIDGE J. Heat treatment effects on microstructure and properties of CVI SiC/SiC composites with SylramicTM-iBN SiC fibers. Journal of the European Ceramic Society, 2023, 43(6):2376. |

| [11] | ZHAO Z, LIAO W, CHEN J, et al. Advanced research on the preparation and application of carbide ceramic fibers. Journal of Advanced Ceramics, 2024, 13(9):1291. |

| [12] | LV X, YUE M, FENG X, et al. Rare earth mono-silicates as oxidation resistant interphase for SiCf/SiC CMC: investigation of SiCf/Yb2SiO5 model composites. Journal of Advanced Ceramics, 2022, 11(5):702. |

| [13] | YAJIMA S, HASEGAWA Y, OKAMURA K, et al. Development of high tensile strength silicon carbide fibre using an organosilicon polymer precursor. Nature, 1978, 273(5663):525. |

| [14] | YAJIMA S, OKAMURA K, HAYASHI J, et al. Synthesis of continuous SiC fibers with high tensile strength. Journal of the American Ceramic Society, 1976, 59(7/8):324. |

| [15] | KANG W, ZHANG Q, GOU Y. Fabrication of highly crystalline titanium-containing SiC fibers with different boron contents exhibiting excellent electromagnetic wave absorption. Journal of Materials Science, 2024, 59(7):2739. |

| [16] | ZHANG Q, CHEN T, KANG W, et al. Synthesis of polytitanocarbosilane and preparation of Si-C-Ti-B fibers. Processes, 2023, 11: 1189. |

| [17] | WU S, GOU Y, XIANG Y, et al. Effect of long-time annealing at high temperature on the microstructure and mechanical properties of different types of SiC fibers. Composites Part A: Applied Science and Manufacturing, 2024, 185: 108291. |

| [18] | GOU Y, KANG W, ZHANG Q. Preparation of nearly stoichiometric SiC(Ti) fibers with highly crystalline microstructure from polytitanocarbosilane. Journal of Inorganic Materials, 2024, 39(12):1377. |

| [19] | BUNSELL A R, PIANT A. A review of the development of three generations of small diameter silicon carbide fibres. Journal of Materials Science, 2006, 41(3):823. |

| [20] | WANG P, LIU F, WANG H, et al. A review of third generation SiC fibers and SiCf/SiC composites. Journal of Materials Science and Technology, 2019, 35(12):2743. |

| [21] | SCHAWALLER D, CLAUSS B, BUCHMEISER M R. Ceramic filament fibers-a review. Macromolecular Materials and Engineering, 2012, 297(6):502. |

| [22] | ISHIKAWA T, KOHTOKU Y, KUMAGAWA K, et al. High- strength alkali-resistant sintered SiC fibre stable to 2200 ℃. Nature, 1998, 391(6669):773. |

| [23] | TAKEDA M, SAEKI A, SAKAMOTO J I, et al. Effect of hydrogen atmosphere on pyrolysis of cured polycarbosilane fibers. Journal of the American Ceramic Society, 2000, 83(5):1063. |

| [24] | BHATT R, SOLA F, EVANS L, et al. Microstruc-tural, strength, and creep characterization of Sylramic™, Sylramic™-iBN and super Sylramic™-iBN SiC fibers. Journal of the European Ceramic Society, 2021, 41(9):4697. |

| [25] | ZHANG Y, WU C, WANG Y, et al. A detailed study of the microstructure and thermal stability of typical SiC fibers. Materials Characterization, 2018, 146: 91. |

| [26] | GOU Y, JIAN K, WANG H, et al. Fabrication of nearly stoichiometric polycrystalline SiC fibers with excellent high-temperature stability up to 1900 ℃. Journal of the American Ceramic Society, 2018, 101(5): 2050. |

| [27] | WANG P, GOU Y, WANG H, et al. Revealing the formation mechanism of the skin-core structure in nearly stoichiometric polycrystalline SiC fibers. Journal of the European Ceramic Society, 2020, 40(6):2295. |

| [28] |

YUAN Q, SONG Y. Effect of SiCxOy decomposition on densification of SiCO (Al) fibers during sintering process. Journal of Inorganic Materials, 2016, 31(12):1320.

DOI |

| [29] | USUKAWA R, ODA H, ISHIKAWA T, et al. Conversion process of amorphous Si-Al-C-O fiber into nearly stoichiometric SiC polycrystalline fiber. Journal of the Korean Ceramic Society, 2016, 53(6):610. |

| [30] | OKAMURA K, SHIMOO T, SUZUYA K, et al. SiC-based ceramic fibers prepared via organic-to-inorganic conversion process-a review. Journal of the Ceramic Society of Japan, 2006, 114(1330):445. |

| [31] | JACOBSON N S, KLINE S E. A thermoanalytical study of the conversion of amorphous Si-Ti-C-O fibers to SiC. International Journal of Applied Ceramic Technology, 2012, 9(4):816. |

| [32] | SNEAD L L, NOZAWA T, KATOH Y, et al. Hand-book of SiC properties for fuel performance modeling. Journal of Nuclear Materials, 2007, 371(1/3):329. |

| [33] | VAN DER BERG N, MALHERBE J B, BOTHA A, et al. Thermal etching of SiC. Applied Surface Science, 2012, 258(15):5561. |

| [34] | ZHANG Y, CHEN J, YAN D, et al. Conversion of silicon carbide fibers to continuous graphene fibers by vacuum annealing. Carbon, 2021, 182: 435. |

| [35] | ZHANG Y, CHEN T, CHEN J, et al. The effects of annealing atmosphere and intrinsic component on high temperature evolution behaviors of SiC fibers. Materials Science and Engineering: A, 2022, 848: 143363. |

| [36] | OKUMURA H, SAKUMA E, LEE J, et al. Raman scattering of SiC: application to the identification of heteroepitaxy of SiC polytypes. Journal of Applied Physics, 1987, 61(3):1134. |

| [37] | DONG S, CHOLLON G, LABRUGERE C, et al. Characterization of nearly stoichiometric SiC ceramic fibres. Journal of Materials Science, 2001, 36(10):2371. |

| [38] | LIPOWITZ J. Structure and properties of ceramic fibers prepared from organosilicon polymers. Journal of Inorganic and Organometallic Polymers and Materials, 1991, 1(3):277. |

| [1] | 李廷松, 王文丽, 刘强, 王雁斌, 周真真, 胡辰, 李江. Cr3+掺杂浓度对YAGG:Ce3+,Cr3+发光陶瓷余辉性能的影响[J]. 无机材料学报, 2025, 40(9): 1037-1044. |

| [2] | 陈斌, 任科, 王一光. Mini-SiCf/SiC复合材料长时间高温下的力学性能演变[J]. 无机材料学报, 2025, 40(9): 971-980. |

| [3] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [4] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [5] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [6] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [7] | 樊文楷, 杨潇, 李宏华, 李永, 李江涛. 无压烧结制备(Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7高熵陶瓷及其高温抗CMAS腐蚀性能[J]. 无机材料学报, 2025, 40(2): 159-167. |

| [8] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [9] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [10] | 郝永鑫, 孙军, 杨金凤, 赵晨成, 刘子琦, 李清连, 许京军. 近化学计量比铌酸锂晶体的孪晶缺陷研究[J]. 无机材料学报, 2025, 40(2): 196-204. |

| [11] | 于泽龙, 唐春, 饶家豪, 郭恒, 周莹. 碱性电解水大电流密度电催化剂的制备及经济性研究[J]. 无机材料学报, 2025, 40(12): 1405-1413. |

| [12] | 缪鹏程, 王丽君, 沈紫怡, 黄莉, 袁宁一, 丁建宁. 微球状Ag2Se的溶剂热合成及其热电性能研究[J]. 无机材料学报, 2025, 40(12): 1373-1378. |

| [13] | 王智祥, 陈莹, 逄清阳, 李鑫, 王根水. 碳酸锰掺杂氧化镁基陶瓷的烧结行为和介电性能[J]. 无机材料学报, 2025, 40(1): 97-103. |

| [14] | 刘磊, 郭瑞华, 王丽, 王艳, 张国芳, 关丽丽. Pt3Co高指数晶面氧还原过程的密度泛函理论研究[J]. 无机材料学报, 2025, 40(1): 39-46. |

| [15] | 张婧慧, 陆晓彤, 毛海雁, 田亚州, 张山林. 烧结助剂对BaZr0.1Ce0.7Y0.2O3-δ电解质烧结行为及电导率的影响[J]. 无机材料学报, 2025, 40(1): 84-90. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||